Large-diameter thin plate sealing diaphragm and method for preventing deformation by turning

A technology of sealing film and large diameter, which is applied in the direction of metal processing equipment, heat exchanger sealing device, metal processing machinery parts, etc., can solve the problems of high cutting heat, large processing volume, and difficult alignment, etc., to ensure processing quality, The effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

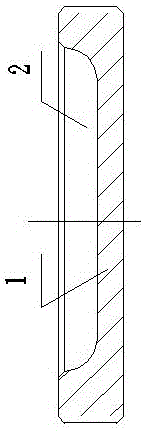

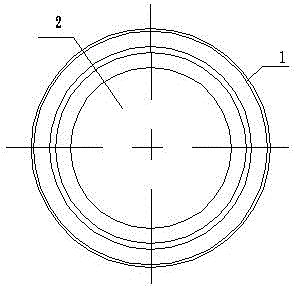

[0021] A method for anti-deformation of large-diameter thin-plate sealing diaphragms, the composition of which includes: processing a disc-shaped steel plate piece 1, cutting a concentric steel plate piece 1 with a diameter smaller than the set The impermeable hole with the diameter and thickness of the disc-shaped steel part described above is less than the thickness of the disc-shaped steel part. The hole is firmly spot-welded with the part, and the assembly is put into a water-filled bowl to fix it, and the vertical lathe is used for underwater processing, and the cutting heat generated during the turning process is dissipated in time during the processing.

Embodiment 2

[0023] The large-diameter sheet sealing diaphragm processed by the method described in Example 1, the thickness of the disc is 8-20mm, the diameter of the disc is 800-2000mm, and the hole processed by the disc is The diameter is 720-1800mm, and the thickness of the hole processed by the disc is 4-10mm.

Embodiment 3

[0025] For the large-diameter sheet sealing diaphragm described in Example 2, the thickness of the disc is 10 mm, the diameter of the disc is 1771 mm, and the diameter of the hole processed by the disc is 1695 mm. The thickness of the hole processed on the wafer is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com