Patents

Literature

102 results about "Tertiary-Butyl Alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As a tertiary alcohol, tert-butyl alcohol is more resistant to oxidation and less reactive than the other isomers of butanol. When tert-butyl alcohol is deprotonated with a strong base, the product is an alkoxide anion.

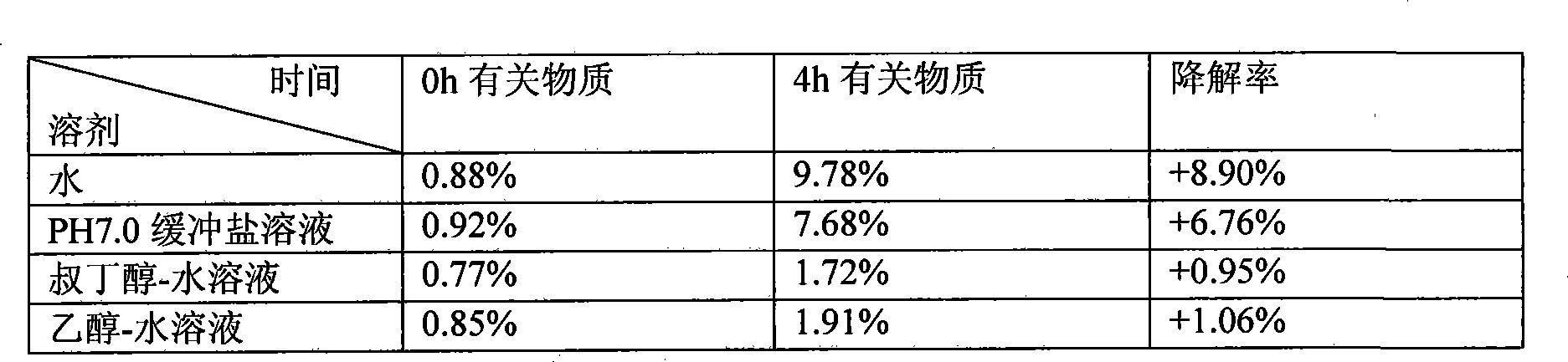

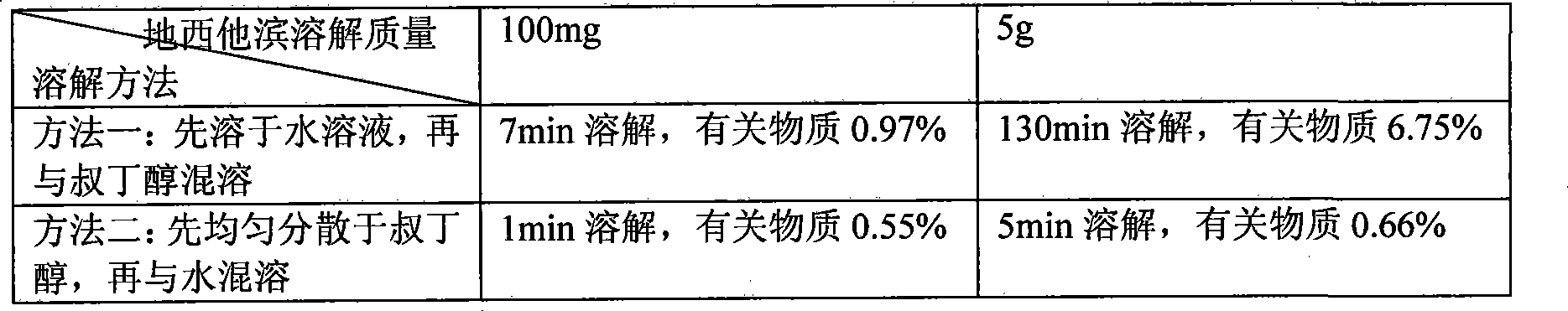

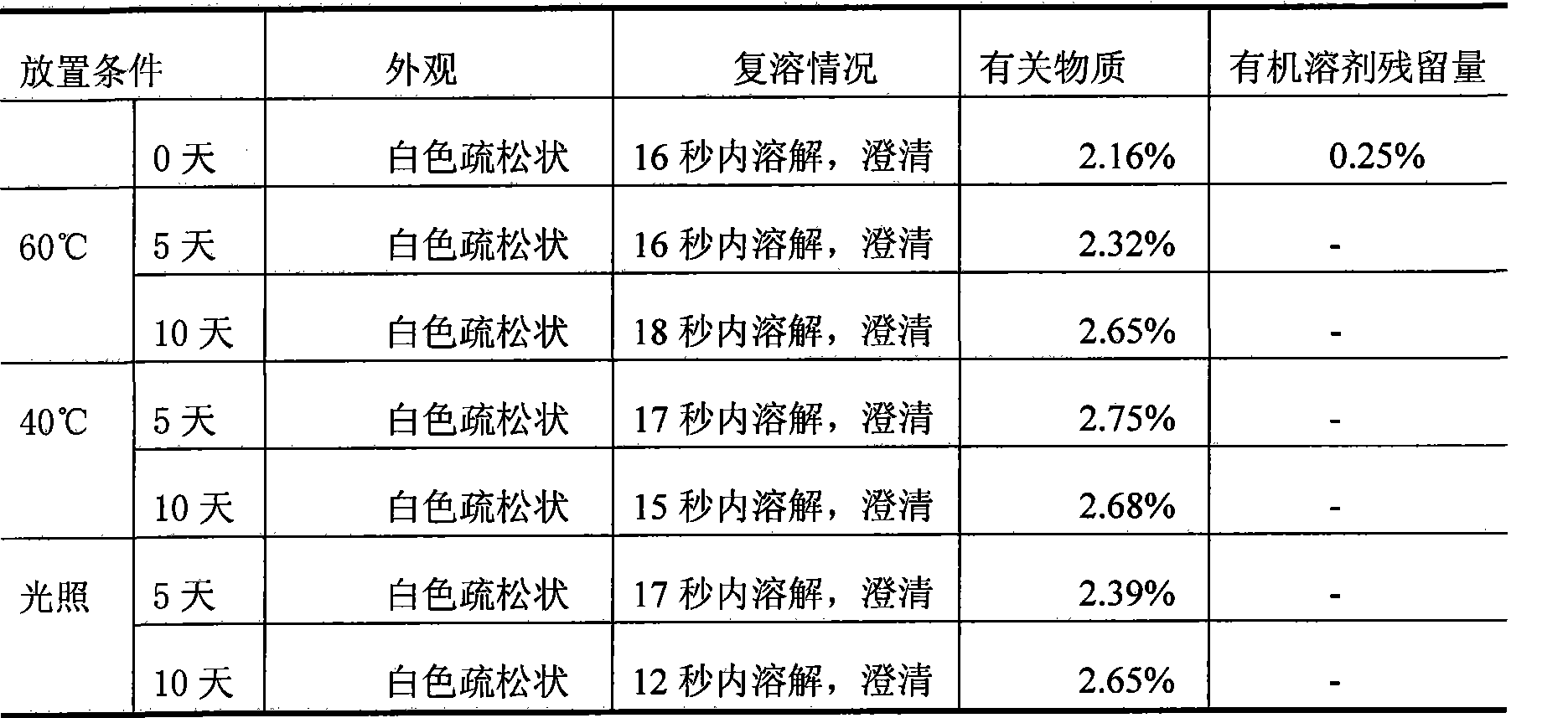

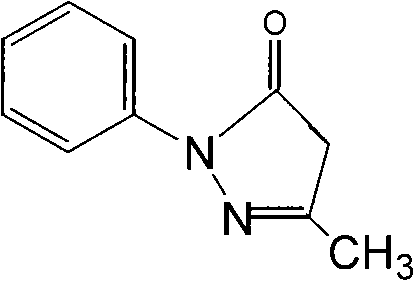

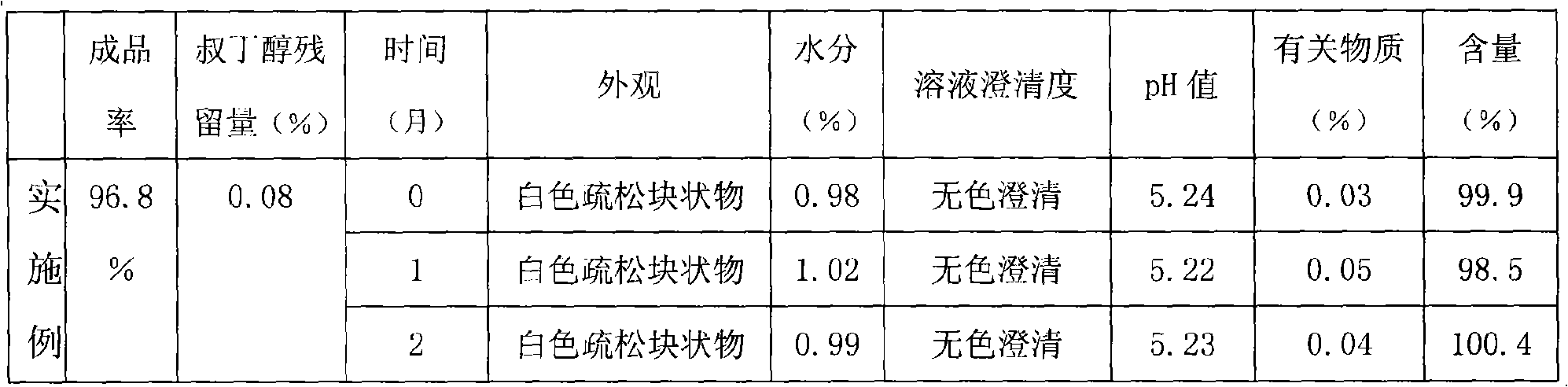

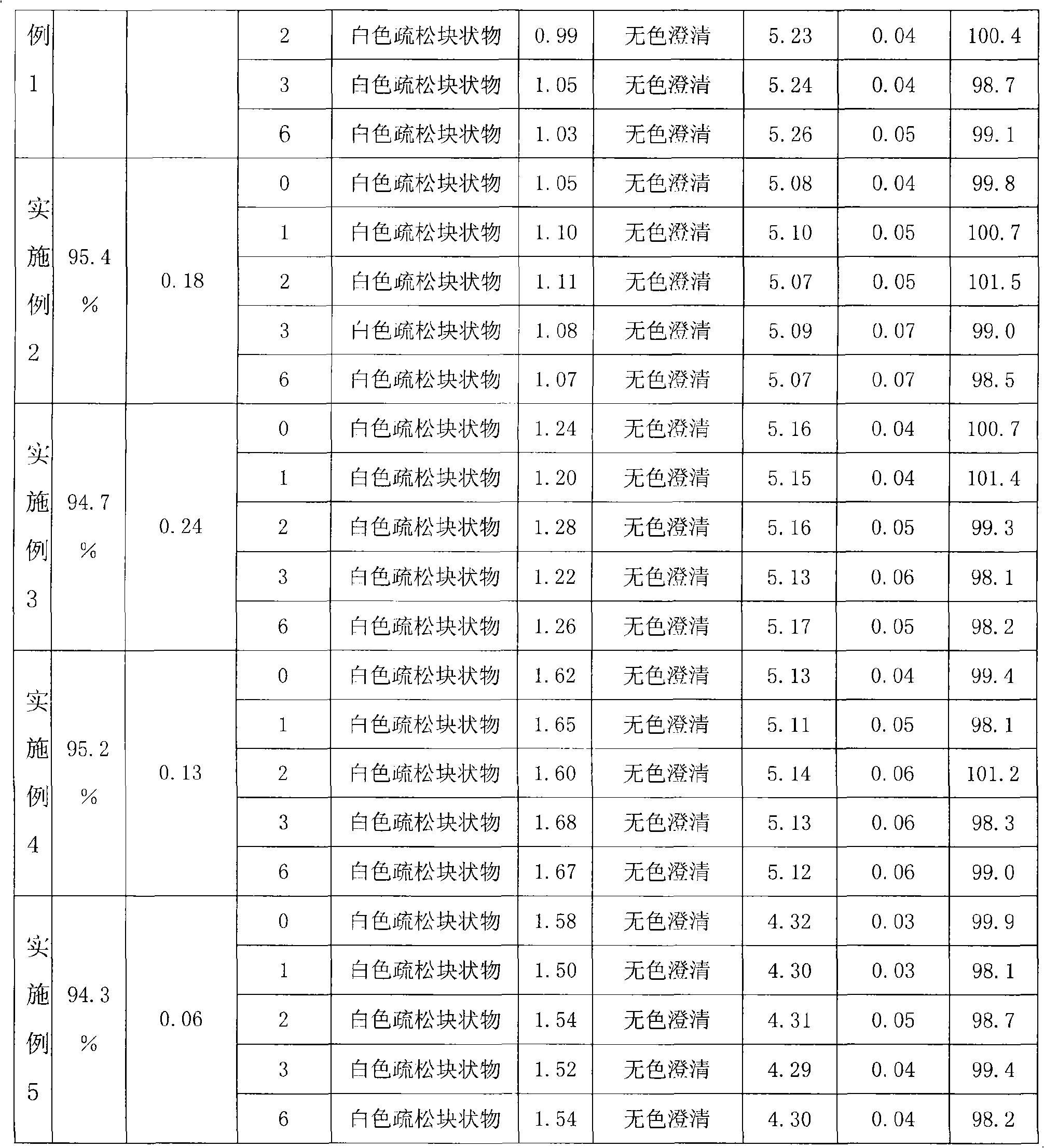

Stable preparation method of decitabine freeze-dry preparation

InactiveCN101361718AAvoid degradationReduce the rate of degradationOrganic active ingredientsPowder deliveryOrganic solventFiltration

The invention discloses a method for preparing a stable Decitabine freeze-dried preparation, which comprises the following steps: Decitabine is uniformly dispersed in at least one of organic solvents including tertiary butyl alcohol, ethanol and methanol or dissolved in the organic solvent dimethyl sulfoxide; and then the mixed solution is mixed with water for injection or the water for injection with freeze-dried propping agents and / or pH regulators dissolved, thus obtaining a new mixed solution and the organic solvent accounting for 5-80 percent of the mixed solution in volume; and organic solution is removed after filtration and freeze drying. The method can prepare a stable Decitabine freeze-dried preparation, in which the residual quantity of organic solvent is not more than 1 percent.

