Patents

Literature

38results about How to "Solve corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

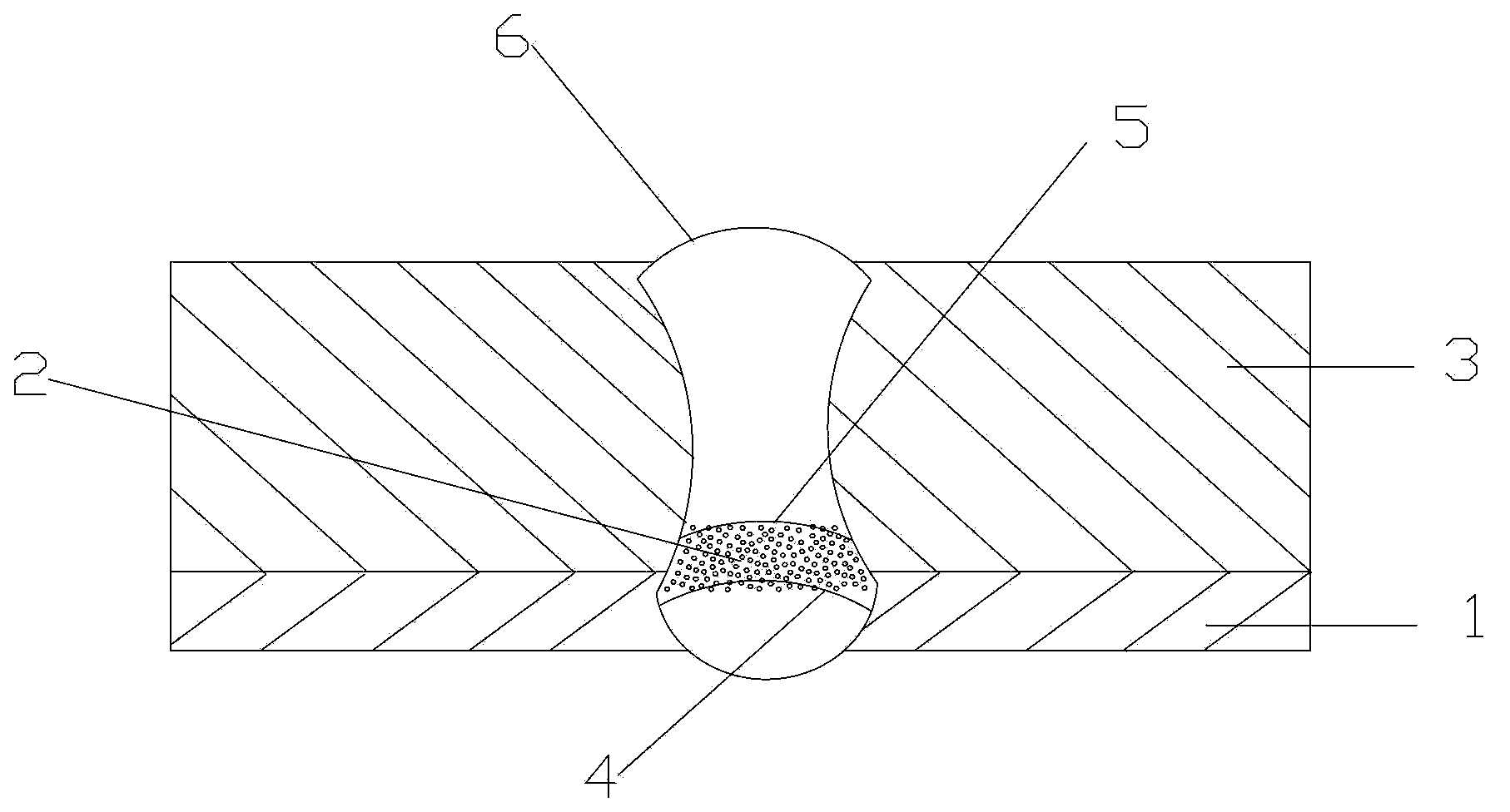

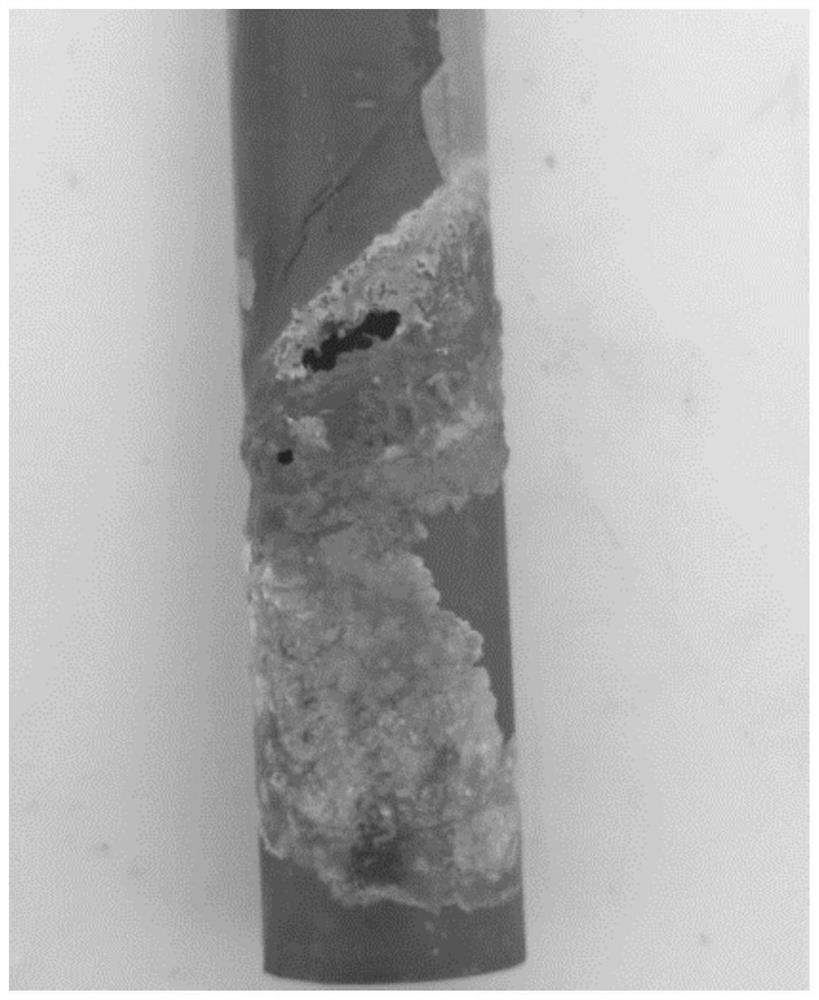

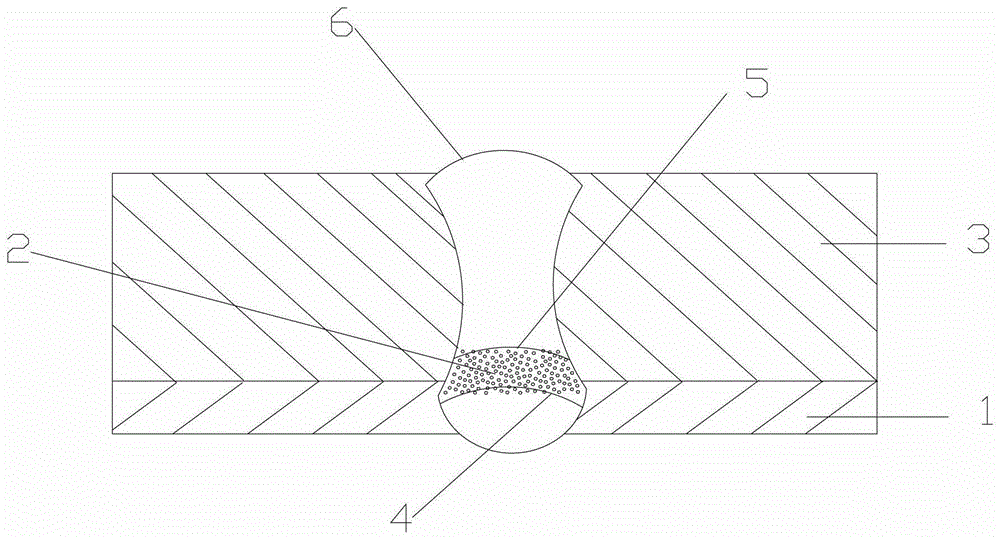

Welding technology for stainless steel composite tubes

ActiveCN103358036ASolve corrosion resistanceReduced corrosion resistanceWorkpiece edge portionsWelding apparatusAlloyCarbon steel

The invention discloses a welding technology for stainless steel composite tubes, which comprises the following steps: (1) conducting welding on the stainless steel composite tube overlying layer to form a welding path I; (2) welding a transition layer between the stainless steel composite tube overlying layer and the substrate layer to form a welding path II; (3) conducting welding on the stainless steel composite tube substrate layer to form a welding path III. According to the welding technology for stainless steel composite tubes provided by the invention, the overlying layer stainless steel (inner layer) of the composite tube is welded first and the substrate carbon steel (outer layer) is welded later, so as to effectively solve the problem that the conventional technology, namely welding carbon steel first and welding stainless steel later, can not weld a composite tube with a diameter smaller than 325, and the welding of the transition layer (welding path II) between the overlying layer and the substrate layer better solves the problem that, in the process of welding overlying layer, the increase of overlying carbon leads to the decrease of overlying layer corrosion, and the problem that, in the process of welding substrate layer, the increase of alloy (chromium and nickel) content leads to the forming of hard organization in the welding line is solved as well.

Owner:DALIAN SAGE GROUP

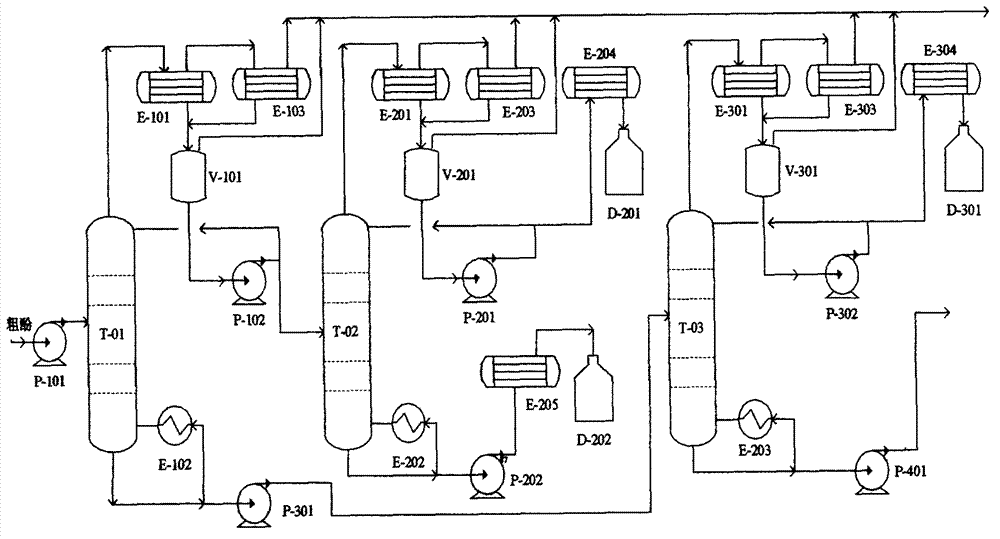

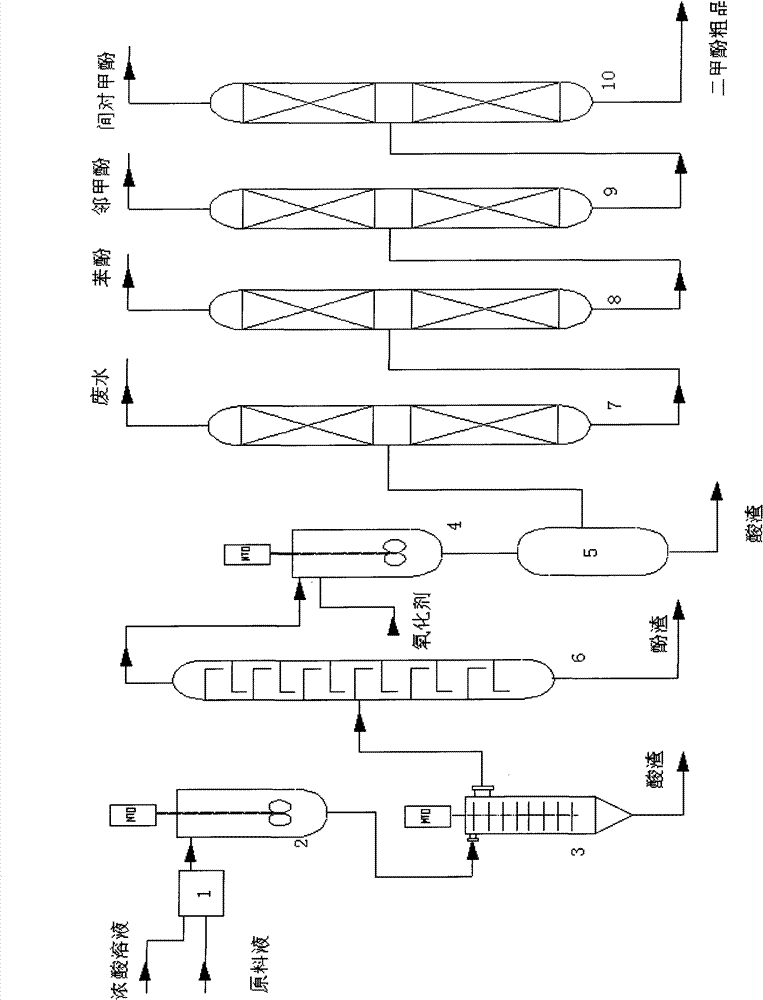

Method and device for continuously rectifying and separating medium/low-temperature coal tar crude phenols

ActiveCN102731264AEfficient separationImprove product qualityOrganic chemistryOrganic compound preparationTowerCoal tar

The invention discloses a method and device for continuously rectifying and separating medium / low-temperature coal tar crude phenols. The method is implemented in a way that: crude phenols extracted from medium / low-temperature coal tar as raw materials are subjected to six-tower continuous rectification to effectively perform impurity removal and separation, thereby obtaining a mixed phenol product containing phenol and orthocresol of which the purities are higher than 99.5% and 2,6-dimethylphenol, 4-methylphenol, 3-methylphenol and 2-methylphenol of which the contents are higher than 99%, a mixed phenol product containing 2,4-dimethylphenol, 2,5-dimethylphenol, 4-methyl-2-ethylphenol and 6-methyl-2-ethylphenol of which the contents are higher than 96%, and the like. The device comprises a light component removal unit, a phenol-orthocresol unit, a meta-paracresol unit, a dimethyl phenol unit a trimethyl phenol unit, a decolorization unit and a vacuum system which are connected through pipelines. In view of the composition characteristics of medium / low-temperature coal tar crude phenols, the invention obtains optimized technique and parameters for separating phenol products; and the whole technical process is reasonable and continuous, has the characteristics of low energy consumption, high product quality, high stability, low production cost and the like, and thus, is an efficient and feasible continuous technique for continuously rectifying and separating medium / low-temperature coal tar crude phenols.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Multi-functional polyethylene tube and manufacturing method thereof

