Purely natural plant hair dye and preparation method thereof

A plant hair dye, natural plant technology, applied in the field of pure natural plant hair dye and its preparation, can solve life-threatening, increased concentration, anaphylactic shock and other problems, to prevent hair breakage and hair loss, excellent dyeing effect, promote blood circulation Effects on Circulation and Metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

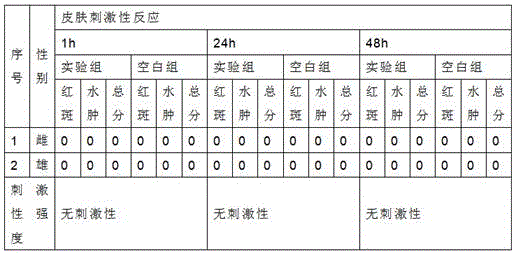

Image

Examples

Embodiment 1

[0033] A preparation method of pure natural plant hair dye, comprising the steps of:

[0034] In step (1), the dried walnut green skin is crushed, extracted twice with ethanol aqueous solution with a volume fraction of 50%, the extract is concentrated by rotary evaporation and the solvent is recovered to obtain an extract;

[0035] The extraction temperature is 70°C, each extraction time is 3h, the solid-liquid ratio of green walnut peel and ethanol aqueous solution is 1:9; the water bath temperature is 80°C during rotary evaporation;

[0036] In step (2), add virgin camellia oil with a quality of 9.9% of the quality of the extract to the extract obtained in step (1), and simultaneously add vitamin B5 with a quality of 1.9% of the extract, and then use a high-pressure homogenizer to homogenize Pure natural plant hair dye can be obtained after sterilization;

[0037] The homogenization pressure is 20 MPa; the homogenization temperature is 55°C, the number of homogenization is ...

Embodiment 2

[0041] A preparation method of pure natural plant hair dye, comprising the steps of:

[0042] In step (1), the dried walnut green skin is crushed, extracted 4 times with an ethanol aqueous solution with a volume fraction of 80%, the extract is concentrated by rotary evaporation and the solvent is recovered to obtain an extract;

[0043] The extraction temperature is 100°C, each extraction time is 5h, the solid-liquid ratio of green walnut peel and ethanol aqueous solution is 1:11; the water bath temperature is 100°C during rotary evaporation;

[0044] In step (2), add virgin camellia oil with a quality of 10.1% of the quality of the extract to the extract obtained in step (1), and simultaneously add vitamin B5 with a quality of 2.1% of the extract, and then use a high-pressure homogenizer to homogenize Pure natural plant hair dye can be obtained after sterilization;

[0045] The homogenization pressure is 100 MPa; the homogenization temperature is 65°C, the number of homogeni...

Embodiment 3

[0049] A preparation method of pure natural plant hair dye, comprising the steps of:

[0050] In step (1), the dried walnut green skin is crushed, extracted three times with an ethanol aqueous solution with a volume fraction of 60%, the extract is concentrated by rotary evaporation, and the solvent is recovered to obtain an extract;

[0051] The extraction temperature is 96°C, each extraction time is 4h, the solid-liquid ratio of green walnut peel and ethanol aqueous solution is 1:10; the water bath temperature is 90°C during rotary evaporation;

[0052] In step (2), add virgin camellia oil with a quality of 10% of the quality of the extract to the extract obtained in step (1), and simultaneously add vitamin B5 with a quality of 2% of the extract, and then use a high-pressure homogenizer to homogenize Pure natural plant hair dye can be obtained after sterilization;

[0053] The homogenization pressure is 80MPa; the homogenization temperature is 60°C, the number of homogenizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com