Special high-flowability resin for polypropylene fibers and preparation method thereof

A polypropylene fiber and high fluidity technology, applied in the field of polypropylene resin, can solve the problems of large fluctuations in product quality melt index, wide molecular weight distribution, broken wires and parallel wires, etc., and achieve short switching cycle, narrow molecular weight distribution, and production The effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

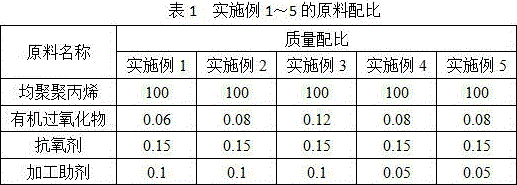

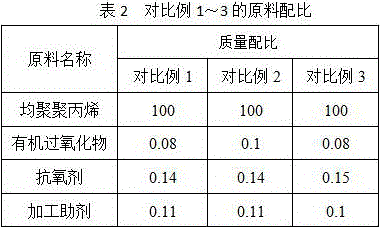

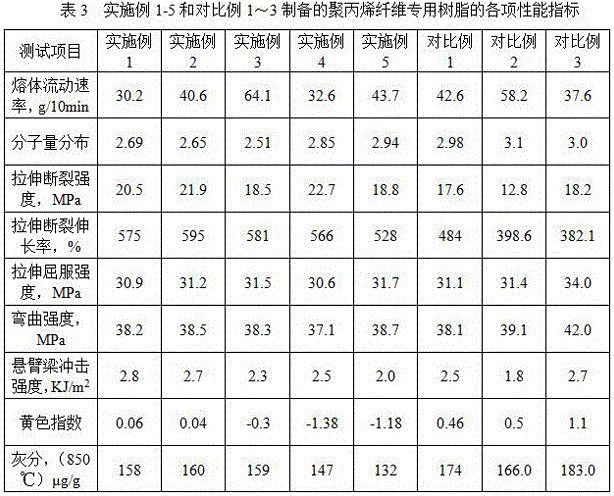

[0027] Get each raw material according to the proportions by weight of homopolypropylene, organic peroxide, nucleating agent, antioxidant and processing aid in Tables 1 and 2 respectively:

[0028]

[0029]

[0030] The homopolypropylene used in Examples 1-4 and Comparative Examples 1-3 is produced by Sinopec Maoming Branch, the brand is PPH-T03, and the melt index is 2.0-5.0 g / 10min. The homopolypropylene used in embodiment 5 is produced by Sinopec Maoming Branch Company, the trade mark is S1003, and the melt index (MFR 2 ) is 2.0~5.0g / 10min.

[0031] Examples 1-5 and Comparative Examples 1-3 organic peroxides are 2,5-dimethyl-2,5-di-tert-butyl peroxyhexane and di-tert-butyl peroxide compound, 2, The mass ratio of 5-dimethyl-2,5-di-tert-butyl peroxide to di-tert-butyl peroxide is 7:3, and the organic peroxide has a half-life of 1 hour, corresponding to a temperature of 130-150°C . The processing aid is calcium stearate or glyceryl monostearate.

[0032] The antioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com