The invention discloses a multi-functional polyethylene tube and a manufacturing method thereof, belonging to a polymer composite material. The multi-functional polyethylene tube is prepared by blending and modifying the following raw materials in parts by mass: 30-50 parts of high-density polyethylene (HDPE), 70-90 parts of ultrahigh molecular weight polyethylene (UHMWPE), 10-15 parts of polyoctene rubber (TOR), 1.5-2.0 parts of nano rare earth beta-nucleating agent, 1.0-1.5 parts of dicumyl peroxide (DCP), 3-5 parts of silicone polymer flame retardant and 3-5 parts of color masterbatch. The invention has the advantage that the problems of low-temperature brittleness, abrasive resistance, corrosion resistance, ageing resistance, heat resistance, processability, flame retardancy, and the like of the polyethylene tube are solved. The invention can be widely applied to the fields of water supply and drainage, sewage discharge, oil gas, coal power, mining industry, gas supply, heating, chemical industry, power communication, ocean, dredging, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

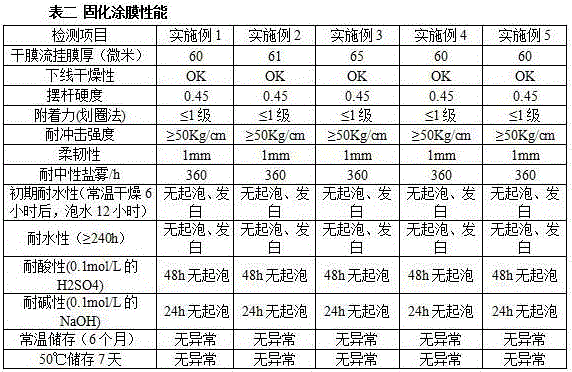

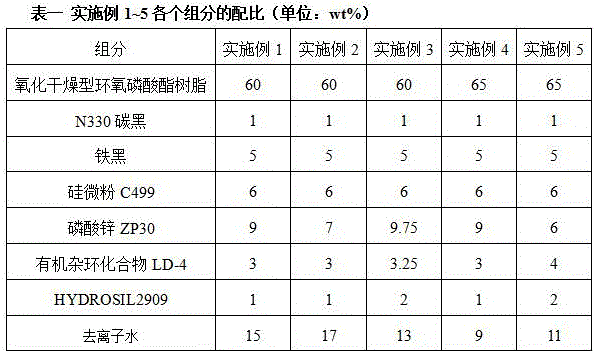

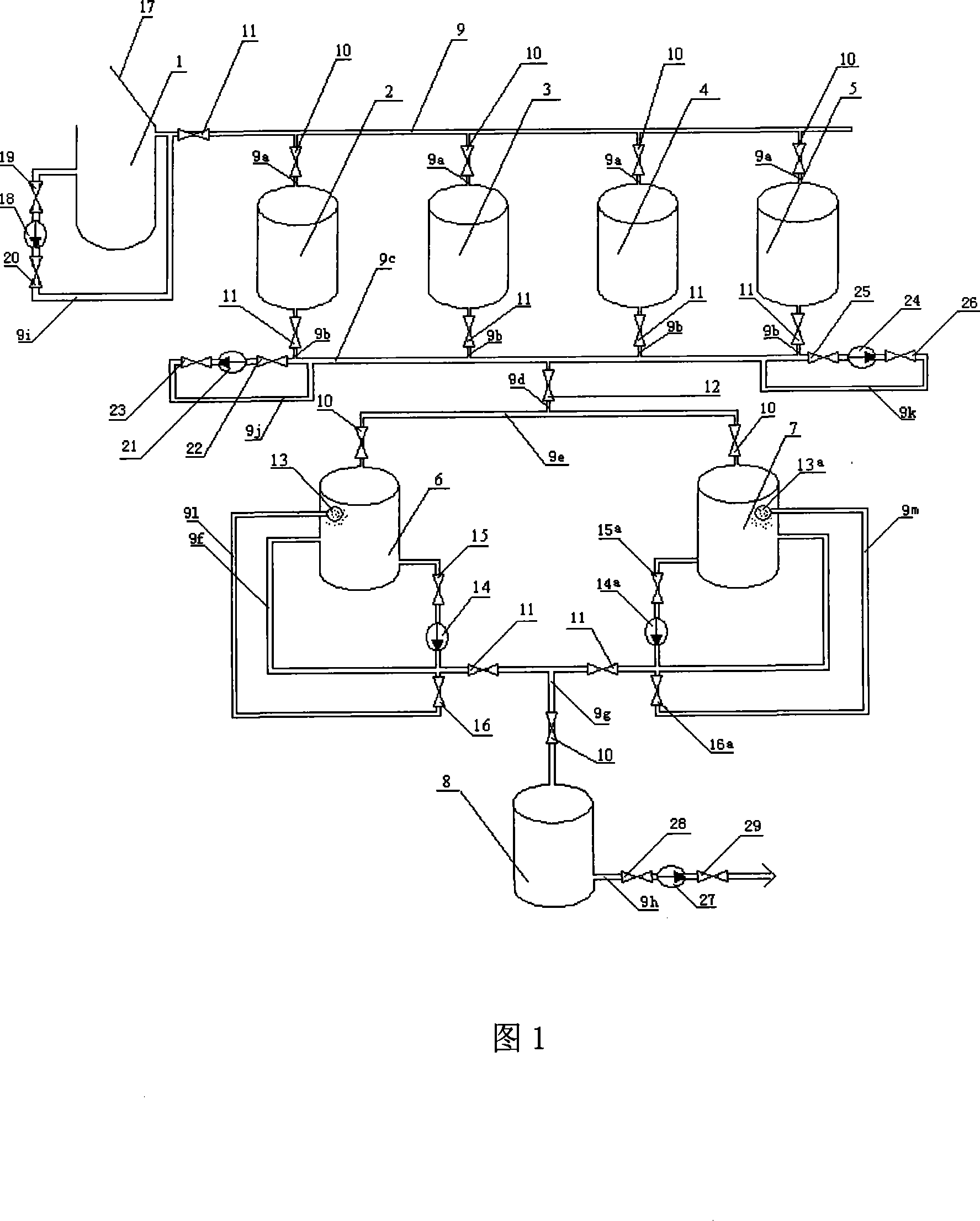

Disc-type electrostatic coating process for vehicle transmission shaft aqueous anticorrosion coating material

ActiveCN106566363AGood storage stabilityGood compatibilityLiquid surface applicatorsAnti-corrosive paintsPhosphateLow temperature curing

The invention discloses a disc-type electrostatic coating process for a vehicle transmission shaft aqueous anticorrosion coating material, wherein an aqueous anticorrosion coating material is sprayed on a steel structure member by using a disc-type electrostatic spraying gun and then drying is performed, wherein the surface of the steel structure member is subjected to iron-based phosphating treatment, and the aqueous anticorrosion coating material comprises, by weight, 50-70% of an oxidative drying type epoxy phosphate resin, 5-15% of pigment and filler, 5-15% of a functional antirust pigment, 1-2% of a functional accelerant, and 10-20% of deionized water. The present invention further discloses the aqueous coating material. According to the present invention, the problem of the corrosion resistance of the aqueous single-component coating in the iron-based phosphating treatment of the steel structure member, the problems of the offline drying and the sticking resistance of the low-temperature curing single-component coating, and the technical problem of the meeting of the sagging and the leveling of the disc-type electrostatic coating with the single-component aqueous coating material technology are solved.

Owner:GUANGZHOU KINTE IND

Composite gasoline of methanol and method for producing the same

InactiveCN101195771AAvoid mechanical propertiesResolve dynamicsLiquid carbonaceous fuelsPhysical chemistryGasoline

The invention discloses methanol compound gasoline, the methanol compound gasoline is composed of methanol, gasoline, propanone, ethylether, tertiary butyl alcohol, nitric acid cerous cerium, isopropyl alcohol and combined additive agent. The preparation method of the invention is to perform the convection to the methanol, the gasoline, the propanone, the ethylether, the tertiary butyl alcohol, the nitric acid cerous cerium, the isopropyl alcohol and the combined additive agent from different directions and to inject into a mixing tank simultaneously, an oil pump is used to inject the all to the mixing tank, the circulating oil pump is used in the tank to perform the mixing and circulating, finally, the preparation is finished after the oil pump is used to inject into a finished product oil tank. The methanol compound gasoline of the invention can solve a series of problems that the mechanical performance, the dynamic performance, the safety performance and the starting performance of vehicles are bad. Simultaneously, the invention can simultaneously perform the function of the cleanness and the environment protection, and the advantages of reducing the gasoline cost and reducing the fuel oil consumption of the vehicles.

Owner:北京金鑫世纪电力环保科技有限公司

High efficiency and energy saving fly ash sintered brick making method

ActiveCN104129972AEasy to transformLow drying efficiencySolid waste managementBrickResource utilization

The invention provides a high efficiency and energy saving fly ash sintered brick making method. The optimization of granularity graduation of shale powder and the introduction of a single layer drying process capable of realizing large-scale continuous production solve the problems of low strength and easy deformation of green bricks in the drying process of ultrahigh-content fly ash sintered bricks, and multi-time mixing, forced mixing, heat insulation time prolongation processes further improve the product stability, so the large-scale industrial production of ultrahigh-content fly ash sintered bricks is successfully realized, the sintered bricks obtained in the invention has high yield, excellent strength and reduced weight, and energy consumed by sintering is effectively reduced. The selection of a kiln top and a hanging structure made of a sintered refractory material improves the acid corrosion resistance of a kiln body, can effectively adapt to the production of high--sulfur high-carbon fly ash sintered bricks, solves the problem of difficult utilization of fly ash from a circulating fluidized bed power plant, and improves the resource utilization rate.

