Method of Manufacturing Cylindrical Battery Case with Improved Surface Roughness

A cylindrical battery, surface roughness technology, applied in the direction of cylindrical shell battery/battery, small-sized battery/battery pack, manufacturing tools, etc., can solve the problem of low corrosion resistance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0069] In order to manufacture the cylindrical secondary battery according to the present invention, a step of punching and drawing a nickel-plated substrate (#1) and a step of idling the substrate may be performed. A cylindrical battery case is manufactured through the following steps: a step of drawing a base material to form a battery case (where the drawing process is performed four times) (#4 to #7); performing deep drawing on the base material and main body thinning drawing Step of deep drawing (#8); step of drawing base material (#9); step of step drawing and body thinning drawing of base material (#10); forming taper and flange on base material the step (#11); the step of forming an air vent in the base material (#12); and the step of trimming the base material (#13).

[0070] Specifically, the thinning drawing process at step #8 was performed to reduce the thickness of the base material by 0.04 mm, and the thinning drawing process at step #10 was performed to reduce t...

experiment example 1

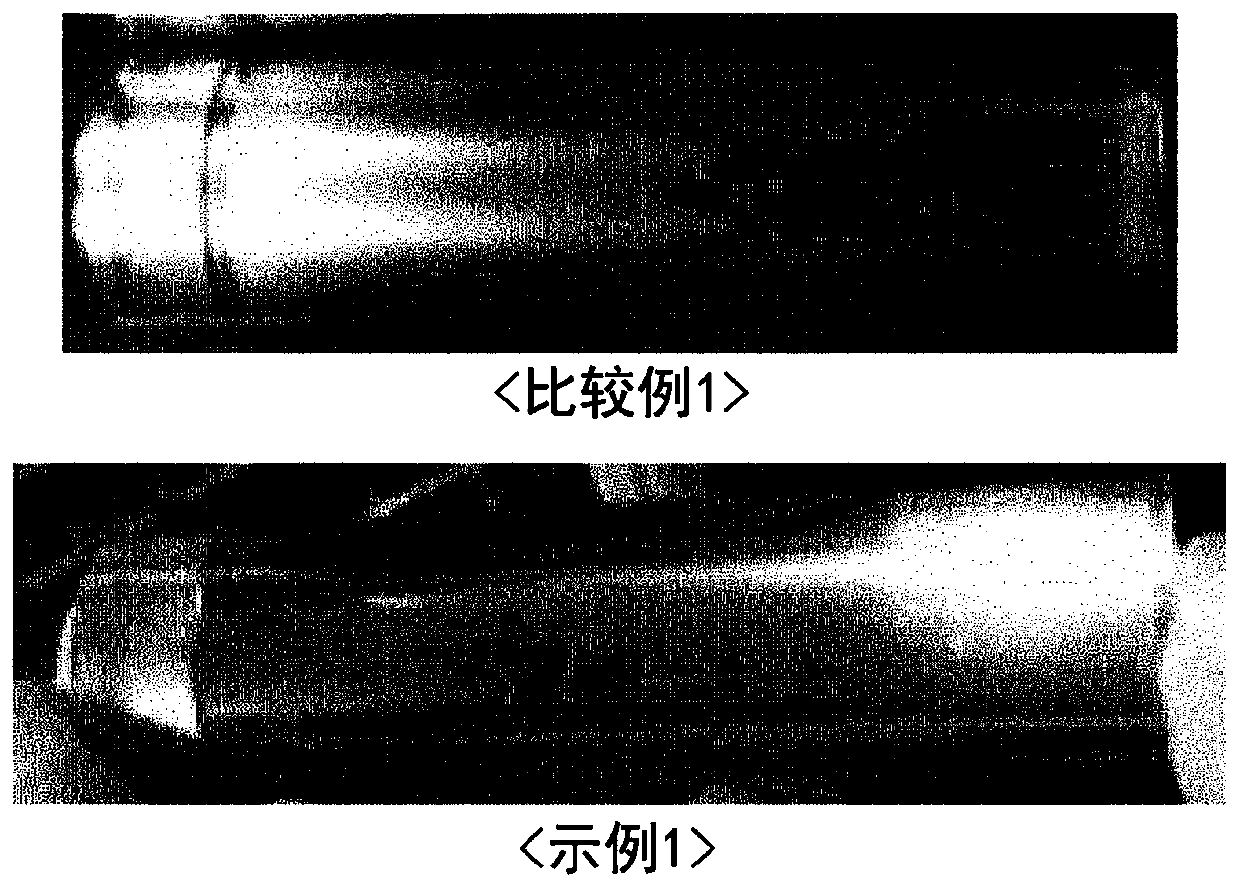

[0075] A corrosion resistance test was performed on the cylindrical battery cases manufactured according to Example 1 and Comparative Example 2.

[0076] The corrosion resistance test of the cylindrical secondary battery case was performed under high temperature and high humidity conditions. Specifically, the cylindrical battery case was kept at a temperature of 60° C. and a humidity of 95% RH for 7 days, and the appearance of the cylindrical battery case was photographed to determine whether the surface of the cylindrical battery case was corroded. The corrosion test results of the cylindrical battery case are shown in Figure 4 in the photo.

[0077] refer to Figure 4 , it can be seen that the cylindrical battery case manufactured according to Example 1 was not corroded, but pitting corrosion was observed on the surface of the cylindrical battery case manufactured according to Comparative Example 1.

experiment example 2

[0083]The surface roughness of the cylindrical battery cases manufactured according to Example 1, Comparative Example 2 and Comparative Example 3 was measured using a surface roughness measuring instrument SJ-411 from Mitutoyo Corporation. As the surface roughness, Ra and Rz were measured, and a 4 mm section of the middle portion of each cylindrical battery case was measured in the height direction (vertical direction) of the cylindrical battery case. Measure the surface roughness of cylindrical battery cases based on ISO4287:1997.

[0084] Figure 5 The measurement results of the surface roughness of the cylindrical battery case are shown in the table of .

[0085] refer to Figure 5 , the minimum, maximum and average values of the surface roughness Ra of the cylindrical battery case manufactured according to Example 1 were 0.022, 0.040 and 0.03, respectively, and the surface roughness Ra of the cylindrical battery case manufactured according to Comparative Example 2 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com