Inner stereoscopic light projection curing forming 3D printing equipment and forming method thereof

A solidification molding and 3D printing technology, applied in the field of 3D printing, can solve the problems of limited speed mechanical equipment, low equipment molding speed, and failure to meet manufacturing requirements, so as to reduce variable factors, increase molding speed, and fast molding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

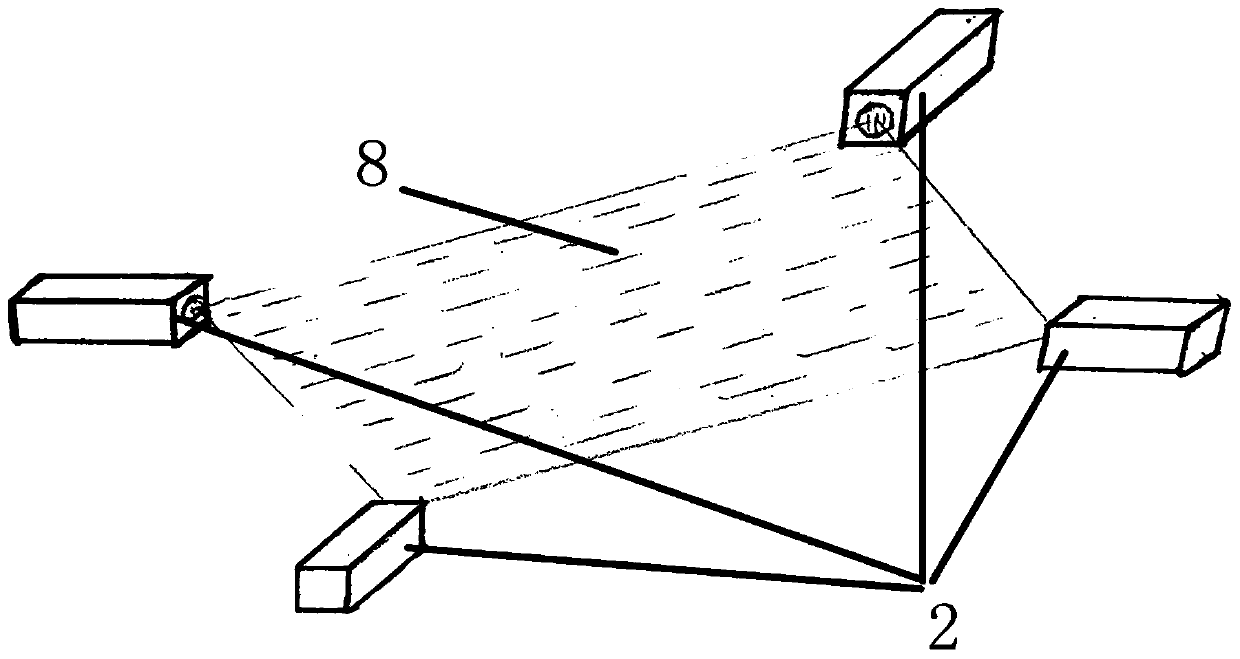

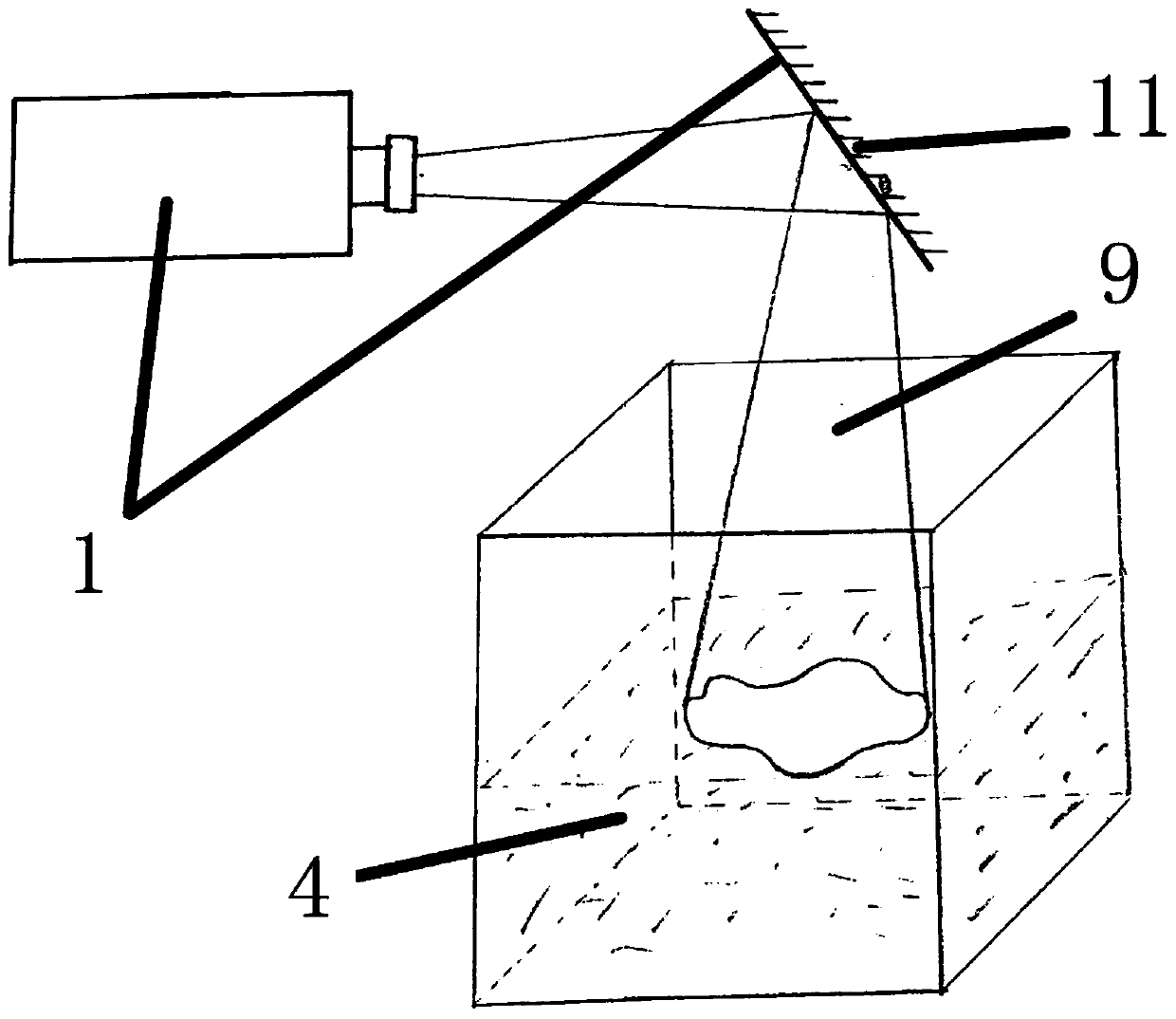

