Mainboard coating device based on artificial intelligence

A technology of artificial intelligence and coating device, which is applied to the device for coating liquid on the surface, spray device, coating, etc., can solve the problems of low product forming rate, uneven coating, and material cannot be quickly cooled, and achieve The effect of increasing molding rate and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

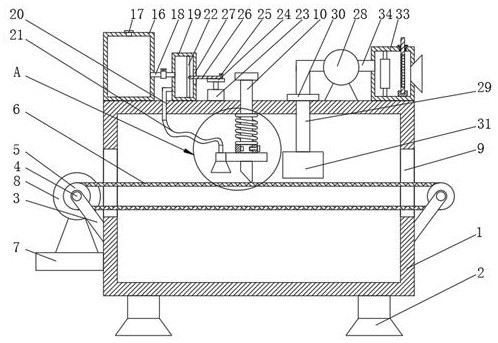

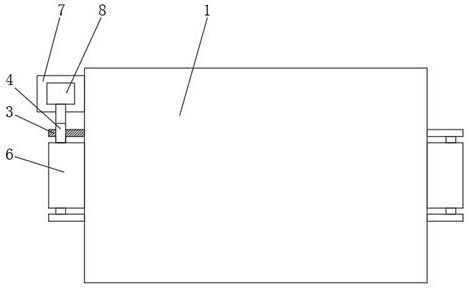

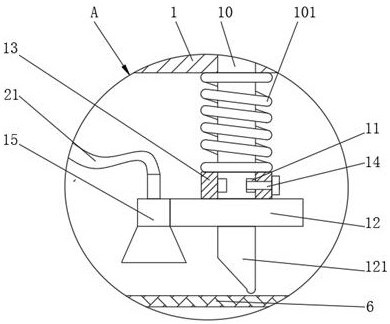

[0026] A main board coating device based on artificial intelligence, comprising a box body 1 and a connecting plate 12, the bottom of the box body 1 is fixedly connected with support legs 2, and the outside of the box body 1 is fixedly connected with four evenly distributed supports A frame 3, a rotating shaft 4 is connected to rotate between the two supporting frames 3, and a guide roller 5 is fixedly connected to the outside of the rotating shaft 4, and a conveyor belt 6 is jointly arranged between the two guide rollers 5, and the box The outside of the body 1 is welded with a motor base 7, the upper end of the motor base 7 is equipped with a first motor 8, the output shaft of the first motor 8 is fixedly connected with the left rotating shaft 4, and the box body 1 is provided with Two symmetrically distributed openings 9, the conveyor belt 6 passes through the openings 9, the inside of the box 1 is threaded with a threaded rod 10, and the threaded rod 10 is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com