Multi-stage processing, coring and peeling machine with flexible feeding mechanism

A feeding mechanism and core removal technology, which is applied in the fields of vegetable or fruit peeling, fruit core removal device, food science, etc., can solve the problem that the core and peeling is not clean and hygienic, the lantern-shaped pulp cannot be obtained, and the processing efficiency is high. problem, to achieve the effect of good processing effect, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

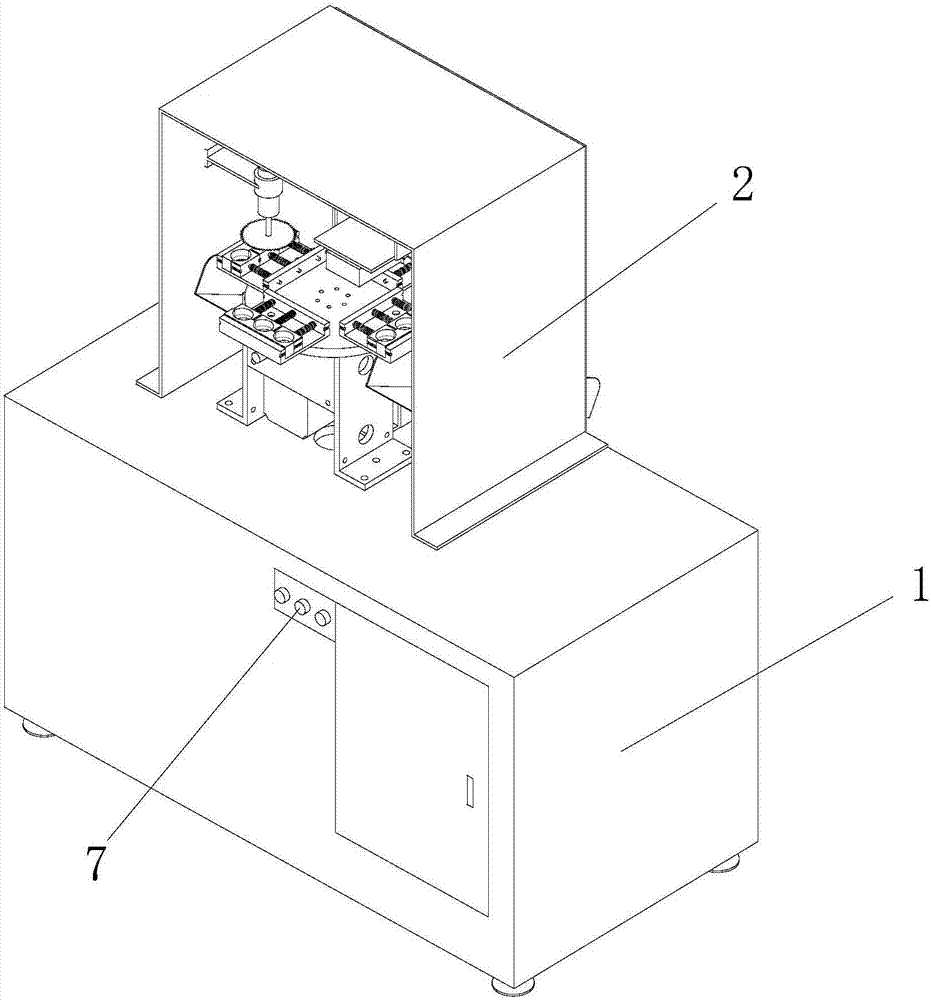

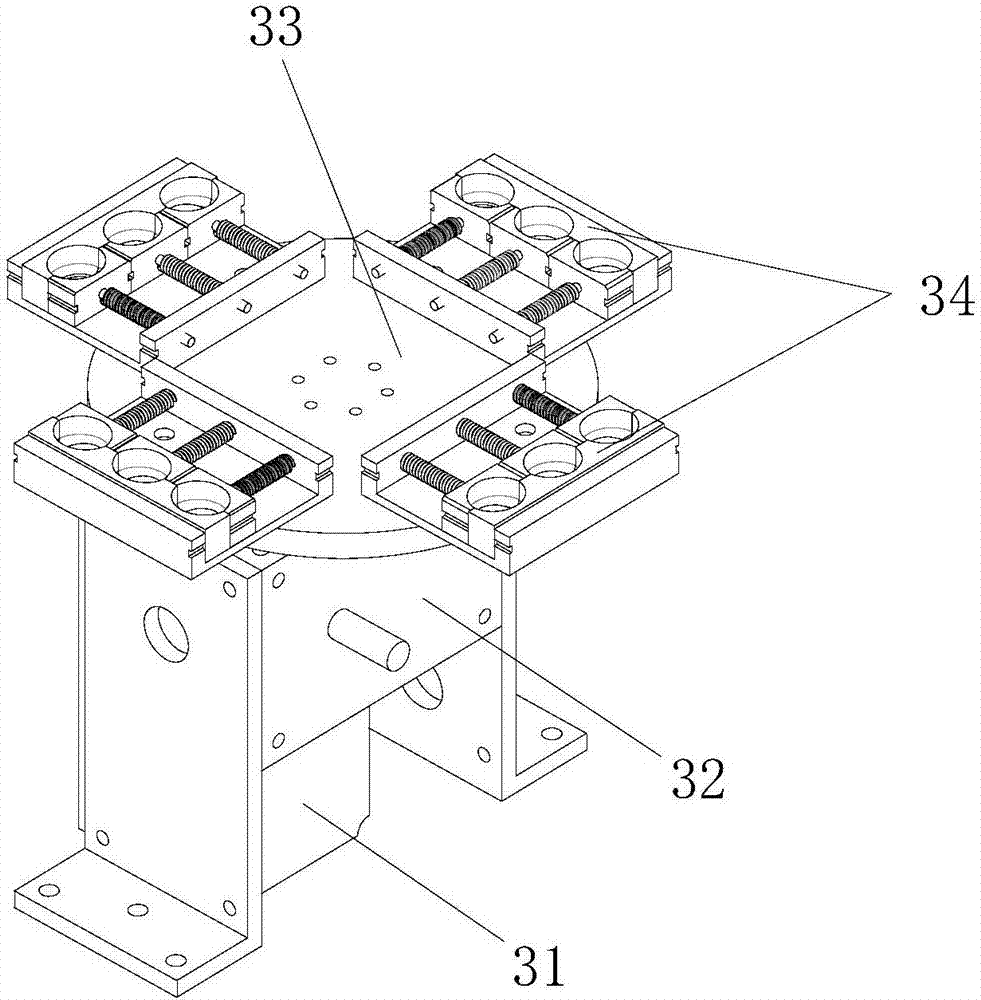

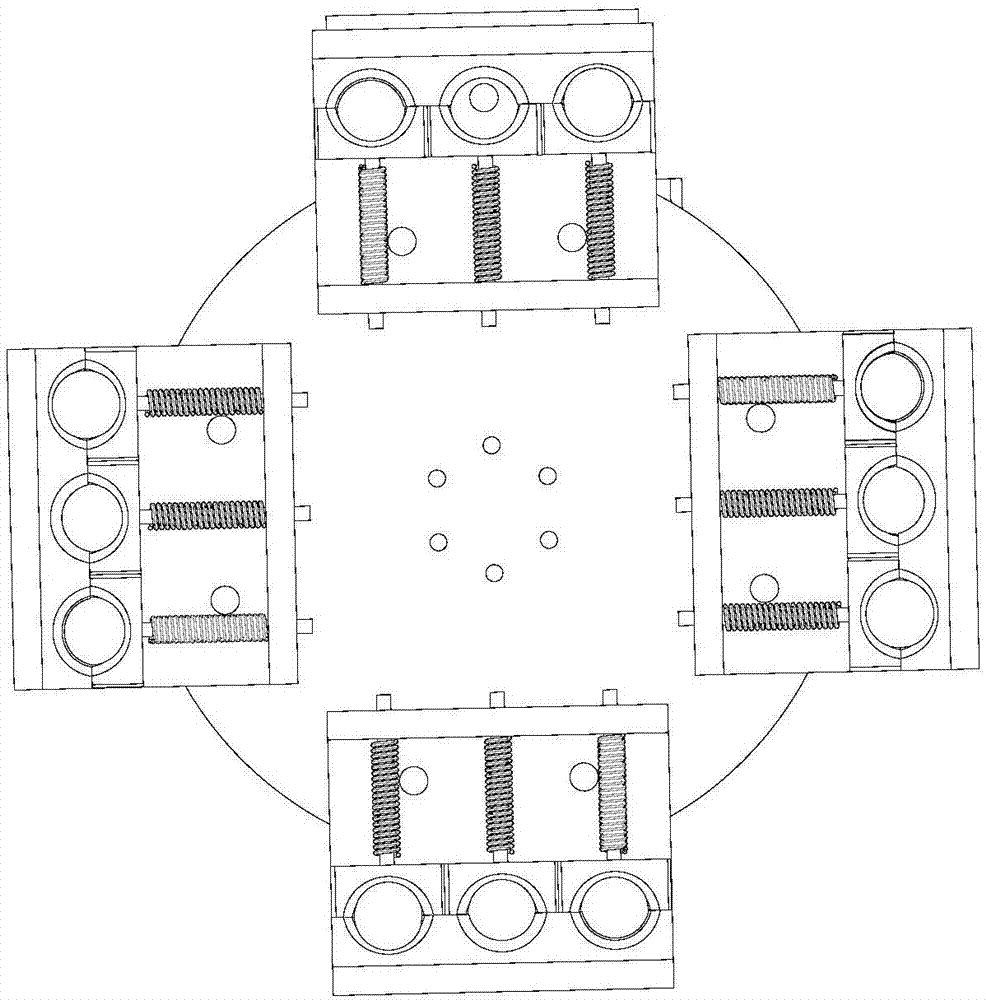

[0054] Such as figure 1 As shown, the present invention discloses a multi-stage processing coring and peeling machine provided with a flexible feeding mechanism. The coring and peeling machine mainly includes a box body 1 for supporting and fixing, a The gantry 2 and the flexible feeding mechanism, the controller for controlling the cooperative work of each part, and the pre-cut mechanism for removing the fruit pedicels installed on the gantry 2, the core removal and peeling mechanism and the machine for removing the husk Go to the scrap agency. When working, the worker first puts the fruit into the flexible feeding mechanism, then the fruit is sent to the pre-cutting mechanism to remove the fruit stalk, and then sent to the coring and peeling mechanism to perform the pitting and pulping operations, and finally the remaining The husks are sent to the waste mechanism for collection and enter the next round of charging operation.

[0055] Specifically, the controller is instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com