Owner:深圳万乐药业有限公司

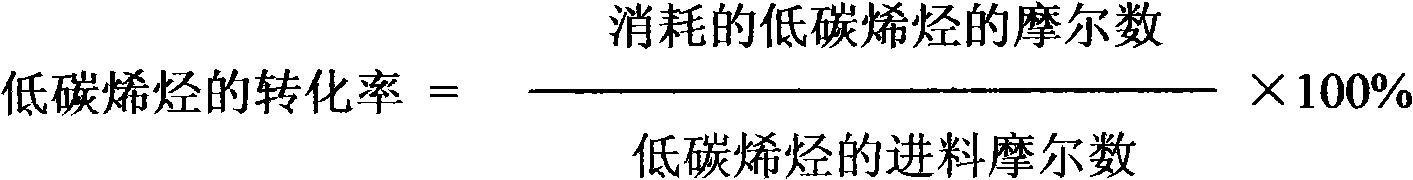

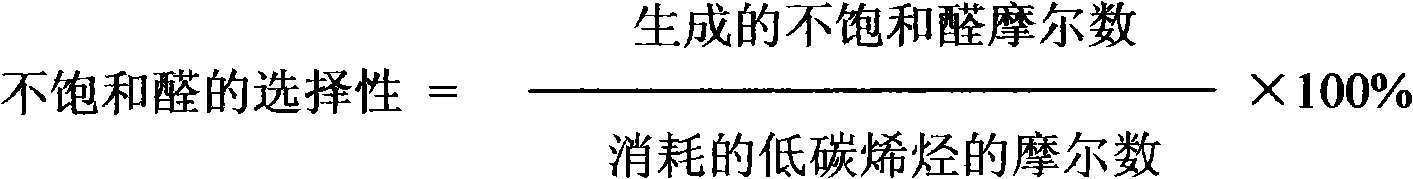

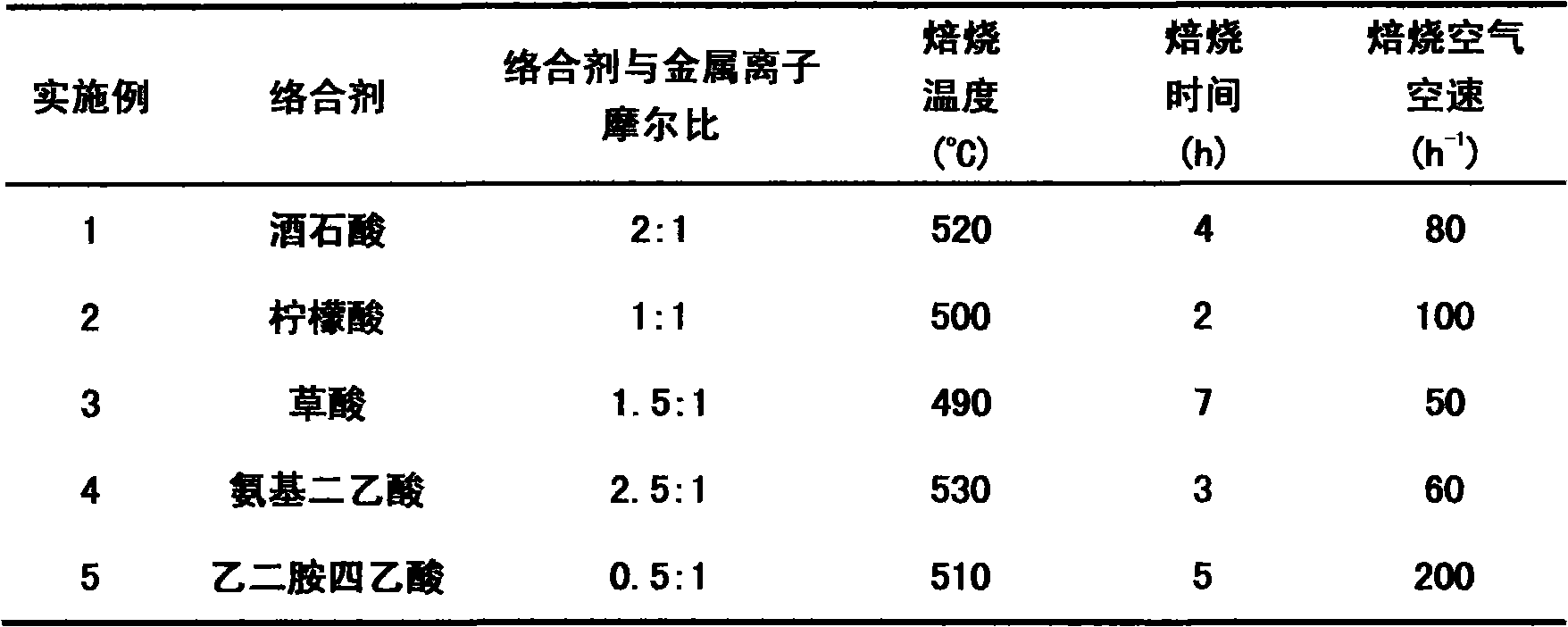

Method for preparing catalyst applied to low-carbon olefin selective oxidization for undersaturation aldehyde preparation

InactiveCN101579631AHigh activityGood choiceOrganic compound preparationHeterogenous catalyst chemical elementsGas phaseAqueous solution

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

Oxaliplatinum liposome glucose preparation and its preparation method and application

ActiveCN101103972AImprove the quality of lifeReduce inhibitionPowder deliveryPharmaceutical non-active ingredientsCholesterolLiposome

The invention discloses an oxaliplatin liposome glucose preparation and the preparation method and application, relating to an oxaliplatin liposome glucose solution preparation used for tumor resistance and the preparation method and application. An oxaliplatin liposome glucose preparation is formed by liposome which prepared by oxaliplatin, hydrogenated phosphorus, cholesterol and DSPE-PEG2000, and is dissolved in glucose solution; wherein the weight ratio of the hydrogenated phosophorus and the oxaliplatin is 1:1-50; the weight ratio of the hydrogenated phosophorus, cholesterol and the DSPE-PEG2000. The preparation method is that the hydrogenated phosophorus, cholesterol and the DSPE-PEG2000 are weighed according to proportioning by weight in a description and then fixed together; tertiary butyl alcohol is added into the fixture for the fixture to be stirred and dissolved, then the fixture is precooled; the oxaliplatin saturated water solution with 4-10 percent of glucose after cooling and drying is stirred, dissolved and emulsified by an emulsion balancing machine and then prepared into liposome solution by a homogenizer and a nanometer extruder, separated and refined through a filter column to prepare the oxaliplatin liposome glucose solution.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

Biodiesel based fuel oil and preparation thereof

The invention provides biodiesel based fuel oil which comprises the following components by weight: 50-80 percent of crude biodiesel, 4-35 percent of compound emulsifying agent, and one or two mixture of water and methanol, wherein the compound emulsifying agent is the mixture of the two types of materials, the first-type material is one or the mixture of a plurality of oleic acid, palmitoleic acid, naphthenic acid, aliphatic amine polyethenoxy ether with C atomicity being 40-100, dehydration sorbitan fatty acid ester with C atomicity being 40-100, polyoxyethylenec dehydration sorbitan fatty acid ester with C atomicity being 40-100; the second-type material is one or the mixture of a plurality of monoethanol amine, diethanolameine, trolamine, diglycol amine, 1-octanol and tertiary butyl alcohol. The preparation method is as follows: the mixtures are mixed according to the percent by weight and are mixed uniformly so as to obtain transparent solution. The fuel oil has good stability, non layering for a long time, no discolor and no turbidity, and is directly prepared by adopting the crude biodiesel. Methanol or water or the mixture of the water and the methanol is added, thus the consumption of the biodiesel is saved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Edaravone lyophilized preparation and preparation technique thereof

ActiveCN101288650ASimple preparation processSuitable for industrial productionPowder deliveryOrganic active ingredientsFreeze-dryingFreeze dry

The invention relates to a stable edaravone freeze-dried preparation, a preparation process and a using method. The preparation is composed of edaravone and a freeze-dried stabilizer. The preparation process is that the edaravone and the freeze-dried stabilizer are dissolved in a mixed solvent system with tertiary butyl alcohol / water, and the freeze-drying process is carried out for freeze-drying. The preparation has stable quality and the preparation process is applicable to the industrial production.

Owner:JIANGSU SIMCERE PHARMA +1

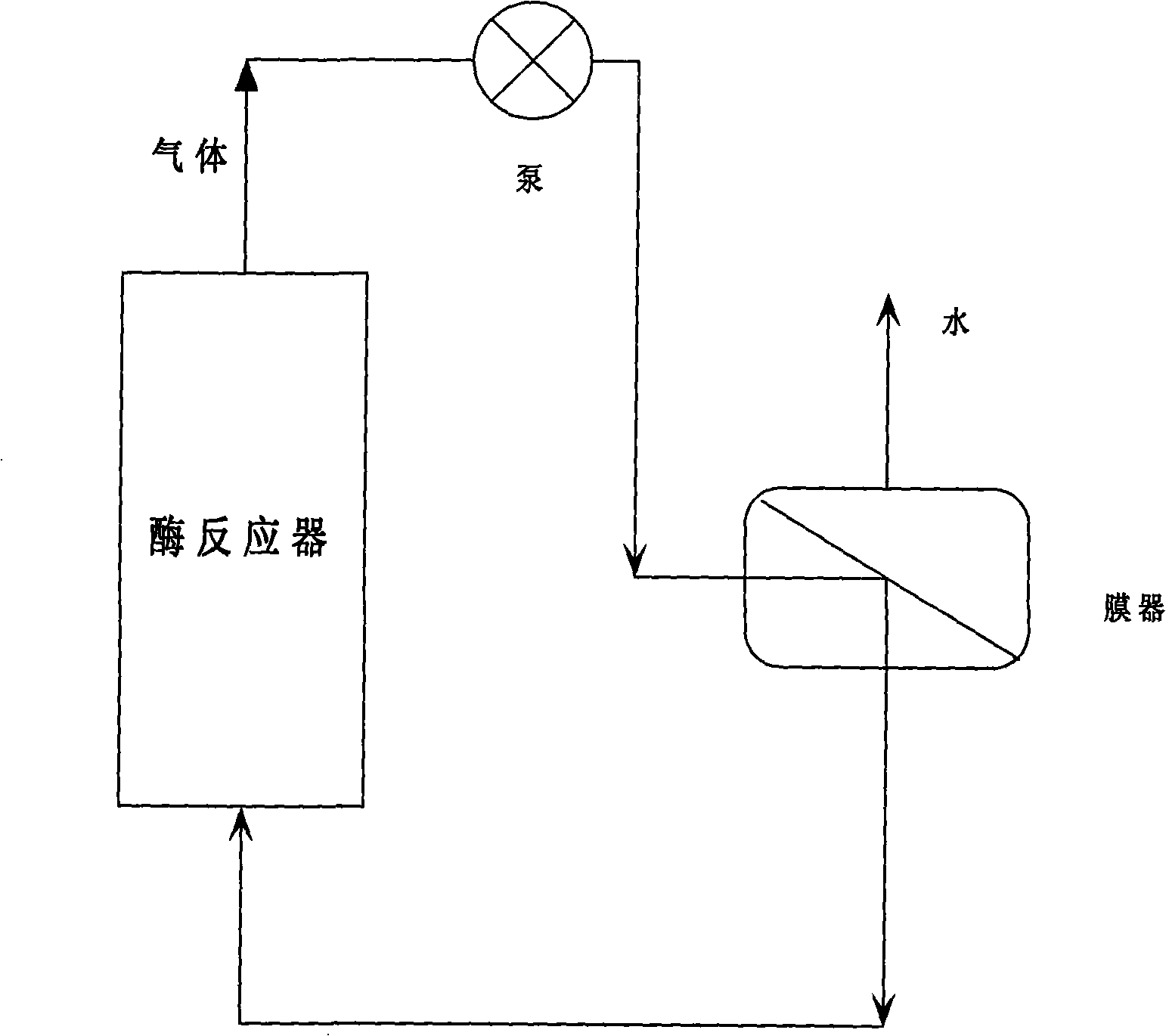

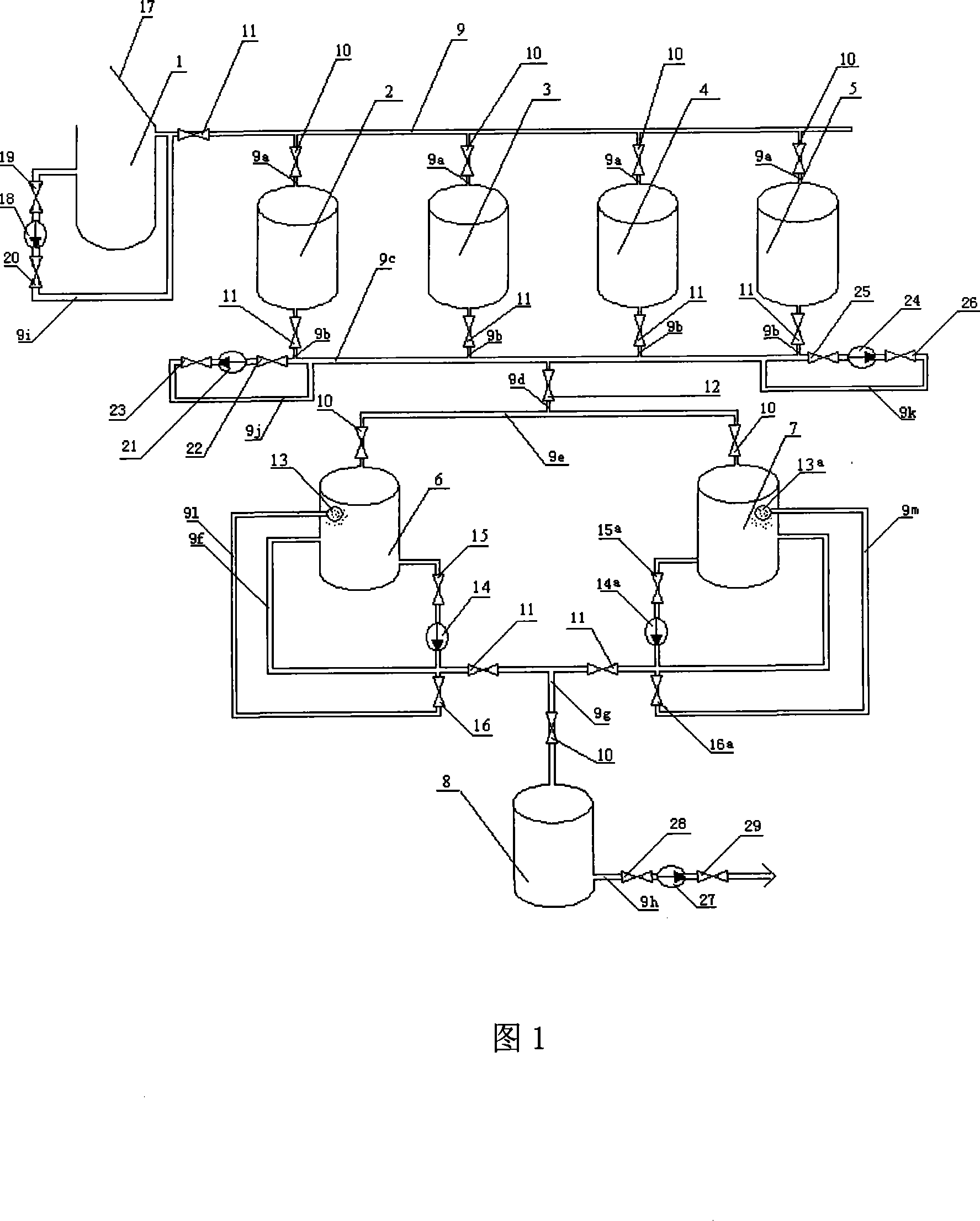

Bio diesel oil preparation technique using enzyme method of membrane on-line dehydration

ActiveCN101358216AImprove reaction efficiencyHigh yieldBiofuelsLiquid hydrocarbon mixture productionChemical synthesisOil and grease

A process for preparing biodiesel by utilizing the enzymatic method of membrane online dehydration belongs to the field of biological and chemical synthesis. During the reaction of preparing the biodiesel by enzymatic grease with tertiary butyl alcohol as the reaction medium, volatilizable gases in the reaction system are directly used as the circulation dynamic force of the liquid in a reactor; the by-product water produced during the reaction is carried out from the enzyme reactor by the volatilizable gas and passes through a water-permselective membrane device so as to realize the online separation of the by-product water; the volatilizable gases such as the tertiary butyl alcohol and short chain alcohol still return to the enzyme reactor after passing through the membrane device and the circulation continues. The transmission of the membrane to water is more than 90 percent; the transmission of the membrane to the tertiary butyl alcohol is below 5 percent. The process for preparing biodiesel by utilizing the enzymatic method of membrane online dehydration has the advantage that the enzymatic reaction efficiency as well as the yield of the biodiesel are greatly improved, and is significant for the continuous production of preparing the biodiesel by the industrial enzymatic method.

