Zn-Al-Mg-Si alloy plated steel product having excellent corrosion resistance and method for preparing the same

A corrosion-resistant, zn-al-mg-si technology, used in metal material coating processes, hot-dip plating processes, and other household appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0061] A cold-rolled steel sheet (thickness 0.8 mm) that has passed through a usual hot-rolling and cold-rolling process is used as a material to perform hot-dip Zn-Al-Mg-Si coating. A non-oxidizing furnace-reduction furnace type production line is used for plating. After plating, the gas wiping method is used to adjust the coating adhesion, and then it is cooled, and finally zero-spangle (Zero Spangle) treatment is applied. Specimens were produced by making various changes in the composition of the plating bath in order to study the characteristics of these specimens. It should be noted that the plating bath may contain unavoidable impurities brought about by the plating equipment or the cover plate in the plating bath, and as such impurities, about 1 to 2% of Fe is generally contained. The bath temperature was set at 600-650°C. The coating was peeled off from the obtained coated steel sheet, and the composition and adhesion amount of the coating were measured by chemical an...

Embodiment 2 and comparative example 2

[0105] A cold-rolled steel sheet having a thickness of 0.8 mm was used as a material, which was dipped in a Zn-Al-Mg-Si alloy plating bath having a bath temperature of 630° C. for 3 seconds to perform hot-dip plating. After plating, use the gas wiping method to adjust the coating adhesion to 90g / m 2 , and then cooled at a rate of 30°C / sec.

