Polyether ether ketone pipe joint and welding method thereof

A technology of polyetheretherketone pipe and welding method, which is applied in the field of pipe joints, can solve problems such as inability to achieve effective welding, and achieve the effects of good sealing performance, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

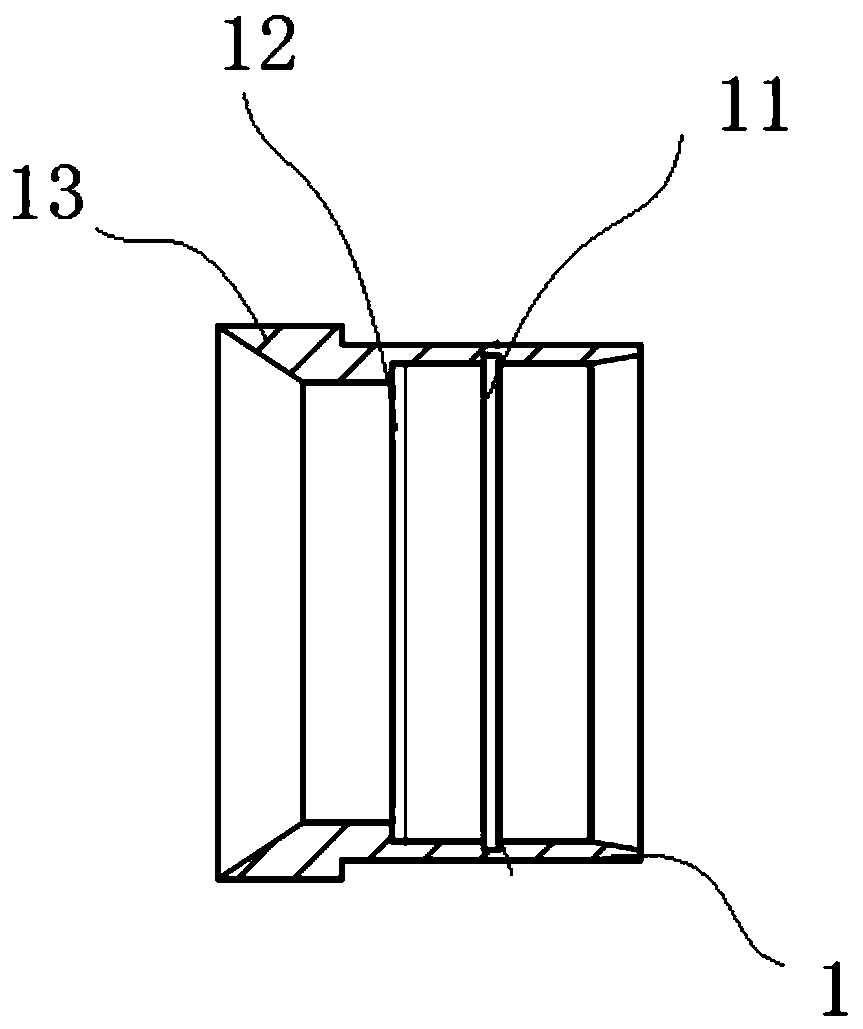

[0065] A polyether ether ketone pipe fitting, such as figure 1 As shown, it includes the joint body 1, the joint body 1 is hollow cylindrical, the two ends of the joint body 1 are provided with openings, the inner wall of the joint body 1 is provided with an annular groove 11 and a stopper 12, the annular groove 11 and the joint body 1 is set coaxially, the annular groove 11 is located between the limiter 12 and the end of the joint body 1, the limiter 12 is columnar, the limiter 12 is coaxially arranged with the joint body 1, the end of the joint body 1 and the limiter Between the pieces 12 is a welded part, and the number of annular grooves 11 is set according to actual needs. When there are multiple annular grooves 11, the plurality of annular grooves 11 are equidistantly distributed along the axial length direction of the welded part.

[0066] In order to facilitate the matching connection between the joint body 1 and the hydraulic balance distributor, one end of the joint...