Owner:TSINGHUA UNIV +1

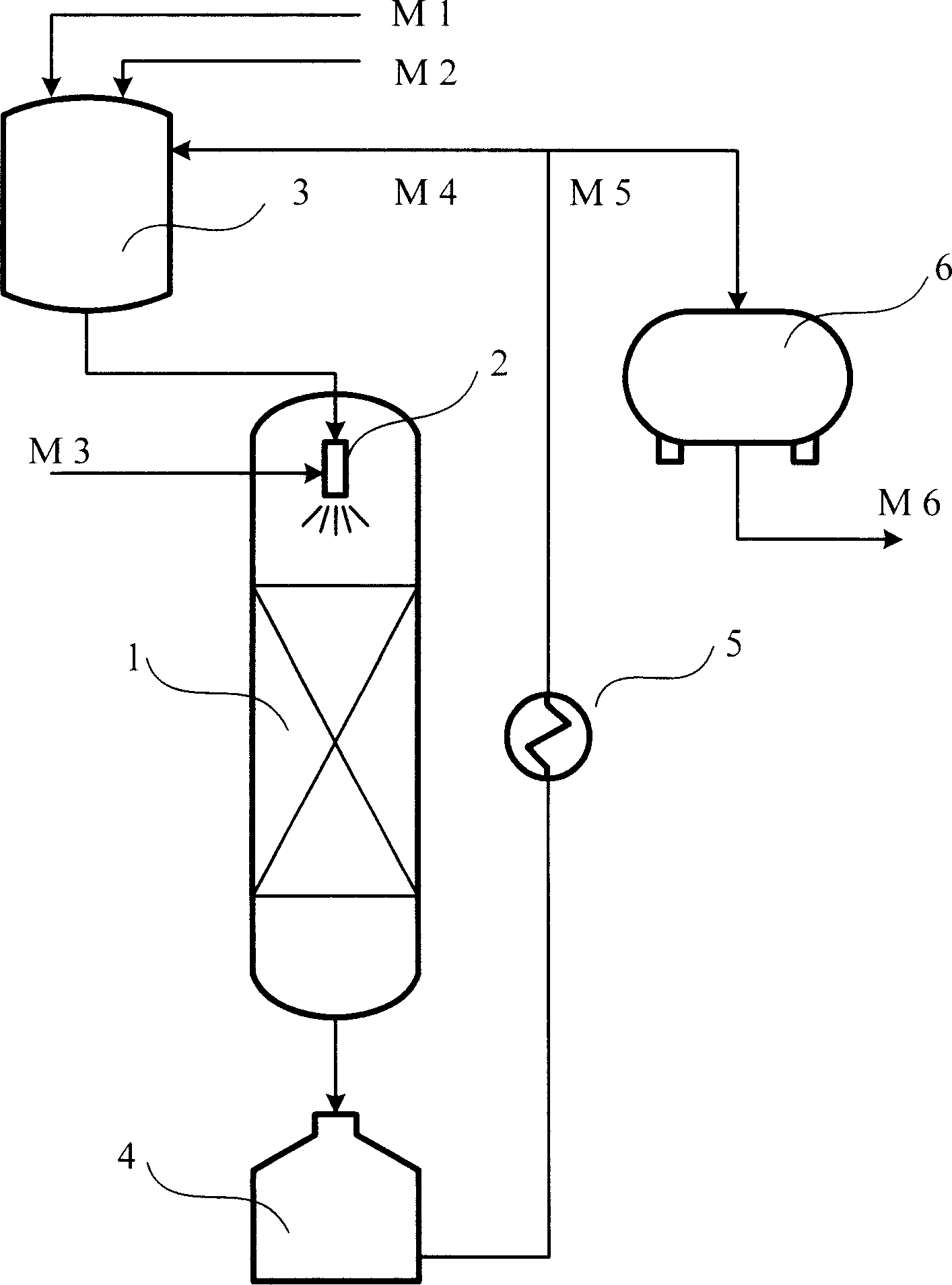

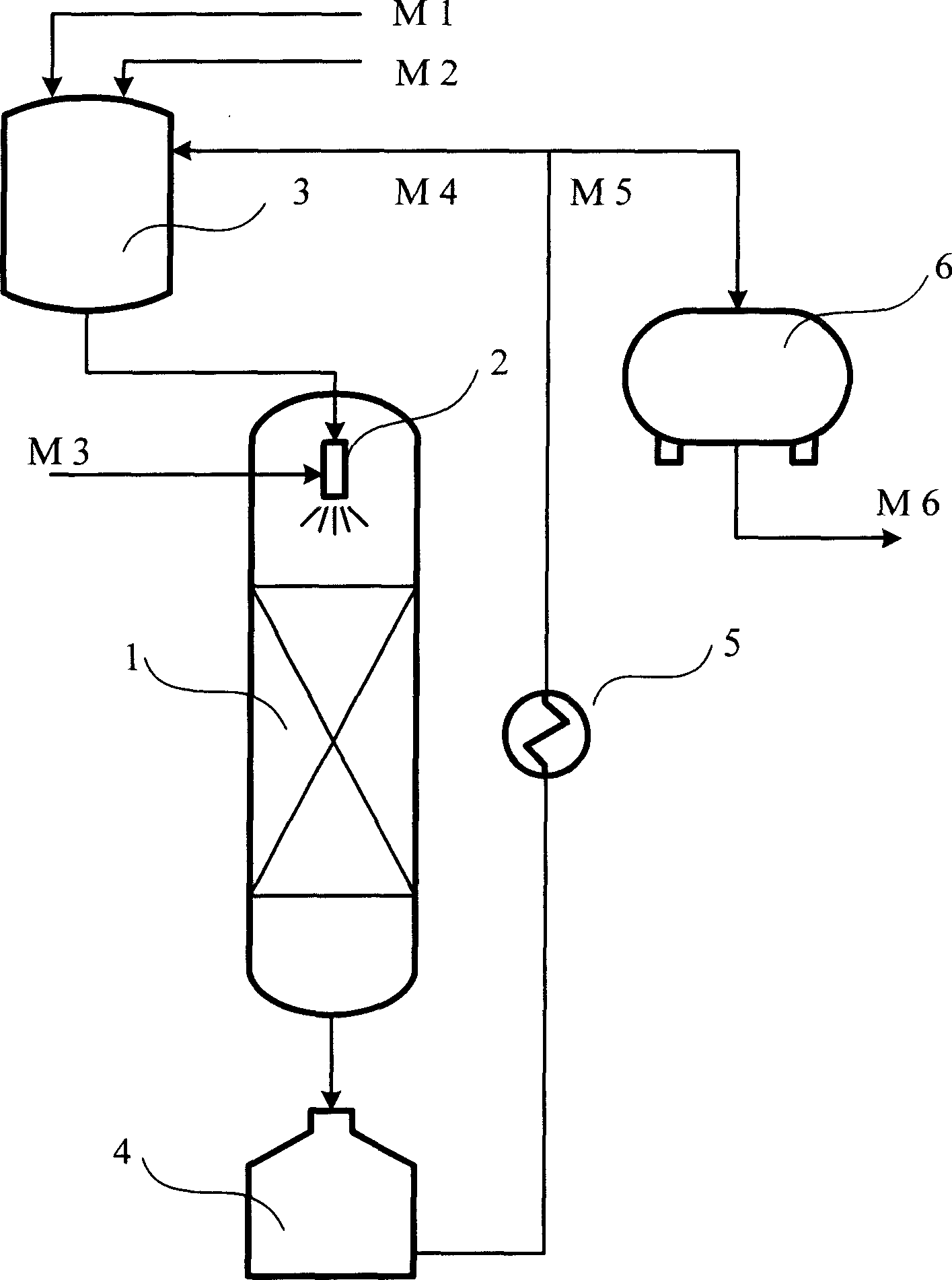

Method of preparing cyclopentene by continuous hydrogenation of cyclopentadiene

InactiveCN1911877AWell mixedImprove mass transfer efficiencyHydrocarbon by hydrogenationCyclopenteneFixed bed

The continuous cyclopentadiene hydrogenating process to prepare cyclopentene is one continuous catalytic hydrogenation reaction of the mixture of cyclopentadiene, solvent and hydrogen in a fixed bed catalyst bed. The catalyst includes gamma-Al2O3 as carrier and Pa as active component. The solvent is any one of benzene, toluene, cyclohexane, ethanol, methanol, tertiary amyl alcohol and tertiary butyl alcohol. The molar ratio between cyclopentadiene and hydrogen is 1 to 1.5-3.5, and the reaction system has pressure of 0.9-1.5 MPa and temperature of 30-55 deg.c. The reacted liquid is discharged partially and externally circulated partially with the weight ratio being 1 to 6-12, and the externally circulated liquid after being cooled is mixed with cyclopentadiene material and solvent before being mixed with hydrogen in venturi ejector, atomized into gas-liquid mixture and reacted in the catalyst bed. The catalyst load is 4-7 / hr accounted in liquid phase material, and the reacted heat is transferred via external circulation.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

Purification of tertiary butyl alcohol

InactiveCN1860090AEasy to recycleHydroxy compound separation/purificationPurification methodsImpurity

The invention is a method to purify tertiary butyl alcohol by contact with at least two solid adsorbents comprising aluminum oxide and a large pore zeolite such as zeolite X. The purification method successfully improves product quality and reduces the amount of impurities in the tertiary butyl alcohol.

Owner:LYONDELL CHEM TECH LP

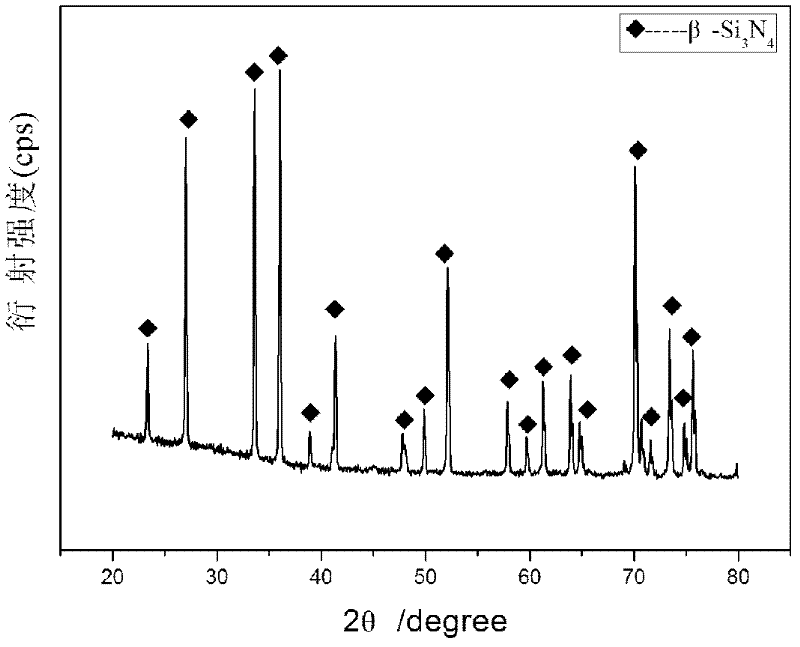

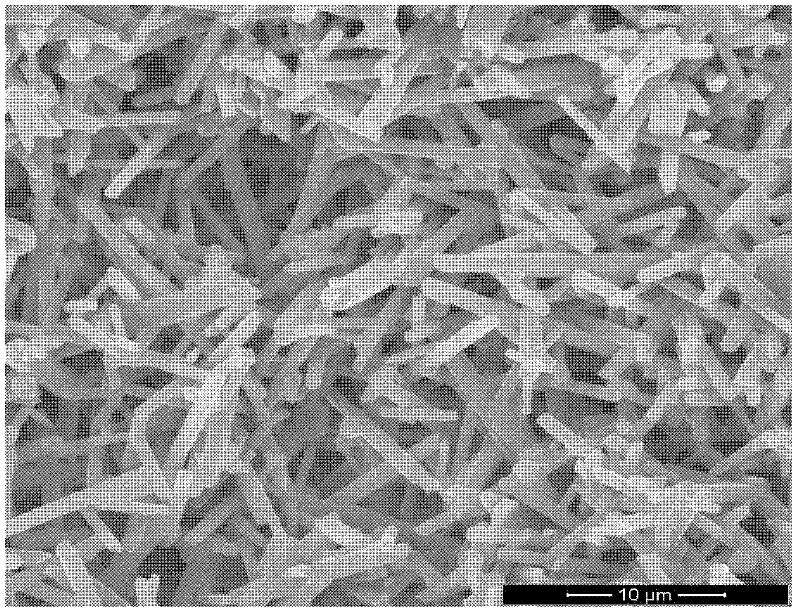

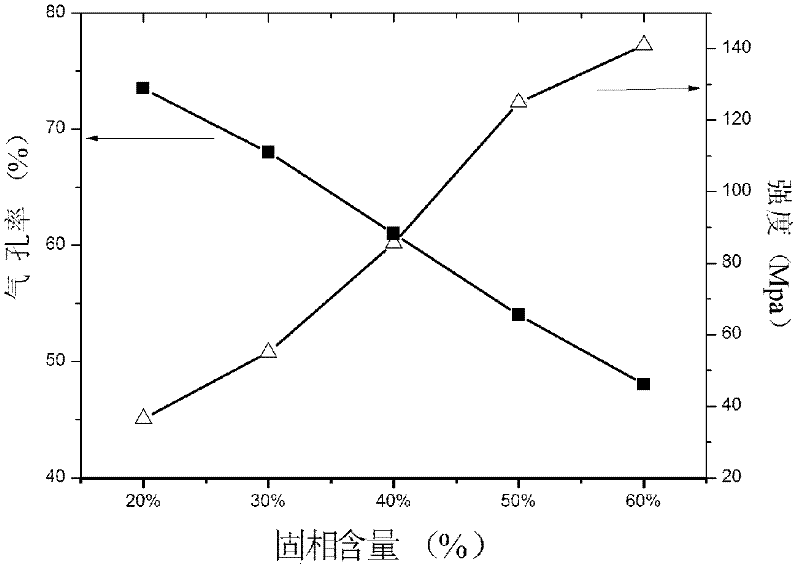

Forming method for preparing Si3N4 porous ceramic through tertiary butyl alcohol (TBA)-based gel casting method

The invention discloses a forming method for preparing Si3N4 porous ceramic through a tertiary butyl alcohol (TBA)-based gel casting method, belonging to the field of porous ceramic. In the method, TBA is used as a new solvent instead of the solvent water in the traditional water-based gel casting forming. The method comprises the following steps: dissolving acrylamide, N,N'-methylene bisacrylamide and polyvinyl pyrrolidone in the TBA, and preparing into a premixed liquid; then adding Si3N4, Al2O3 and Y2O3, and carrying out ball milling for 12 hours; and carrying out forming, drying, binder removal, sintering and other procedures to prepare high-porosity high-strength silicon nitride porous ceramic, wherein the porosity of the ultimately prepared Si3N4 porous ceramic ranges between 40% and 75%, and the strength is 40-140 Mpa. The method has the following advantages: (1) the problem of Si3N4 hydrolysis in the conventional water-based gel casting forming process is avoided; and (2) the problem of high cracking possibility during the forming and drying of water-based gel casting is solved, and the forming and drying process of gel casting is simplified.