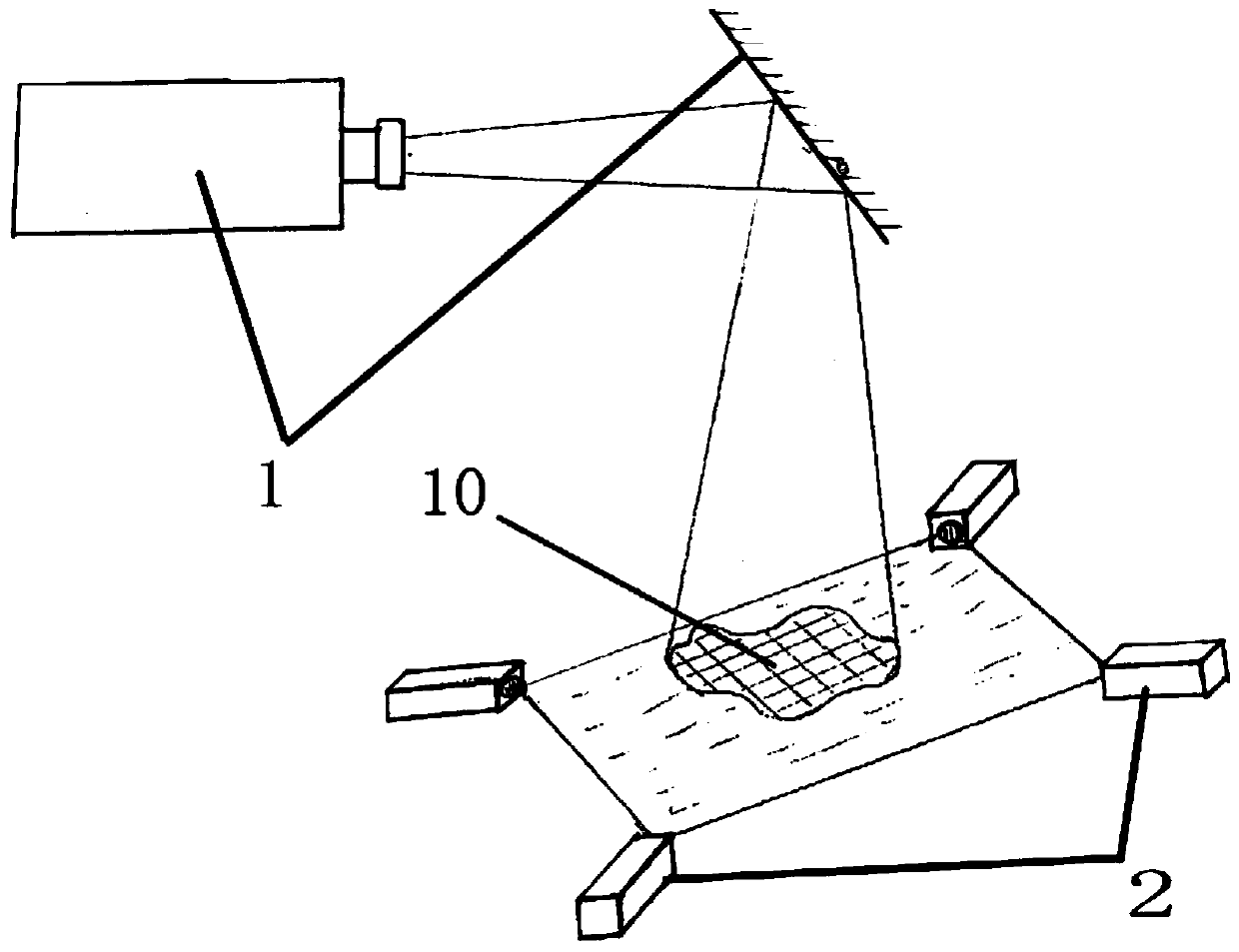

[0046] Such as Figure 5-13 Shown: a 3D printing device for internal stereoscopic light projection curing molding, mainly including a laser projection module 1, an optical reference plane module 2, an optical reference plane module lifting system 3, a resin tank 4, a molding platform 5, and a molding platform lifting system 6, Control system, power supply system and main frame 7, described main frame 7 is the base of the whole equipment, and other components are all installed on the main frame 7; Described laser projection module 1 is fixed on the top of main frame 7, provides for the whole equipment Shape the projection beam, and project the beam into the resin tank 4; the optical reference plane module lifting system 3 is installed inside the main frame 7, and an optical reference plane module mounting plate 31 is arranged in the middle, and the optical reference plane module 2 is installed on the On it, a square through hole is opened in the middle of the optical reference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com