Owner:西安瑞泰机械设备制造有限公司

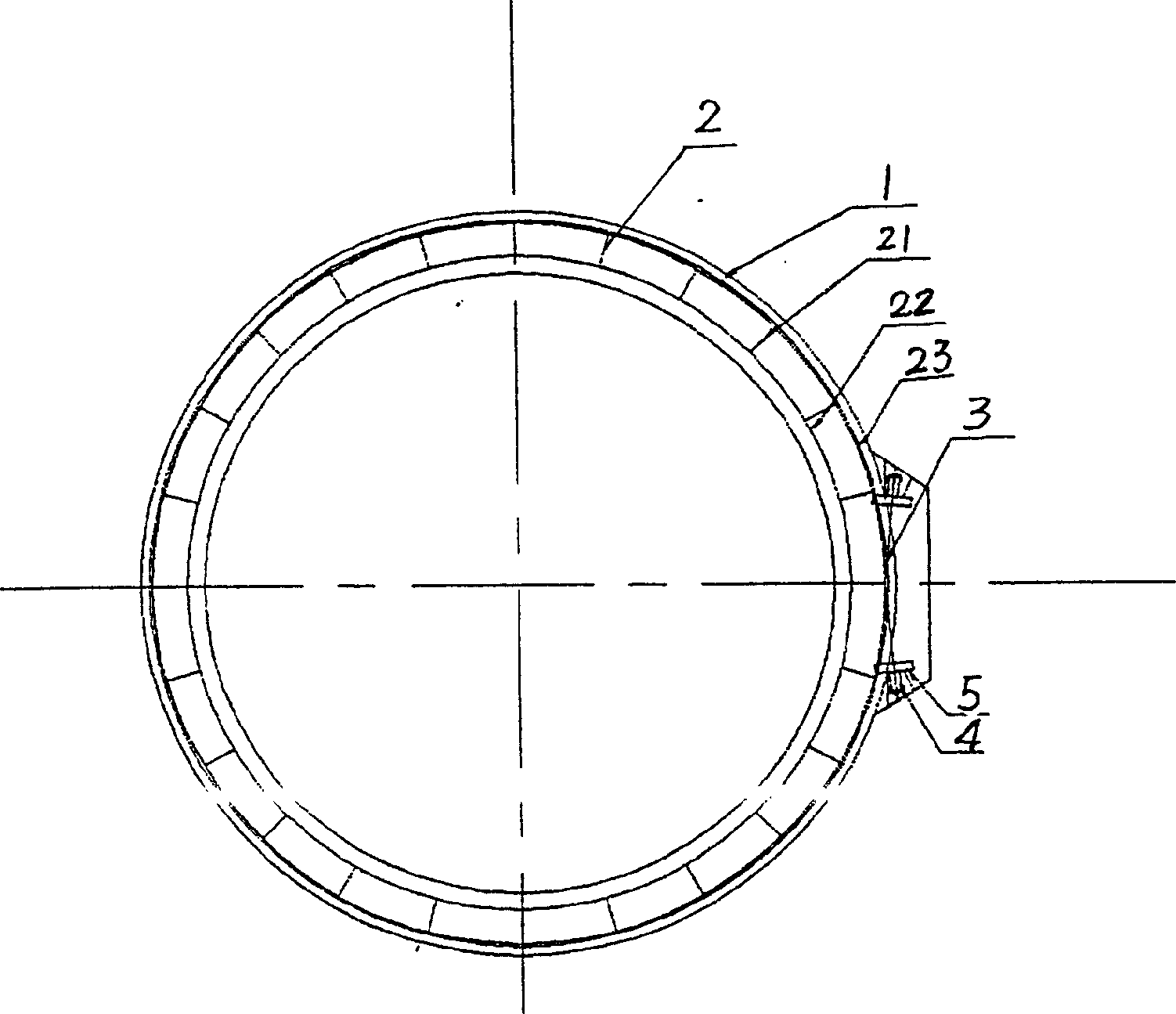

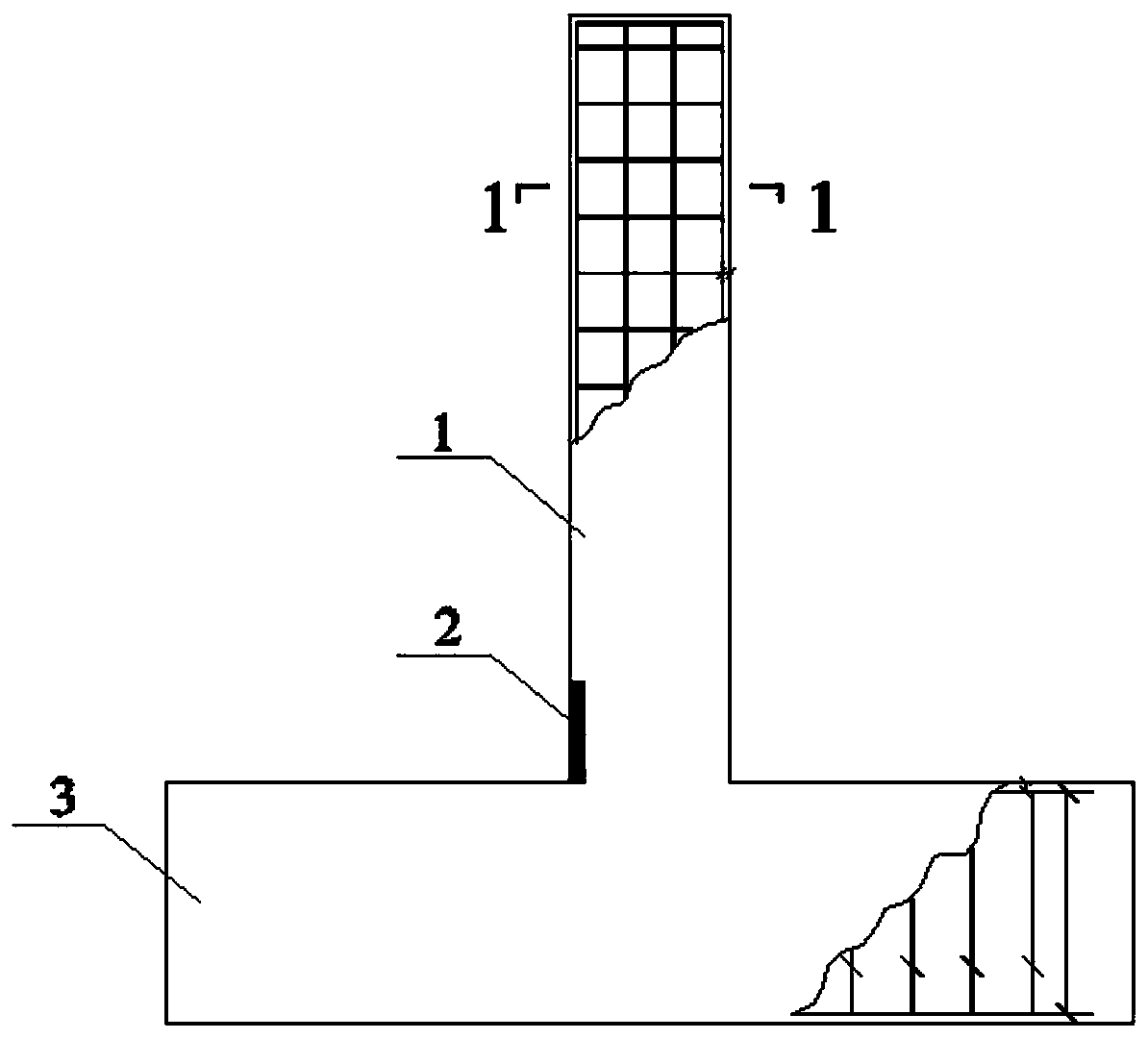

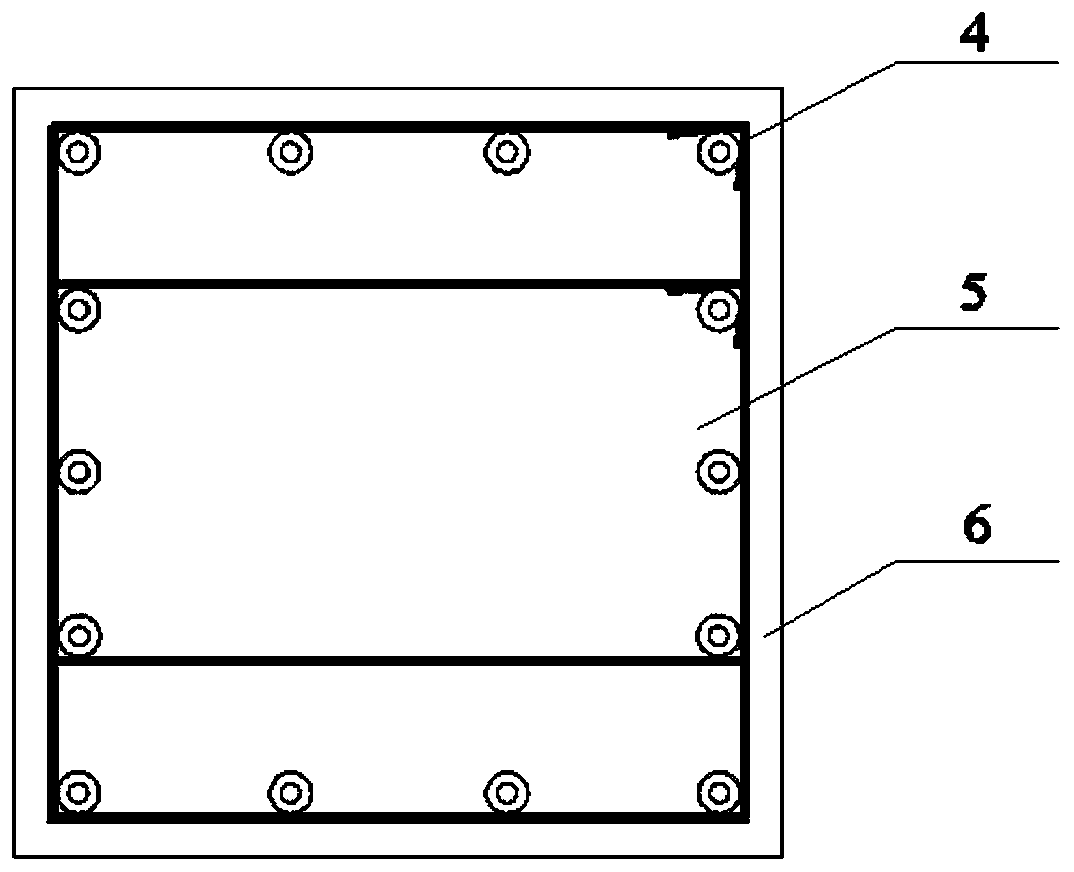

Secondary stage prestress concrete water transport pipe and producing method

InactiveCN1587773AUniform and reliable applied prestress valueSolve corrosion resistanceRigid pipesPre stressWater transport

The invention relates to a two-phase prestressing force concrete pipes and its manufacturing method. It includes pipe body made up of steel frame and concrete, the mentioned steel rib frame includes lengthwise rib, internal ring rib and external ring rib, there arranges with steel strand cables around the frame. The manufacturing method includes following steps: 1. the steel strand cables are tied on the steel frame along the round of the frame; 2. a cushion board and an embedded parts are arranged on the fixed position to be welded, and they are fixed with screw; 3. puts on stress to the pipe core through dragging the steel strand cable after the intensity of the pipe achieves the preset intensity; 4. cuts residual steel strand cable after the platform is regular, and seals the plastic cap, the external part is filled with concrete.

Owner:XINLIN PIPELINE GUANGDONG

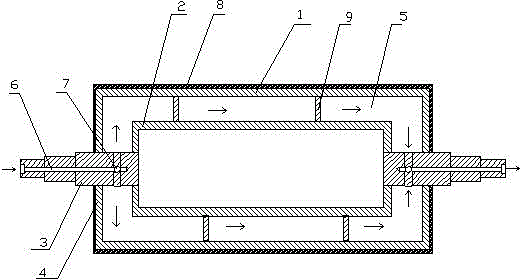

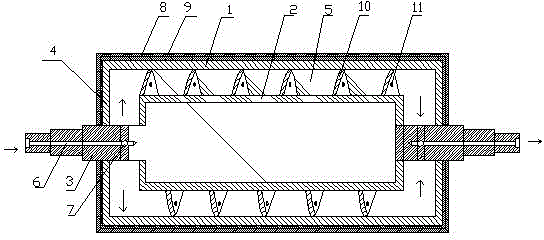

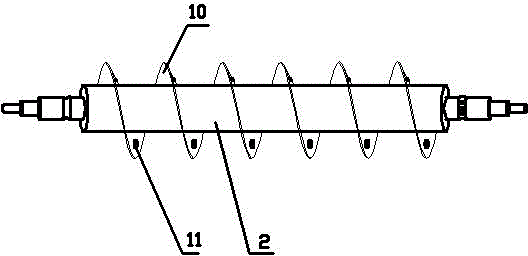

Ceramic cooling roll

InactiveCN104595351AExtended service lifeSolve corrosion resistanceShaft and bearingsEnergy industryProduction lineMetallurgy

The invention relates to a cooling device. In order to solve the technical problem in the prior art, the invention provides a ceramic cooling roll. The ceramic cooling roll comprises an outer roller and a liner roller which are coaxially arranged, wherein the left end and the right end of the liner roller are respectively provided with a shaft head; the left shaft head and the right shaft head penetrate through an end-part sealing plate of the outer roller respectively; a water cavity is formed between the outer roller and the liner roller; the axis positions of the end parts of the left shaft head and the right shaft head are internally provided with sinking holes parallel to the shaft heads; and the sinking holes extend to the inner parts of the shaft heads to be between the end part of the outer roller and the end part of the liner roller, and a plurality of through holes communicated with the sinking holes are radially formed in the shaft head walls of the area. The ceramic cooling roll is characterized in that a ceramic layer is arranged on the surface of the outer roller. The ceramic cooling roll provided by the invention is reasonable in structure and simple in manufacture and can be widely applied to linkage production line equipment of papermaking, plastics and rubber and the like.

Owner:WEIHAI FENGTAI NEW MATERIAL SCI & TECH

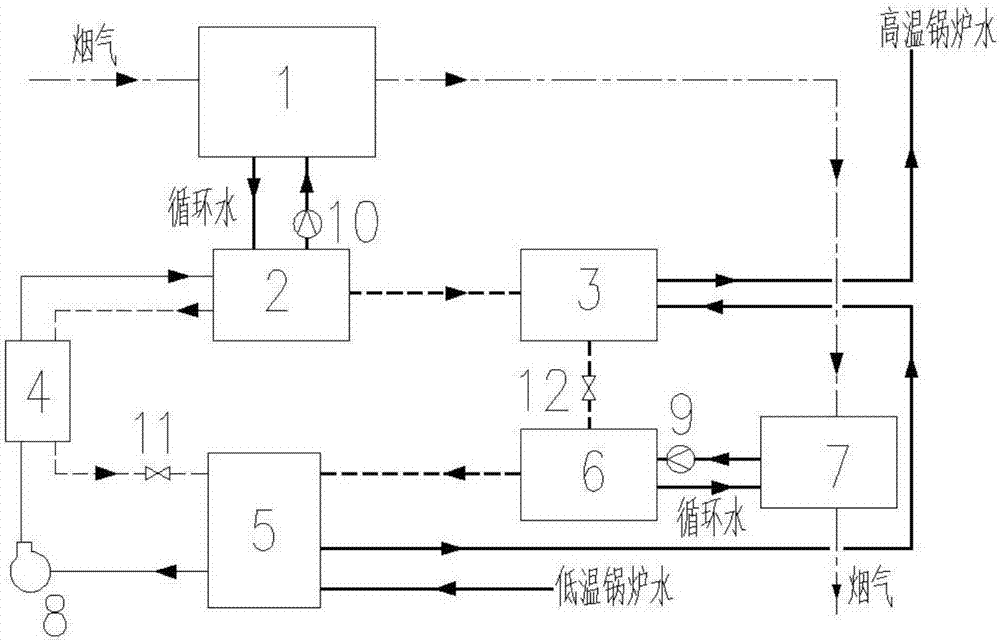

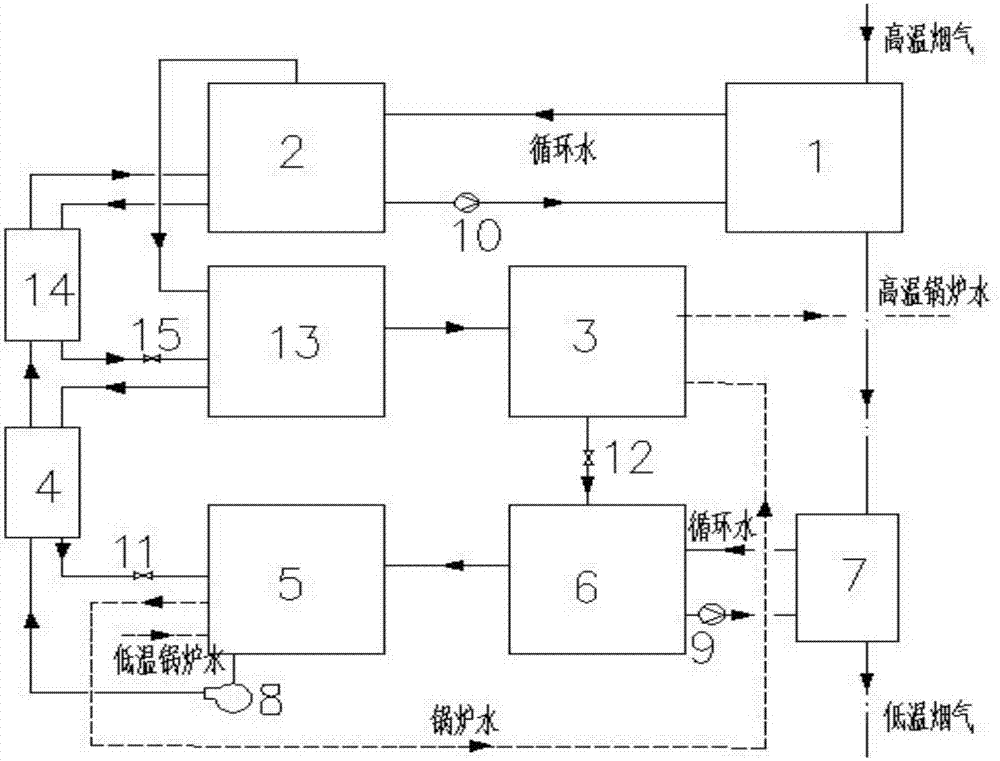

Novel incinerator fuel gas excess heat deeply-recycling and energy level improving technology system

InactiveCN107448965AReduce depthReduce utilizationEnergy efficient heating/coolingClimate change adaptationLithium bromideHigh pressure

The invention discloses a novel incinerator fuel gas excess heat deeply-recycling and energy level improving technology system. The novel incinerator fuel gas excess heat deeply-recycling and energy level improving technology system comprises a high-pressure heat exchanging system, a lithium bromide solution circulating system and a low-temperature fuel gas heat exchanging system. The high-pressure heat exchanging system comprises a high-pressure heat exchanger, a second circulating water pimp and a generator. The lithium bromide solution circulating system comprises a generator, a solution exchanger, an absorber, an evaporator, a condenser, a lithium bromide solution circulating pump, a lithium bromide solution throttling device and a refrigerant water throttling device. The low-temperature fuel gas heat exchanging system comprises an anti-corrosion heat exchanger for circulating water heating, a frist circulating water pump and an evaporator. According to the novel incinerator fuel gas excess heat deeply-recycling and energy level improving technology system, the recovery efficiency of tail gas incinerator fuel gas excess heat can be improved, and the problems of plugging and corrosion during recycling the tail gas incinerator fuel gas excess heat less than an acid dew point are avoided.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