Embodiment 2

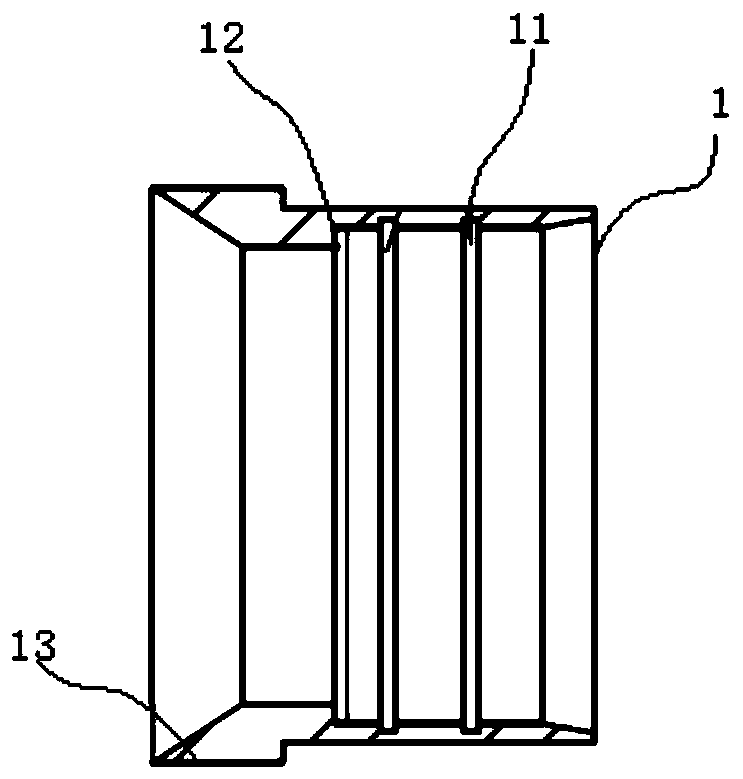

[0071] The difference between this embodiment and Embodiment 1 is that the outer diameter of the joint body 1 is 25 mm, and the wall thickness of the joint body 1 is 1.5 mm, such as figure 2 As shown, the number of annular grooves 11 is 2, the width of the annular grooves 11 is 1mm, the depth of the annular grooves 11 is 0.5mm, and the two annular grooves 11 are equidistantly distributed on the welding length.

[0072] In this embodiment, the tolerance of the outer diameter of the welding end of the PEEK tube 2 is within ±0.12 mm, and the tolerance of the wall of the PEEK tube 2 is within ±0.12 mm. The inner diameter of the joint body 1 is 0.1-0.2mm smaller than the outer diameter of the PEEK tube 2, ensuring that the interference fit between the inner wall size of the PEEK tube joint and the outer diameter of the PEEK tube 2 is 0.1-0.2mm .

Embodiment 3

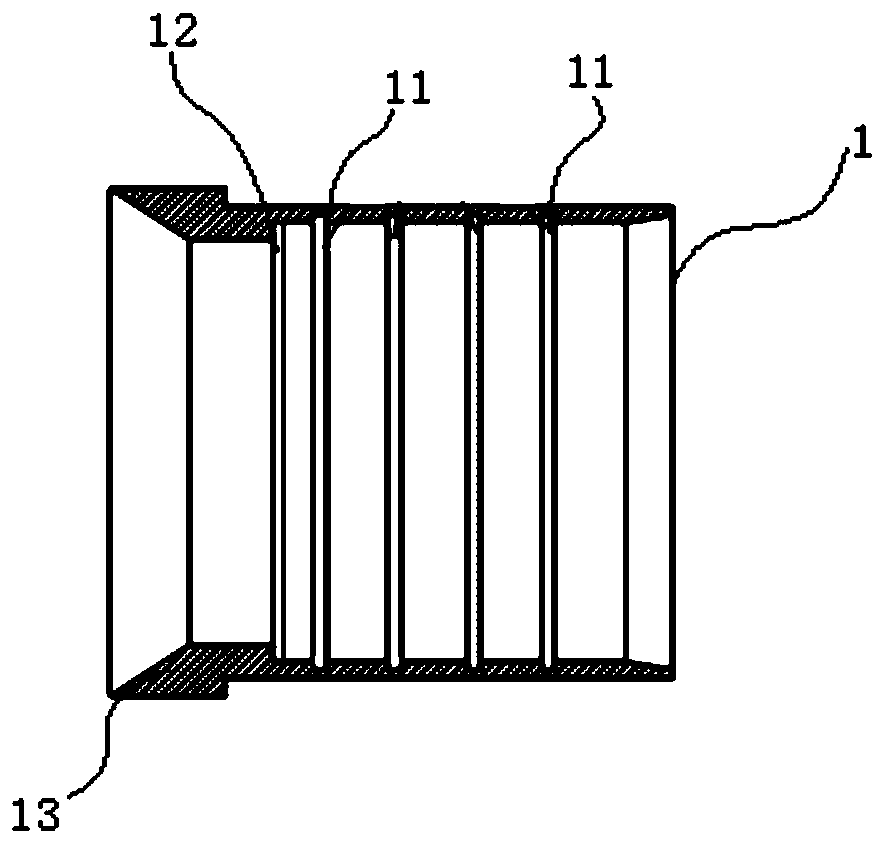

[0074] The difference between this embodiment and Embodiment 1 is that the outer diameter of the joint body 1 is 38 mm, and the wall thickness of the joint body 1 is 1.5 mm, such as image 3 As shown, the number of annular grooves 11 is at least 3, the width of the annular grooves 11 is 2mm, the depth of the annular grooves 11 is 0.5mm, and the annular grooves 11 are equidistantly distributed on the welding length.

[0075] In this embodiment, the tolerance of the outer diameter of the welding end of the PEEK tube 2 is within ±0.2 mm, and the tolerance of the wall of the PEEK tube 2 is within ±0.2 mm. The inner diameter of the joint body 1 is 0.2-0.3 mm smaller than the outer diameter of the PEEK tube 2 , ensuring that the interference fit between the inner wall size of the PEEK tube joint and the outer diameter of the PEEK tube is 0.2-0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com