Owner:XI AN JIAOTONG UNIV

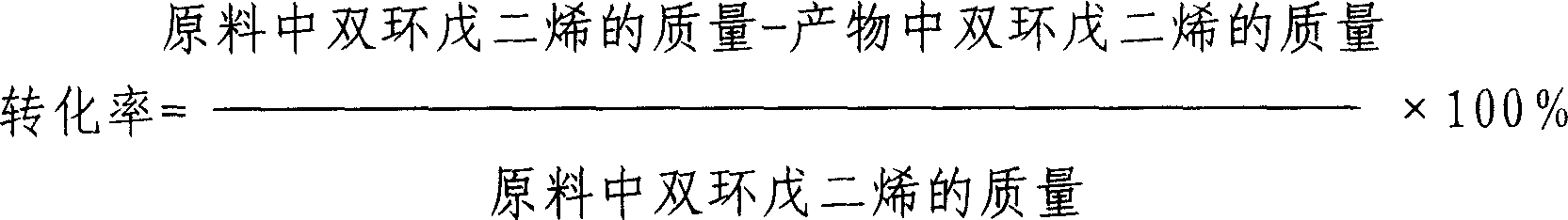

Method of preparing tetrahydrobicyclo pentadiene by continuous hydrogenation of bicyclopentadiene

InactiveCN1911878AWell mixedImprove mass transfer efficiencyHydrocarbon by hydrogenationFixed bedSolvent

The continuous dicyclopentadiene hydrogenating process to prepare tetrahydro dicyclopendiene is one continuous catalytic hydrogenation reaction of the mixture of dicyclopentadiene, solvent and hydrogen in a fixed bed catalyst bed. The catalyst includes gamma-Al2O3 as carrier and Pa as active component. The solvent is any one of cyclopentane, n-hexane, cyclohexane, benzene, toluene, cyclohexane, ethanol, methanol, and tertiary butyl alcohol. The reacted liquid is discharged partially and externally circulated partially with the weight ratio being 1 to 5-12, and the externally circulated liquid after being cooled is mixed with dicyclopentadiene material and solvent before being mixed with hydrogen in venturi ejector, atomized into gas-liquid mixture and reacted in the catalyst bed. The catalyst load is 2.0-4.0 / hr accounted in liquid phase material, and the reacted heat is transferred via external circulation. The present invention has high tetrahydro dicyclopendiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

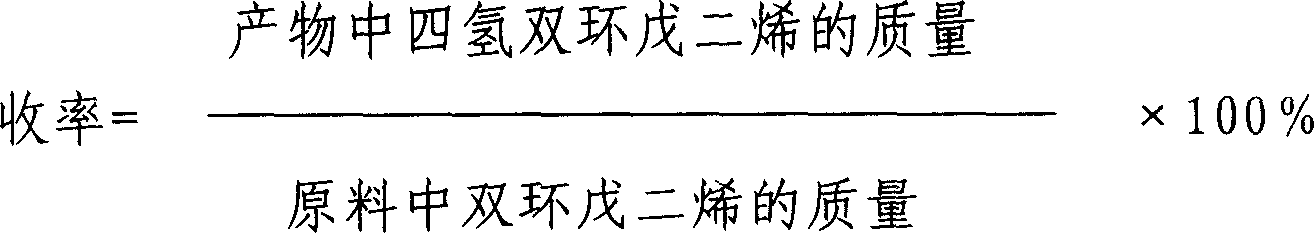

Utilization method of tertiary butyl alcohol coproduced by using device for producing epoxypropane by using propene and iso-butane cooxidation method

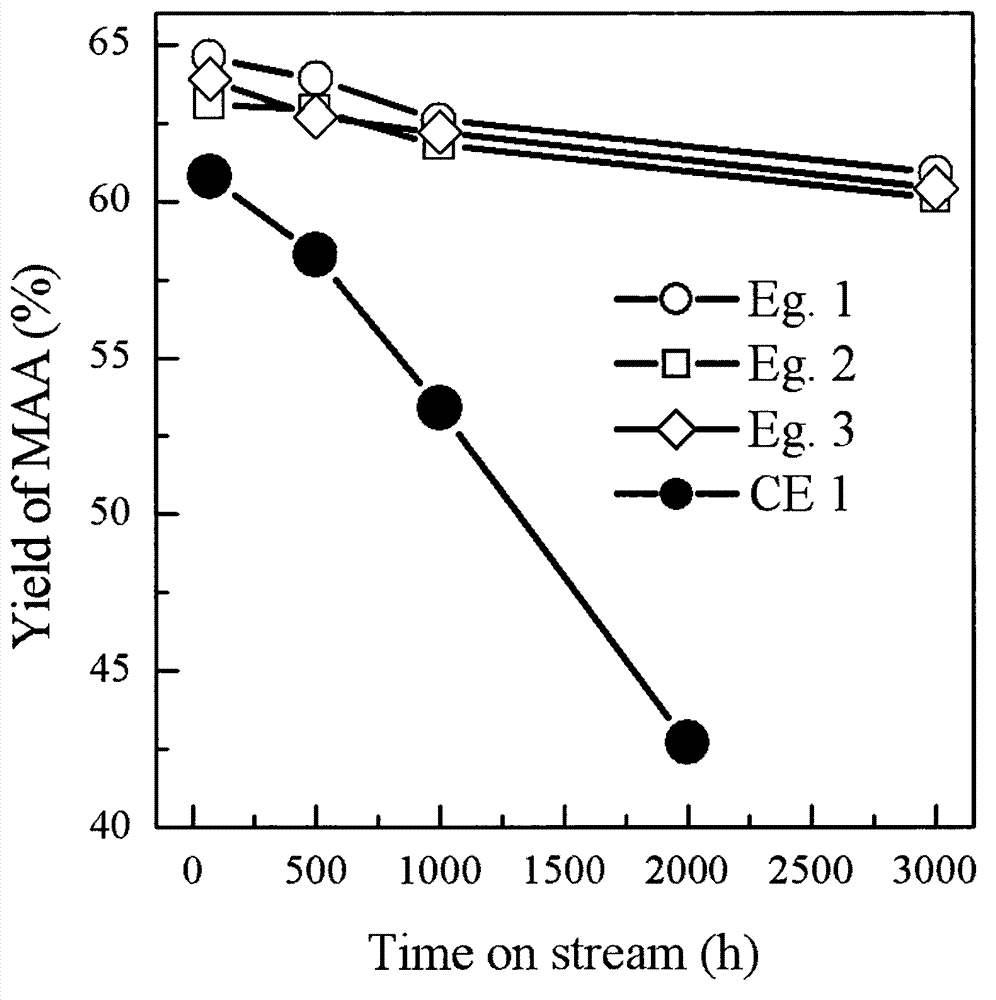

ActiveCN103086874AHigh activityAcid controlOrganic compound preparationCarboxylic compound preparationAqueous solutionButane

The invention relates to a utilization method of tertiary butyl alcohol coproduced by using a device for producing epoxypropane by using a propene and iso-butane cooxidation method. According to the method, after an acetone containing tertiary butyl alcohol solution by-produced by the device is evaporated, the evaporated solution, air and diluent gas and the like constitute mixed gas according to certain proportion, and after the mixed gas is preheated, the mixed gas is subjected to first-stage oxidation. After the composition and temperature of oxidative products obtained through the first-stage oxidation are adjusted, the oxidative products are subjected to second-stage oxidation. After oxidative products obtained through the second-stage oxidation are absorbed, a crude methacrylic acid aqueous solution capable of being used for refining is obtained. By using the method disclosed by the invention, coproduced tertiary butyl alcohol can be directly used for preparing methacrylic acid without refining and purification.

Owner:WANHUA CHEM GRP CO LTD +1

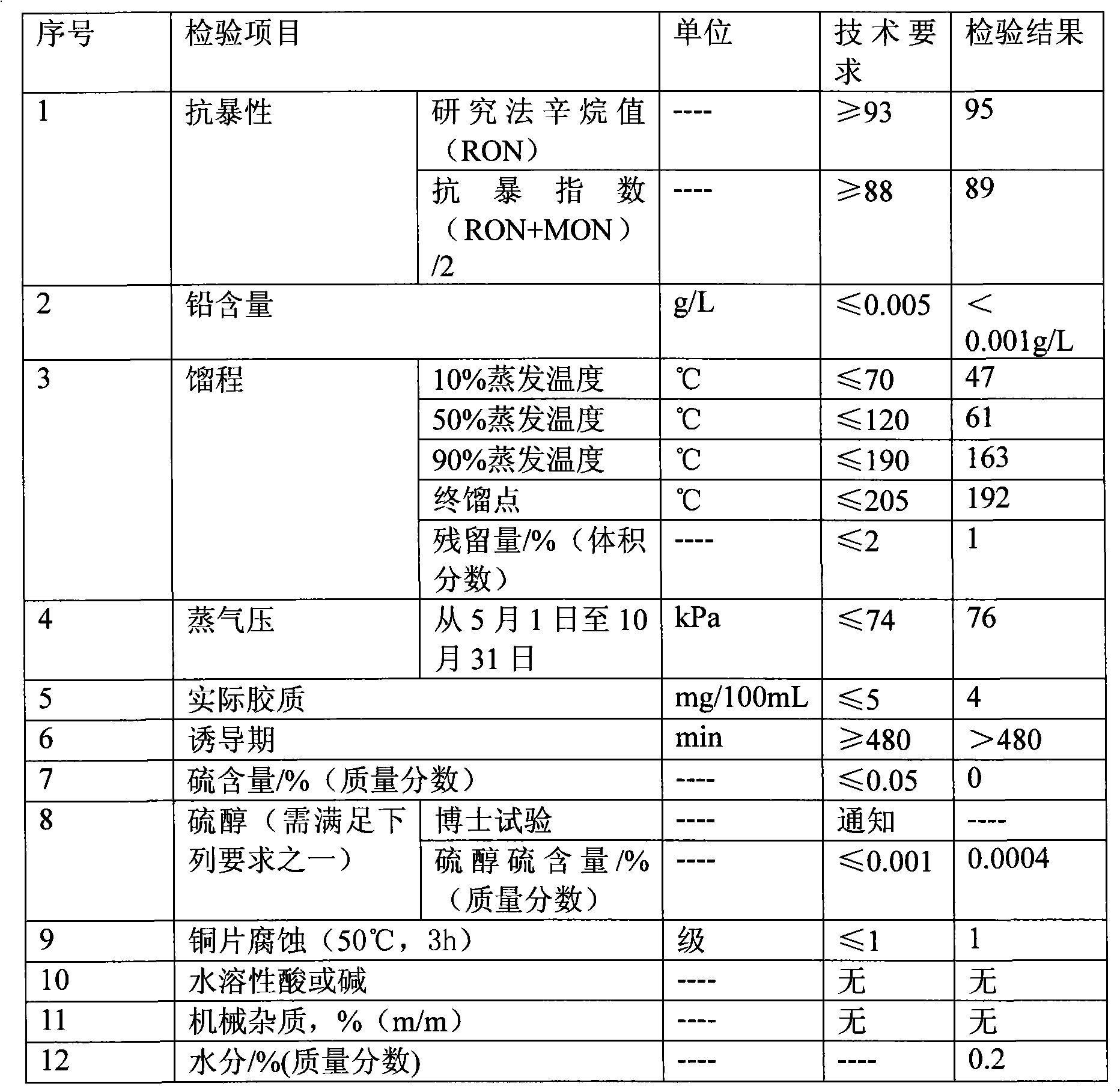

Ethanol gasoline for motor-vehicle and method of preparing the same

InactiveCN101358151AAchieve the effect of processingOctane reductionLiquid carbonaceous fuelsChemical reactionFiltration

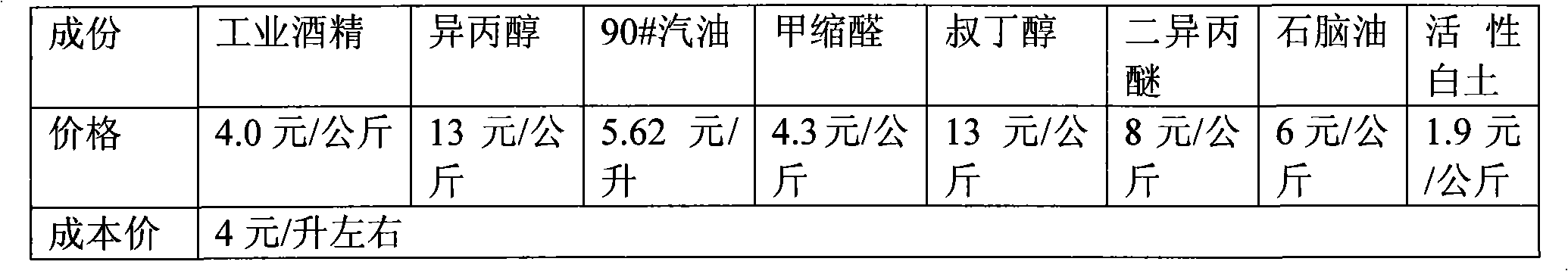

The present invention relates to clean fuel, in particular to automotive ethanol gasoline and a preparation method thereof. The automotive ethanol gasoline is composed of the following ingredients in the weight percentage: 15.0 percent to 25.0 percent of industrial alcohol; 0.60 percent to 5.0 percent of isopropanol; 30.0 percent to 50.0 percent of gasoline; 29.0 percent to 45.0 percent of methylal; 4.0 percent to 15.0 percent of tertiary butyl alcohol; 2.0 percent to 10.0 percent of diisopropyl ether; and 1 percent to 5 percent of naphtha; after the ingredients are mixed, 1 percent to 6 percent of active floridin is added; and after stirring, physical and chemical reactions and filtration, the automotive ethanol gasoline is prepared. The automotive ethanol gasoline is characterized by high octane value and strong explosive force, the production cost is reduced, the emitted tail gas is smokeless and smellless, therefore the pollution of the automotive tail gas is reduced, and moreover, the automotive ethanol gasoline has no adverse effect on an automotive engine and can partially replace the prior gasoline.

Owner:郭国星

Catalyst and method of producing unsaturated aldehyde and unsaturated carboxylic acid

InactiveCN102046289AImprove friction resistanceReduce the probability of selectionOrganic compound preparationOrganic chemistry methodsGas phaseIsobutylene

Provided is a catalyst which can prevent a lowering in selectivity for a target product in a gas-phase catalytic reaction and has an excellent frictional resistance. A catalyst which is a supported catalyst comprising an inert support that is coated with a catalyst powder, characterized in that the inert support is ring-shaped and has an outer periphery that is curved in the lengthwise direction of the support, and the catalyst is produced by granulation in a moisten environment. The above-described catalyst is useful in the gas-phase oxidation of propylene, isobutylene, tertiary-butyl alcohol or methyl tertiary-butyl ether to thereby produce an unsaturated aldehyde corresponding thereto, or in the gas-phase oxidation of such an unsaturated aldehyde as described above to thereby produce an unsaturated carboxylic acid.

Owner:NIPPON KAYAKU CO LTD

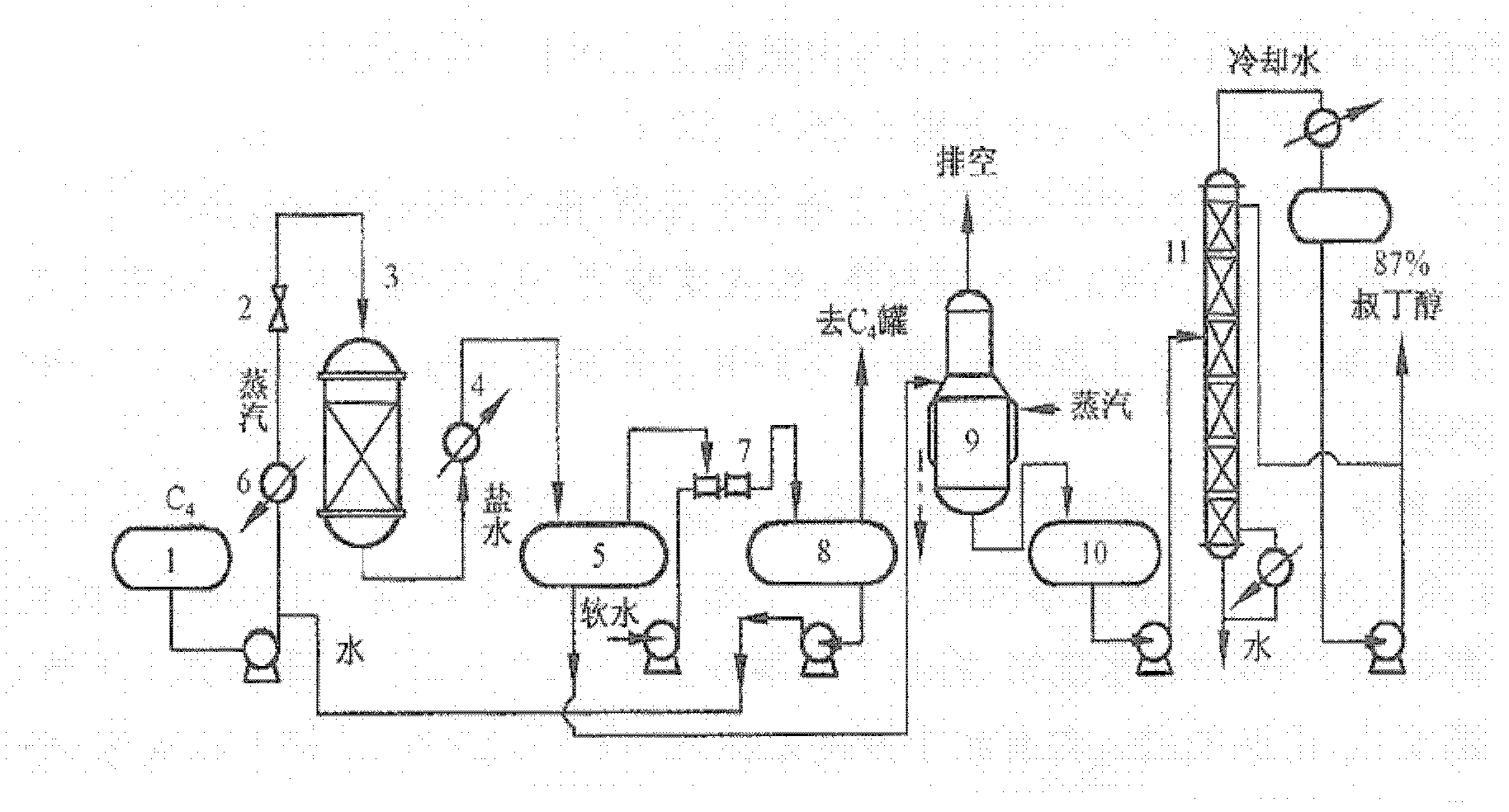

Method for producing tertiary butyl alcohol

Disclosed is a method for producing a tertiary butyl alcohol wherein the hydration rate of isobutylene is high. Also disclosed is a method for producing a tertiary butyl alcohol wherein a low-concentration isobutylene is used as a raw material and the hydration rate of isobutylene is high. In this method, a tertiary butyl alcohol is produced from isobutylene and water in the presence of an cation-exchange resin catalyst and at least one solvent selected from the group consisting of sulfones and organic carboxylic acids, using a reaction distillation apparatus. Preferably, at least one solvent selected from the group consisting of sulfolane, dimethyl sulfone and acetic acid is used as the solvent in this method.

