Method and device for the additive manufacturing of components

A technology of additive manufacturing and components, applied in the direction of additive manufacturing, processing manufacturing, manufacturing tools, etc., to achieve the effect of expanding technical capabilities, reducing investment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

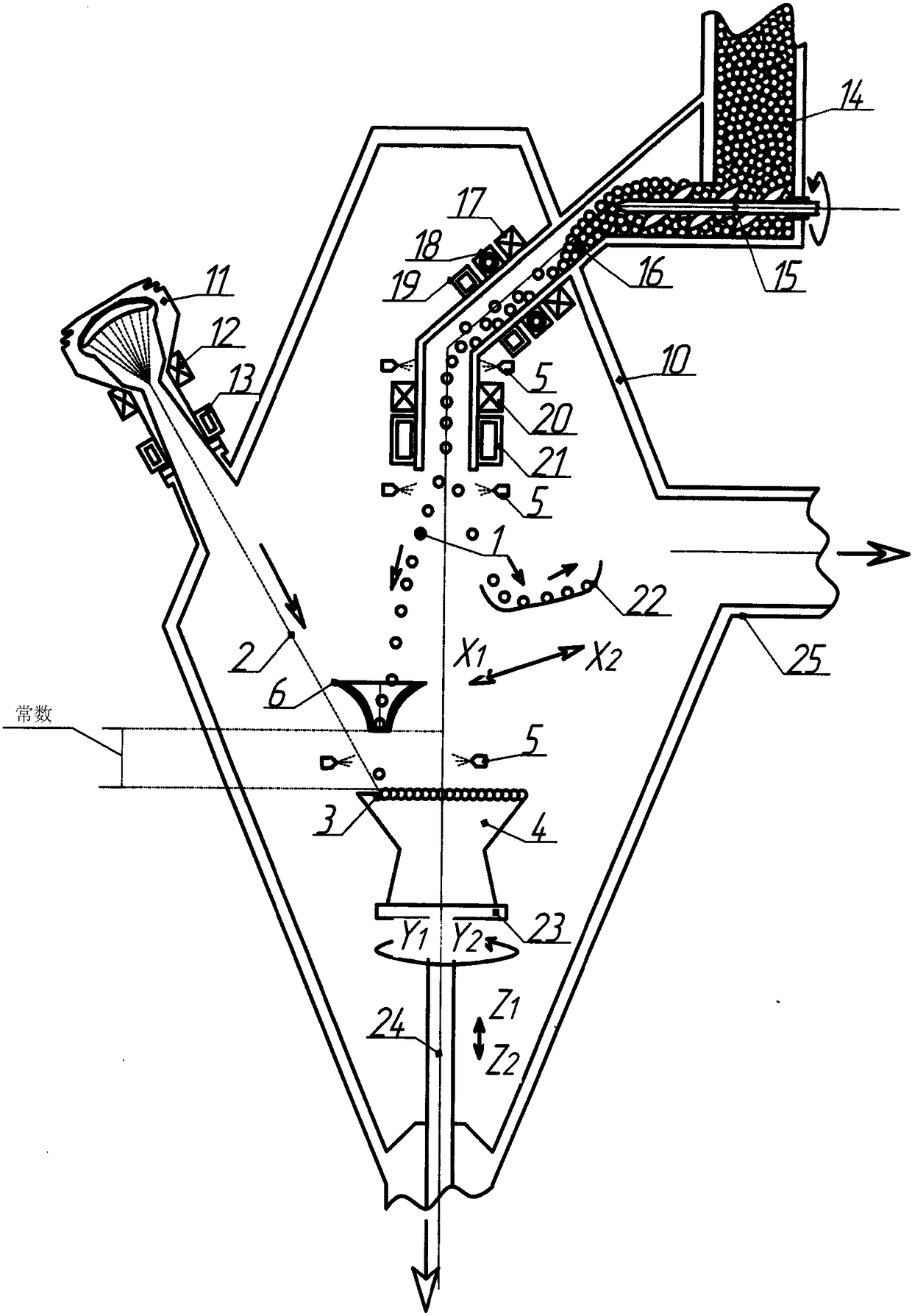

[0039] The disclosed methods for forming additive parts and their implementing devices are related to each other through a common invention design, and are illustrated by the following specific application examples.

