A welding process for producing stainless steel composite pipe

A welding process and stainless steel technology are applied in the field of welding process for producing stainless steel composite pipes to achieve the effect of reducing corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

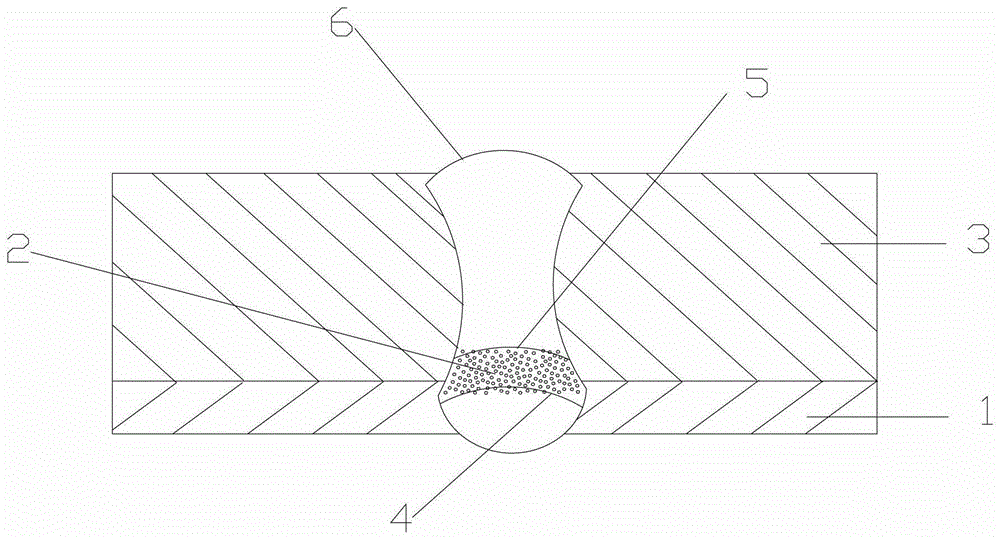

[0020] like figure 1 As shown, a welding process for producing stainless steel composite pipes comprises the following steps:

[0021] (1) Weld the cladding layer 1 of the stainless steel composite pipe to form a weld bead 4; the welding of the weld bead 4 should adopt TIG, MIG, or laser welding methods to ensure that the weld bead is free of dross, which is conducive to the welding of the next weld bead .

[0022] (2) A transition layer 2 is welded between the cladding layer 1 and the base layer 3 of the stainless steel composite pipe to form a weld bead 2 5; the welding of the weld bead 2 5 uses electrodes with high chromium and nickel content, such as: A302, A307, It can reduce the impact on the cladding material when welding the base material.

[0023] (3) Weld the base layer 3 of the stainless steel composite pipe to form the third weld bead 6; the welding of the third weld bead 6 adopts the submerged arc welding method, and the welding material adopts the same material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com