Preparation method of anticorrosive paint for offshore petroleum pipeline

An anti-corrosion coating, offshore oil technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of reduced anti-corrosion performance, accelerated corrosion rate of pipeline surface, disappearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing an anti-corrosion coating for offshore oil pipelines, the coating comprising component A and component B prepared by mixing component A and component B in a mass ratio of 6:1;

[0048] The component A includes the following raw materials in parts by weight: 50 parts of modified epoxy resin emulsion, 15 parts of modified graphene, 2 parts of dispersant, 1 part of leveling agent, 1 part of defoamer, 10 parts of film-forming aids, 20 parts of deionized water;

[0049] Component A is made by the following steps:

[0050] The above-mentioned raw materials are stirred for 1 h under the condition that the rotating speed is 1500 r / min to obtain component A;

[0051] Component B is ethylenediamine, benzoyl peroxide, and ethylene glycol mixed in a mass ratio of 1:1:10.

[0052] The modified epoxy resin emulsion is made by the following steps:

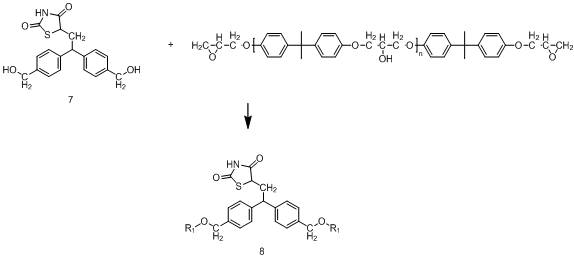

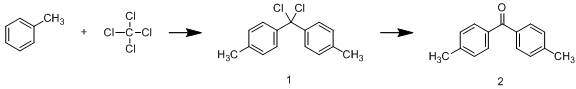

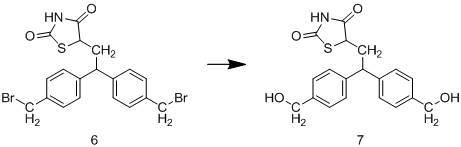

[0053] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, under the condition...

Embodiment 2

[0061] A method for preparing an anti-corrosion coating for offshore oil pipelines, the coating comprising component A and component B prepared by mixing component A and component B in a mass ratio of 6:1;

[0062] The component A includes the following raw materials in parts by weight: 65 parts of modified epoxy resin emulsion, 18 parts of modified graphene, 3 parts of dispersant, 2 parts of leveling agent, 2 parts of defoamer, 15 parts of film-forming aids, 25 parts of deionized water;

[0063] Component A is made by the following steps:

[0064] The above-mentioned raw materials are stirred for 2h under the condition that the rotating speed is 1500r / min to obtain component A;

[0065] Component B is ethylenediamine, benzoyl peroxide, and ethylene glycol mixed in a mass ratio of 1:1:10.

[0066] The modified epoxy resin emulsion is made by the following steps:

[0067] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, under the condition...

Embodiment 3

[0075] A method for preparing an anti-corrosion coating for offshore oil pipelines, the coating comprising component A and component B prepared by mixing component A and component B in a mass ratio of 6:1;

[0076] The component A includes the following raw materials in parts by weight: 80 parts of modified epoxy resin emulsion, 30 parts of modified graphene, 5 parts of dispersant, 3 parts of leveling agent, 3 parts of defoamer, 20 parts of film-forming aids, 30 parts of deionized water;

[0077] Component A is made by the following steps:

[0078] The above-mentioned raw materials are stirred for 2h under the condition that the rotating speed is 2000r / min to obtain component A;

[0079] Component B is ethylenediamine, benzoyl peroxide, and ethylene glycol mixed in a mass ratio of 1:1:10.

[0080] The modified epoxy resin emulsion is made by the following steps:

[0081] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, under the condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com