Multi-functional polyethylene tube and manufacturing method thereof

A polyethylene pipe, multi-functional technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of not being exposed to the sun and rain for a long time, high requirements for stacking PE pipes, and brittle polyethylene pipes, etc. problems, achieve the effect of promoting the miniaturization of grain size, shortening the molding cycle and improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

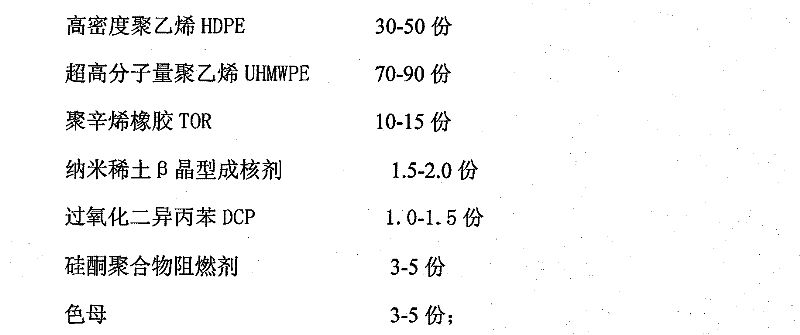

[0048] The formula is: 70 parts of high-density polyethylene (HDPE), 70 parts of ultra-high molecular weight polyethylene (UHMWPE), 10 parts of polyoctene rubber (TOR), 1 part of dicumyl peroxide (DCP), nanometer rare earth β crystal 1.5 parts of nucleating agent, 3 parts of silicone polymer flame retardant, 3 parts of color masterbatch, and produce sample tubes according to the above-mentioned manufacturing method. After testing the sample tube, the low temperature brittleness temperature 2 , oxygen index 85%, self-extinguishing time 1S, surface resistivity 1.8×10 9 Ω, coefficient of friction 0.04, mortar wear rate 0.1%, longitudinal retraction rate 1%, hydrostatic test and thermal stability test under hydrostatic state no leakage, no rupture, the pipe conforms to "drinking water transmission and distribution equipment and protection Material Safety Evaluation Criteria”.

Embodiment 2

[0050] The formula is: 40 parts of high-density polyethylene (HDPE), 90 parts of ultra-high molecular weight polyethylene (UHMWPE), 15 parts of polyoctene rubber (TOR), 1.5 parts of dicumyl peroxide (DCP), nanometer rare earth β crystal 2 parts of nucleating agent, 5 parts of silicone polymer flame retardant, 5 parts of color masterbatch, and produce sample tubes according to the above-mentioned manufacturing method. After testing the sample tube, the low temperature brittleness temperature 2 , oxygen index 88%, self-extinguishing time 1S, surface resistivity 1.8×10 9 Ω, friction coefficient 0.02, mortar wear rate 0.05%, longitudinal retraction rate 1.6%, hydrostatic test and thermal stability test under hydrostatic state, no leakage, no cracks, pipes comply with "Drinking Water Transmission and Distribution Equipment and Protection Material Safety Evaluation Criteria”.

Embodiment 3

[0052] The formula is: 30 parts of high-density polyethylene (HDPE), 80 parts of ultra-high molecular weight polyethylene (UHMWPE), 10 parts of polyoctene rubber (TOR), 1 part of dicumyl peroxide (DCP), nanometer rare earth β crystal 1.5 parts of nucleating agent, 3 parts of silicone polymer flame retardant, 3 parts of color masterbatch, and produce sample tubes according to the above-mentioned manufacturing method. After testing the sample tube, the low temperature brittleness temperature 2 , oxygen index 85%, self-extinguishing time 1S, surface resistivity 1.8×10 9 Ω, friction coefficient 0.03, mortar wear rate 0.08%, longitudinal retraction rate 1.2%, hydrostatic test and thermal stability test under hydrostatic state, no leakage, no cracks, pipes comply with "Drinking Water Transmission and Distribution Equipment and Protection Material Safety Evaluation Criteria”.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com