Aluminum casting motor casting equipment

A casting equipment and aluminum casting technology, applied in the field of aluminum casting motor casting equipment, can solve the problems of slow cooling rate, reduced production rate, low product forming rate, etc., and achieve the effects of convenient use, improved product quality, and improved product forming rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

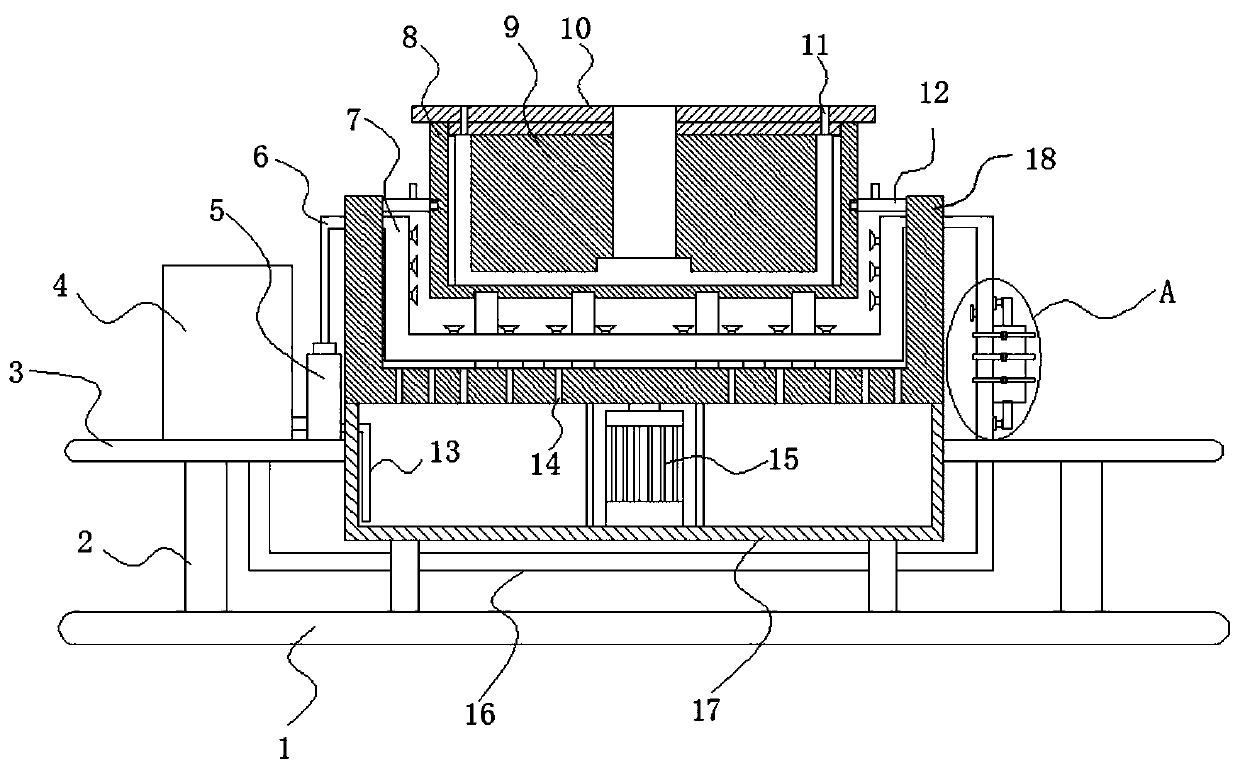

[0029] see Figure 1-3 , an aluminum casting motor casting equipment, including a bottom plate 1, a horizontal plate 3, a base 17, a rotary seat 18, a lower mold 8, a mold core 9, and an upper template 10, and the horizontal plate 3 is horizontally fixed on the bottom plate 1 through a support column 2 Above, the base 17 is fixed on the horizontal plate 3, and the revolving seat 18 is movable above the base 17, and the motor 15 that drives the revolving seat 18 to rotate is fixed in the base 17.

[0030] The top of the revolving seat 18 is open, the revolving seat 18 is detachably provided with a lower mold 8, the top of the lower mold 8 is provided with an upper template 10, the bottom surface of the upper template 10 is fixed with a mold core 9, and the mold core 9 and the lower mold 8 A mold cavity is formed between them, and a heat dissipation gap is left between the outer wall of the lower mold 8 and the inner wall of the rotary seat 18, and drain holes 14 are distributed...