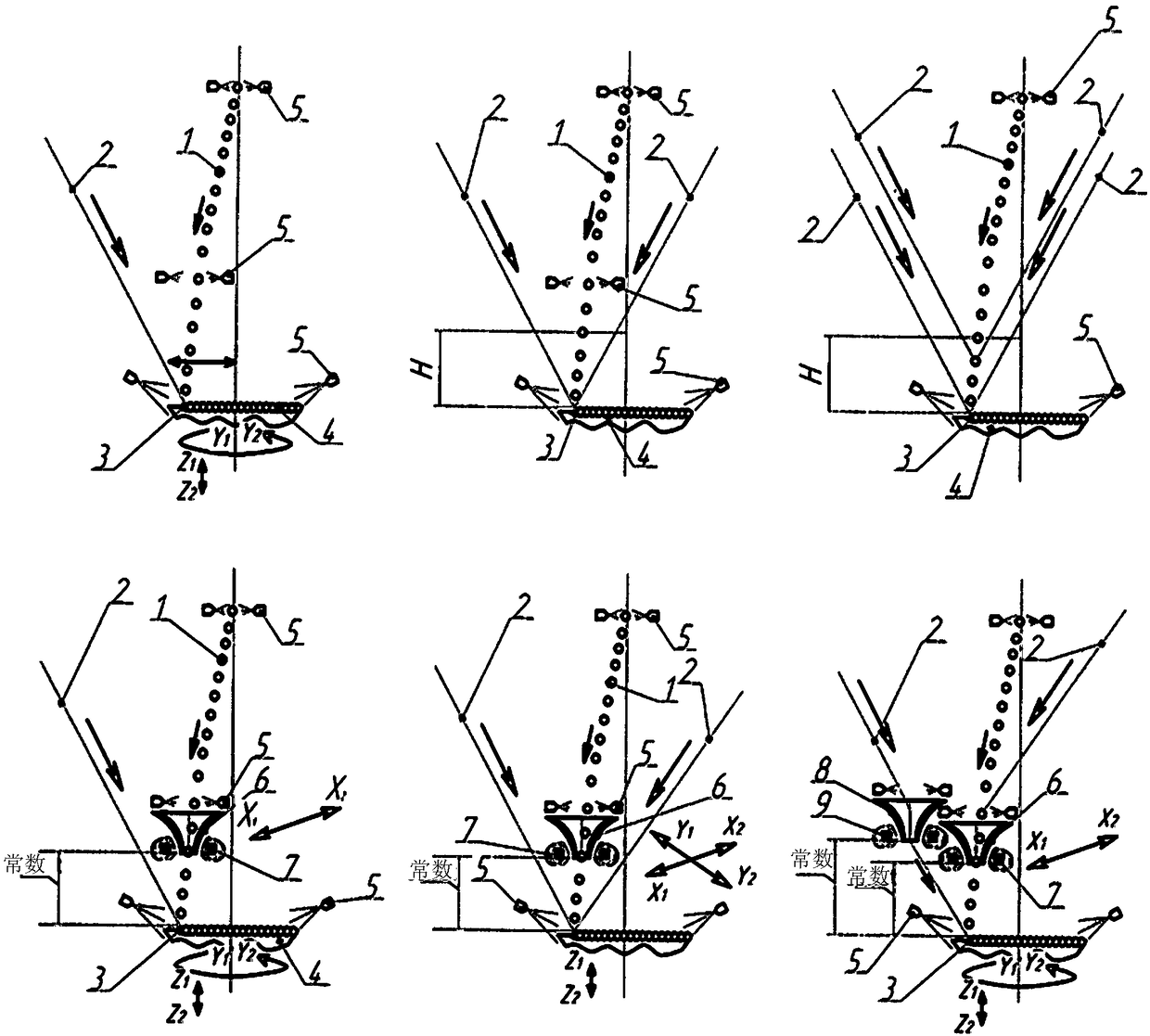

[0040] figure 2 The main proposed method of manufacturing a component 4 is shown in which direct particles 1 are deposited into a molten pool melt 3 formed by a jet 2 , where a material falling path is formed under an electromagnetic field and monitored by a sensor 5 throughout the movement path, The sensor 5 can be used as a radar, scanner, pyrometer, spectrometer, etc. when required.