Owner:MITSUBISHI RAYON CO LTD

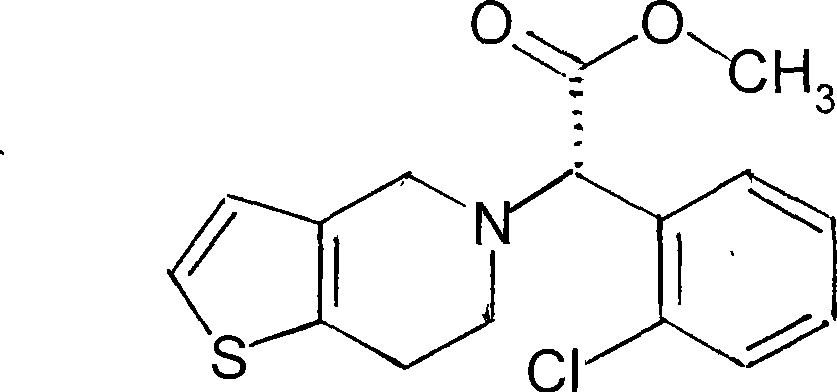

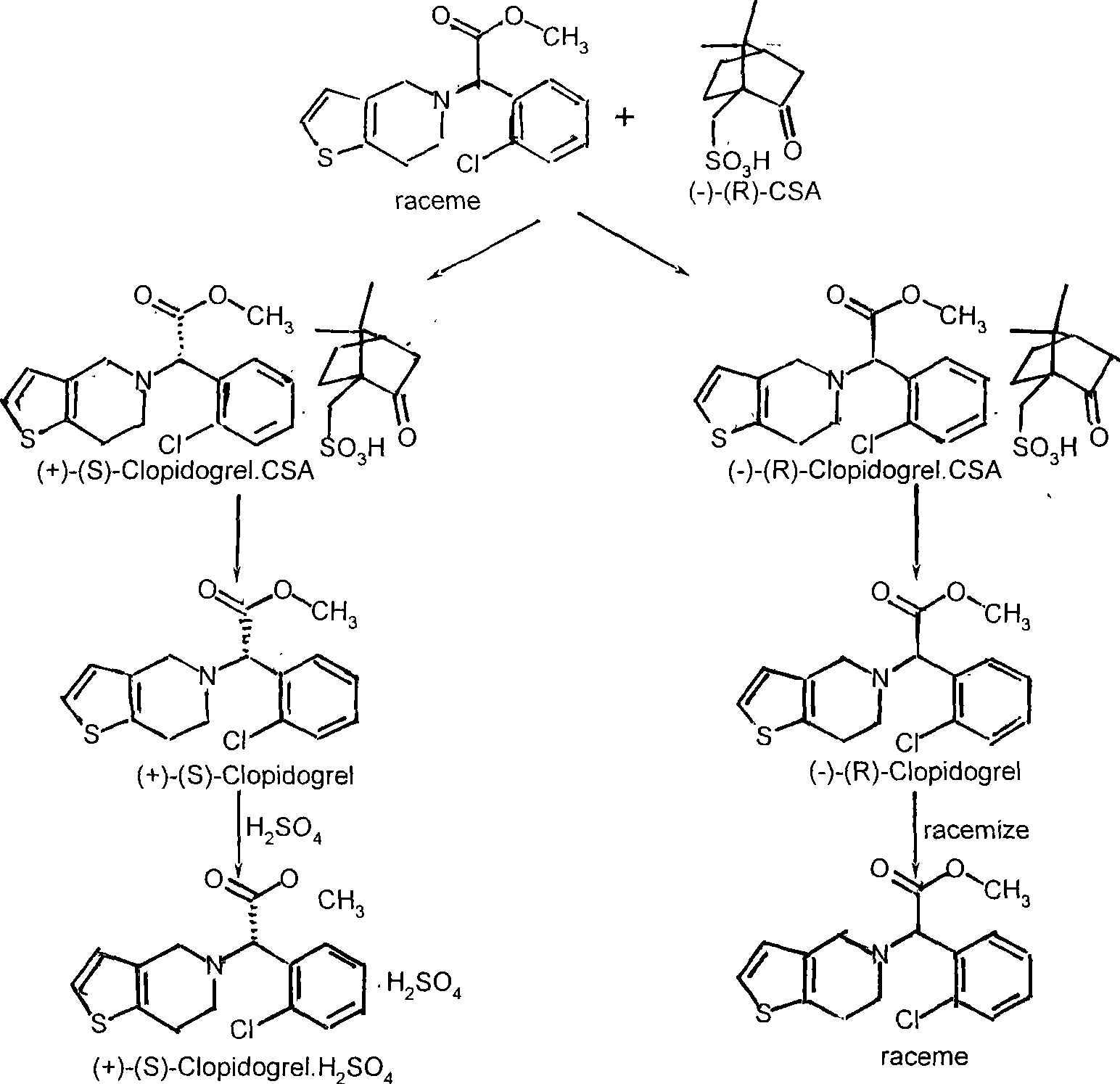

Production method of (-)-(R)- clopidogrel (-)-(R)-camphorsulfonate racemisation

ActiveCN101463038AEasy industrial operationQuality improvementOrganic chemistryBlood disorderPotassiumEthyl acetate

The invention discloses a racemization production method of (-)-(R)-clopidogrel(-)-(R)-camphorsulfonate. The racemization production method comprises the following steps: allowing (-)-(R)-camphorsulfonate mother liquor concentrate of (-)-(R)-clopidogrel to react with sodium methylate in methanol, which replaces expensive tertiary butyl alcohol and potassium tertbutoxide in U.S. patents; and then extracting and condensing with ethyl acetate, and salifying in isopropyl alcohol to obtain clopidogrel sulfate with high quality and high yield. The racemization production method of the (-)-(R)-clopidogrel(-)-(R)-camphorsulfonate is characterized by convenient industrial operation, stable quality and high yield, and is more favorable for large-scale industrialized production.

Owner:TIANJIN CENT PHARM CO LTD

Efficient cyhalothrin

InactiveCN101434562AShort process routeImprove reaction efficiencyCarboxylic acid nitrile preparationOrganic compound preparation4-pentenoic acidFiltration

The invention relates to an efficient cyhalothrin and a manufacturing technology thereof, the manufacturing technology is as follows: (1) layer addition-reaction materials are 3, 3-dimethyl-4-pentenoic acid methyl ester and trichlorotrifluoroethane; (2) cyclization- reaction materials are tertiary butyl alcohol, Bifenthrin and sodium tert-butoxide; (3) elimination of hydrolysis-reaction materials are potassium hydroxide and cyclic Bifenthrin, and by exsolution, hydrolysis, separation and filtration 2-cis-3-(2-chloro-3, 3, 3-trifluro-1-propenyl)-2, 2-dimethyl cyclopropane carboxylic acid can be prepared; (4) chloroformylation-reaction materials are thionyl chloride, methylbenzene and 2-cis-3-(2-chloro-3, 3, 3-trifluro-1-propenyl)-2, 2-dimethyl cyclopropane carboxylic acid, and by exsolution and distillation, 3-(2-chloro-3, 3, 3-trifluoro-1-propenyl)-2, 2-dimethylcyclopropane carbonyl chloride is obtained; (5) esterification- reaction materials are phenylate aldehyde, sodium cyanide, PTC and 3-(2-chloro-3, 3, 3-trifluoro-1-propenyl)-2, 2-dimethylcyclopropane carbonyl chloride, by water rinse, exsolution and distillation, the cyhalothrin is prepared; and (7) epimerization-inoculating crystal is added for carrying out an epimerization reaction, and after the reaction, an end product-the efficient cyhalothrin is obtained by filtration and drying. As the invention adopts the technical proposal, the efficient cyhalothrin prepared by the invention greatly shortens the technological route and obviously improves the reaction efficiency through the improvement of technical skills, thereby reducing the cost of industrialization.

Owner:JIANGSU HUANGMA AGROCHEM

Composite gasoline of methanol and method for producing the same

InactiveCN101195771AAvoid mechanical propertiesResolve dynamicsLiquid carbonaceous fuelsPhysical chemistryGasoline

The invention discloses methanol compound gasoline, the methanol compound gasoline is composed of methanol, gasoline, propanone, ethylether, tertiary butyl alcohol, nitric acid cerous cerium, isopropyl alcohol and combined additive agent. The preparation method of the invention is to perform the convection to the methanol, the gasoline, the propanone, the ethylether, the tertiary butyl alcohol, the nitric acid cerous cerium, the isopropyl alcohol and the combined additive agent from different directions and to inject into a mixing tank simultaneously, an oil pump is used to inject the all to the mixing tank, the circulating oil pump is used in the tank to perform the mixing and circulating, finally, the preparation is finished after the oil pump is used to inject into a finished product oil tank. The methanol compound gasoline of the invention can solve a series of problems that the mechanical performance, the dynamic performance, the safety performance and the starting performance of vehicles are bad. Simultaneously, the invention can simultaneously perform the function of the cleanness and the environment protection, and the advantages of reducing the gasoline cost and reducing the fuel oil consumption of the vehicles.

Owner:北京金鑫世纪电力环保科技有限公司

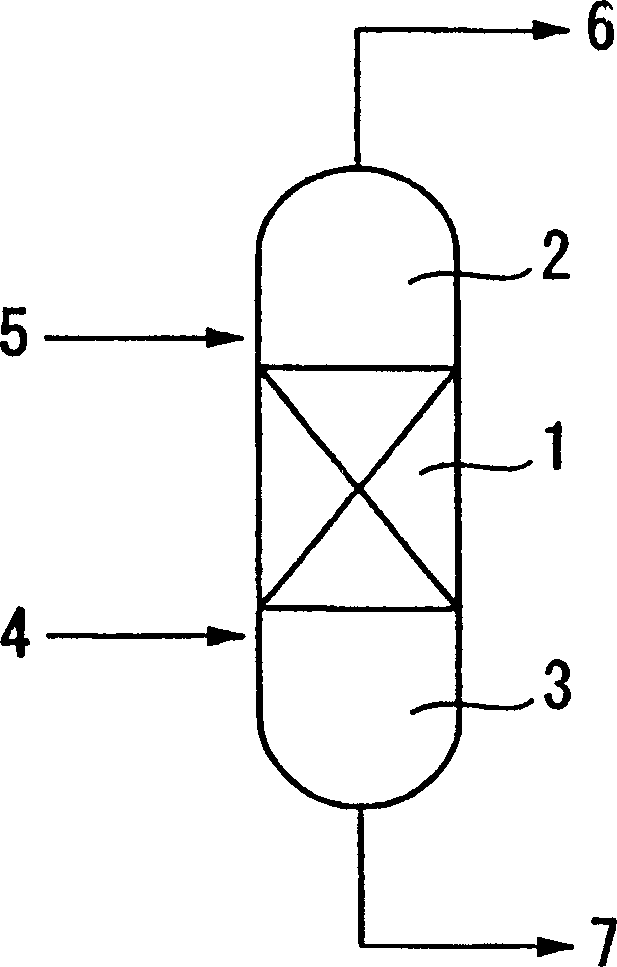

Method for producing (methyl) acrylic acid

ActiveCN101456807AEasy to cleanIncreasing the thicknessCarboxylic preparation by oxidationCatalytic oxidationMethyl group

The invention provides a method for producing (methyl) acrylic acid. The method comprises: selecting at least one of C3 compounds such as propane, propylene, isopropanol, glycerin and acrolein, or at least one of C4 compounds such as isobutene, isobutene, tertiary butyl alcohol and acrylaldehyde as raw materials to carry out catalytic oxidation to prepare a gas mixture containing the (methyl)acrylic acid; absorbing the gas mixture, and separating the (methyl)acrylic acid water solution, wherein a rectifying section of a rectifying tower separating the (methyl)acrylic acid water solution adopts regular packing or parallel-current jet packing trays, or the upper part of the rectifying section adopts the regular packing and the lower part of the rectifying section adopts the parallel-current jet packing trays; and a stripping section adopts directed floating valve trays or vertical sieve trays, or the upper part of the stripping section adopts the directed floating valve trays and the lower part of the stripping section adopts the vertical sieve trays. The rectifying tower with combined tower internal structure embodies a concentrated reflection of the advantages of the regular packing, the parallel-current jet packing trays, the directed floating valve trays and / or vertical sieve trays in the same rectifying system, thereby effectively improving separating capability of the rectifying tower, lowering full-tower pressure drop and operational temperature, avoiding convergescence of the (methyl)acrylic acid at a high temperature, making the water content of tower-bottom discharged material reduced below 0.5 percent, the acetic acid content of the tower-bottom discharged material reduced below 2 percent and the (methyl)acrylic acid content of tower-top water phase reduced below 0.5 percent, further reducing unit consumption of the (methyl)acrylic acid products and improving product quality.

Owner:SHANGHAI HUAYI NEW MATERIAL

Diisobutylene process

ActiveUS20060241326A1Efficient productionOrganic compound preparationHydrocarbon by hydrogenationIsobutyleneSulfonic acid ester

This invention is a process for producing diisobutylene from isobutylene. The process comprises first forming dry sulfonic acid resin by contacting water wet sulfonic acid resin catalyst with a first reaction feed comprising isobutylene under conditions effective to produce tertiary butyl alcohol from the reaction of isobutylene and water, and then contacting the dry sulfonic acid resin with a second reaction feed comprising isobutylene under conditions effective to oligomerize isobutylene to produce diisobutylene.

