Polyurethane resin for impregnation of superfine fiber and preparation method thereof

A polyurethane resin and ultrafine fiber technology, applied in the field of polyurethane resin, can solve the problems of poor solvent resistance and acid and alkali resistance, failure to meet the requirements for impregnation of ultrafine fibers, performance degradation, etc. The effect of dyeability, good surface feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

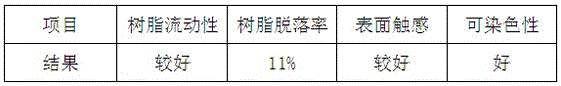

Embodiment 1

[0029] A polyurethane resin for impregnating superfine fibers, prepared from the following components:

[0030] MDI: 105.5g

[0031] PTMEG-1000: 55.5g

[0032] PCL-2000: 66.6g

[0033] PEG-2000: 44.4g

[0034] Ethylene glycol: 28g

[0035] DMF:700g

[0036] Its preparation method is as follows:

[0037] Step 1: Feed 55.5g of PTMEG-1000, 66.6g of PCL-2000 and 44.4g of PEG-2000 into the reactor, heat it to melt into a liquid, put in 28g of chain extender ethylene glycol, and then put in 420g of DMF for synthesis reaction;

[0038] Step 2: After stirring the reaction materials in step 1 for one hour, feed 105.5g MDI twice; at 60°C, put half the amount of MDI in for the first time, and the temperature will rise rapidly after adding MDI. Control the MDI Adding speed, keeping the temperature of 60°C for 20 minutes; for the second time, keeping the temperature of 80°C, put in the remaining amount of MDI, control the adding speed of MDI, stir for 20 minutes after reaching the pr...

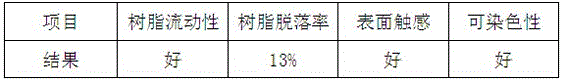

Embodiment 2

[0043] A polyurethane resin for impregnating superfine fibers, prepared from the following components:

[0044] MDI:95g

[0045] PTMEG-1000: 50g

[0046] PCL-2000: 60g

[0047] PEG-2000: 40g

[0048] Ethylene glycol: 25.2g

[0049] DMF:630.9g

[0050] Its preparation method is as follows:

[0051] Step 1: Feed 50g of PTMEG-1000, 60g of PCL-2000 and 40g of PEG-2000 into the reactor, heat it to melt into a liquid, put in 25.2g of chain extender ethylene glycol, and then put in 378.42g of DMF for synthesis reaction;

[0052] Step 2: After stirring the reaction materials in step 1 for one hour, feed 95g of MDI twice; at 60°C, put in half the amount of MDI for the first time, and the temperature will rise rapidly after adding MDI, so control the addition of MDI Speed, keep the temperature at 60°C for 20 minutes; keep the temperature at 80°C for the second time, put in the remaining amount of MDI, control the speed of MDI addition, stir for 20 minutes after reaching the pre-po...

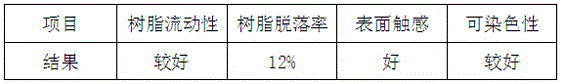

Embodiment 3

[0057]A polyurethane resin for impregnating superfine fibers, prepared from the following components:

[0058] MDI: 80g

[0059] PTMEG-1000: 30g

[0060] PCL-2000: 70g

[0061] PEG-2000: 80g

[0062] Ethylene glycol: 50g

[0063] DMF:690g

[0064] Its preparation method is as follows:

[0065] Step 1: Feed 30g of PTMEG-1000, 70g of PCL-2000 and 80g of PEG-2000 into the reactor, heat it to melt into a liquid, put in 50g of chain extender ethylene glycol, and then put in 420g of DMF for synthesis reaction;

[0066] Step 2: After stirring the reaction materials in step 1 for one hour, feed 80g of MDI twice; at 60°C, add half of the amount of MDI for the first time, and the temperature will rise rapidly after adding MDI, so control the addition of MDI Speed, keep the temperature at 60°C for 20 minutes; for the second time, keep the temperature at 80°C, put in the remaining amount of MDI, control the speed of MDI addition, stir for 20 minutes after reaching the pre-polymeriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com