Clamping mechanism capable of synchronously machining axial holes of multiple shaft parts

A technology of shaft parts and clamping mechanism, which is applied in the direction of metal processing machinery parts, metal processing equipment, clamping, etc., can solve the problems of low work efficiency and difficulty in meeting production needs, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

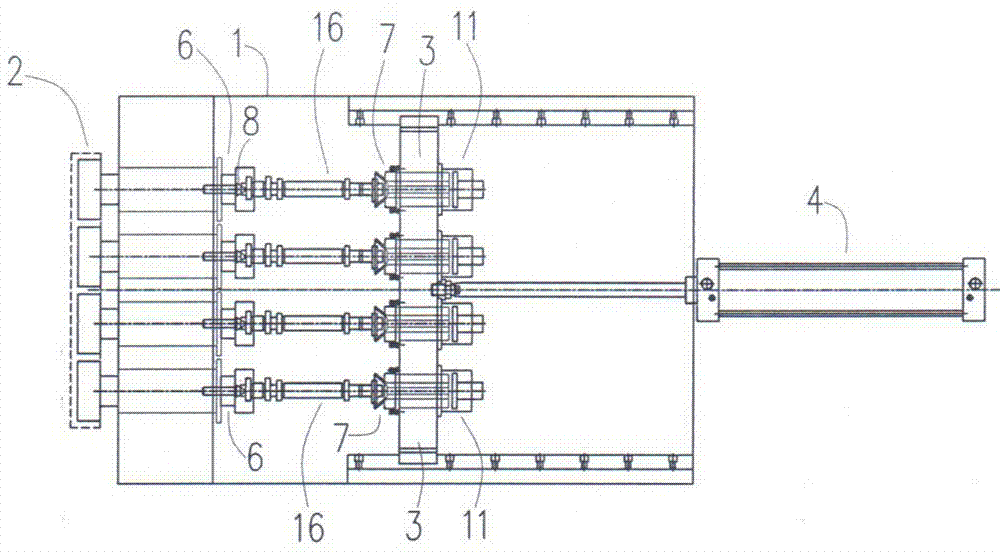

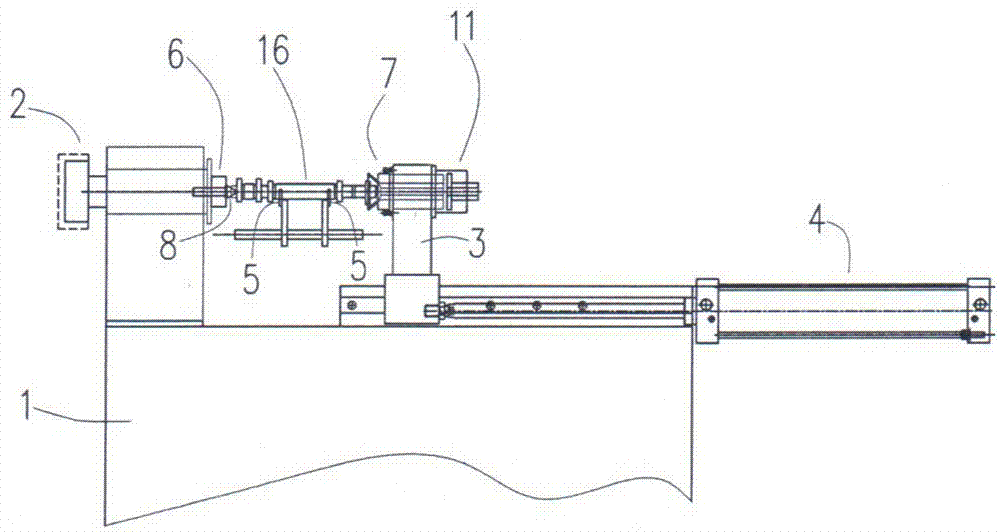

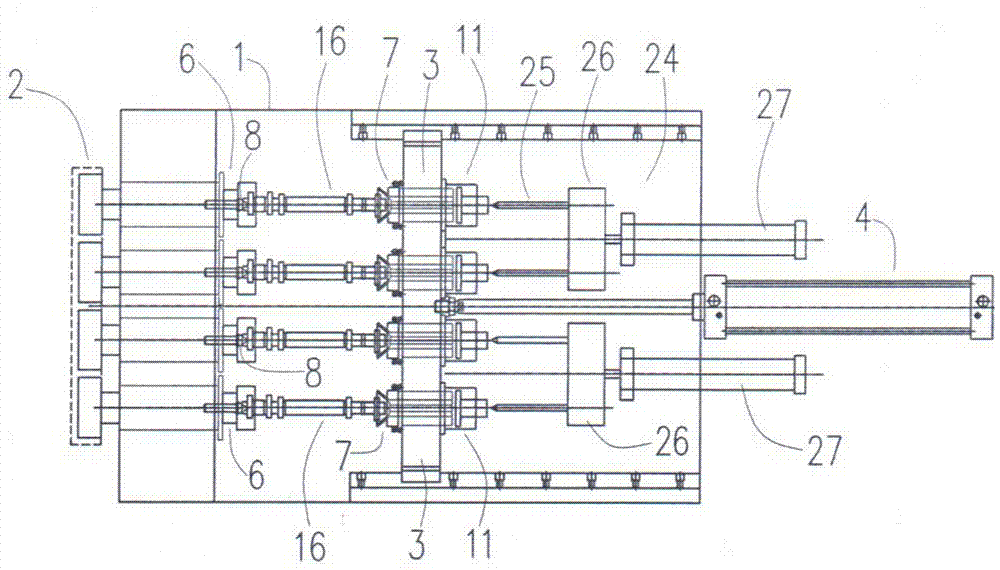

[0022] Such as Figure 1 to Figure 6 As shown, an embodiment of the present invention comprises a machine base 1, which is provided with a motor 2, a first slide 3, a first cylinder 4 and a plurality of juxtaposed work units; each work unit includes a pair of V Type positioning block 5, a front tip mechanism 6, a reverse tip mechanism 7; the first slide seat 3 is provided with the same assembly position as the number of working units; the front tip mechanism 6 includes a rotatable tip body 8 driven by a motor 2 (One embodiment is that the motor 2 drives each tip body 8 to rotate synchronously through a synchronous pulley); the anti-tip mechanism 7 includes a seat cover 9, an anti-tip body 10, and a second cylinder 11; the anti-tip body 10 includes a cone Mouth 12 and barrel portion 13, barrel portion 13 is provided with the first center hole 14 that can accommodate drill bit 25 to pass through; Anti-tip body 10 is installed in seat cover 9 through bearing, and anti-tip body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com