Rapid Commassie brilliant blue staining solution

A Coomassie Brilliant Blue and staining solution technology, which is applied in the field of Coomassie Brilliant Blue staining solution, can solve the problems of poor visualization of low-abundance proteins, inability to achieve rapid experimentation, and low dyeing sensitivity, and achieve improved dyeing sensitivity, easy operation, and mass spectrometry. good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

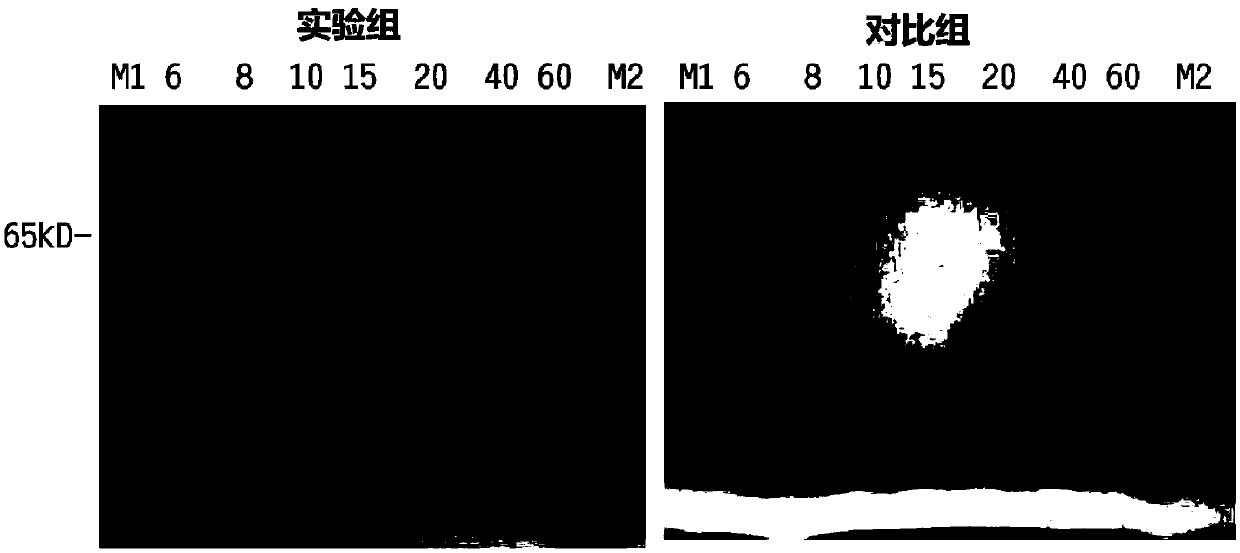

Image

Examples

experiment example

[0018] The rapid Coomassie Brilliant Blue staining solution used in the experimental group consists of the following: the concentration of Coomassie Brilliant Blue G-250 is 500 mg / L, the volume percentage of ethanol is 5%, the volume percentage of phosphoric acid is 3%, and the xylooligosaccharide content is 20g / L; each solution was prepared with double distilled water, and the specific preparation process was as follows:

[0019] (1) Measure 60.0 mL of phosphoric acid with a volume percentage of 50% and add it to 600 mL of double distilled water, and mix well;

[0020] (2) Weigh 20 g of xylooligosaccharides into the mixture prepared in step (1), and stir to completely dissolve the xylooligosaccharides.

[0021] (3) Add 500mg of Coomassie Brilliant Blue G-250 to the mixture prepared in step (2).

[0022] (4) Put the solution prepared in step (3) on a shaker, set the speed at 150rpm, and shake at 37°C for more than one hour to ensure that Coomassie Brilliant Blue G-250 is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com