Disc-type electrostatic coating process for vehicle transmission shaft aqueous anticorrosion coating material

A technology for anti-corrosion coatings and water-based coatings, applied in anti-corrosion coatings, devices for coating liquid on surfaces, coatings, etc., to achieve the effects of increasing storage stability and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

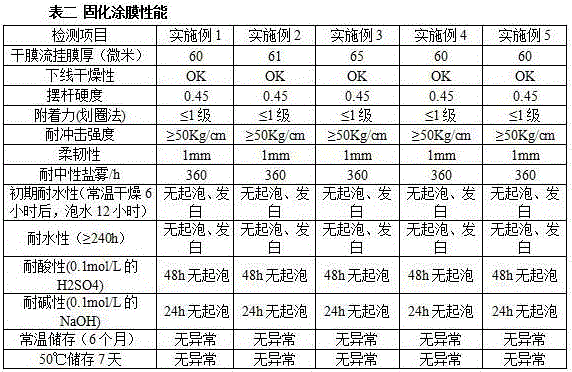

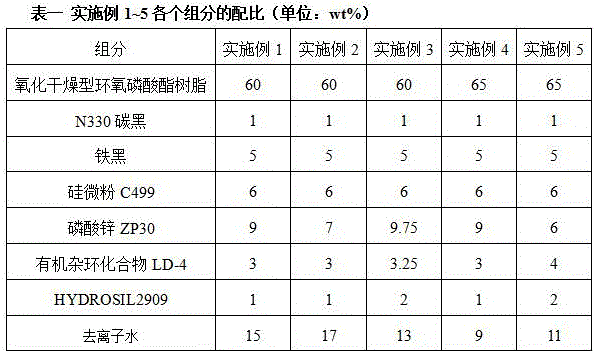

[0029] Some specific examples are listed below to illustrate the present invention. It should be pointed out that the following specific examples are only used to further illustrate the present invention, and do not represent limitations to the protection scope of the present invention. Some non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

[0030] The preparation method of the oxidation-drying type epoxy phosphate resin in the embodiment 1~5: Add co-solvent ethylene glycol monobutyl ether and epoxy resin E03 to the reaction kettle, heat up to 160±5 ℃ to dissolve, at 600 rev / min Stir at a low speed, and then add fatty acid into the reaction kettle, the fatty acid is composed of palmitoleic acid and linolenic acid in a mass ratio of 1:1, and the temperature is raised to 200-240°C for fatty acid-epoxy ring-opening reaction, to the reactant The acid value of the acid value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com