Owner:LYONDELL CHEM TECH LP

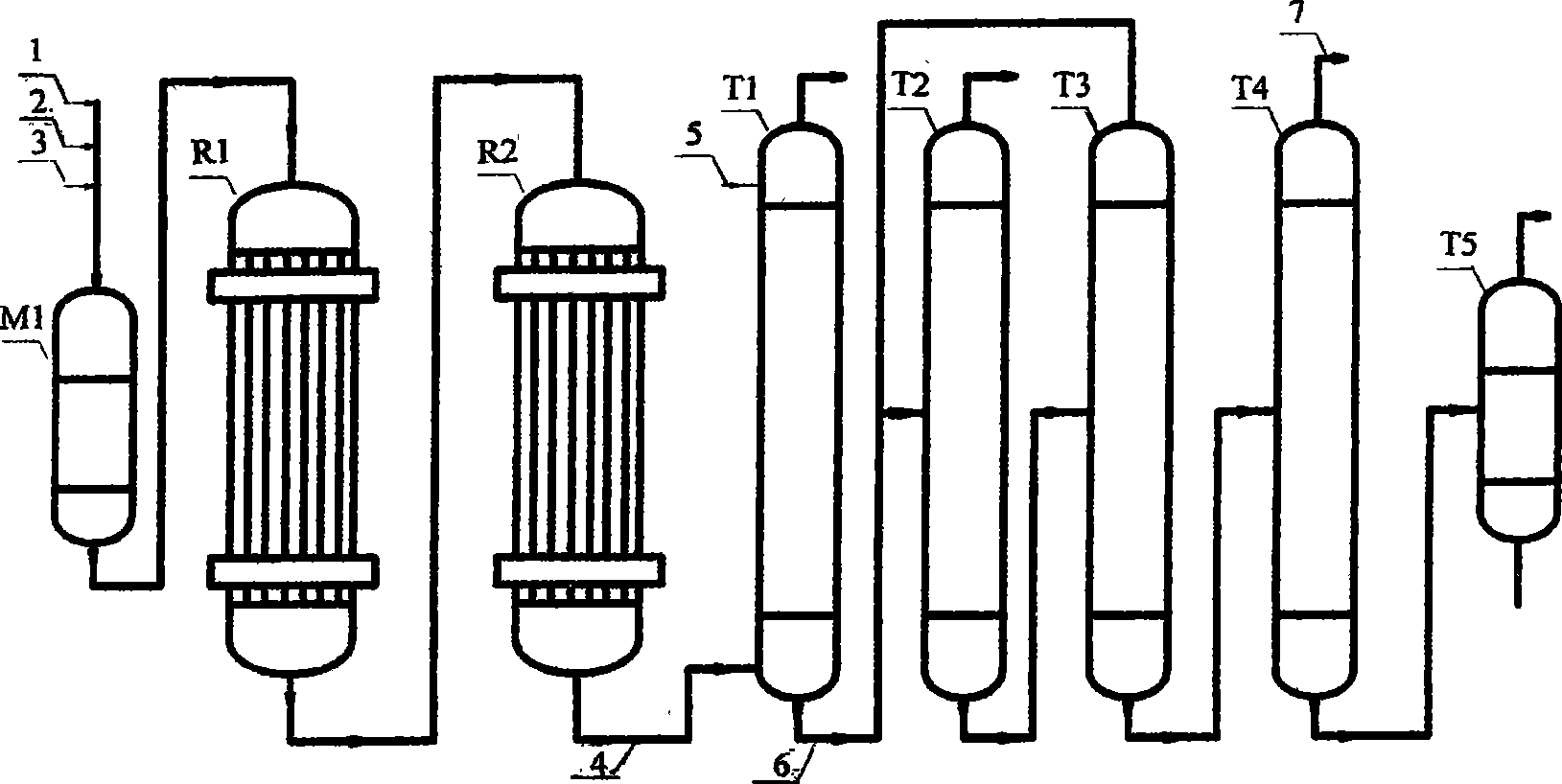

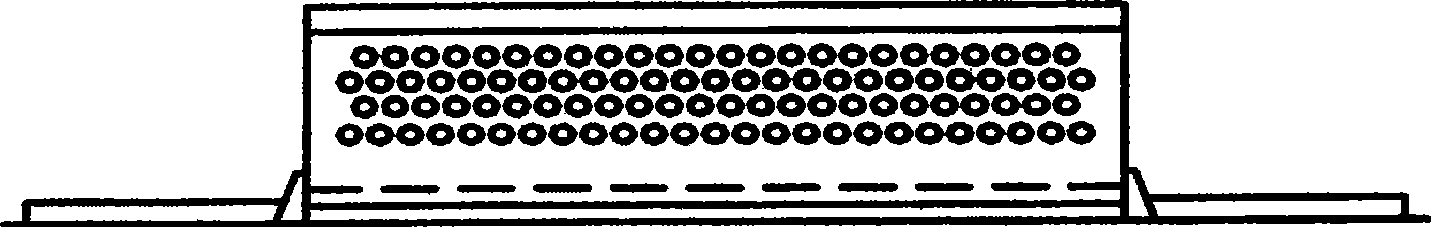

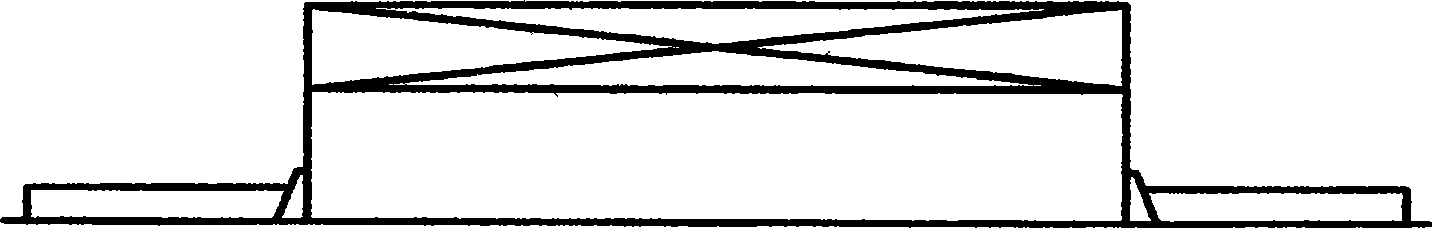

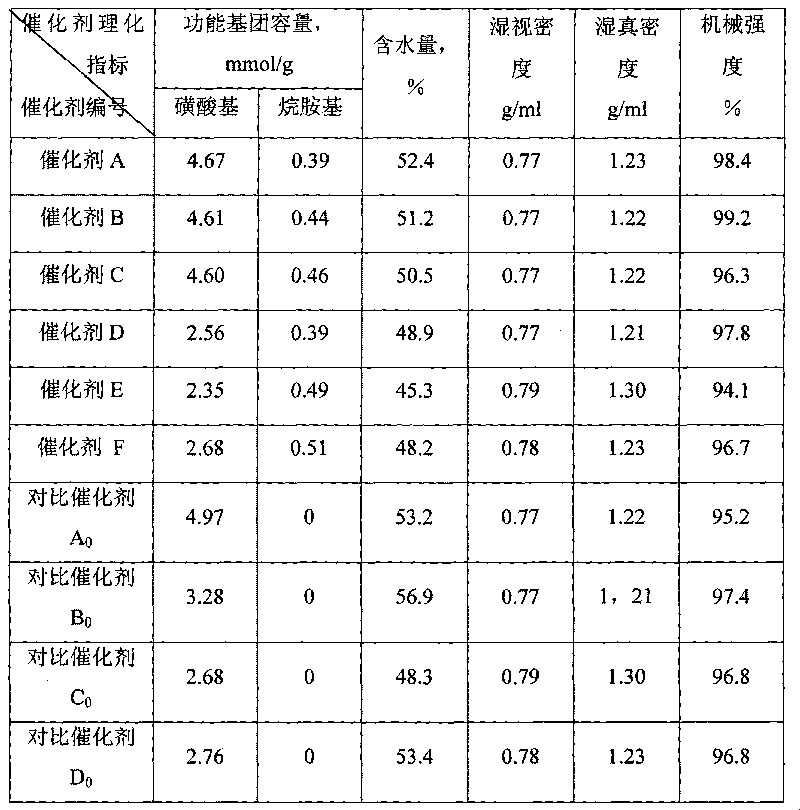

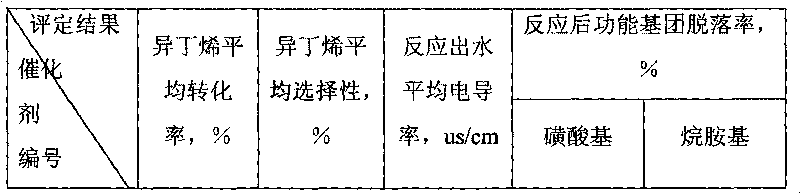

Multi-functional group resin catalyst and preparation method thereof

ActiveCN101757946ALow costReduce the chance of sheddingOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationButeneHydration reaction

The invention provides a multi-functional group resin catalyst particularly suitable for preparing tertiary butyl alcohol (TBA) from isobutene through hydration, preparing n-butyl alcohol (SBA) from n-butene through hydration and preparing isopropyl alcohol (IPA) from propylene through hydration, and a preparation method thereof. By introducing a certain amount of alkylamine lipophilic groups into sulfonic poly-aromatic resin or halogenated aromatic catalysts in the preparation of the multi-functional group catalyst, the invention obviously improves the affinity of the catalyst with olefin and increases the concentration of olefin reactant at the periphery of the active center of the catalyst, thereby significantly increasing the conversion rate in the hydration of olefin.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

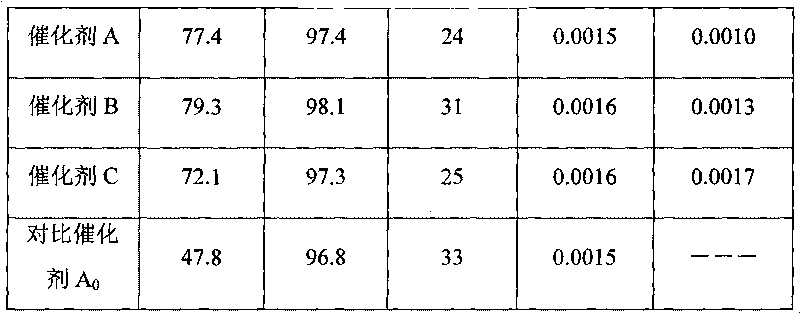

Biological alcohol-based fuel hydrotropy solubilizer

ActiveCN107099345ATurn waste into treasureTurn waste into energyLiquid carbonaceous fuelsFuel additivesNon toxicityDissolution

The invention discloses a biological alcohol-based fuel hydrotropy solubilizer, which is prepared from 55.0 to 61.0 percent of hydrotropy ingredients, 9.0 to 13.0 percent of anti-layering ingredients, 19.0 to 24.0 percent of lubricating ingredients and 8.0 to 12.0 percent of anti-wearing ingredients. The four functional ingredients are uniformly stirred at the normal temperature; a finished product of the biological alcohol-based fuel hydrotropy solubilizer M8509 can be obtained. Petroleum yeast fatty acid with the advantages of cleanness, environment-friendly effect, regeneration performance and degradable performance is selected to be used as a cheap additive; the energy is saved; the emission is reduced. Compared with the prior art, the biological alcohol-based fuel hydrotropy solubilizer has the advantages that the cost is low; non-toxicity and no pollution are realized; the addition quantity is small; no harmful ingredients such as heavy metal and TBA (tertiary butyl alcohol) are contained; the hydrotropy and solubilization effects are obvious; secondary pollution cannot be caused on the environment. The biological alcohol-based fuel hydrotropy solubilizer has the effects of emulsifying alcohols, stabilizing the interface tension, promoting the oil and alcohol mutual dissolution, resisting the abrasion and realizing lubrication; the oil alcohol phase stabilizing period is as long as 180 days; the technical problems of poor compatibility, oil and alcohol layering, lubrication performance reduction, low oil alcohol phase stability and the like are effectively solved.

Owner:LANZHOU YINENG BIOTECHNOLOGY CO LTD

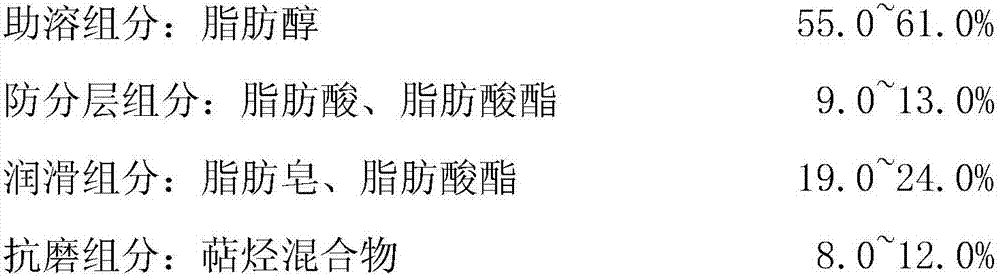

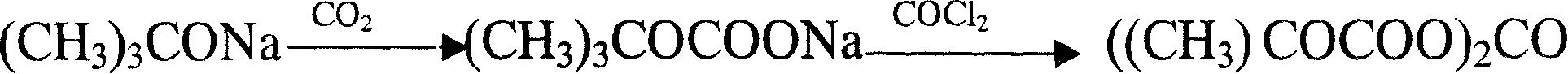

Method for synthesizing di-tert-butyl dicarbonic acid ester

The invention relates to a method for synthetizing di-tert-butyl bicarbonic ester, comprising the steps as follows: tertiary butyl alcohol natrium is used as the raw material, toluol or heptane is used as the solvent, the raw material and the solvent are heated and mixed to dissolve, carbon dioxide gas is inlet under 40 to 80 DEG C, the additive latent solvent of tertiary butyl alcohol or tetrahydrofuran are additionally added to reduce the viscosity of the solution, the temperature is reduced to 0 to 40 DEG C, the catalyst N, N, , -tetramethyl quadrol and cocatalyst of crownether are added in, toluene solution containing diphosgene is dripped in for reacting for 2 to 3 hours, the acquired oil phase liquid is cleaned in alkali and water, decompressed and distilled to produce the di-tert-butyl bicarbonic ester. The method of the invention is characterized in low production cost, short reaction period, stable product quality and good applicability for industrialized production.

Owner:上海中远化工有限公司

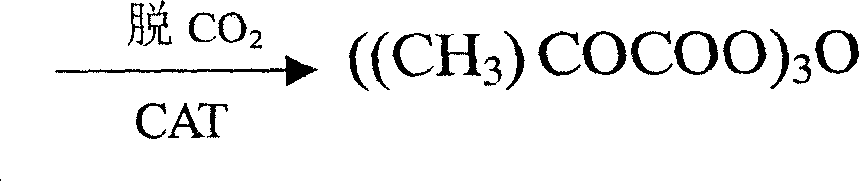

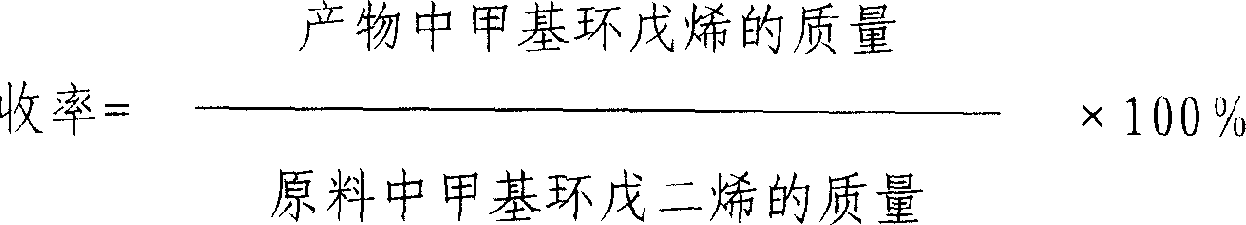

Method of preparing methyl cyclo penlene by continuous hydrogenation of methyl cyclo pentadiene