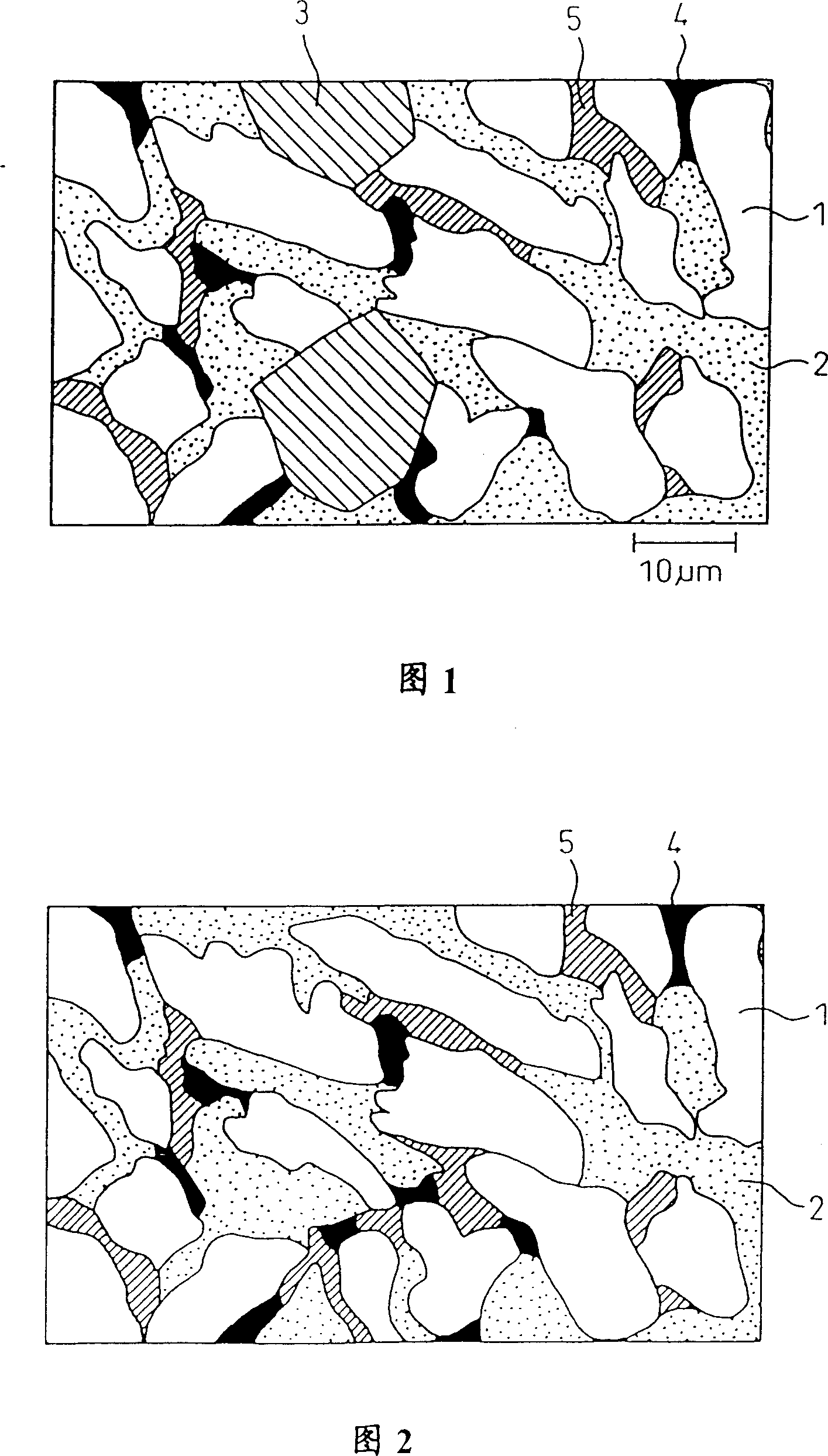

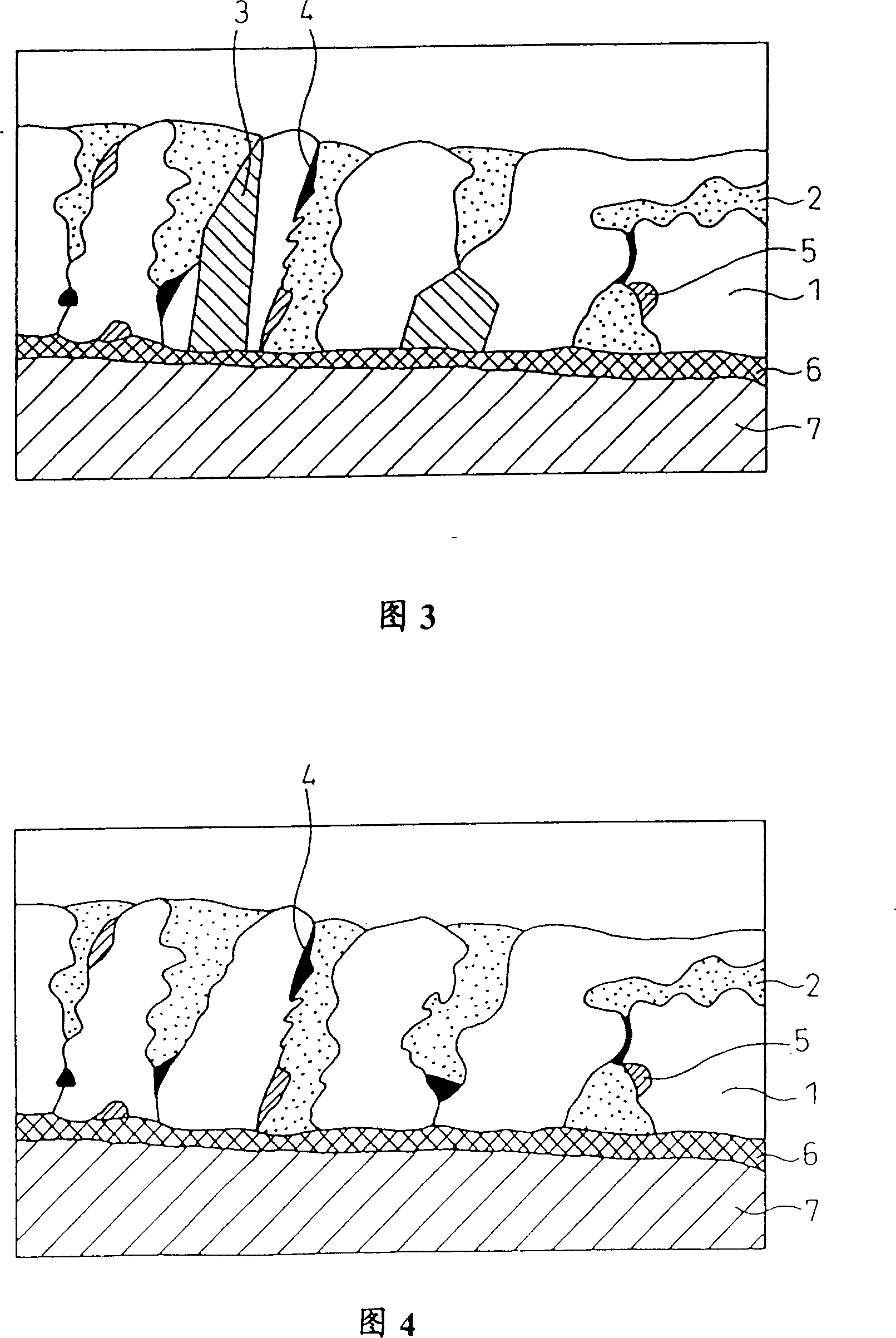

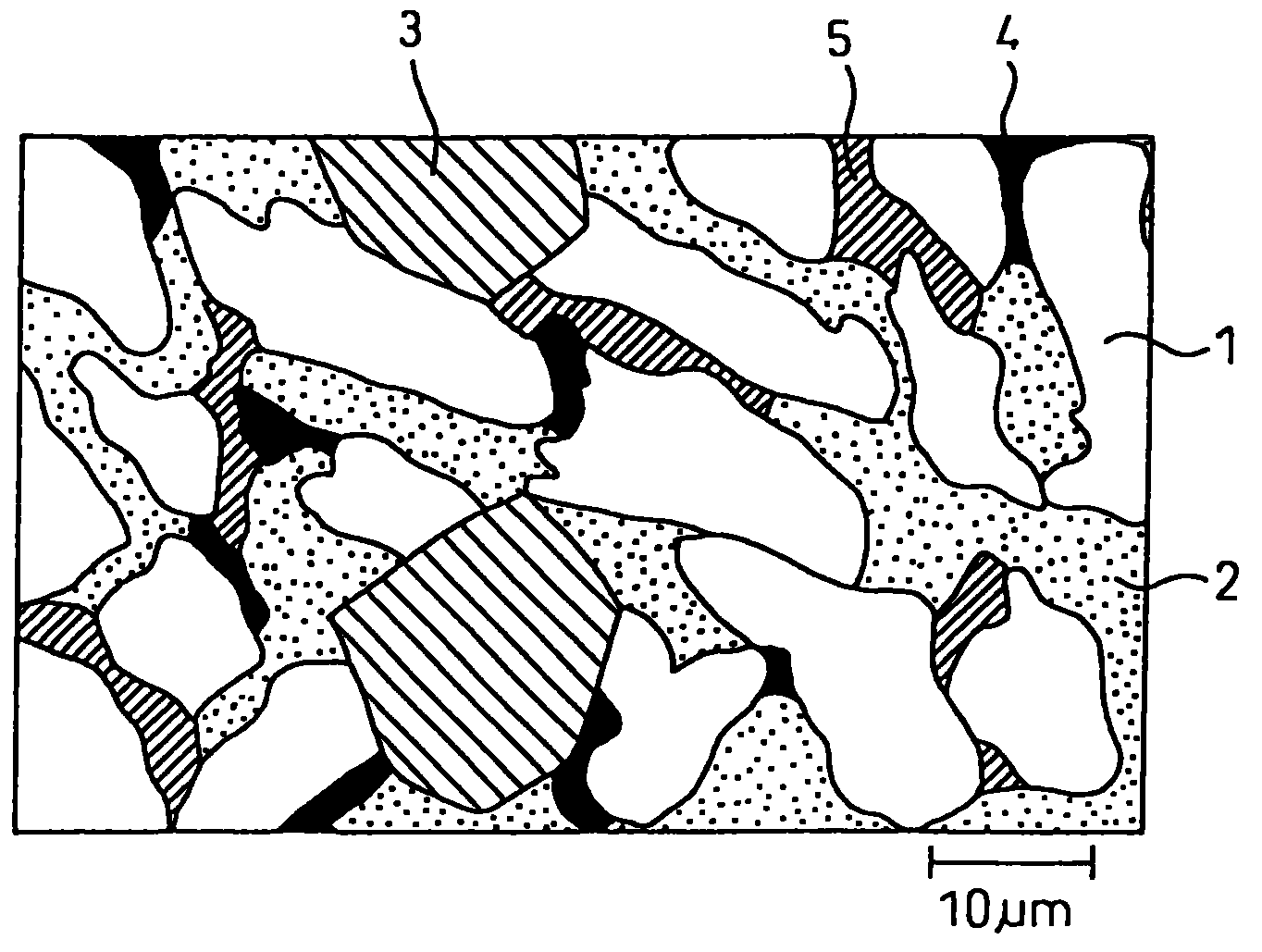

[0106] The coating composition of the obtained Zn-Al-Mg-Si based plated steel sheet was the composition shown in Table 2 and Table 3. Meanwhile, corrosion resistance was evaluated according to the following method. The results are also shown in Table 2 and Table 3. It should be noted that for the structure of these coatings, the results of observation after 5° oblique grinding show that at least in the case of Example 2 (sample Nos. 31 to 34), they are the same as the case of Example 1. Containing massive and flaky Mg as defined in the present invention 2 Si phase organization.

[0107] (1) Corrosion resistance corrosion evaluation

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com