Photocuring three-dimensional printer and three-dimensional object molding method

A technology for 3D printers and 3D objects, applied in the direction of additive processing, etc., can solve the problems of immature technology, impossibility of realization, and high difficulty of realization, and achieve the effects of simple control process, improved forming efficiency, and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

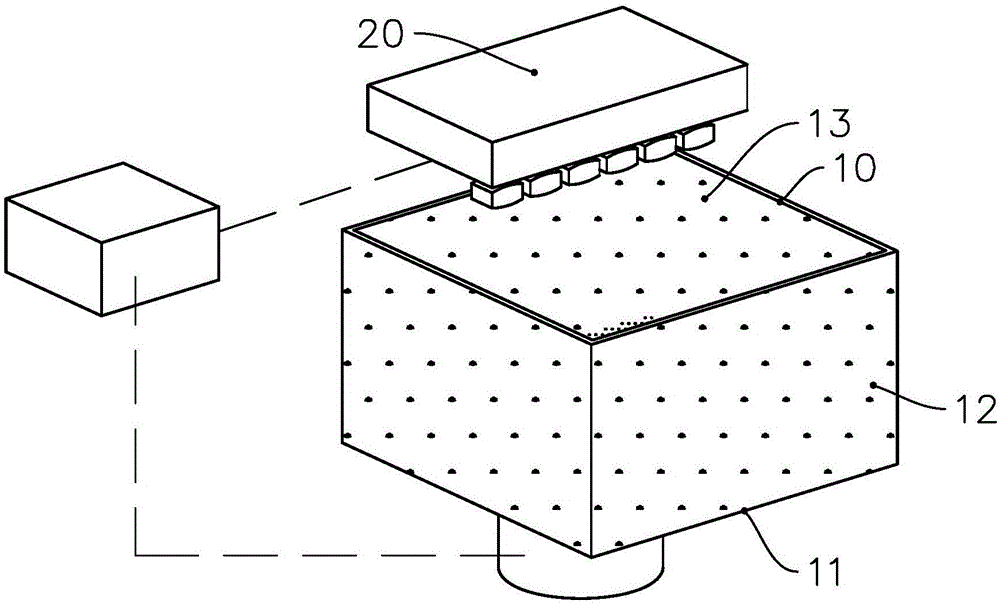

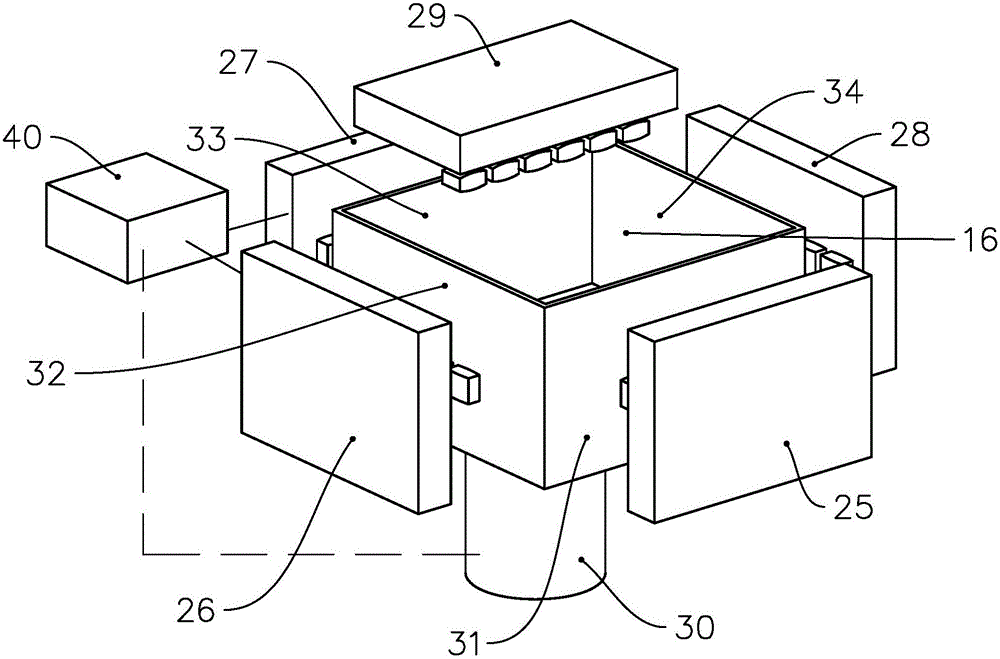

[0039] The method for forming a three-dimensional object includes the following steps. First, a feeding step is performed to add a photosensitive resin into a photosensitive resin tank. The photosensitive resin may be an existing photosensitive resin used for forming a three-dimensional