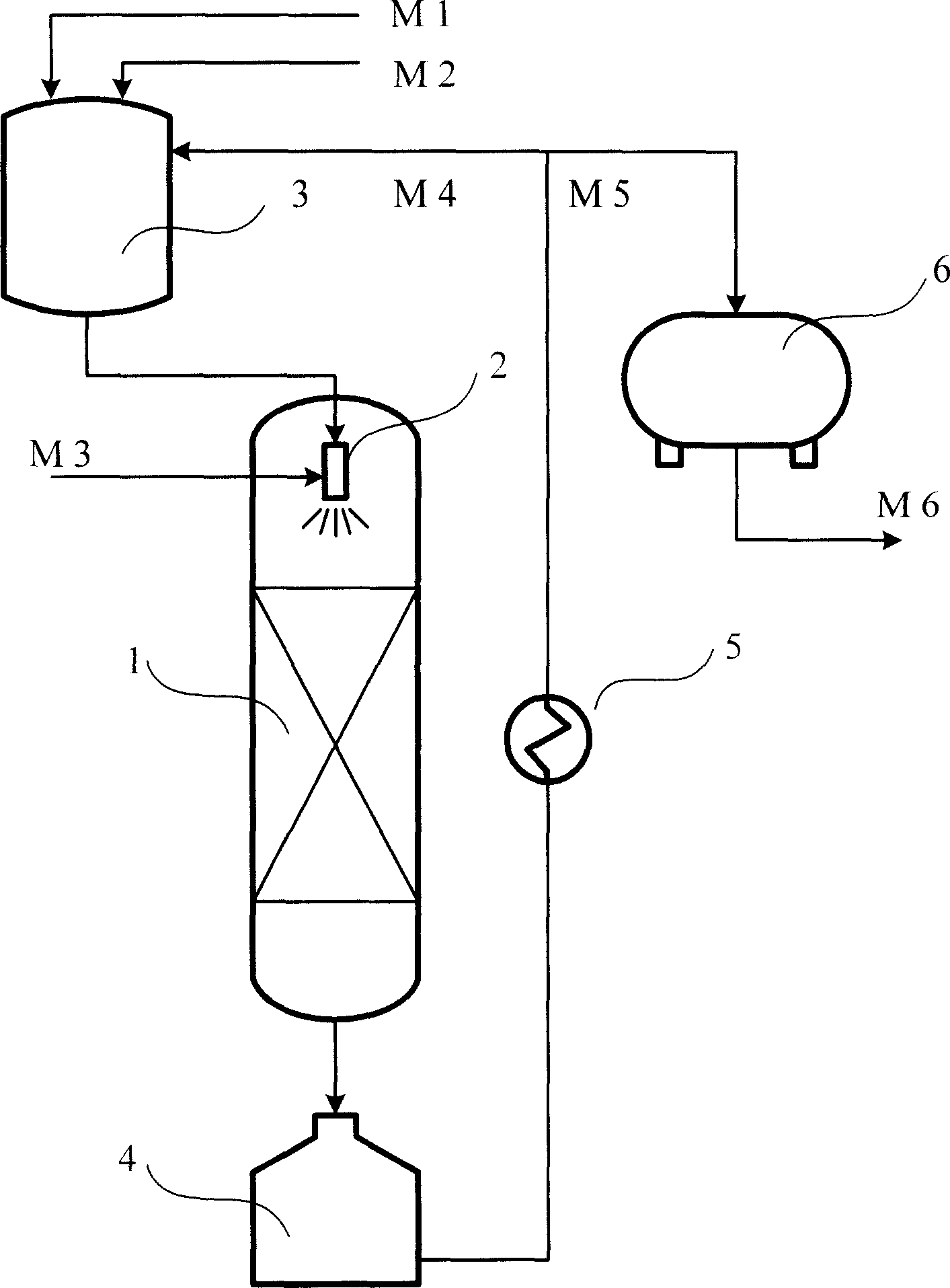

The continuous methyl cyclopentadiene hydrogenating process to prepare methyl cyclopentene is one continuous catalytic hydrogenation reaction of the mixture of methyl cyclopentadiene, solvent and hydrogen in a fixed bed catalyst bed. The catalyst includes gamma-Al2O3 as carrier and Pa as active component. The solvent is any one of benzene, toluene, cyclohexane, ethanol, methanol, tertiary amyl alcohol and tertiary butyl alcohol. The reaction system has pressure of 0.9-1.5 MPa and temperature of 60-100 deg.c. The reacted liquid is discharged partially and externally circulated partially with the weight ratio being 1 to 6-12, and the externally circulated liquid after being cooled is mixed with methyl cyclopentadiene material and solvent before being mixed with hydrogen in venturi ejector, atomized into gas-liquid mixture and reacted in the catalyst bed. The catalyst load is 3-6.0 / hr accounted in liquid phase material, and the reacted heat is transferred via external circulation. The present invention has high yield.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

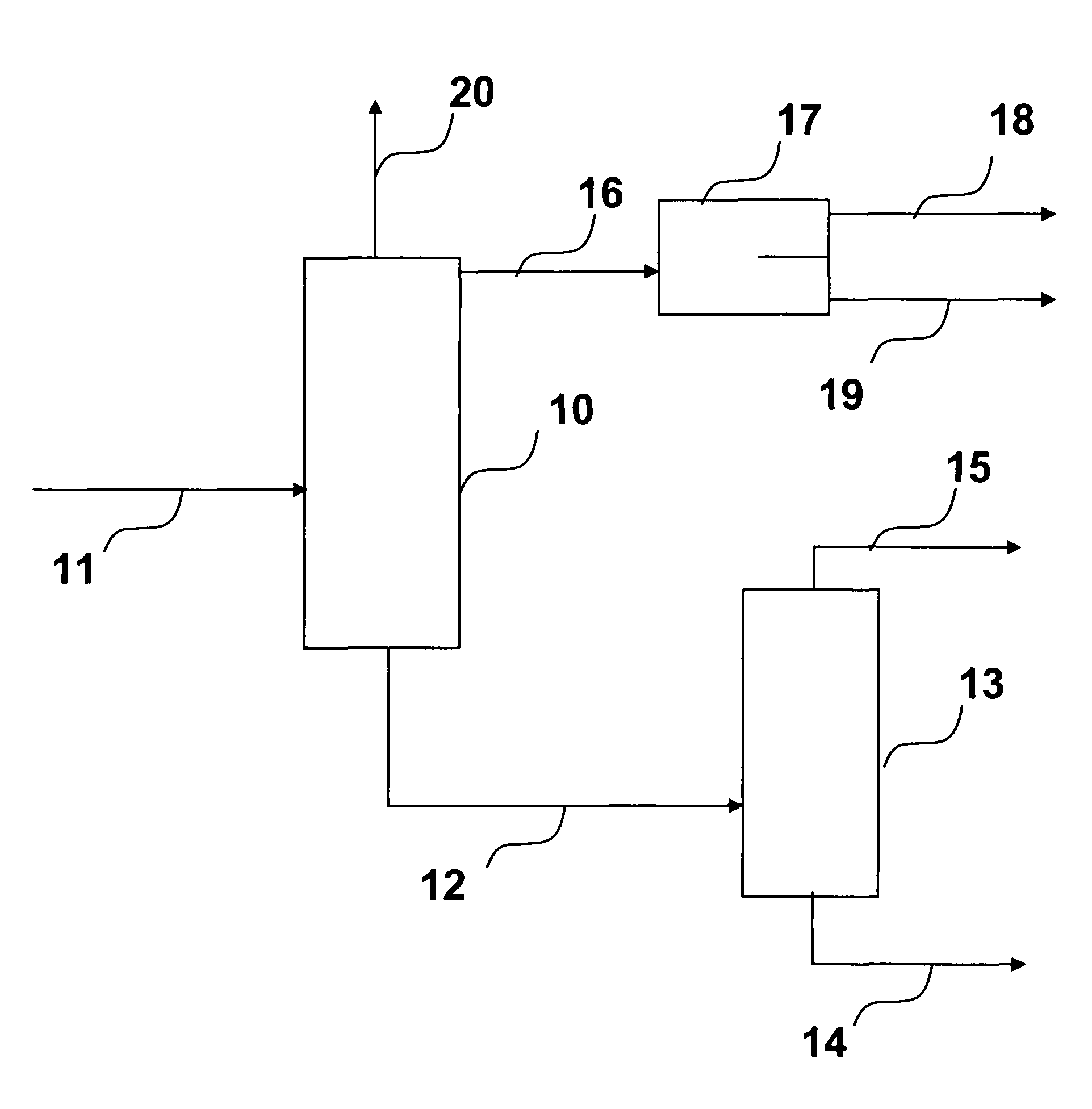

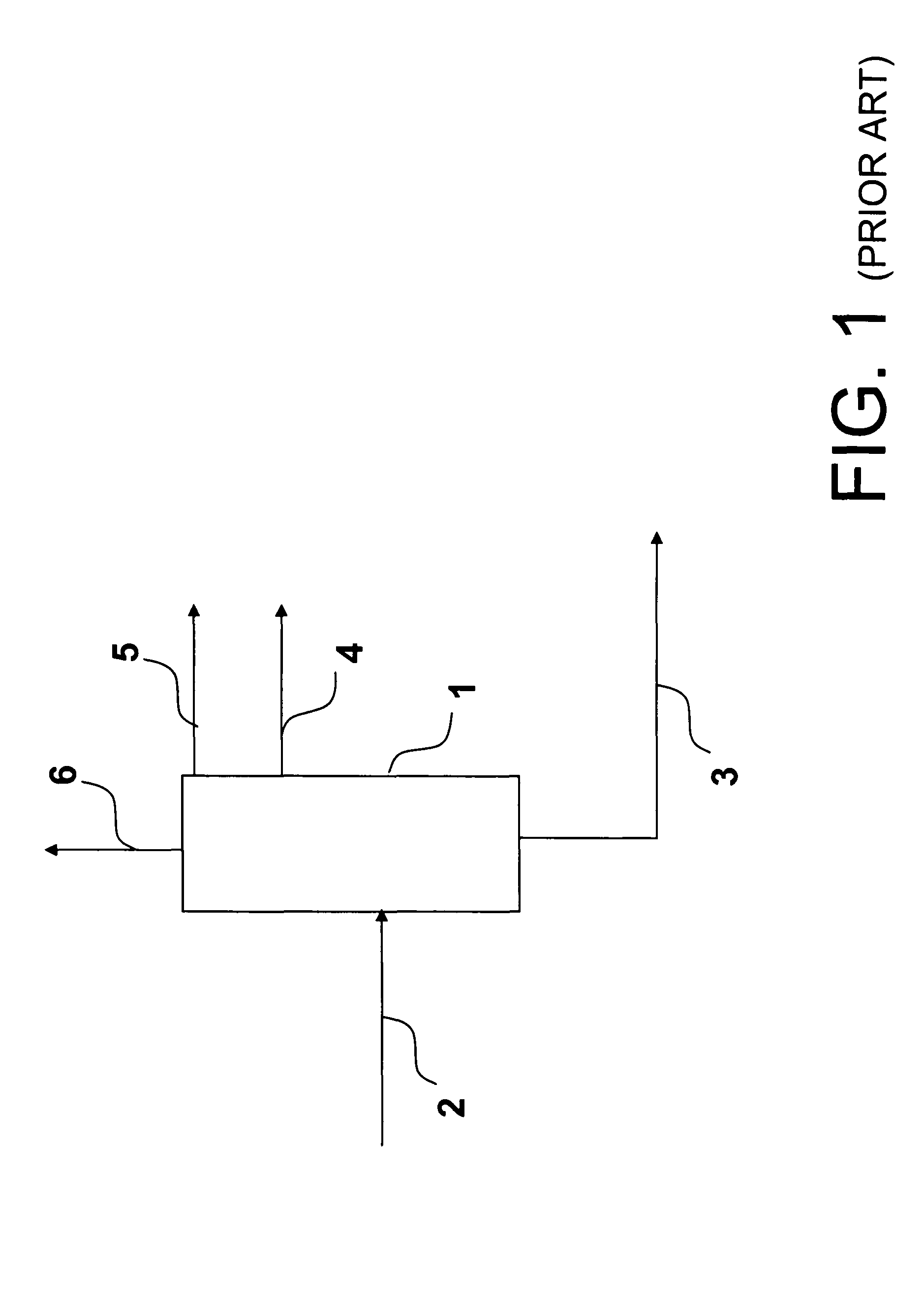

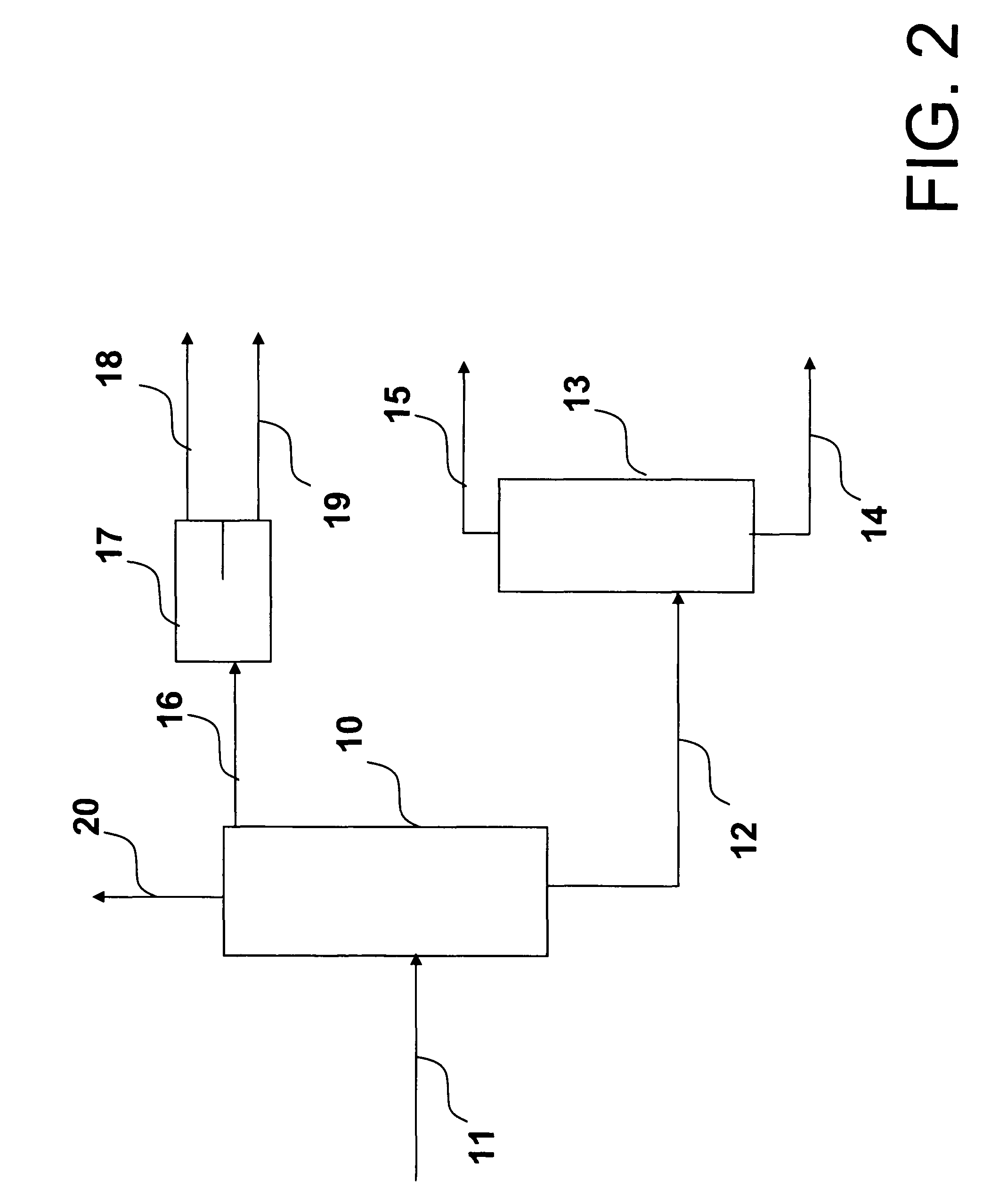

Diisobutylene process

ActiveUS8067655B2Distillation purification/separationHydrocarbons from unsaturated hydrocarbon additionReaction stepIsobutylene

This invention is a process for producing diisobutylene from isobutylene. The process comprises first contacting a sulfonic acid resin with a reaction feed comprising isobutylene and tertiary butyl alcohol to produce a product stream comprising diisobutylene, isobutylene, tertiary butyl alcohol, and water. The product stream is distilled to produce a first overhead stream comprising water and isobutylene and a first bottoms stream comprising diisobutylene and tertiary butyl alcohol. Water is separated from the first overhead stream, and the resulting isobutylene-enriched stream is recycled back to the reaction step. The first bottoms stream is distilled to produce a second overhead stream comprising tertiary butyl alcohol and a bottoms product stream comprising diisobutylene.