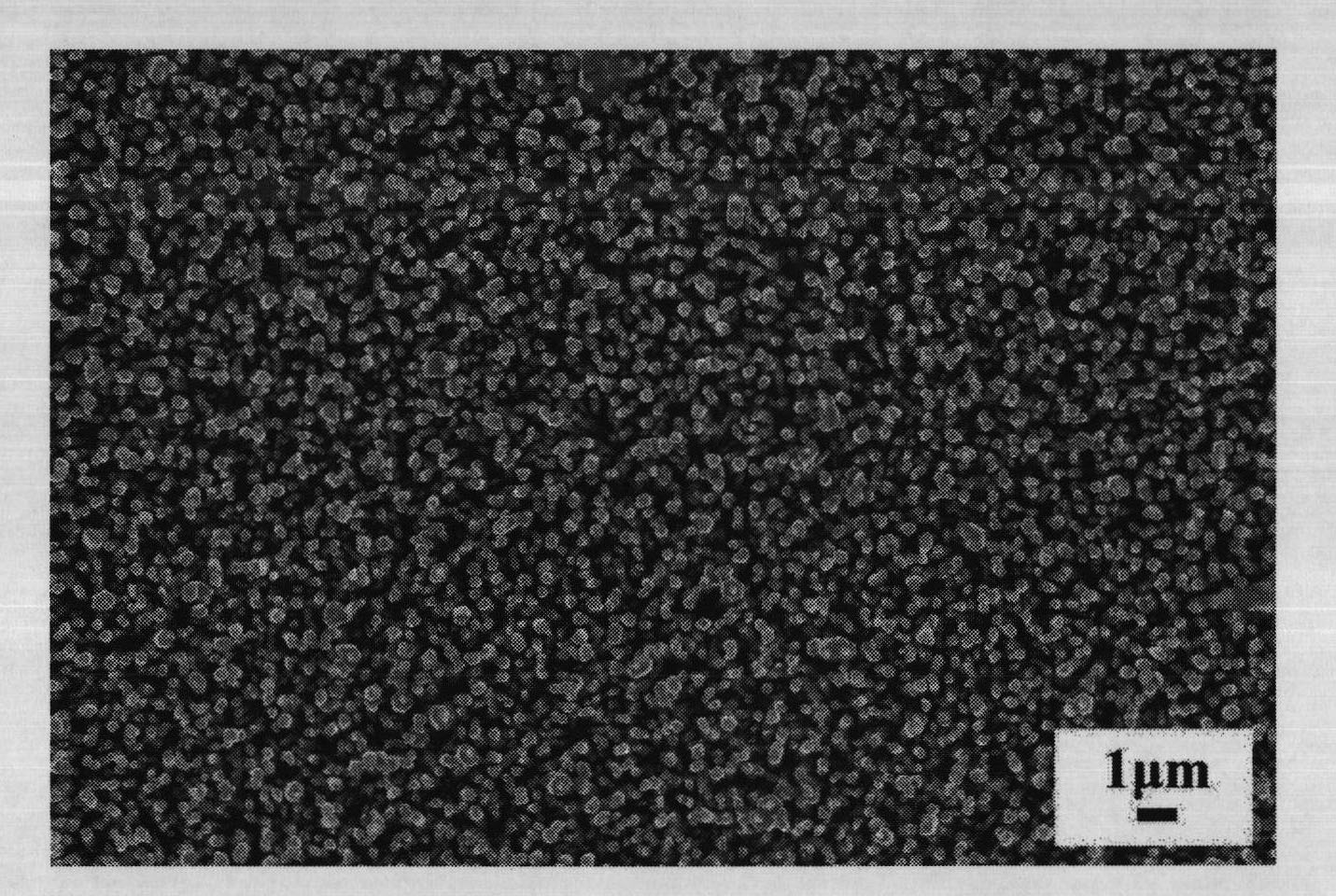

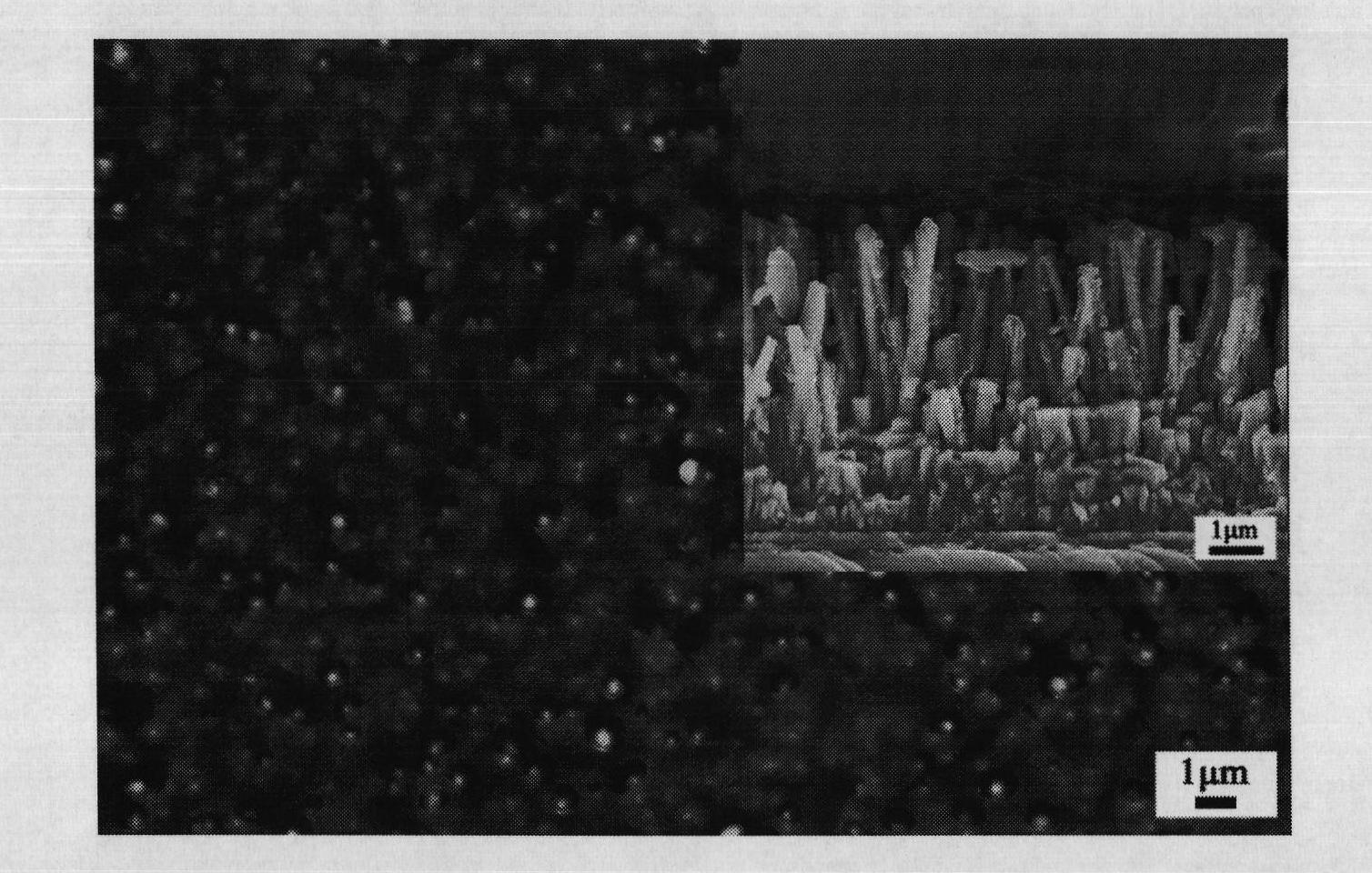

Preparation method for SiO2-ZnO nano-bar array composite electrode

InactiveCN102005304ASolve corrosion resistanceAvoid corrosion damageLight-sensitive devicesFinal product manufactureThermal methodsStrong acids

The invention belongs to the technical field for nanometre materials and relates to a preparation method of a SiO2-ZnO nano-bar array composite electrode. The preparation method is characterized in that: a ZnO nano-bar array prepared by a hydro-thermal method is used as a composite electrode base layer, a rotationally coated silicon oxide gel process is selected as the method for preparing the SiO2-ZnO nano-bar array composite electrode, and the thickness of a SiO2 thin film coating can be reasonably controlled by adjusting the concentration of gel, the number of coatings and the frequency ofsintering, so that adjustment and control on the performance of the composite electrode can be realized. By a method for enhancing the anti-erosion performance of a zinc oxide nano-bar array electrode by coating a silicon oxide protection layer, the SiO2-ZnO nano-bar array composite electrode applicable for an acidic dye-based dye sensitized solar battery is prepared, and has advantages of stableperformance, strong acid resistance, simplicity of preparation method, low cost, high efficiency, wide adjustable area and suitability for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Steel sheet with stanniferous coating and preparation method thereof

InactiveCN103358614ASolve corrosion resistanceReduce dosageMetal layered productsCorrosion resistantPolyethylene glycol

The invention discloses a steel sheet with a stanniferous coating and a preparation method thereof. The method comprises the following steps: 1) subjecting a high-quality low-carbon cold-rolled steel sheet to deoiling, rust removal and cleaning and then to activation with an acid solution and rinsing; 2) carrying out electroplating, wherein an electroplating solution comprises 35 to 45 g / L of Sn(BF4)2, 95 to 105 g / L of Zn(BF4)2 and 1.5 to 2.5 g / L of polyethylene glycol and has a pH value of 1.5 to 2.5; 3) cleaning the electroplated steel sheet with water and subjecting the steel sheet to soft heating, hardening, cleaning with soda and chromate cathodic passivation; and 4) cleaning the passivated steel sheet with water and blow-drying the steel sheet so as to obtain a finished product. The content of a stannum-zinc alloy in the steel sheet with the stanniferous coating prepared in the invention is 0.8 to 16 g / m<2>, the weight percentage of stannum in the tin-zinc alloy coating is 75 to 85%, the usage amount of stannum is reduced, and corrosion resistance of the sheet is obtained.

