Blowing mold with heater

A blow mold and heater technology, applied in the blow mold field, can solve the problems of increased labor intensity, low work efficiency, high investment cost, etc., and achieve the effects of accelerated molding speed, low manufacturing cost, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

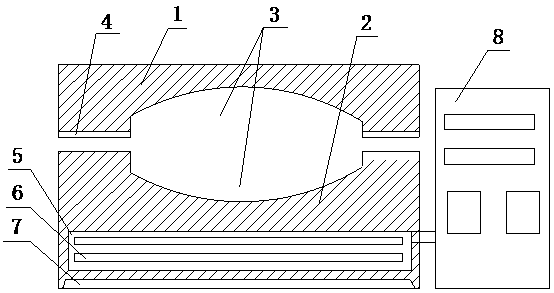

[0012] Such as figure 1 As shown, a blow mold with a heater of the present invention includes a mold body, the mold body includes a female module 1 and a male module 2, the female module 1 and the male module 2 are closed and matched, and the middle part of the female module 1 and the male module 2 There is a mold cavity 3, and the two ends of the mold cavity 3 of the female module 1 are uniformly opened with a plurality of downwardly sunken flow channels 4, and a hollow cavity 5 is provided under the mold cavity 3 of the male module 2, and the hollow cavity 5 A heater 6 is provided, the bottom of the heater 6 is provided with a cooling pad 7, and the heater 6 is controlled by an external intelligent controller 8.

[0013] The advantages of the present invention are: simple structure, convenient use, low manufacturing cost, suitable for the needs of small enterprises, small footprint, saving production cost, the setting of the heater can speed up the molding rate of the articl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com