Owner:LYONDELL CHEM TECH LP

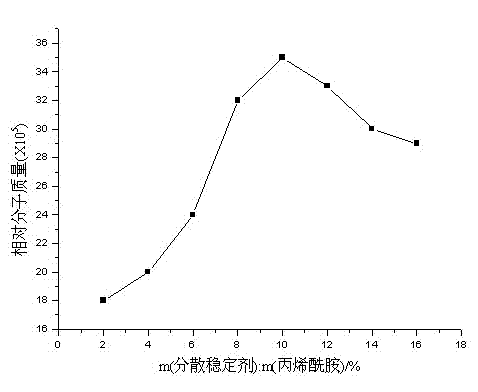

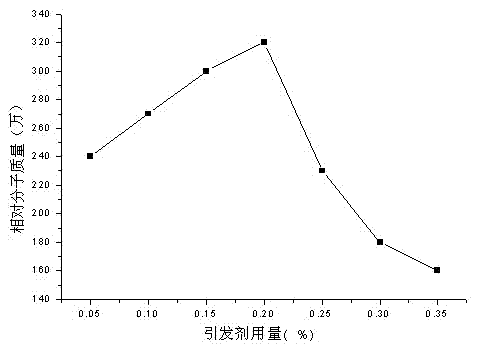

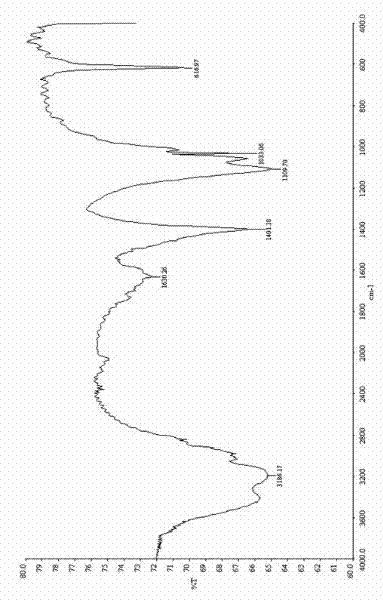

Synthetic method of water-in-water type polyacrylamide emulsion

The invention provides a synthetic method of a water-in-water type polyacrylamide emulsion with good flowability and stability, belonging to the field of chemical synthesis. The synthetic method comprises the following steps of: carrying out dispersion polymerization by taking a mixed system comprising tertiary butyl alcohol, ammonium sulphate and water as a reaction medium, monomer acrylamide and methacryloxy ethyl trimethyl ammonium chloride as raw materials, a mixture containing ammonium persulfate, sodium sulfite and 2,2'-azo[2-(2-imidazoline-2-group)-propane] dihydrochloride as a composite initiator and a polymer containing acrylamide and vinyl caprolactam as a dispersion stabilizer so as to obtain the polyacrylamide emulsion with good flowability and stability, wherein the relative average molecular weight of the polyacrylamide emulsion is 2,800,000-3,200,000; and the transformation ratio of the monomer acrylamide is more than 99.5 percent.

Owner:临泽县奋君矿业有限公司

Process for preparing alkylated dihydroxybenzene

InactiveUS20030125586A1Conserve costLess catalystOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationBenzeneSolid acid

Owner:COUNCIL OF SCI & IND RES

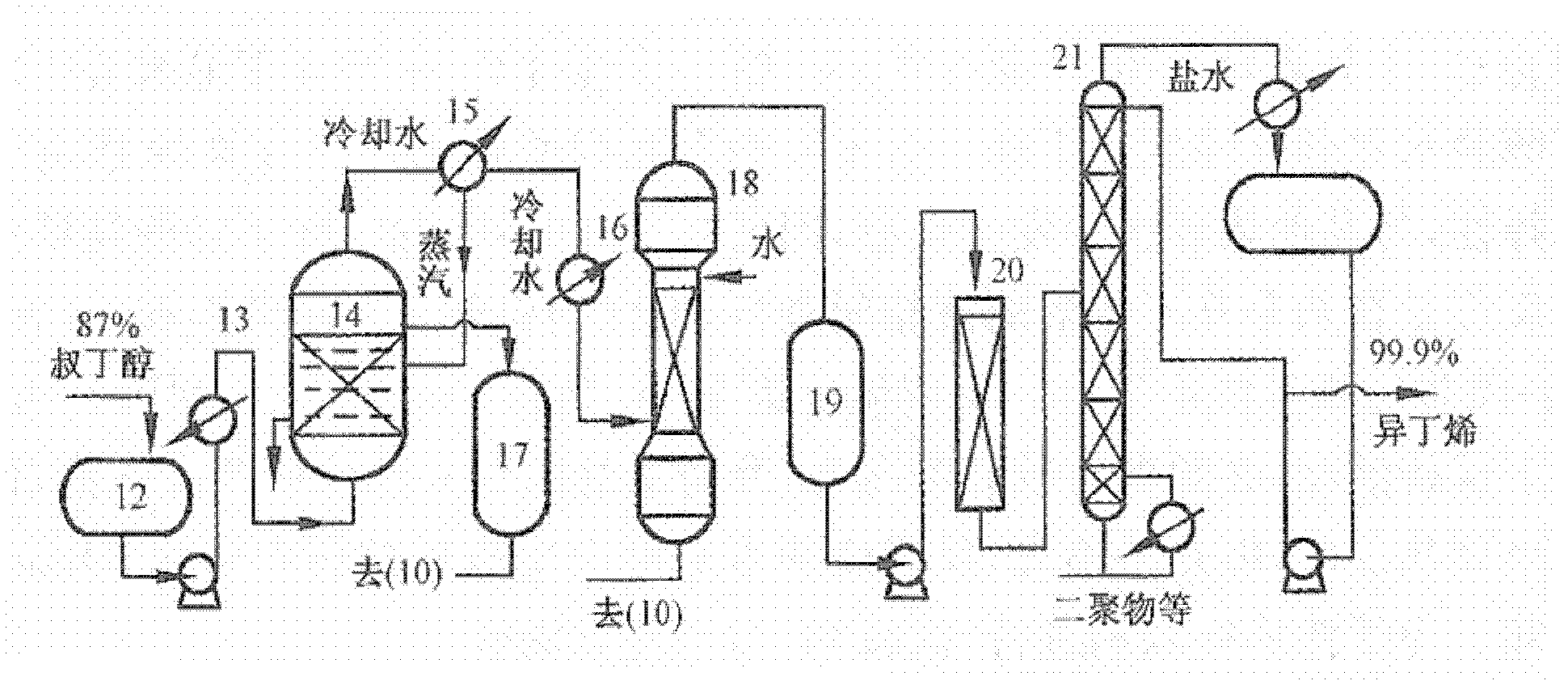

Method for preparing isobutene through direct hydration method

InactiveCN102329182AHydrocarbon from oxygen organic compoundsChemical modification purification/separationGas phaseTwo step

The invention discloses a method for preparing isobutene through a direct hydration method. The method for preparing isobutene through separation is carried out by adopting strongly acidic cation exchange resin as a catalyst to separate the isobutene from a C4 mixture through two steps of: firstly, mixing isobutene in the C4 mixture to generate tertiary butyl alcohol through hydration; and secondly, dehydrolyzing the tertiary butyl alcohol to obtain high-purity isobutene. Since the porous strongly acidic cation exchange resin is adopted as the catalyst which has very high selectivity and low possibility of reaction with other alkenes, the purity of the tertiary butyl alcohol is high, and the purity of the isobutene is also high. Gas-phase isobutene is guaranteed to be condensed through circulating water, therefore the operating pressure is generally 0.35-0.4MPa (gauge pressure). The method disclosed by the invention has the advantages of reasonable process and simple preparation, thereby being a simplest, most convenient and ideal method for preparing isobutene.

Owner:TIANJIN TAIYUAN INDAL GAS

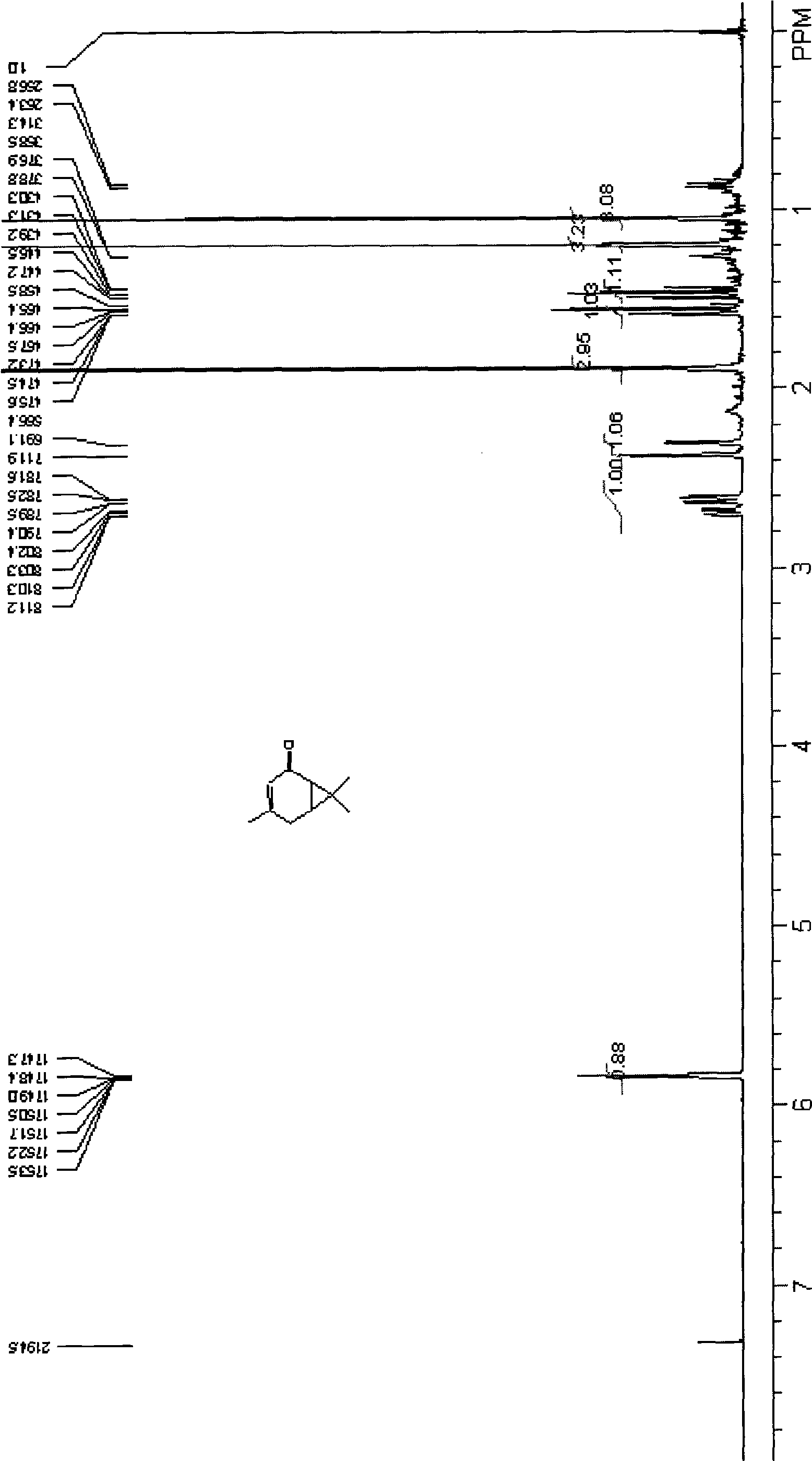

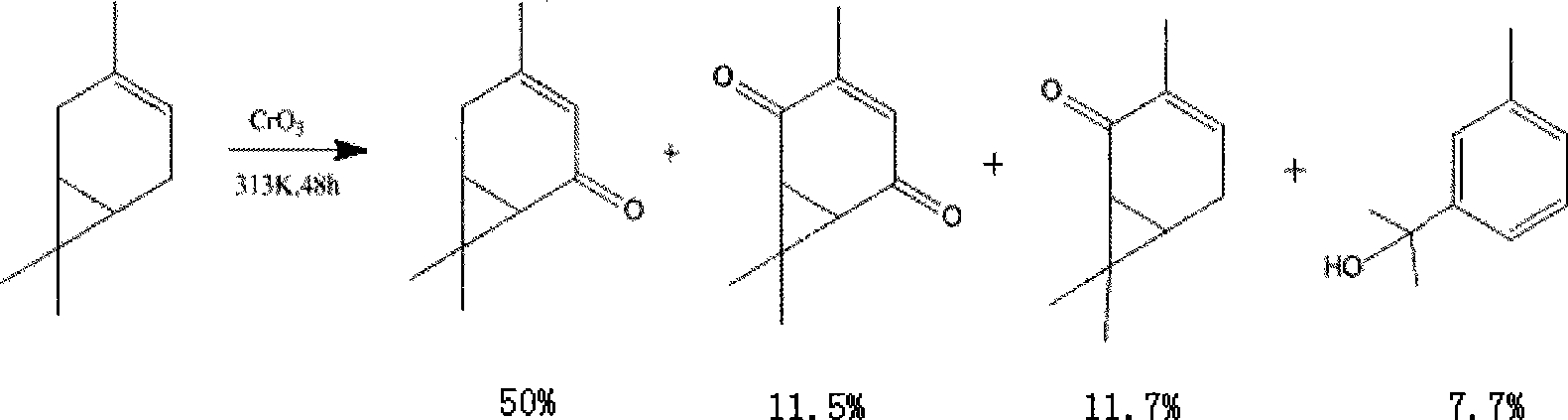

Preparation method of 3- careen-5-keto

InactiveCN101475457AImprove conversion rateShort reaction timeCarbonyl compound preparation by oxidationChromium trioxideSodium bicarbonate

The invention discloses a method for preparing 3-carene-5-ketone. The method comprises the following steps: a,evenly mixing tertiary butyl alcohol and benzene with volume ratio of 1.7-4.3:1, and then adding chromium trioxide solid into the mixture to stir for half an hour, and separating and extracting the mixture to prepare an oil layer which is an oxidant in the next reaction; b, mixing a raw material 3-carene and the chromium trioxide with mol ratio of 1:1.5-2.5 at a temperature of between 40 and 45 DEG C to react for 1 to 3 hours under the condition of applying 100 to 700w ultrasonic wave; and c, adding an oxalic acid solution in the reaction liquid to continue reacting for 1 hour after reaction is finished, finally extracting an organic phase by aether, washing the organic phase by 4 percent sodium bicarbonate aqueous solution to prepare an orange transparent solution, and concentrating and separating the orange transparent solution by column chromatography to prepare the target product 3-carene-5-ketone. The method shortens reaction time from 48 hours to 3 hours, and also improves conversion rate of the reactant and the yield of the target product.

Owner:SHANGHAI INST OF TECH

Method for preparing 2-tert-butyl-5-methyl phenol with H beta zeolite as catalyst

InactiveCN1634827AGood choiceImprove conversion rateOrganic chemistryOrganic compound preparationIsobutyl alcoholReaction temperature

The present invention provides a method for preparing 2-tert-butyl-5-methyl phenol with H beta zeolite as catalyst. A building up reaction is carried out between alkylating agent and m-methyl phenol with H beta zeolite as catalyst under 50 to 180 degrees centigrade and normal pressure, then a 2-tert-butyl-5-methyl phenol is obtained, wherein the H beta zeolite is made by modifying Na beta zeolite with a silica alumina ratio of 5-40, the alkylating agent is tertiary butyl alcohol, methyl tert-butyl ether or isobutyl alcohol, the mol ratio between alkylating agent and m-methyl phenol is 1-5:1, and the weight ratio between H beta zeolite and m-methyl phenol is 0.02-0.08:1 when reacting in tank reactor, while the liquid hourly space velocity is 0.2-5 h-1 when reacting in fixed bed. The method has the advantages of friendly environment, high conversion rate, good selectivity, low reaction temperature, short reaction time, etc.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com