Method for preparing high-adsorption-capacity crystal glue microsphere particles

A high-adsorption, quantitative crystal technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low adsorption capacity of biological macromolecules, small specific surface area of biological substances, etc. Adsorption efficiency, improvement of carbon content and adsorption performance, effect of promoting aromatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

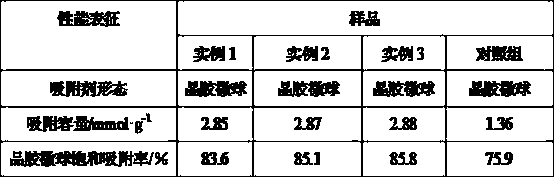

Examples

example 1

[0018] According to the mass ratio of 1:3, the semi-coke powder and the sewage sludge were stirred and mixed to obtain the mixture. In terms of parts by weight, 45 parts of 5% sulfuric acid solution by mass fraction, 55 parts of zinc chloride solution and 10 parts of the mixture were weighed and placed In a beaker, stir and mix and soak for 10 hours, filter to get the filter residue, dry at 100°C for 20 hours, after the drying is completed, collect the dry matter and put it in a mold, press it at 50MPa for 3 minutes, collect the pressed blank and put it in a resistance furnace , After activation at 120°C for 1 hour, pass nitrogen to remove the air, control the rate of nitrogen flow to 55mL / min, under nitrogen atmosphere, raise the temperature to 550°C, heat-preserve and calcinate to obtain carbonized product, rinse the carbonized product with 10% hydrochloric acid for 3 times Finally, wash with deionized water until the washing liquid is 6.0, vacuum dry and ball mill, and pass ...

example 2

[0020] According to the mass ratio of 1:3, the semi-coke powder and the sewage sludge were stirred and mixed to obtain the mixture. In terms of parts by weight, 47 parts of 5% sulfuric acid solution by mass fraction, 57 parts of zinc chloride solution and 12 parts of the mixture were weighed and placed In a beaker, stir and mix and soak for 11 hours, filter to get the filter residue, dry at 102°C for 22 hours, after the drying is completed, collect the dry matter and place it in a mold, press it at 7MPa for 4 minutes, collect the pressed blank and place it in a resistance furnace , after activation at 125°C for 2 hours, pass nitrogen to remove the air, control the rate of nitrogen flow to 57mL / min, under nitrogen atmosphere, raise the temperature to 600°C, heat-preserve and calcinate to obtain carbonized product, rinse the carbonized product with 10% hydrochloric acid for 4 times Finally, wash with deionized water until the washing liquid is 6.0, vacuum dry and ball mill, and p...

example 3

[0022] According to the mass ratio of 1:3, the semi-coke powder and the sewage sludge were stirred and mixed to obtain the mixture. In terms of parts by weight, 50 parts by mass fraction of 5% sulfuric acid solution, 60 parts of zinc chloride solution and 15 parts of the mixture were weighed and placed In a beaker, stir and mix and soak for 12 hours, filter to get the filter residue, dry at 105°C for 24 hours, after the drying is completed, collect the dry matter and put it in a mold, press it at 10MPa for 5 minutes, collect the pressed blank and put it in a resistance furnace , After activation at 130°C for 2 hours, pass nitrogen to remove the air, control the rate of nitrogen flow to 60mL / min, under nitrogen atmosphere, raise the temperature to 750°C, heat-preserve and calcinate to obtain carbonized product, rinse the carbonized product with 10% hydrochloric acid for 5 times Finally, wash with deionized water until the washing liquid is 6.0, vacuum dry and ball mill, and pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com