Modified resin catalyst and preparation method thereof

A technology for modifying resins and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydroxyl addition preparation, etc. It can solve problems such as poor affinity and impact on catalytic activity, and achieve increased production capacity, low drop-off rate, The effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

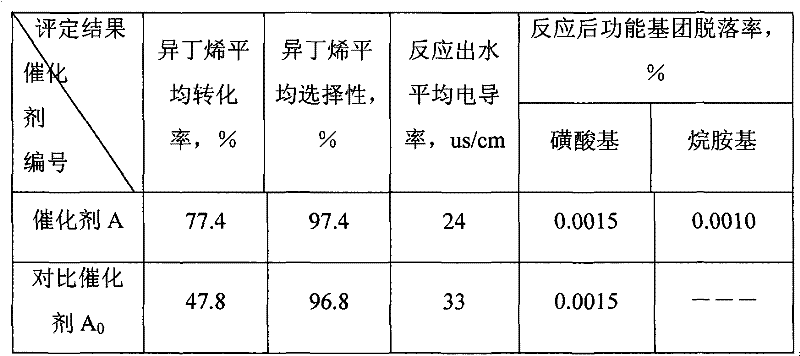

Embodiment 1

[0021] Take 100g of the D006 type macroporous strong acid cation resin catalyst produced by Kairui Chemicals and add it to a 2000ml reactor, add 400ml of pure water, 16.4g of dihexadecylmethylamine and 20.3g of dioctadecyldimethylammonium chloride The mixture was reacted at 95° C. for 10 hours to obtain 135.6 g of the final product—catalyst A, whose physical and chemical indicators were listed in Table 1.

Embodiment 2

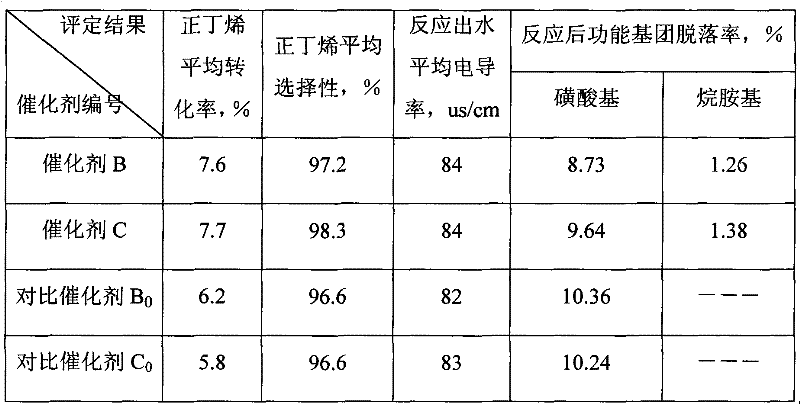

[0023] Take 100 g of the D008 type high-temperature-resistant macroporous strong acid cation resin catalyst produced by Kairui Chemical Industry that introduces electron-withdrawing group Cl on the benzene ring and add it to a 2000ml reactor. A mixture of g dodecylamine-1, 17.8g ditetradecyl secondary amine, 16.4g dihexadecylmethylamine and 20.3g dioctadecyldimethylammonium chloride, react at 25°C In 20 hours, 189.6g of the final product—catalyst B was obtained, and its measured physical and chemical indicators were listed in Table 1.

Embodiment 3

[0025] Take 100 g of a commercially available high-temperature-resistant macroporous strong acid cation resin catalyst with electron-withdrawing group Br introduced on the benzene ring and add it to a 2000 ml reaction kettle, add 400 ml of pure water, 12.5 g of dodecyl primary amine-1 and 15.3 g of double ten The mixture of octaalkyldimethylammonium chloride was reacted at 30° C. for 0.5 hour to obtain 132.5 g of the final product—catalyst C, whose physical and chemical indicators were listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com