Owner:武汉钢铁有限公司

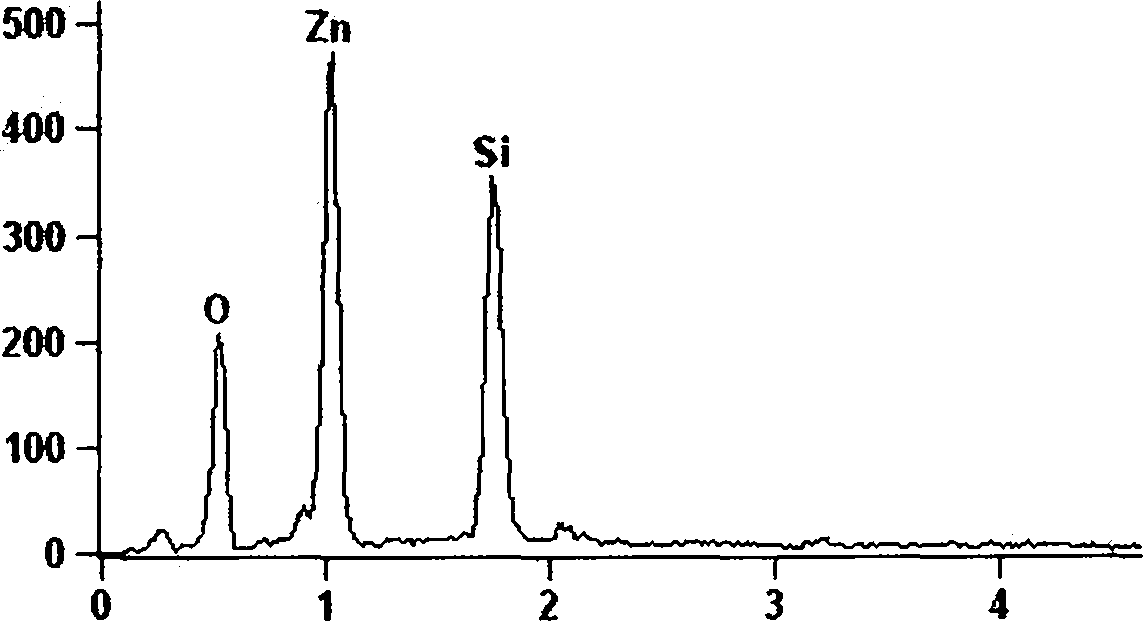

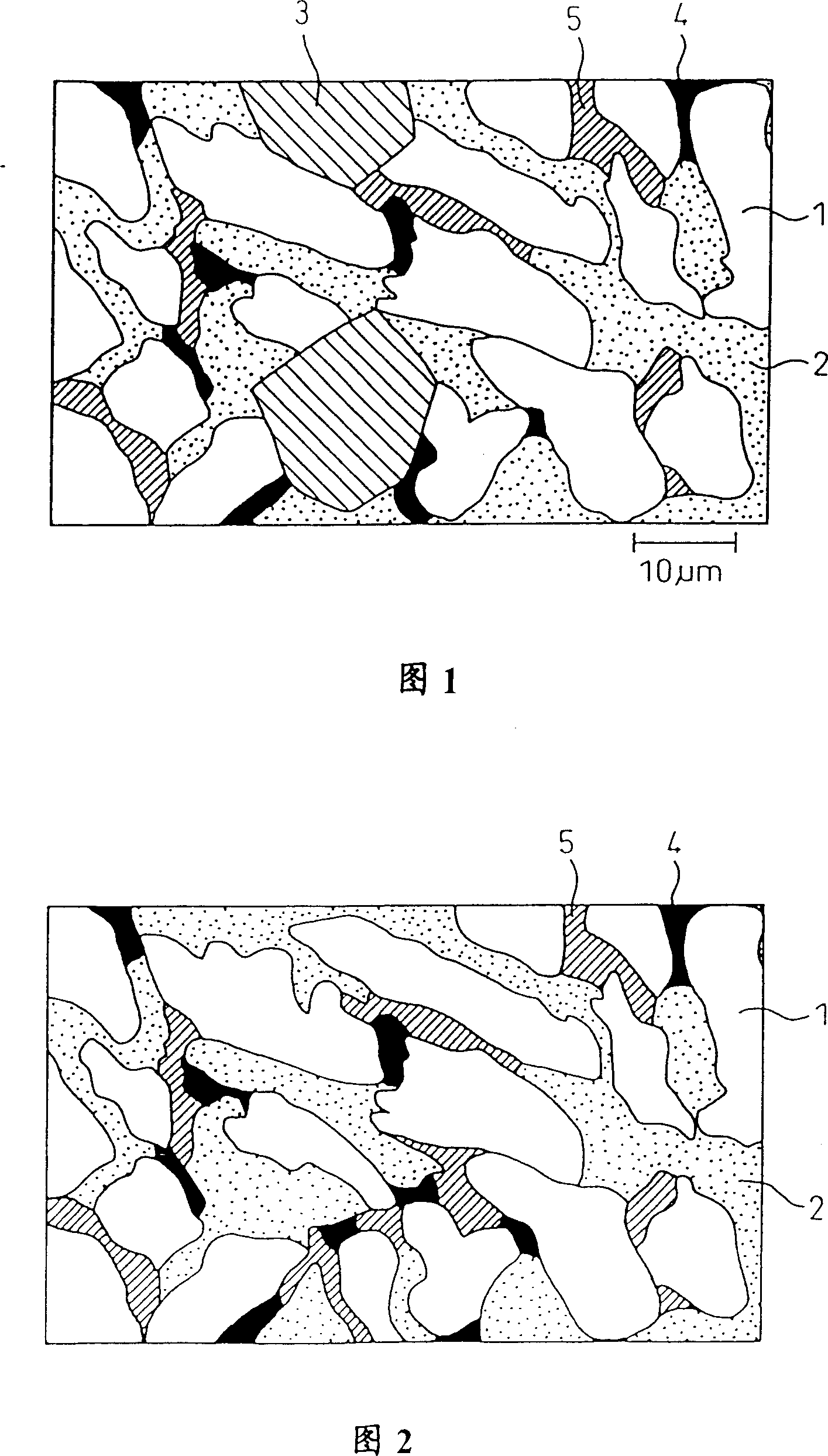

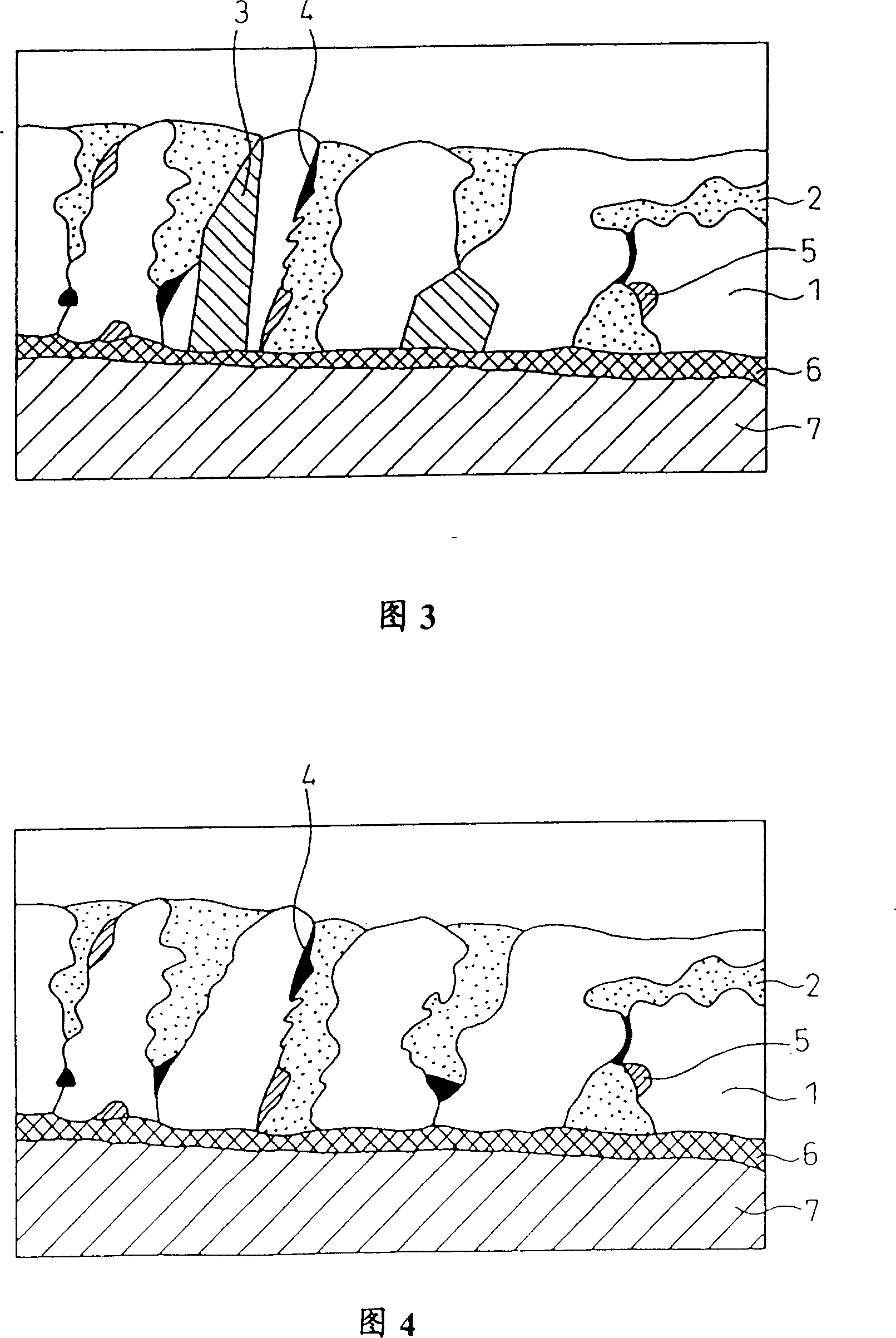

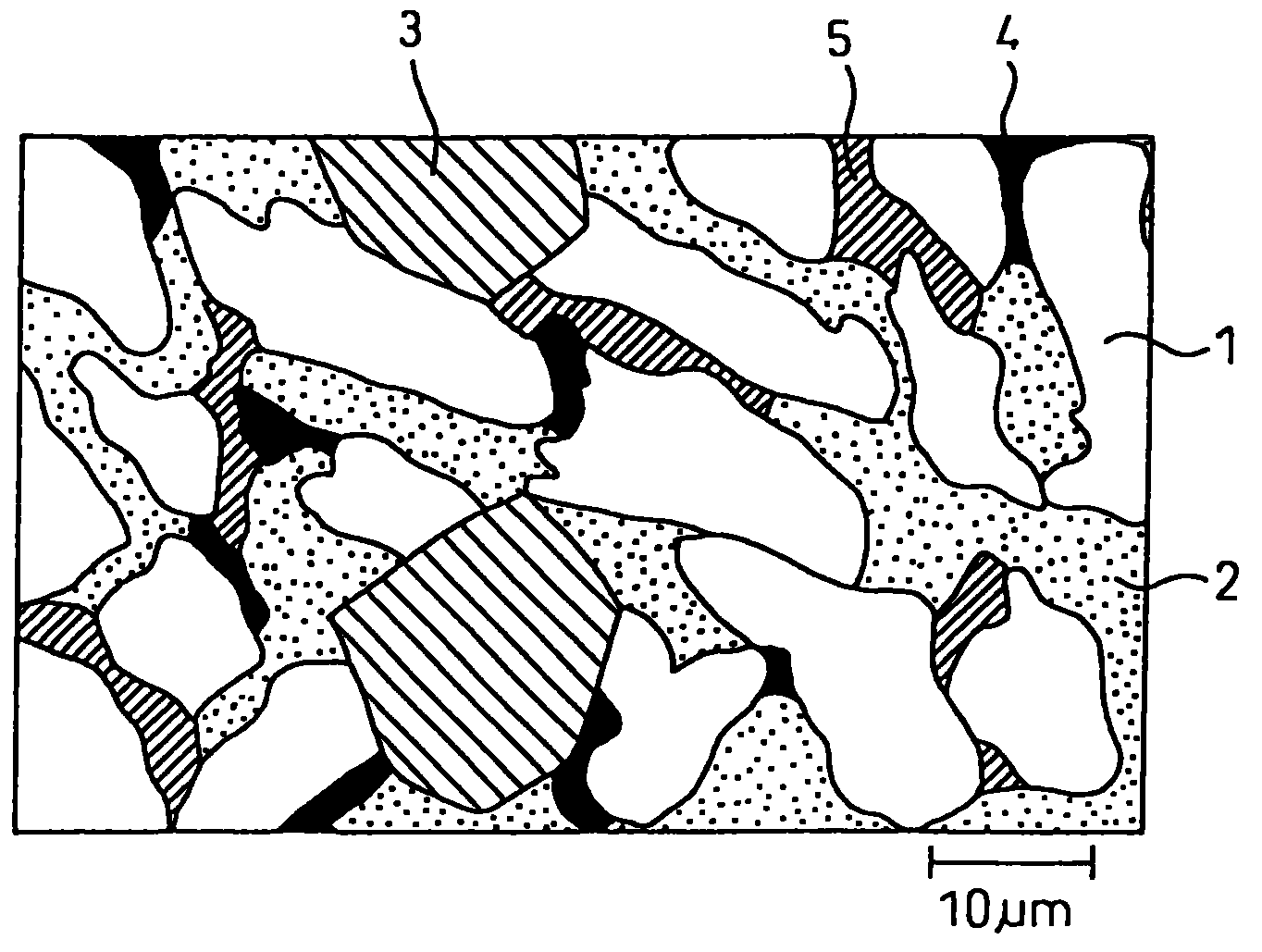

Zn-Al-Mg-Si alloy plated steel product having excellent corrosion resistance and method for preparing the same

InactiveCN100334250CSolve corrosion resistanceSolve the problem of edge creep resistanceHot-dipping/immersion processesDomestic articlesAlloyImpurity

A Zn-Al-Mg-Si alloy-plated steel material with excellent corrosion resistance, characterized by comprising, in terms of wt%, Al: at least 45% and no greater than 70%, Mg: at least 3% and less than 10%, Si: at least 3% and less than 10%, with the remainder Zn and unavoidable impurities, wherein the Al / Zn ratio is 0.89-2.75 and the plating layer contains a bulky Mg2Si phase; also, a Zn-Al-Mg-Si alloy-plated steel material with excellent corrosion resistance, characterized by comprising, in terms of wt%, Al: at least 45% and no greater than 70%, Mg: at least 1% and less than 5%, Si: at least 0.5% and less than 3%, with the remainder Zn and unavoidable impurities, wherein the Al / Zn ratio is 0.89-2.75 and the plating layer contains a scaly Mg2Si phase.

Owner:NIPPON STEEL CORP +1

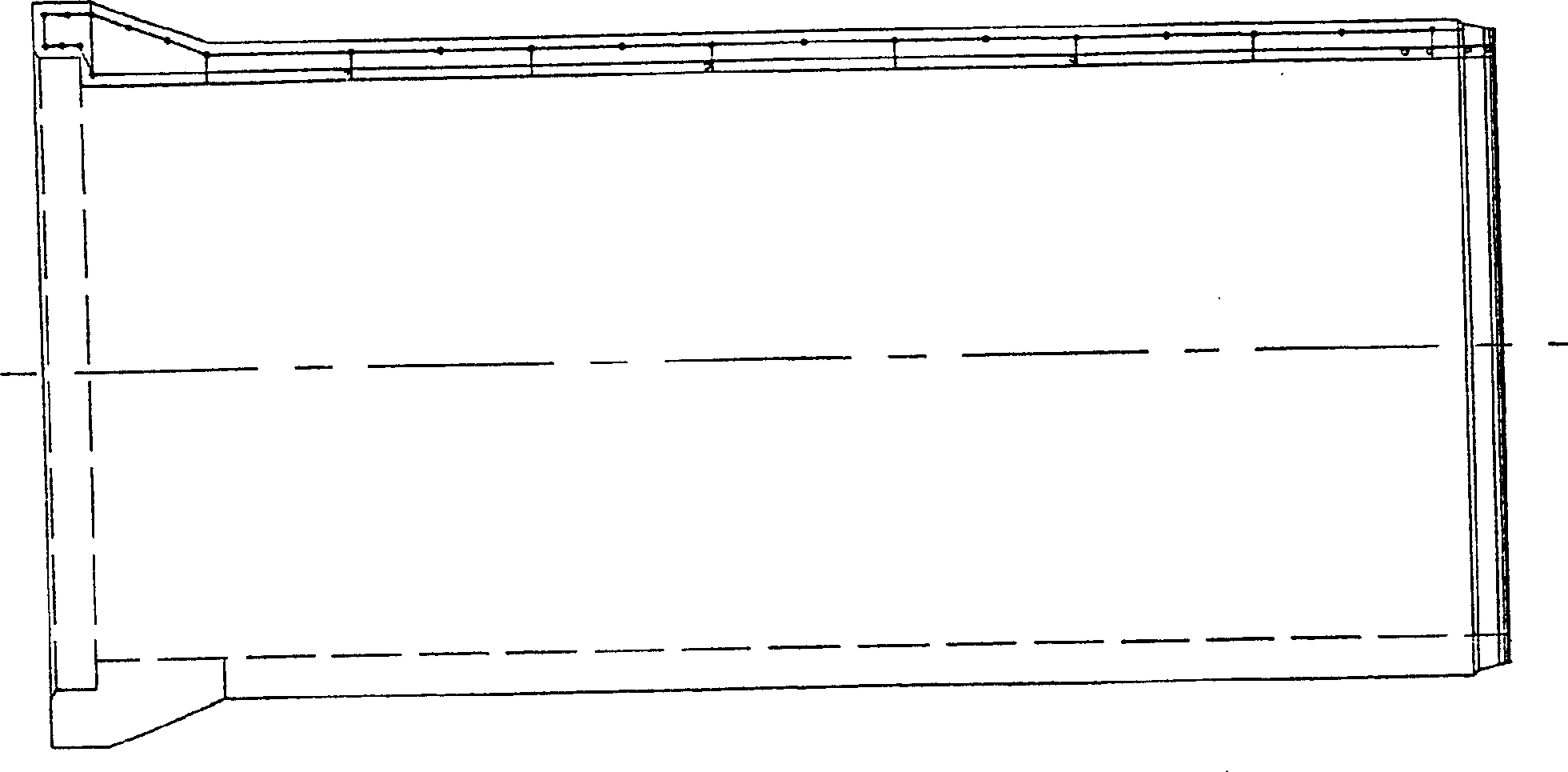

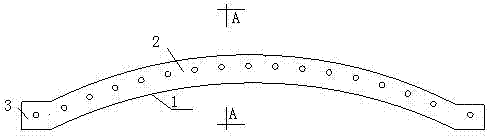

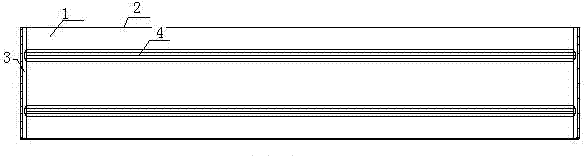

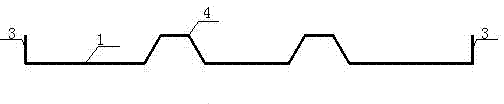

Closed air collecting arch-shaped cover plate of sewage pond

InactiveCN104763046ASolve corrosion resistanceSolve agingSewerage structuresWater/sewage treatmentEngineeringSewage

The invention provides a closed air collecting arch-shaped cover plate of a sewage pond. The closed air collecting arch-shaped cover plate comprises a cover body with an arc-shaped section; pond body connecting flanges are bent at two long sides of the cover body; cover plate connecting flanges are bent at two short sides of the cover body; concave reinforcing strips with trapezoidal sections are pressed at intervals on the cover body; the cover plate is of an arc-shaped structure and formed by a single stainless steel arch-shaped plate. Compared with the prior art, the closed air collecting arch-shaped cover plate is manufactured from stainless steel and is simple in structure. The closed air collecting arch-shaped cover plate has the advantages of being high in strength, resistant to corrosion, long in service life, high in safety, free of special corrosion preventing treatment, and convenient to manufacture and mount; different arch height can be set according to the width of a pond body; therefore, the problem that the corrosion resistance, the ageing resistance and the strength of the cover plate of the sewage pond are reduced as time goes on can be effectively solved; the manufacturing and mounting are convenient; the manufacturing cost is small; secondary pollution is avoided.

