Composite gasoline of methanol and method for producing the same

A technology of gasoline and methanol, which is applied in the field of high-clean and environmentally friendly methanol compound gasoline for automobiles and its preparation, to achieve the effects of reducing emissions, reducing fuel consumption, and purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Methanol 35L Gasoline 40L Acetone 4L

[0073] Diethyl ether 7L tert-butanol 4L Cerous nitrate 2L

[0074] Isopropyl Alcohol 2L Combined Additive 6L;

[0075] The components of the combined additive are: 2.6L of active zinc oxide, 1.5L of isopropyl nitrate, 1.5L of triamine, 0.08L of xylene, and 0.32L of hydrogen peroxide.

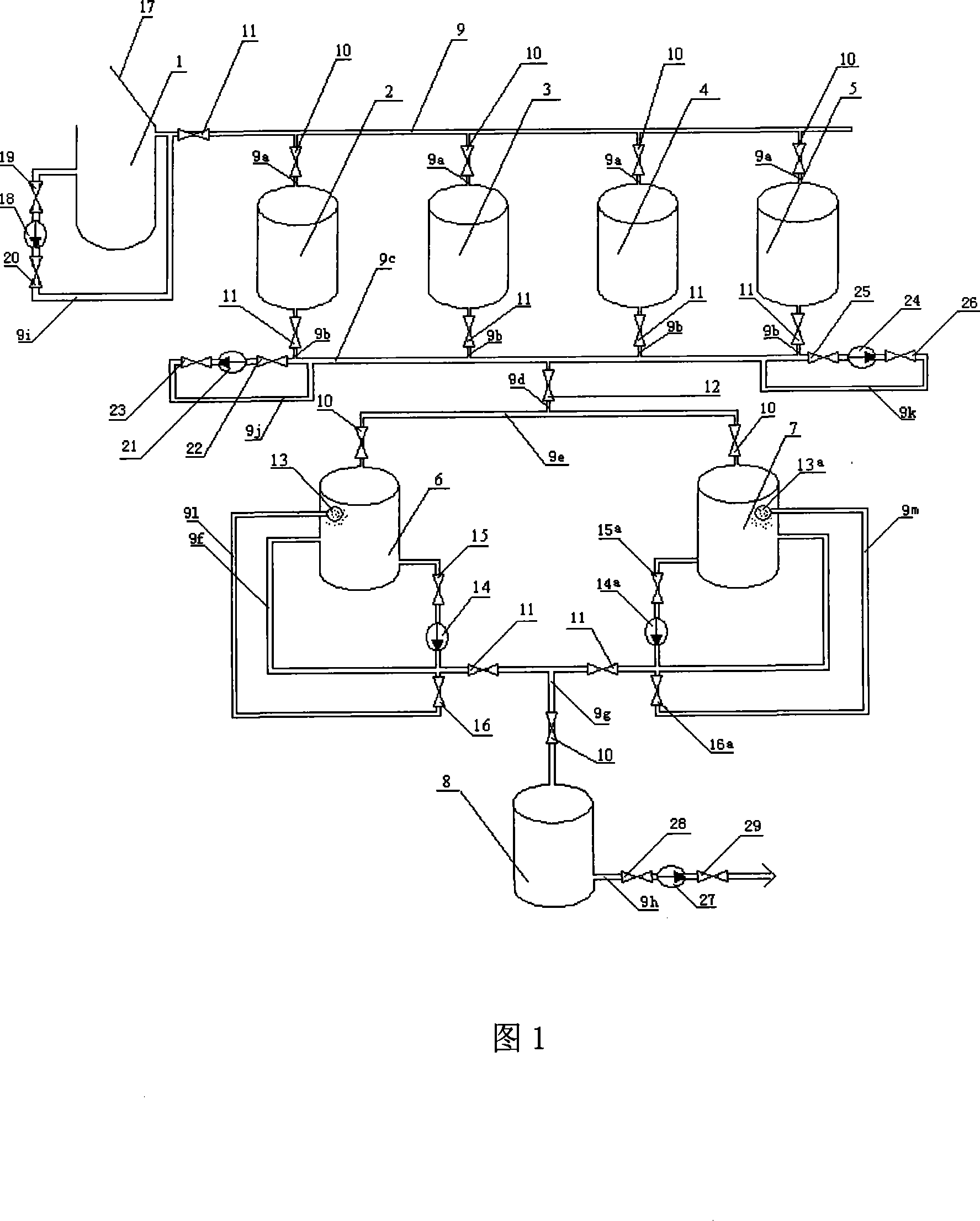

[0076] 1) Input methanol into the additive tank 1, cover the sealing cover 17, open the additive pump input control valve 19 and the additive pump output control valve 20 on the pipeline 9i, simultaneously open the output control valve 11 on the pipeline 9, and turn the methanol tank 2 The input control valve 10 of the pipeline 9a above is opened, methanol flows through the pipeline 9i from the additive tank 1, and then the methanol is output to the methanol tank 2 through the pipelines 9 and 9a by the pressure of the additive pump 18 for standby;

[0077] 2) Acetone, ether, tert-butanol, cerous nitrate, and isopropanol are input into the additive ...

Embodiment 2

[0083] Methanol 35L 90# domestic petrochemical gasoline 38L

[0084] Acetone 3L Diethyl ether 4.5L

[0085] Tert-Butanol 2.5L Cerous Nitrate 3L

[0086] Isopropyl Alcohol 3L Additive Combination 5.5L;

[0087] The components of the combined additive are: 2.2L of active zinc oxide, 1.35L of isopropyl nitrate, 1.59L of triamine, 0.06L of xylene, and 0.3L of hydrogen peroxide.

[0088] Convectively inject methanol, 90# domestic petrochemical gasoline, acetone, ethyl ether, tert-butanol, cerous nitrate, isopropanol and combined additives into the mixing tank from different directions at the same time. The oil pump is injected into the mixing tank, and the circulating oil pump is used in the tank to carry out mixing and circulation for 30 minutes, and finally the oil pump is used to inject into the finished product oil tank to complete the preparation.

Embodiment 3

[0090] Methanol 35L 90# domestic petrochemical gasoline 38L

[0091] Acetone 3L Diethyl ether 4.5L

[0092] Tert-Butanol 2.5L Cerous Nitrate 3L

[0093] Isopropyl Alcohol 3L Additive Combination 5.5L;

[0094] The components of the combined additive are: 2.2L of active zinc oxide, 1.35L of isopropyl nitrate, 1.59L of triamine, 0.06L of xylene, and 0.3L of hydrogen peroxide.

[0095] 1) Input methanol into the additive tank 1, cover the sealing cover 17, open the additive pump input control valve 19 and the additive pump output control valve 20 on the pipeline 9i, simultaneously open the output control valve 11 on the pipeline 9, and turn the methanol tank 2 The input control valve 10 of the pipeline 9a above is opened, methanol flows through the pipeline 9i from the additive tank 1, and then the methanol is output to the methanol tank 2 through the pipelines 9 and 9a by the pressure of the additive pump 18 for standby;

[0096] 2) Acetone, ether, tert-butanol, cerous nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com