Anti-corrosion anti-seismic combined column component and construction method thereof

A technology of combining columns and components, applied in the direction of earthquake resistance, building components, columns, etc., can solve the problems of reducing the earthquake resistance of bridges, affecting the service life of bridges, polluting air and water quality, etc., reducing cement consumption, realizing garbage recycling, The effect that the construction method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

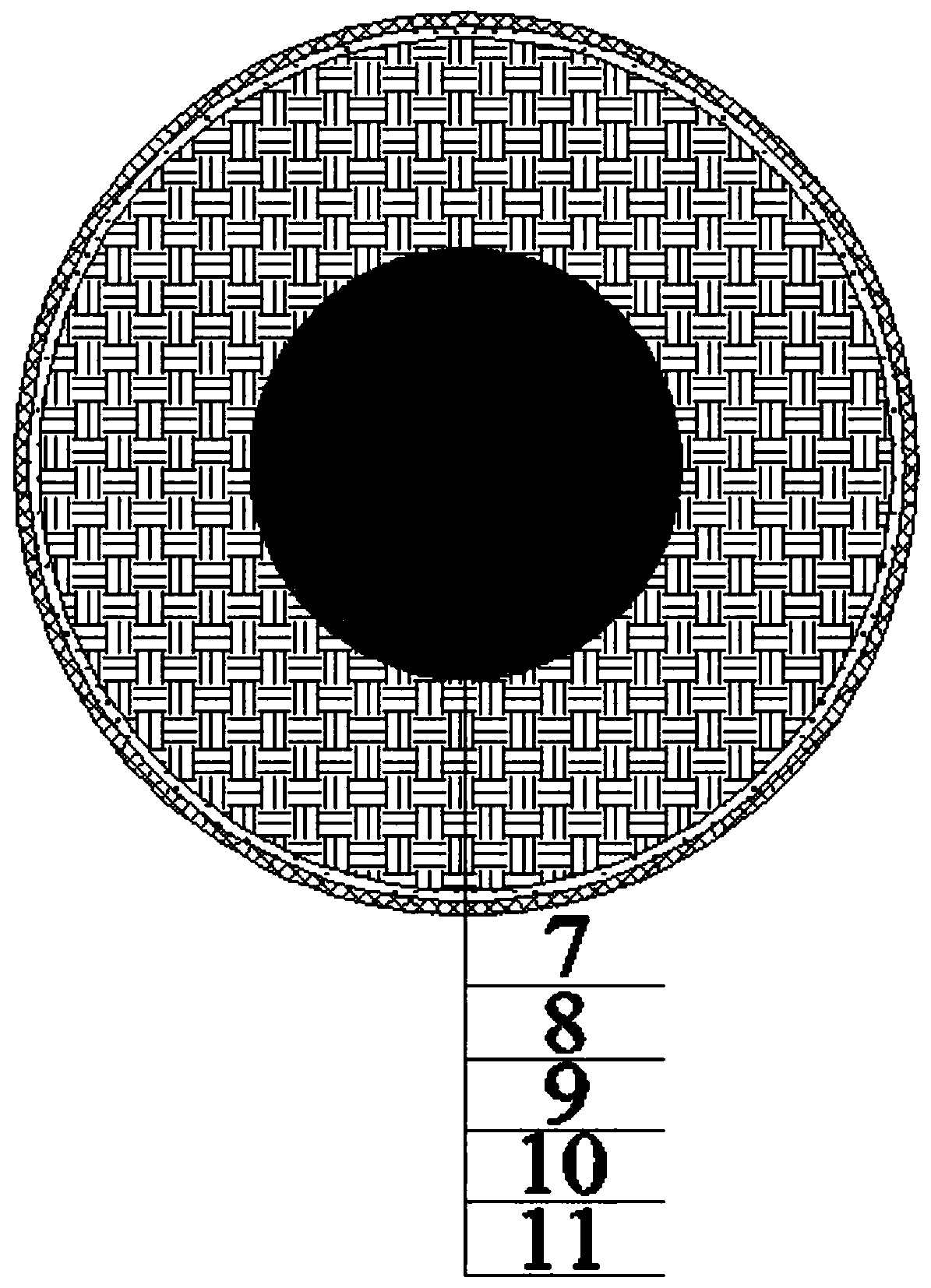

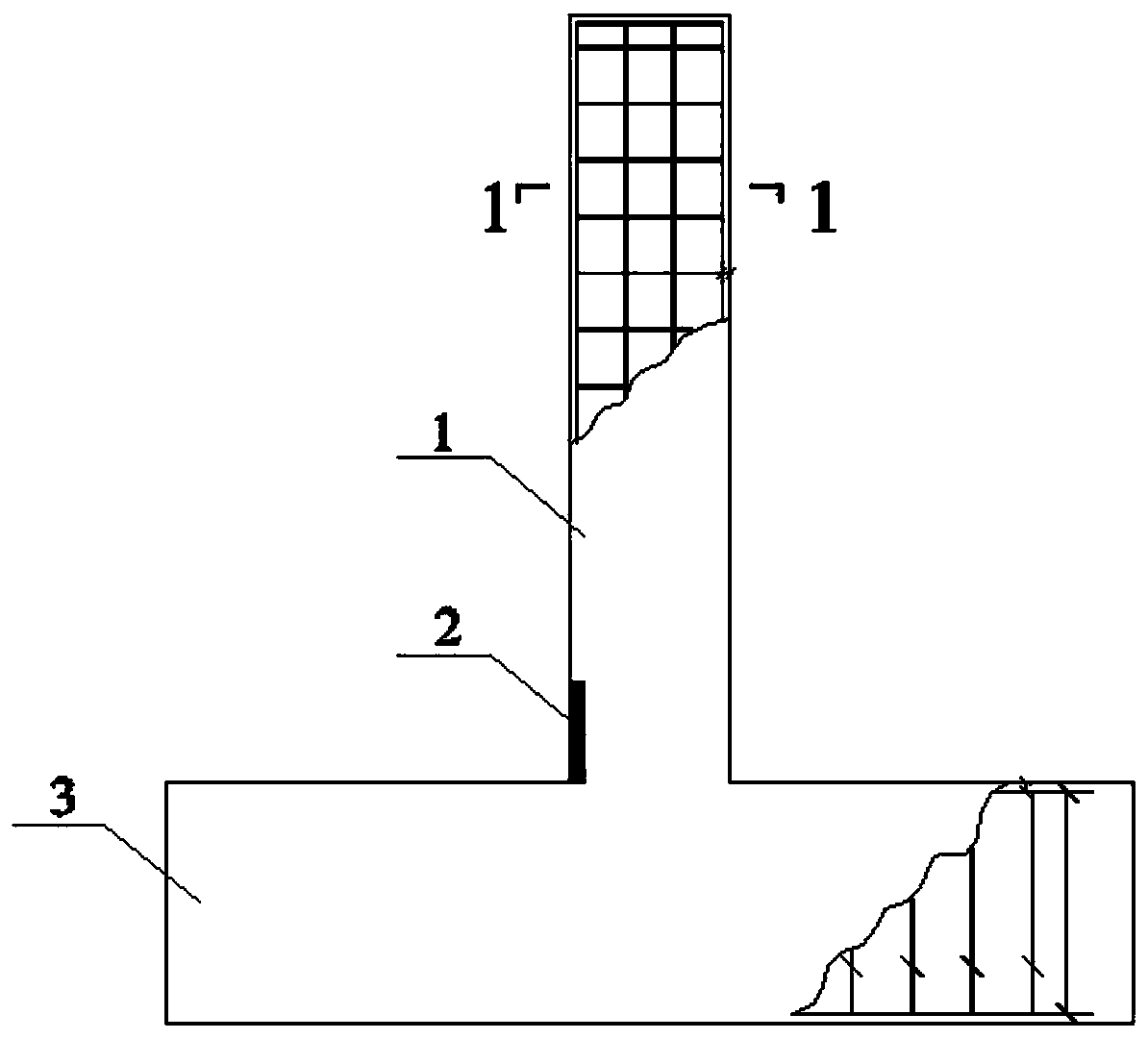

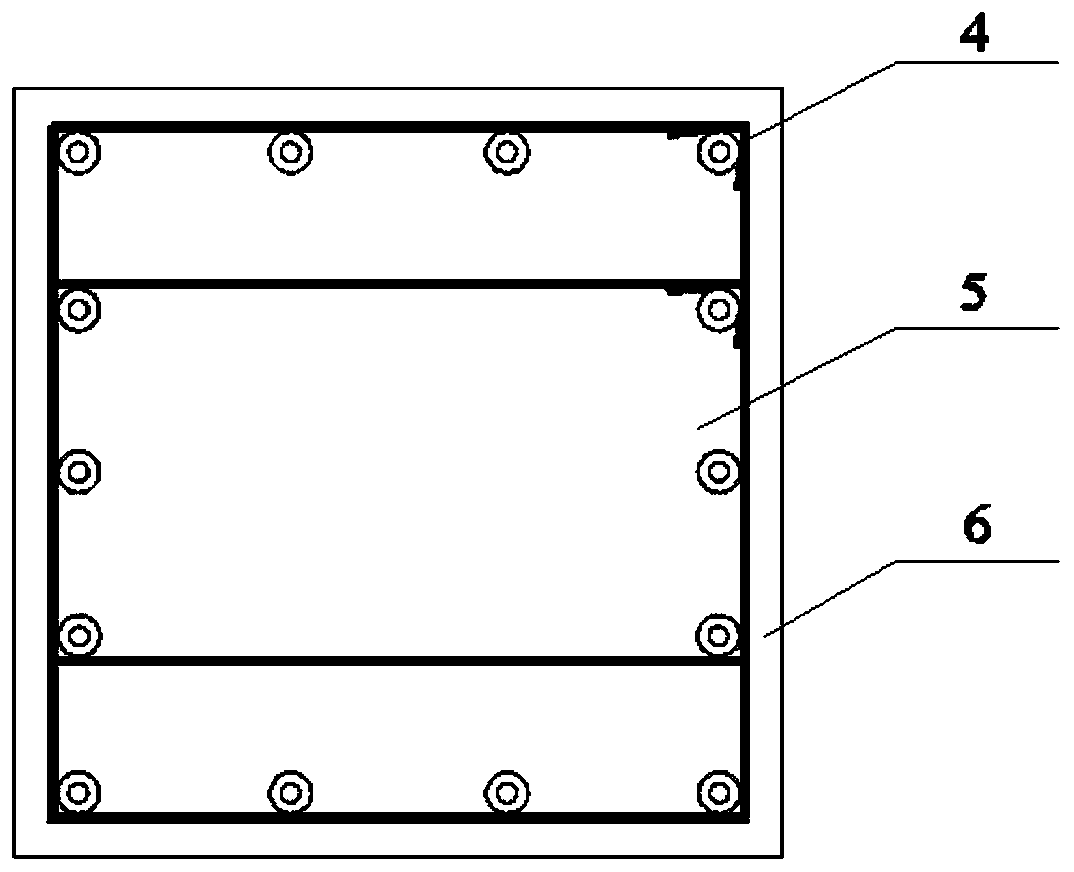

[0035] see Figure 1-3 Describe this embodiment, an anti-corrosion and anti-seismic composite column member, which includes longitudinal reinforcement 7, grouting material 8, composite material sleeve 9, rubber material layer 10 and grid layer 11, and the longitudinal reinforcement 7 is located in the plastic hinge area 2, The composite material sleeve 9 is sleeved on the outside of the longitudinal rib 7, and the grouting material 8 is filled between the longitudinal rib 7 and the composite material sleeve 9, and a rubber material layer 10 is arranged on the outside of the composite material sleeve 9, and the glue A mesh layer 11 is arranged outside the material layer 10, and the composite material sleeve 9 is a polyvinyl alcohol cement composite material mixed with solid waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com