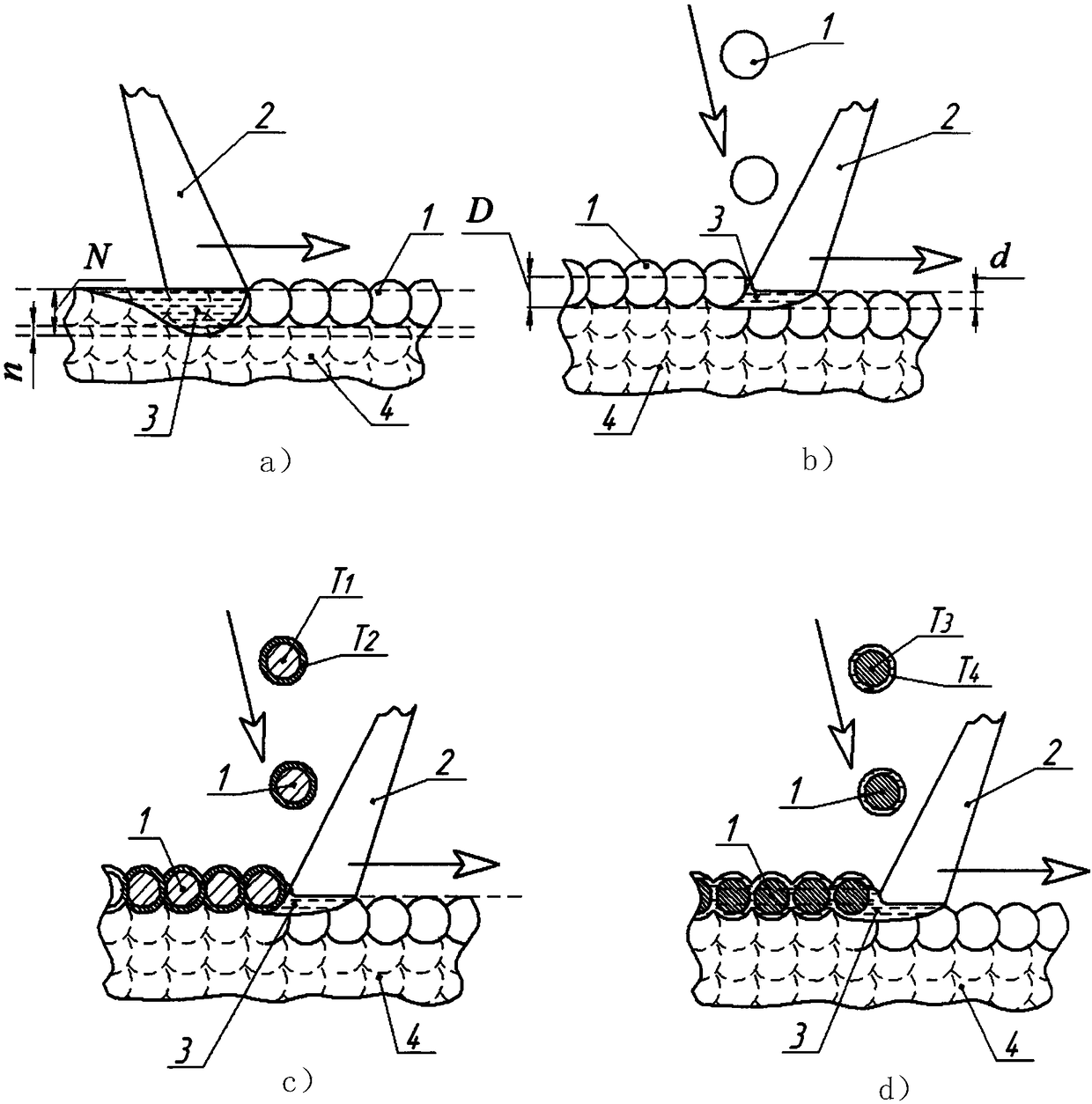

[0041] figure 2 a shows the use of a jet 2 to generate a molten pool melt 3 in the body of a component 4 formed by particles 1 falling from a height under the action of gravity and controlled by an electromagnetic field. Sensors 5 are installed along the particle movement path; they determine the coordinates of the particle at a specific moment, its speed, direction, temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com