object. The photosensitive resin can be a liquid, preferably, the liquid has a certain viscosity. The adding method of photosensitive resin can be added at one time or adopt automatic adding system to realize the continuous replenishment of the photosensitive resin in the photosensitive resin tank. In such an embodiment, the notch of the photosensitive resin tank may be closed.

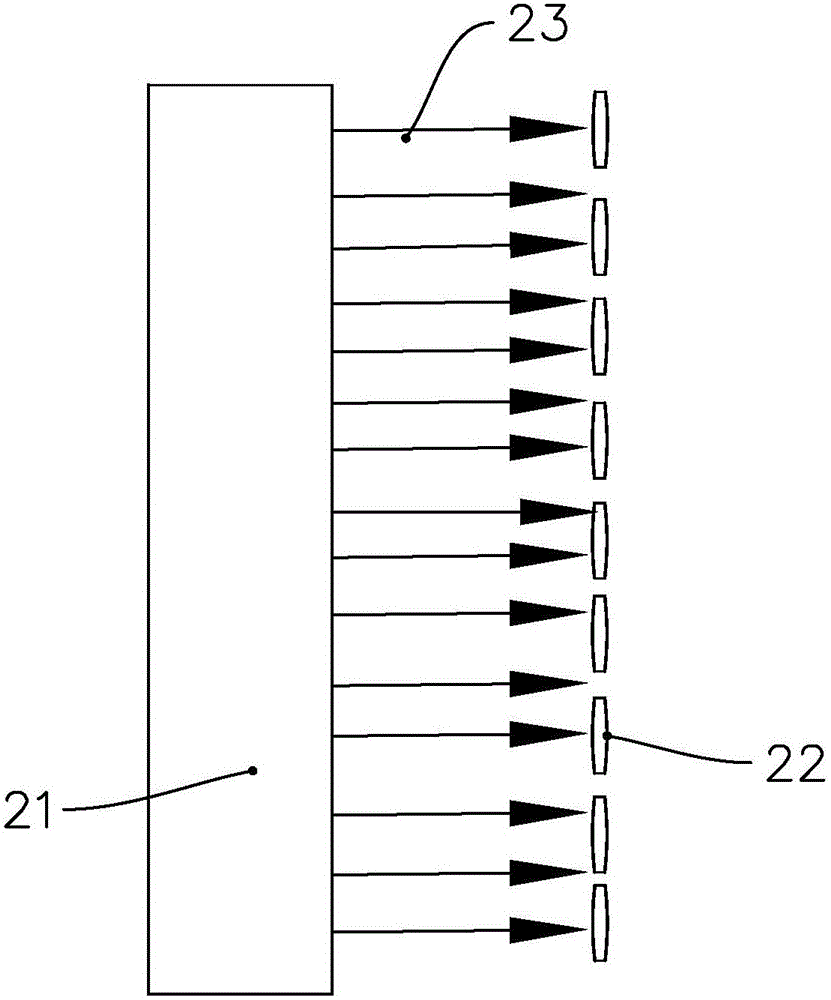

[0040] Next, the planar laser generation step is performed, the laser emits a planar laser beam, and the planar laser beam enters the inside of the photosensitive resin tank. At the same time, the focusing lens moves relative to the laser to adjust the focus position of the laser beam. The intensity of the planar lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com