Embodiment 2

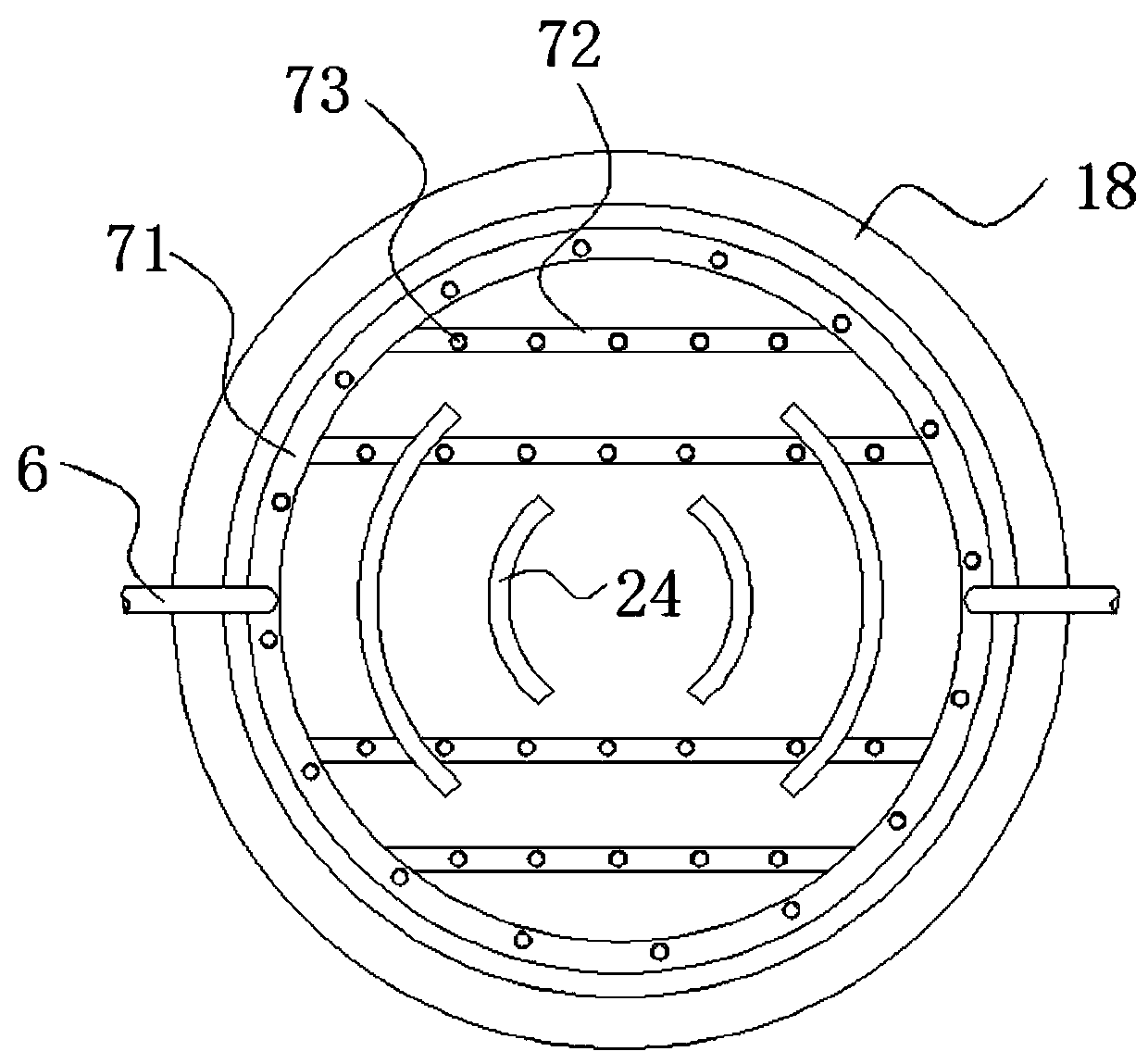

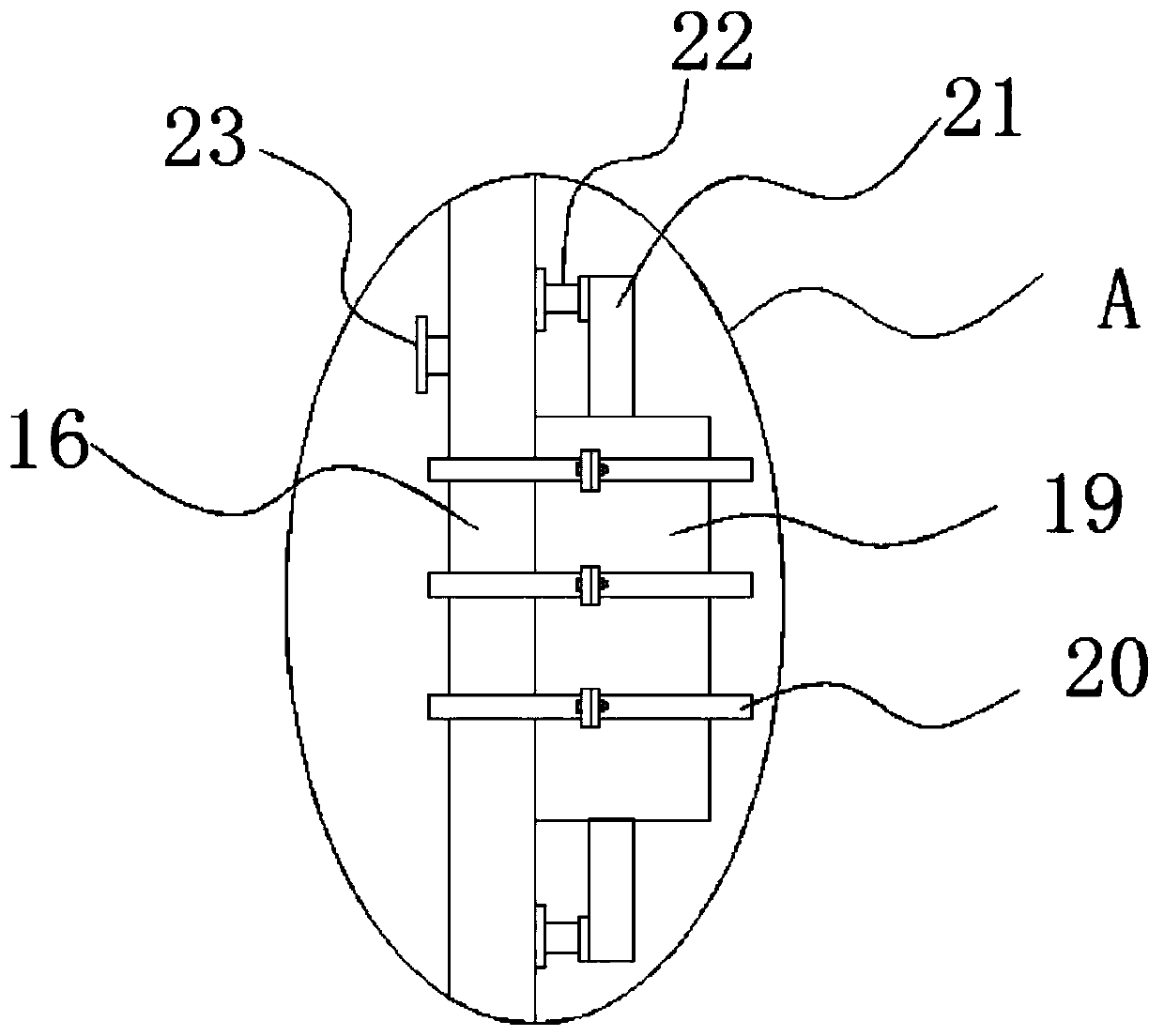

[0042] see Figure 4The opening of the rotary seat 18 is provided with a positioning mechanism for fixing the lower mold 8, and the positioning mechanism includes an annular fixed plate 12, the fixed plate 12 is fixed on the open inner wall of the rotary seat 18, and the top of the fixed plate 12 Notches are distributed in the circumferential direction of the surface, and the side of the fixed plate 12 is provided with several through holes corresponding to the notches. A slider 25 sliding along its length direction is arranged in the notch, and the bottom surface of the slider 25 is connected to the bottom surface of the notch. A gap is left, and a threaded hole is longitudinally provided in the slide block 25, and a positioning bolt 27 is spirally arranged at the threaded hole, and a positioning pin 26 is slidably arranged in the through hole, and the inner end of the positioning pin 26 is fixed with the slide block 25, and the end of the positioning pin 26 Out of the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com