Owner:JIANGSU LANCHEN E P SCI & TECH

Surface coating method of aluminum alloy wheel

PendingCN111763944AImprove bindingImprove stress residueVacuum evaporation coatingPretreated surfacesTitanium fluorideOxygen ions

The invention discloses a surface coating method for an aluminum alloy wheel. The surface coating method comprises the following steps of S1, grinding and polishing the aluminum alloy wheel; S2, cleaning the aluminum alloy wheel; S3, immersing the aluminum alloy wheel in a titanium fluoride / zirconium fluoride solution, thereby forming an Al2O3.ZrO2.TiO2 conversion film on the surface of the aluminum alloy wheel; S4, ionizing oxygen with the concentration of 99.999% through radio frequency, and forming oxygen ions to treat the surface of the aluminum alloy wheel; S5, adding acetylene gas whilecarrying out magnetron sputtering coating; and S6, spraying a transparent protective layer, baking and curing. The coating film is better in corrosion resistance, low in cost and low in energy consumption, toxic metal such as hexavalent chromium is not contained, and the technological process is green and environmentally friendly.

Owner:CITIC DICASTAL

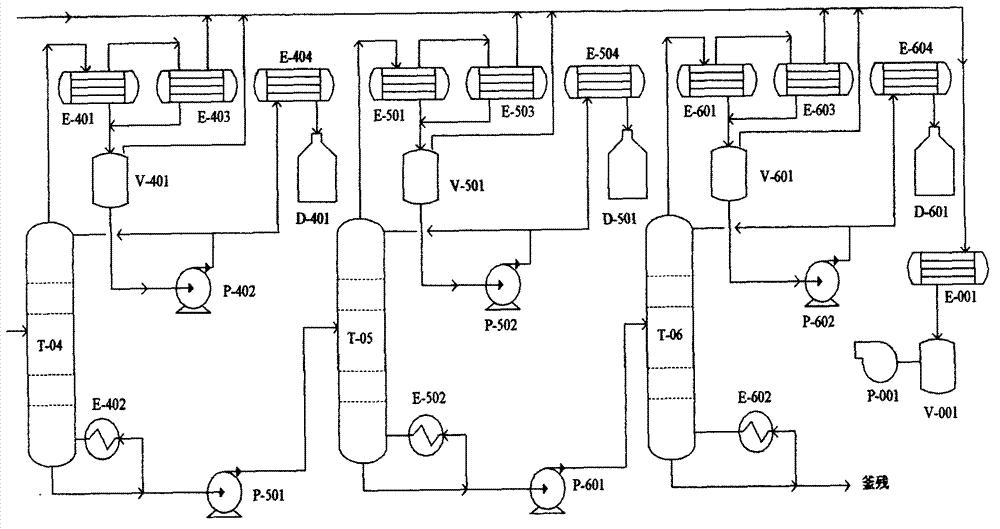

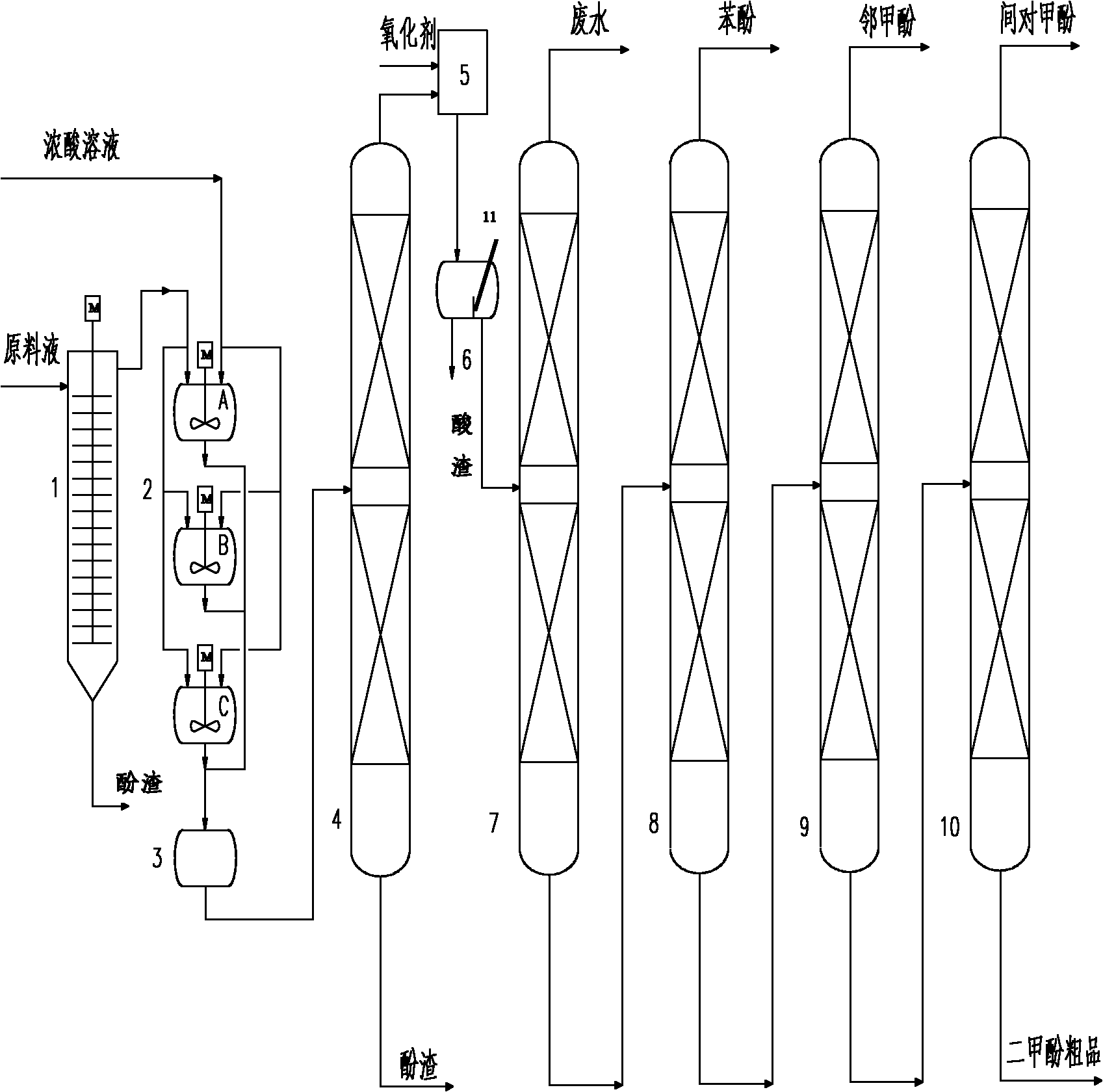

Continuous refining separation device and method for coal gasification crude phenol

ActiveCN102153449BSolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationPhenolP-Cresol

The invention discloses a continuous rectification separation device and a continuous rectification separation method for coal gasification crude phenol. The device comprises a first-level pretreatment acidifying unit consisting of a film scraping evaporator, a primary acid regulating tank group and a buffer tank, a second-level pretreatment oxidizing unit consisting of a static mixer and a secondary acid regulating tank and a rectifying tower system consisting of a deslagging tower, a dehydrating tower, a phenol refining tower, an o-cresol refining tower and a m, p-cresol refining tower, wherein the first-level pretreatment acidifying unit is connected with the phenol deslagging tower; and the phenol deslagging tower is connected with the second-level pretreatment oxidizing unit and is connected with each rectifying tower system respectively. By the device and the method, the raw material of the coal gasification crude phenol is subjected to decoloration, deodorization, desulfuration, impurity removal and the like effectively, so that products of high-purity phenol with the purity of more than 99.5 weight percent, high-purity o-cresol with the purity of more than 96.0 weight percent, high-purity m, p-cresol with the purity of more than 99.0 weight percent, mixed xylenol and phenol residual oil can be obtained. The method has the characteristics of reasonable process, high automaticity, low process energy consumption, high quality of products, high stability and the like, and is an efficient and feasible continuous rectification separation process for the coal gasification crude phenol.

Owner:天津美科泰化工科技有限公司

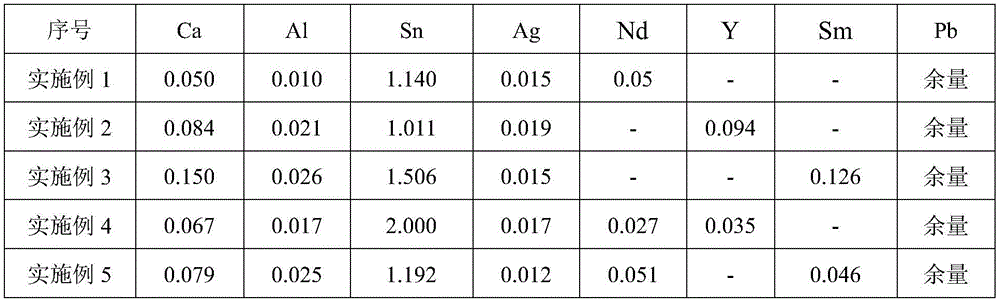

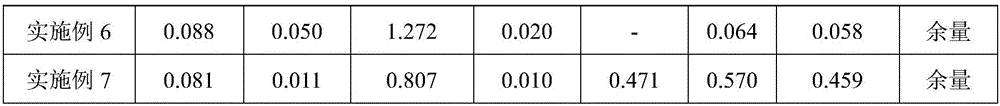

Rare earth grid alloy for lead-acid storage batteries and production method thereof

InactiveCN106684391AReduce lossReduce cold cracking and other phenomenaElectrode carriers/collectorsCapacity lossRare-earth element

The invention discloses a rare earth grid alloy for lead-acid storage batteries. The rare earth grid alloy for lead-acid storage batteries comprises the following raw materials in percentage by weight: 0.05-0.15% of Ca, 0.8-2.0% of Sn, 0.01-0.05% of Al, 0.01-0.02% of Ag, 0.05-0.15% of rare earth element and the balance of Pb, wherein the rare earth element may be one or more of Nd, Y and Sm. The rare earth element added to the grid alloy improves the corrosion resistance of the alloy, prolongs the cycle lives of the storage batteries, strengthens the charge receptivity of the batteries, and obviously improves the early capacity loss phenomenon of the batteries.

Owner:HENAN CHAOWEI POWER SUPPLY

Anti-corrosion anti-seismic combined column component and construction method thereof

PendingCN111549975ASolve corrosion resistanceSolve pollutionStrutsBridge structural detailsBridge engineeringPolyvinyl alcohol

The invention provides an anti-corrosion anti-seismic combined column component and a construction method thereof, and belongs to the technical field of constructional engineering and bridge engineering. The problems that in the prior art, a column is poor in corrosion resistance and seismic resistance are solved, and meanwhile the problem that existing solid waste cannot be easily utilized so asto cause environmental pollution is solved. The component comprises a longitudinal bar, a grouting material, a composite material sleeve, a sizing material layer and a grid layer, wherein the longitudinal bar is located in a plastic hinge area, the longitudinal bar is sleeved with the composite material sleeve, the space between the longitudinal bar and the composite material sleeve is filled withthe grouting material, the sizing material layer is arranged on the outer side of the composite material sleeve, the grid layer is arranged on the outer side of the sizing material layer, and the composite material sleeve is a polyvinyl alcohol cement composite material doped with solid waste powder. The component is mainly used for column components of constructional engineering and bridge engineering technologies.

