Three-head helix milling machine

A milling machine and spiral technology, which is applied in the field of machine tools for simultaneous milling of spiral grooves, can solve problems such as high labor intensity, burns and scratches on operators, and harsh environments, and achieve the effects of improving processing quality, improving the production environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

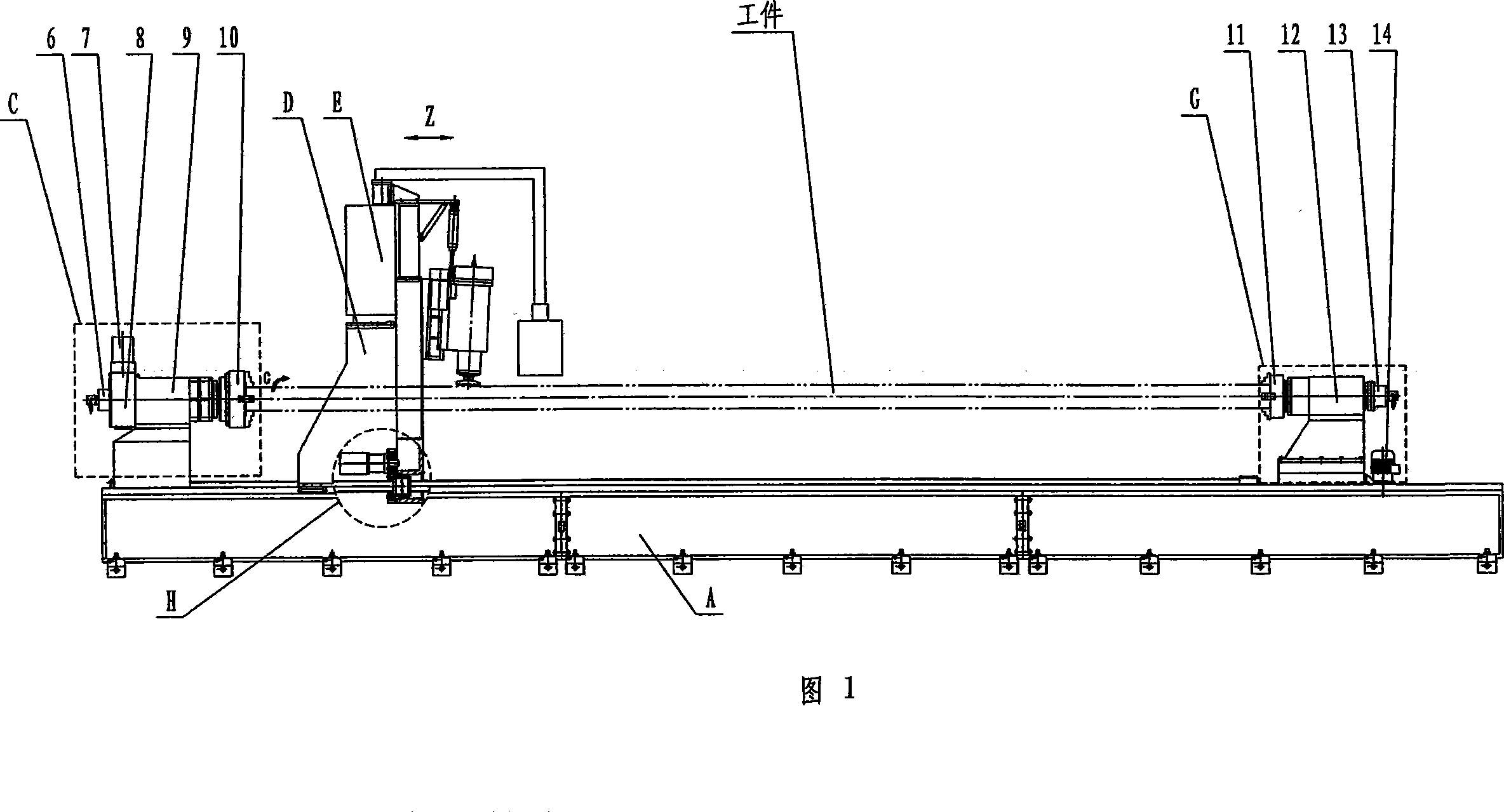

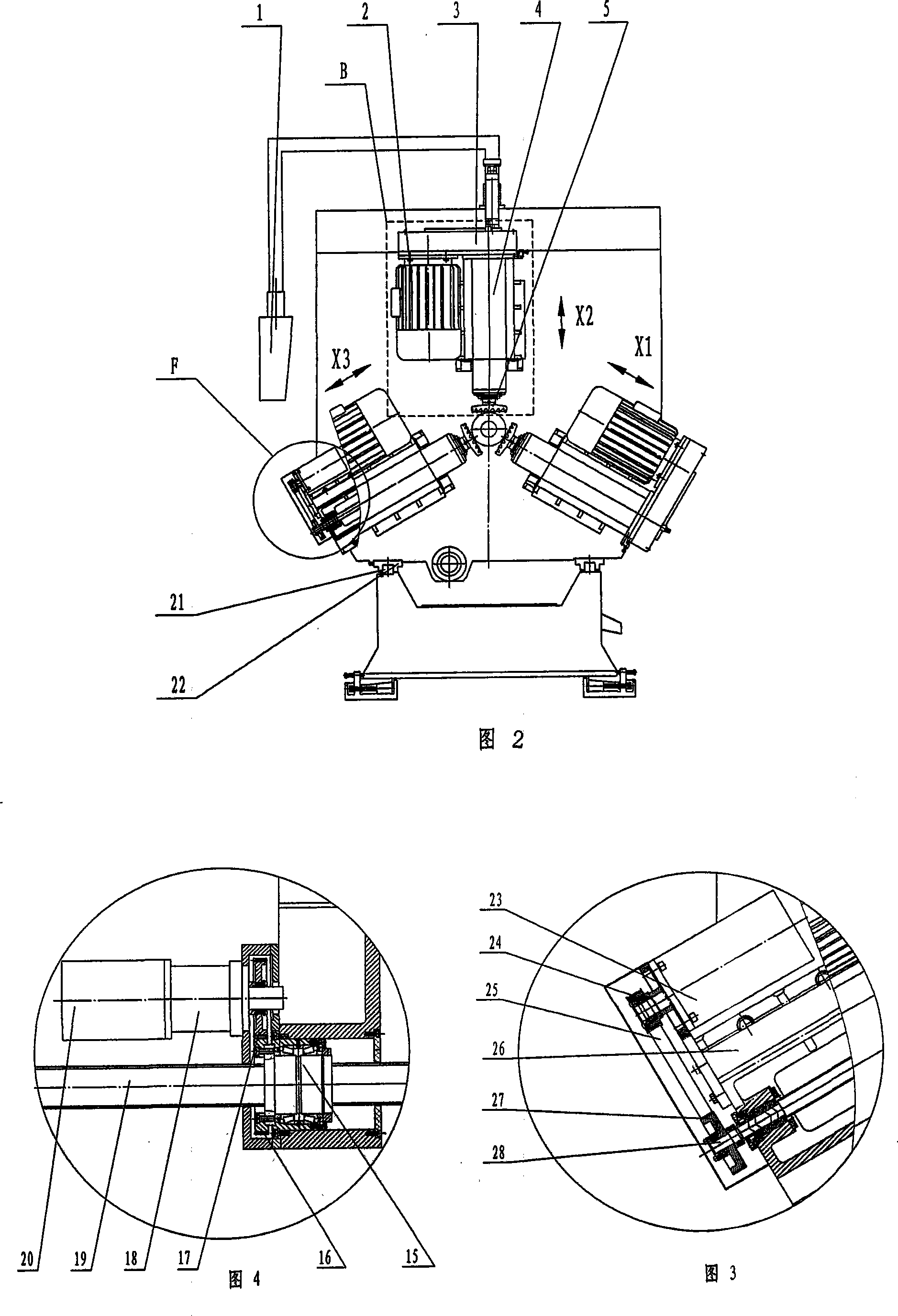

[0021] In the figure, a rolling guide rail 21 is fixed on the bed A (three-section splicing), and a rolling guide rail slide seat 22 is fixed on the lower part of the Z-direction sliding table D, and the Z-direction sliding table D can move along the Z direction on the rolling guide rail 21 .

[0022] The Z-direction drive device H in the dotted line frame is made up of a servo motor 20, a speed reducer 18, a gear 17, a gear 16, a ball screw nut 15, a ball screw 19 and the like. Its working principle is: the servo motor 20 drives the gear 17 fixed on the shaft end of the reducer 18 to rotate through the reducer 18, and the gear 17 meshes with the gear 16 fixed on the ball screw nut 15, so that the ball screw nut 15 Rotate around the ball screw 15 to push the Z-direction sliding table D to move back and forth along the Z direction.

[0023] The three X-direction sliding tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com