Photocuring three-dimensional printer and printing method thereof

A 3D printer and light curing technology, applied in the direction of additive processing, etc., can solve the problems of liquid surface sloshing, waste, waste of space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

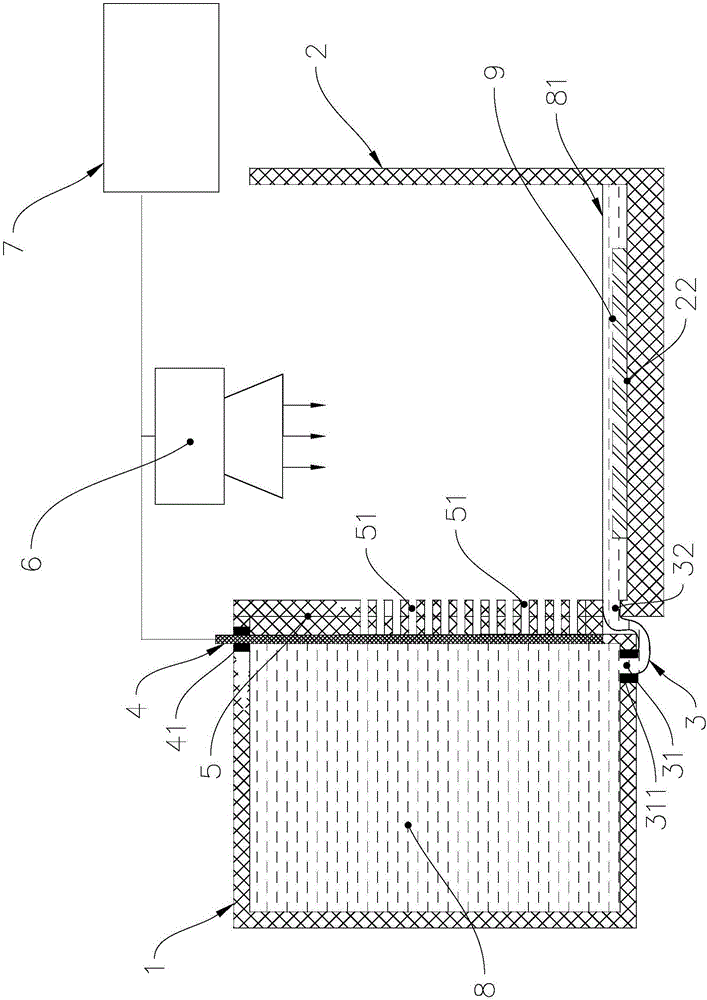

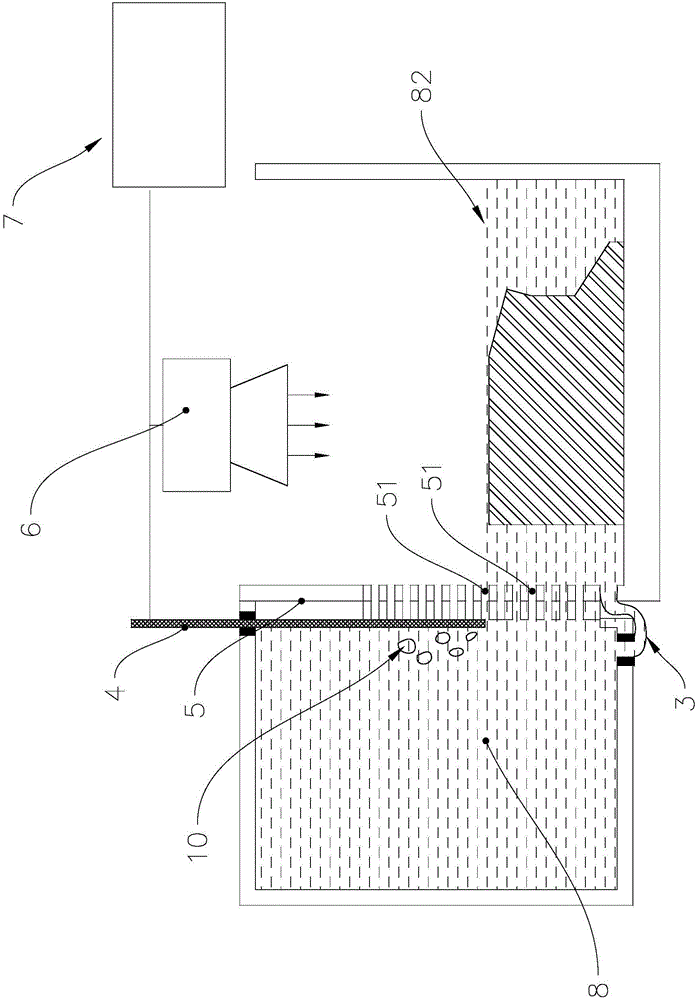

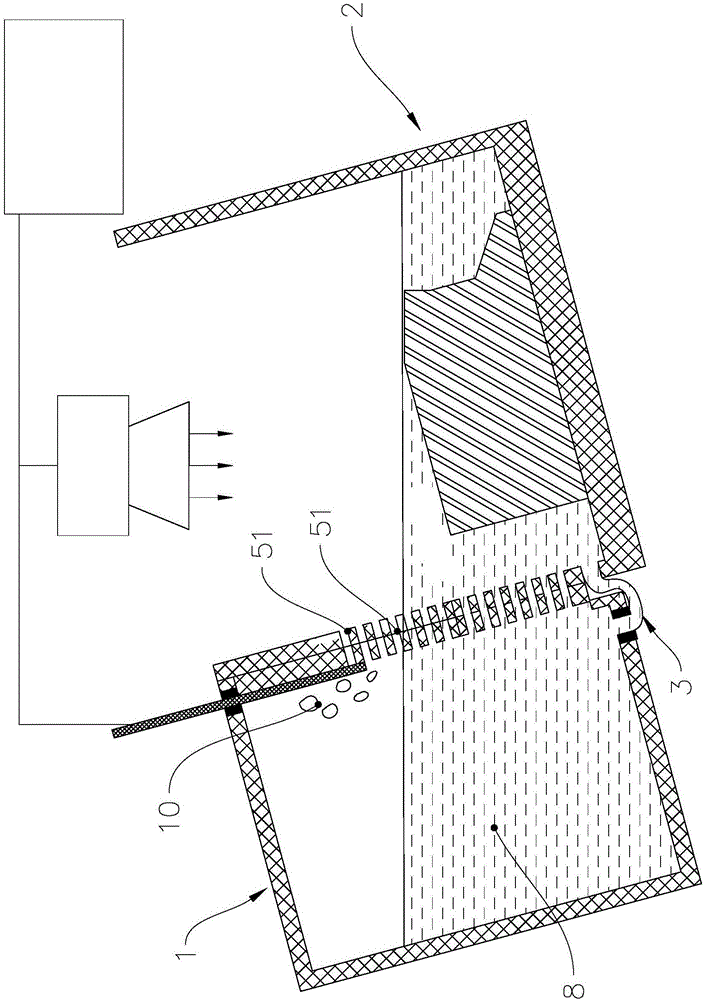

[0032] Photocuring 3D printer embodiment

[0033] see figure 1 , figure 1 It is the structural diagram of the photo-curing 3D printer. The light-curing three-dimensional printer of the present invention includes an accommodating chamber 1 and a forming tank 2 that communicate with each other. The bottom of the forming tank 2 is a printing platform 22. The molding material 8 is accommodated in the accommodating cavity 1 and can flow from the accommodating cavity 1 to the forming tank 2, forming The photocuring device 6 above the tank 2 irradiates and cures the molding material 8 .

[0034] Both the outer wall of the housing cavity 1 and the outer wall of the molding groove 2 are made of non-transparent materials, and a communication channel 3 is provided between the housing cavity 1 and the molding tank 2, and the communication channel 3 realizes the formation of the molding material 8 in the housing cavity 1 and the molding tank 2 flow between. The communication passage 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com