Owner:HARBIN INST OF TECH

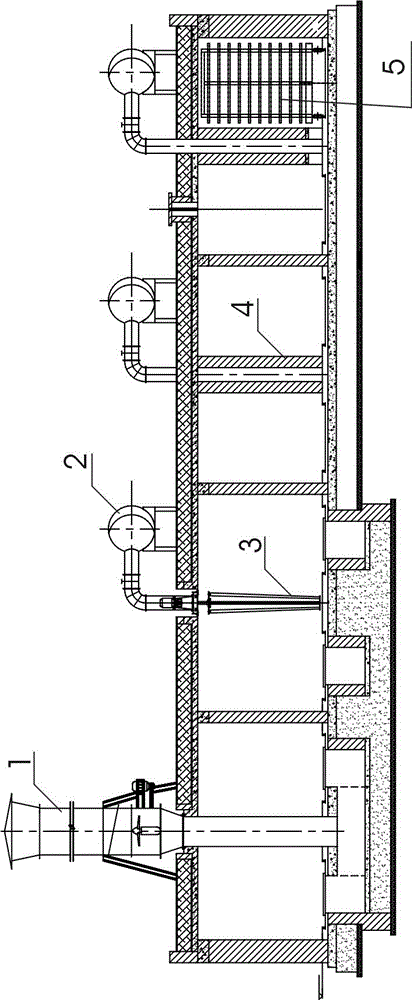

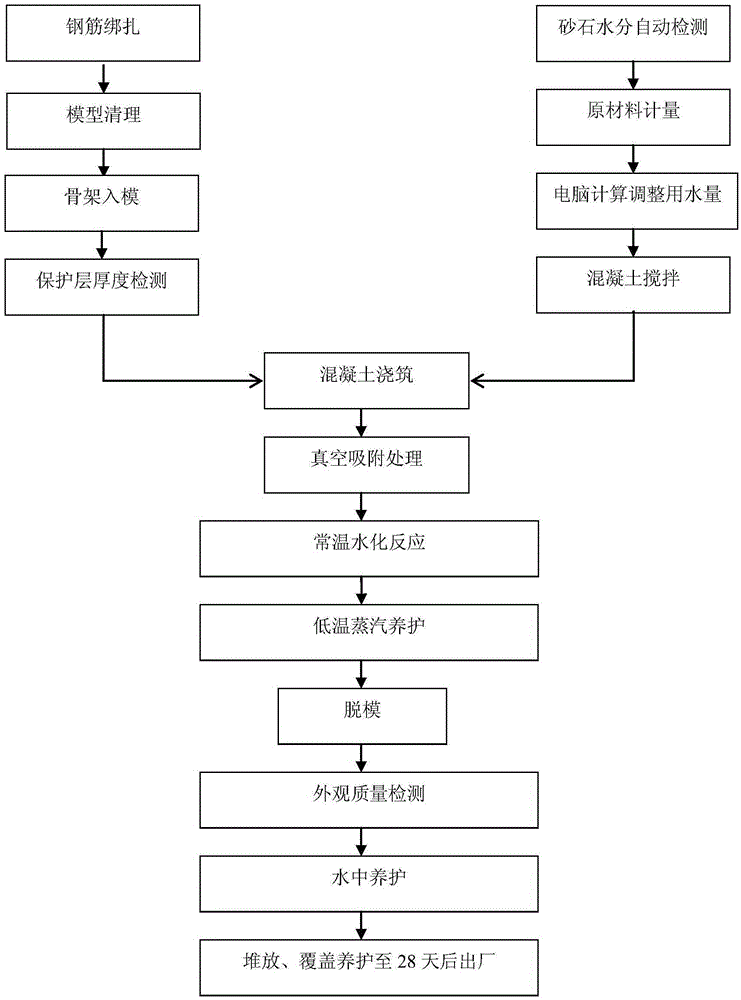

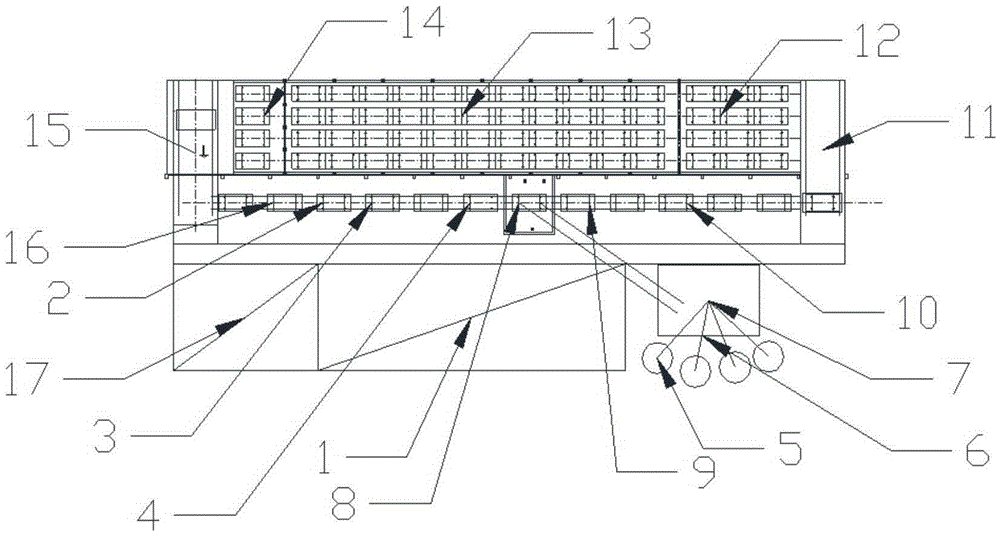

A kind of automatic production process of concrete prefabricated product

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD

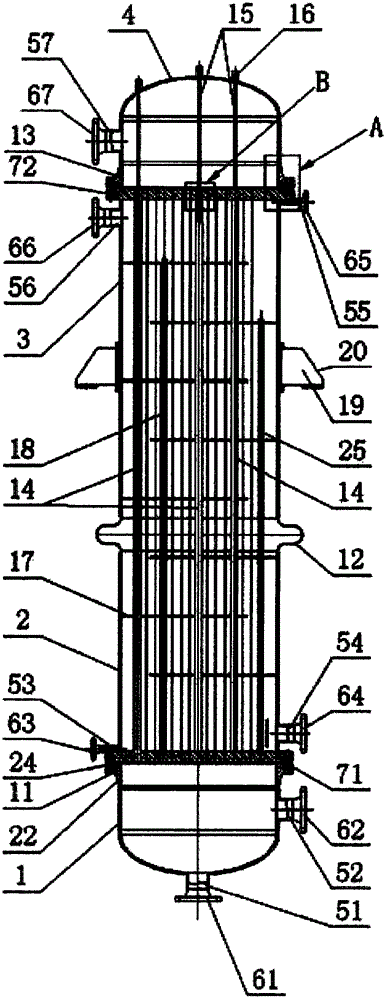

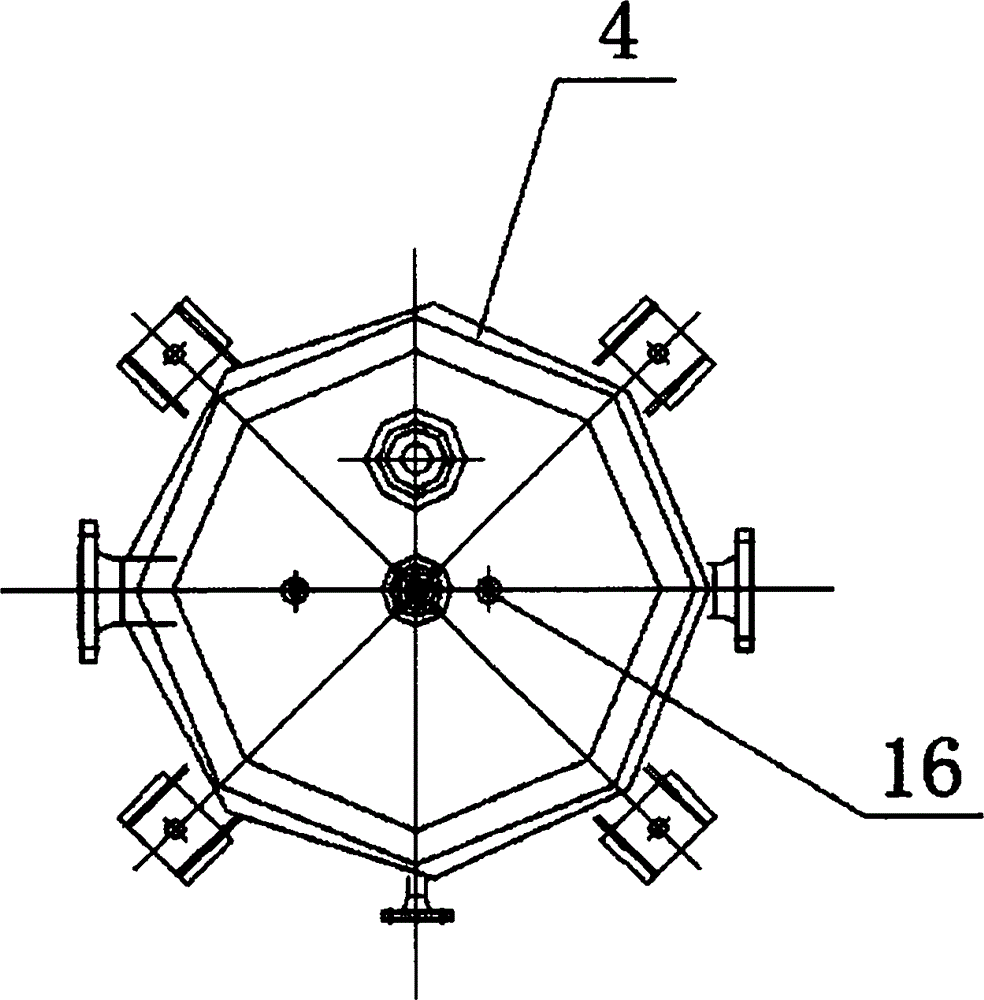

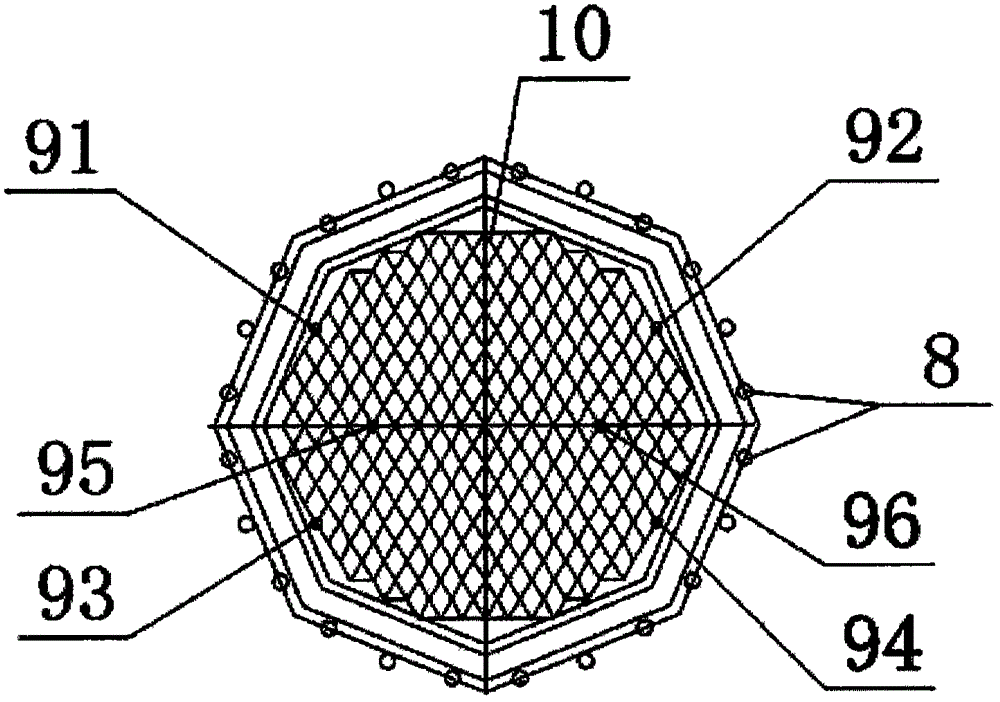

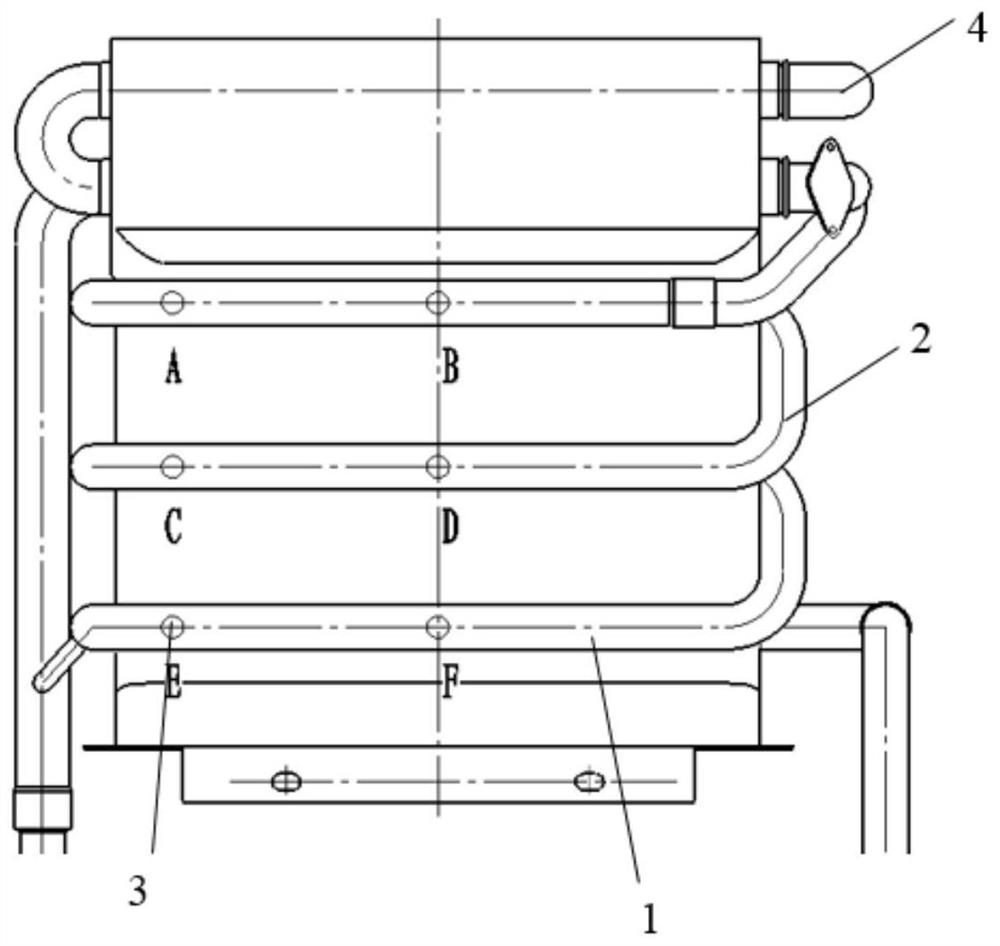

Heat exchanging device based on hydrogen compound

InactiveCN104315887AHigh temperature protectionIncrease local temperatureCorrosion preventionStationary tubular conduit assembliesEngineeringHot Temperature

The invention discloses a heat exchanging device based on hydrogen compound. The heat exchanging device based on the hydrogen compound comprises an upper short joint, a lower short joint, an upper cylinder body and a lower cylinder body, wherein a first connecting pipe is connected at the bottom of the lower short joint, a second connecting pipe is connected with the lower short joint, a lower pipe board is arranged between the lower short joint and the lower cylinder body, a pipe net is laid inside the lower pipe board, a connecting hole is formed in the lower pipe board, a pulling rod hole is formed in the pipe net, a lower connecting head sleeves the lower short joint, and the lower connecting head and the lower pipe board are fixedly arranged; a third connecting pipe is connected onto the side surface of the lower cylinder body, a fourth connecting pipe is connected with the third connecting pipe, an expansive joint is connected to the lower cylinder body, the upper cylinder body is fixedly arranged with the upper short joint through an upper pipe board, a fifth connecting pipe is arranged on the top part of the upper cylinder body, a sixth connecting pipe is connected with the fifth connecting pipe, an upper connecting head sleeves the upper short joint, a seventh connecting pipe is connected with the upper short joint, a heat exchanging pipe is arranged on the upper pipe board, a temperature testing pipe is arranged inside the heat exchanging pipe, the top end of the temperature testing pipe is connected with a temperature testing joint, a baffling board is arranged inside the cylinder body, a pulling rod is connected to the baffling board, and the pulling rod is inserted into a corresponding pulling rod hole. The heat exchanging device is high temperature resistant and high in energy converting efficiency.

Owner:徐永权

Steel core wire for electric power transmission and twisted line steel wire organosilicon coating component

InactiveCN101096562ASolve corrosion resistanceSolve the decline in mechanical propertiesCoatingsInsulating conductors/cablesOrganosiliconBenzene

The invention discloses a steel-cored wire to transmit electric power and organosilicon paint of strand cable wire, which comprises the following steps: allocating 15-35% organosilicon resin, 65-85% solvent, 0.15-1.5% hardener and 1.0-3.0% toughening agent, wherein the organosilicon adopts polysiloxane or polyfunctional hydrolytic silane modified organic resin; the solvent is selected from alcohol compound such as alcohol, butanol and so on or other ester, benzene and ketone solvents; the hardener can be triethylene tetramine or tetraethylene pentamine; the toughening agent is phthalandione dibutyl vinegar or phthalandione dioctyl, which can be added with fitful quantity of inhibitor to lengthen the using time of organosilicon paint during coating stage.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Metal chemical heat treatment nitrogen earbon oxygen multi-element copermeation method and its mitrogen carbon oxygen multielement copermeation agent formula

InactiveCN100425728CSolve corrosion resistanceSolid state diffusion coatingOxygenPotassium carbonate

Owner:王锡良

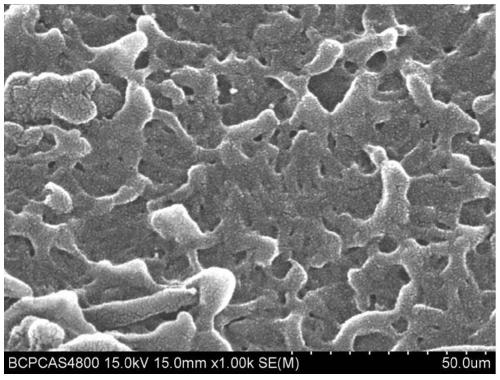

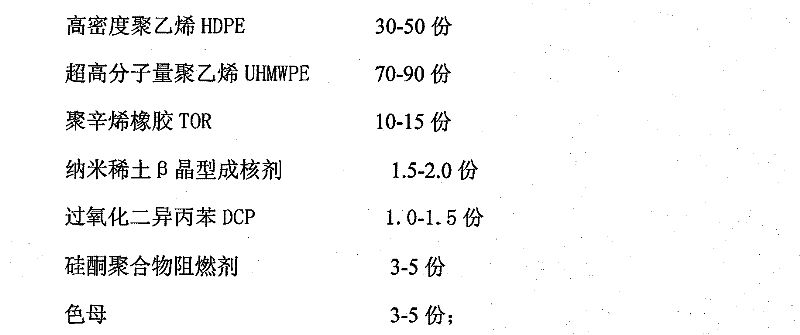

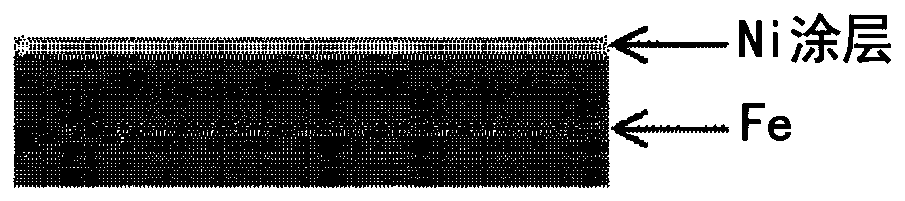

A flame-retardant ABS resin-based barrier explosion-proof material suitable for metal coating and preparation method thereof

ActiveCN108192270BSolve corrosion resistanceImprove mechanical propertiesCoatingsMetal coatingPolymer science

The invention discloses a flame-retardant ABS resin-based barrier explosion-proof material suitable for metal plating and belongs to the technical field of barrier explosion prevention. The flame-retardant ABS resin comprises 100 parts by weight of ABS resin, 25 to 45 parts by weight of a flame retardant system, 0 to 5.0 parts by weight of a lubricating agent and 0.2 to 0.6 part by weight of an antioxidant. The preparation method comprises the following steps: mixing the ABS resin, the flame retardant, the lubricating agent and the antioxidant uniformly, melting, blending and granulating the mixture by a double-screw extruding machine, performing injection molding on the flame-retardant ABS resin granules to prepare the barrier explosion-proof material with a specific structure, and coating the surface of the barrier explosion-proof material prepared by a plastic electroplating or chemical plating process with one layer of meta such as nickel and chromium to obtain flame-retardant ABSresin-based barrier explosion-proof material with the metal plating on the surface. The surface of the existing injection molded barrier explosion-proof material is coated with one metal layer with high corrosion resistance, so the flame-retardant ABS resin-based barrier explosion-proof material has excellent explosion-proof property and is more suitable for a fuel system containing strongly polarliquid.

Owner:军事科学院系统工程研究院军事新能源技术研究所

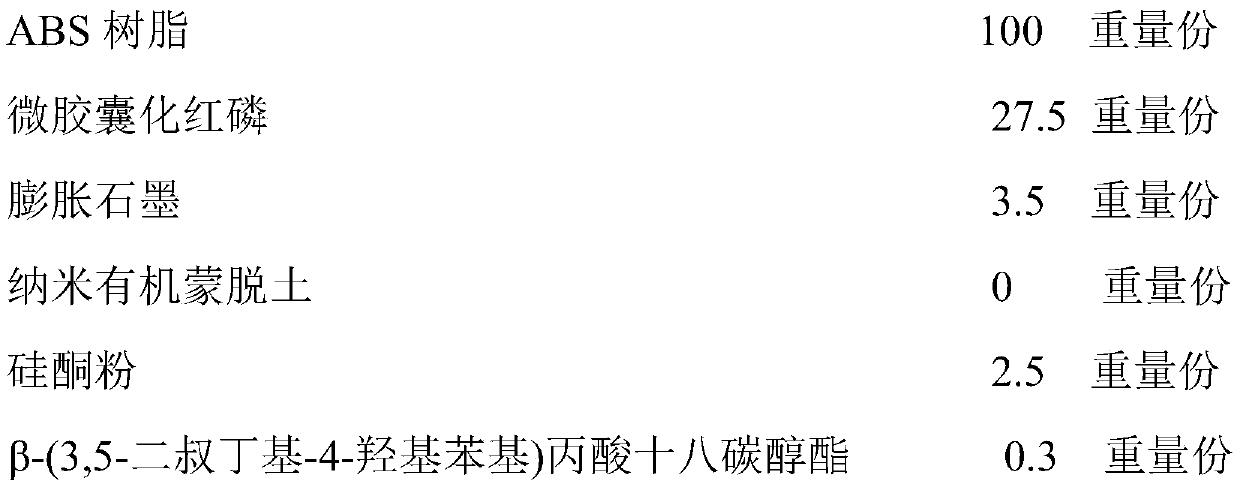

Multi-functional polyethylene tube and manufacturing method thereof

ActiveCN101974177BGood chemical stabilityGood chemical resistanceRigid pipesChemical industryPolymer science

The invention discloses a multi-functional polyethylene tube and a manufacturing method thereof, belonging to a polymer composite material. The multi-functional polyethylene tube is prepared by blending and modifying the following raw materials in parts by mass: 30-50 parts of high-density polyethylene (HDPE), 70-90 parts of ultrahigh molecular weight polyethylene (UHMWPE), 10-15 parts of polyoctene rubber (TOR), 1.5-2.0 parts of nano rare earth beta-nucleating agent, 1.0-1.5 parts of dicumyl peroxide (DCP), 3-5 parts of silicone polymer flame retardant and 3-5 parts of color masterbatch. Theinvention has the advantage that the problems of low-temperature brittleness, abrasive resistance, corrosion resistance, ageing resistance, heat resistance, processability, flame retardancy, and the like of the polyethylene tube are solved. The invention can be widely applied to the fields of water supply and drainage, sewage discharge, oil gas, coal power, mining industry, gas supply, heating, chemical industry, power communication, ocean, dredging, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

A kind of aluminum nitride nano-particle transformer oil with strong oxidation resistance and corrosion resistance and preparation method thereof

ActiveCN104099156BImprove antioxidant capacityImprove moisture resistanceAdditivesMoisture resistanceOxidation resistant

The invention discloses aluminium nitride nanoparticle transformer oil with high oxidation resistance and high corrosion resistance. The aluminium nitride nanoparticle transformer oil is characterized by being prepared from the following raw materials in parts by weight: 1000-1200 parts of naphthenic base oil, 3-5 parts of aluminium nitride, 0.2-0.5 part of 2,6-Di-tert-butyl-p-Ethyl-phenol, 0.2-0.5 part of 2-mercapto benzothiazole, 0.2-0.5 part of sodium benzoate, 0.2-0.5 part of diboride vanadium, 0.3-0.5 part of benzotriazole, 0.4-0.8 part of molybdenum disulfide, 0.4-0.6 part of zirconium oxide and 0.5-1.0 part of an additive. According to the invention, the added aluminium nitride nanoparticles enhance the thermal conduction, stability and insulativity; the added additive enhances the oxidation resistance, the moisture resistance and the waterproofness of the transformer oil; the added benzotriazole and zirconium oxide improve the corrosion resistivity of the transformer oil; the nanoparticles are manufactured through the anhydrous ethanol ball milling method, the equipment in use is simple and easy to operate; the problem that the conventional transformer oil is poor in oxidation resistance and corrosion resistance is effectively solved, and the thermal conduction, the stability, the insulativity and the moisture resistance are enhanced.

Owner:TONGLING SANJIA TRANSFORMER

Tin-containing coated steel sheet and preparation method thereof

InactiveCN103358614BSolve corrosion resistanceReduce dosageMetal layered productsPolyethylene glycolZinc alloys

The invention discloses a steel sheet with a stanniferous coating and a preparation method thereof. The method comprises the following steps: 1) subjecting a high-quality low-carbon cold-rolled steel sheet to deoiling, rust removal and cleaning and then to activation with an acid solution and rinsing; 2) carrying out electroplating, wherein an electroplating solution comprises 35 to 45 g / L of Sn(BF4)2, 95 to 105 g / L of Zn(BF4)2 and 1.5 to 2.5 g / L of polyethylene glycol and has a pH value of 1.5 to 2.5; 3) cleaning the electroplated steel sheet with water and subjecting the steel sheet to soft heating, hardening, cleaning with soda and chromate cathodic passivation; and 4) cleaning the passivated steel sheet with water and blow-drying the steel sheet so as to obtain a finished product. The content of a stannum-zinc alloy in the steel sheet with the stanniferous coating prepared in the invention is 0.8 to 16 g / m<2>, the weight percentage of stannum in the tin-zinc alloy coating is 75 to 85%, the usage amount of stannum is reduced, and corrosion resistance of the sheet is obtained.

Owner:武汉钢铁有限公司

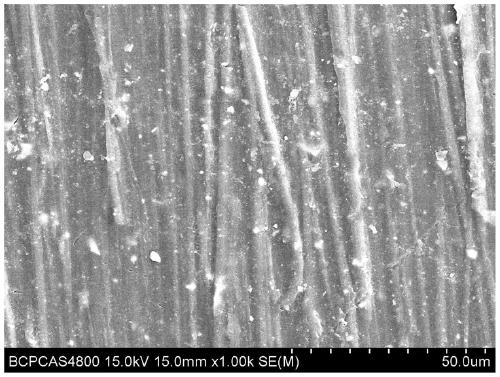

Method of Manufacturing Cylindrical Battery Case with Improved Surface Roughness

ActiveCN110506344ASolve corrosion resistanceImprove corrosion resistanceFinal product manufactureSmall-sized cells cases/jacketsSurface roughnessCorrosion

The present invention relates to a manufacturing method of a cylindrical battery case with improved surface roughness of the battery case by performing an ironing process among manufacturing processesa plurality of times in order to improve corrosion characteristics of the battery case. The present invention has an effect of reducing the surface roughness and improving the corrosion characteristics by the surface roughness by changing a body outer diameter completion process of a cylindrical battery to a thickness reduction process when manufacturing the cylindrical battery case.

Owner:LG ENERGY SOLUTION LTD

Preparation method of anticorrosive paint for offshore petroleum pipeline

InactiveCN114836098AAvoid adsorptionSolve corrosion resistanceAntifouling/underwater paintsPaints with biocidesEpoxySide chain

The invention relates to the technical field of coating preparation, and discloses a preparation method of an anticorrosive coating for offshore petroleum pipelines, and the coating is prepared by mixing a component A and a component B according to a mass ratio of 6: 1, the component A is prepared from the following raw materials in parts by weight: 50 to 80 parts of modified epoxy resin emulsion, 15 to 30 parts of modified graphene, 2 to 5 parts of dispersing agent, 1 to 3 parts of flatting agent, 1 to 3 parts of defoaming agent, 10 to 20 parts of coalescing agent and 20 to 30 parts of deionized water; a main chain of a molecular chain of the modified epoxy resin emulsion contains sulfur atoms, the sulfur atoms are easily combined with sulfydryl through hydrogen bonds, an amino acid structure necessary for growth and reproduction of bacteria contains sulfydryl, so that amino acid required by the bacteria can be combined with the molecular chain of the epoxy resin emulsion, and then bacterial metabolism is influenced; and marine organisms can be prevented from being adsorbed on the surface of the coating, so that the influence of the marine organisms and microorganisms on corrosion resistance is avoided.

Owner:东营峻茂石油科技有限公司

Corrosion liquid and application thereof

The invention belongs to the technical field of metal material corrosion, and particularly relates to corrosion liquid and application thereof. The corrosion liquid comprises chloride ions, carbonateions, sulfate ions and water, wherein the concentration of the chloride ions is 0.1 mol / L-2 mol / L, the concentration of the carbonate ions is 0.01 mol / L-0.03 mol / L, and the concentration of the sulfate ions is 0.01 mol / L-0.3 mol / L. The corrosion liquid can be applied to corrosion of red copper, stainless steel and heat exchangers made of the red copper or the stainless steel. Due to adoption of the corrosion liquid for corroding the heat exchanger, tap water corrosion can be simulated, and the corrosion time can be shortened, so that the problem that the corrosion-resistant effect of the heatexchanger can be obtained only by a relatively long period at present is solved.

Owner:VATTI CORP LTD

Continuous refinement separation device and method of coked crude phenol

InactiveCN101704726BSolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationSeparation technologyP-Cresol

Owner:天津美科泰化工科技有限公司 +1

A welding process for producing stainless steel composite pipe

ActiveCN103358036BSolve corrosion resistanceSolve the decrease of corrosion resistanceArc welding apparatusLaser beam welding apparatusAlloyCarbon steel

The invention discloses a welding technology for stainless steel composite tubes, which comprises the following steps: (1) conducting welding on the stainless steel composite tube overlying layer to form a welding path I; (2) welding a transition layer between the stainless steel composite tube overlying layer and the substrate layer to form a welding path II; (3) conducting welding on the stainless steel composite tube substrate layer to form a welding path III. According to the welding technology for stainless steel composite tubes provided by the invention, the overlying layer stainless steel (inner layer) of the composite tube is welded first and the substrate carbon steel (outer layer) is welded later, so as to effectively solve the problem that the conventional technology, namely welding carbon steel first and welding stainless steel later, can not weld a composite tube with a diameter smaller than 325, and the welding of the transition layer (welding path II) between the overlying layer and the substrate layer better solves the problem that, in the process of welding overlying layer, the increase of overlying carbon leads to the decrease of overlying layer corrosion, and the problem that, in the process of welding substrate layer, the increase of alloy (chromium and nickel) content leads to the forming of hard organization in the welding line is solved as well.

Owner:DALIAN SAGE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com