Preparation method for SiO2-ZnO nano-bar array composite electrode

A nanorod array and composite electrode technology, applied in the field of nanomaterials, can solve the problems of dye-sensitized solar cell conversion efficiency limitation and various improvement effects, and achieve the effects of strong acid resistance, stable sensitization performance, and inhibition of corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] 1. Dissolve chemically pure zinc nitrate and hexamethylenetetramine in equimolar amounts into deionized water to prepare a reaction solution with a molar concentration of 0.05 mol / L.

[0024] 2. Select 5 pieces of FTO conductive glass coated with 100nm thick ZnO film as the seed layer prepared by homogenization method and cut into 2cm×2cm size as the growth substrate, put them into the reaction solution and grow in a sealed manner at 95°C for 24 hours.

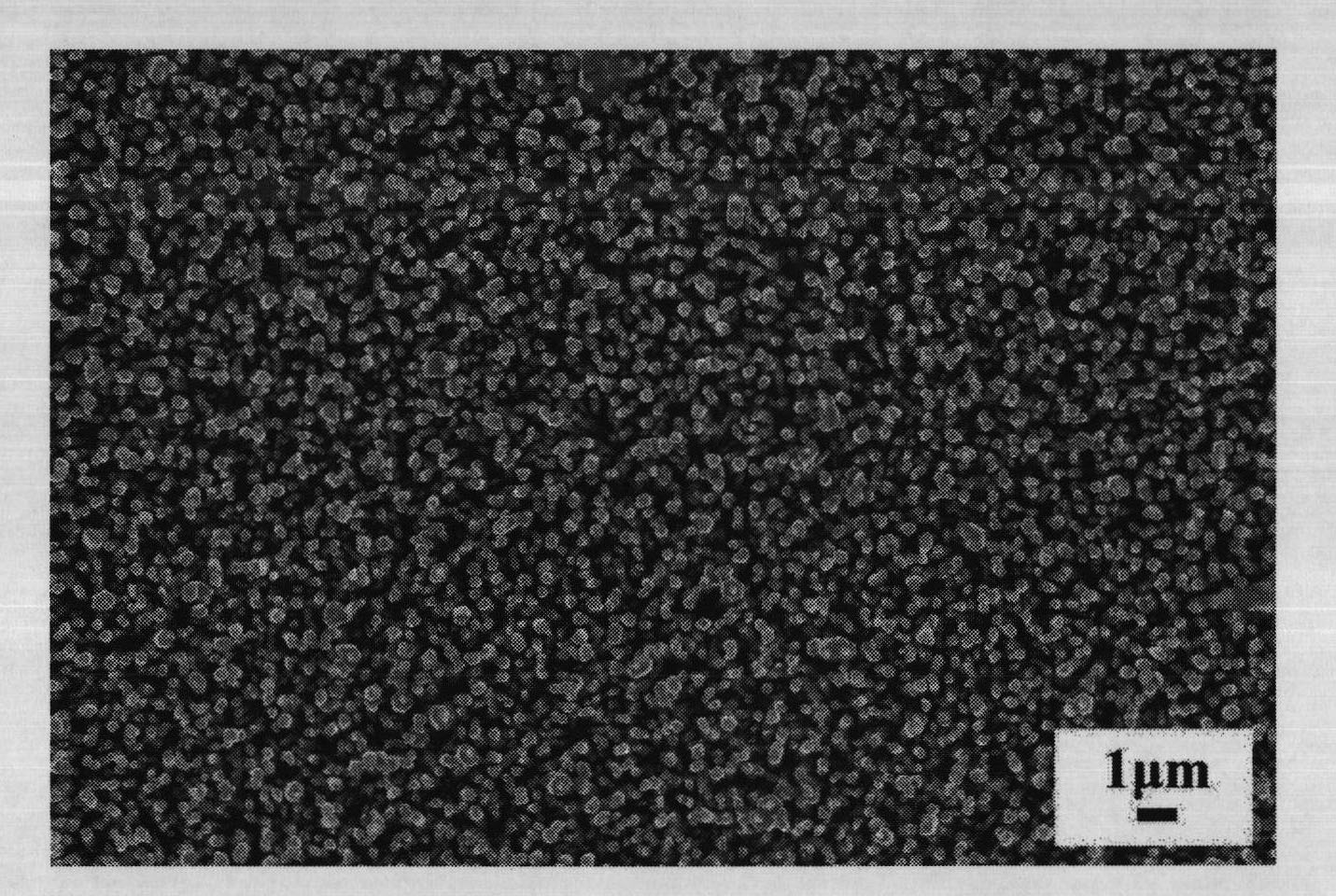

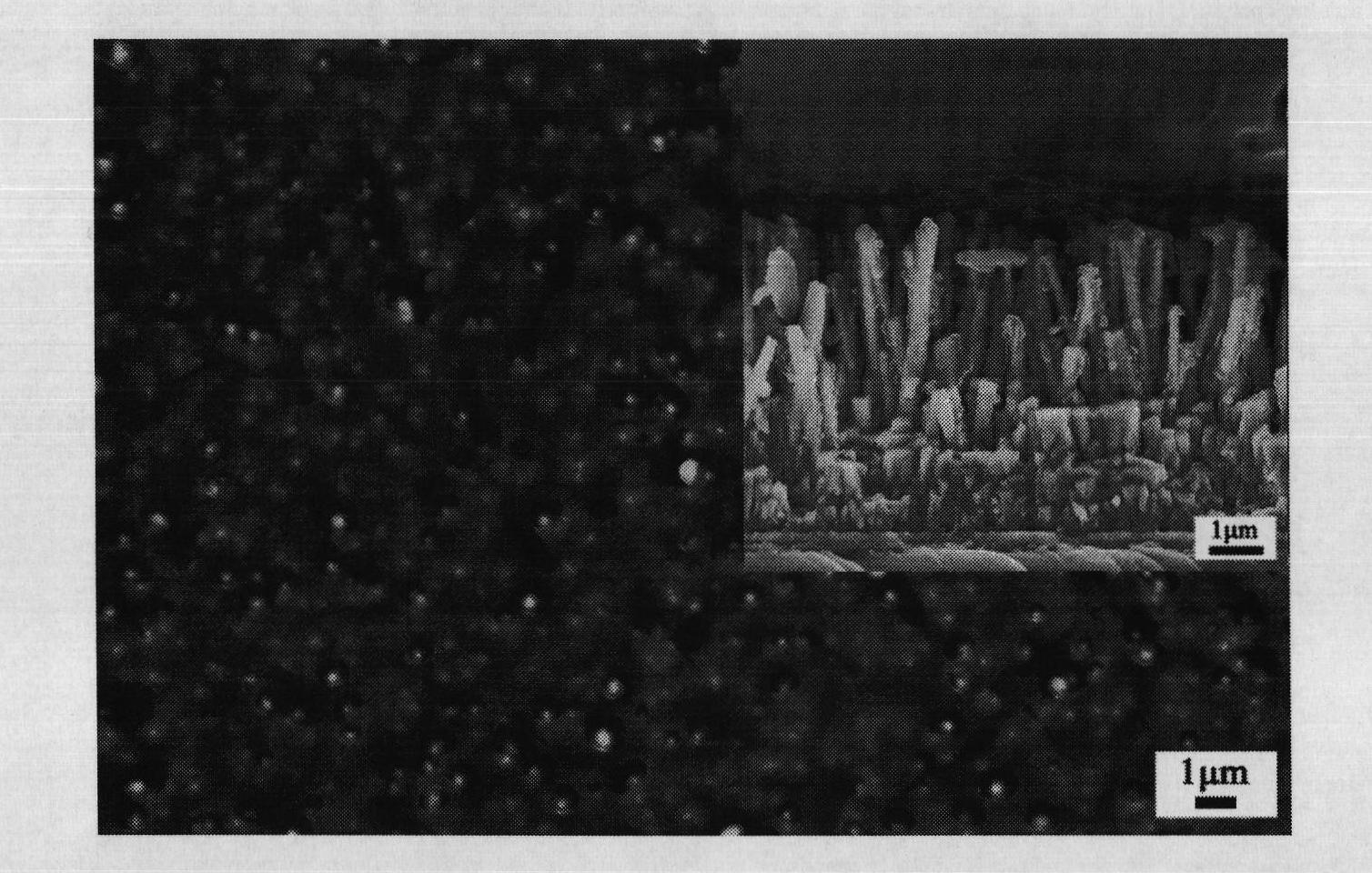

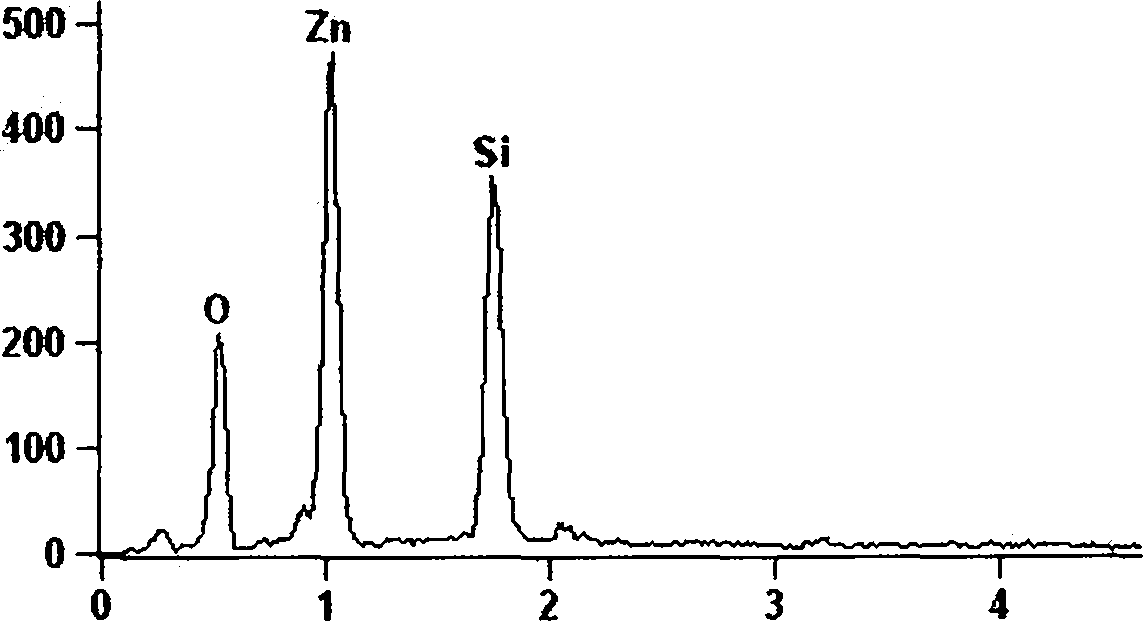

[0025] 3. After the reaction, the substrate was rinsed repeatedly with deionized water. After drying, a uniform translucent white film was formed on the substrate, which was the prepared ZnO nanorod array.

[0026] 4. Take a silica sol with a concentration of about 11-13 wt%, and after ultrasonic treatment for 15 minutes, obtain a colloidal solution with an appropriate viscosity. Use a dropper to draw the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin...

example 2

[0029] 1. Dissolve chemically pure zinc nitrate and hexamethylenetetramine in equimolar amounts into deionized water to prepare a reaction solution with a molar concentration of 0.15 mol / L.

[0030] 2. Select 5 pieces of aluminum plated with 100nm thick ZnO thin film as the seed layer prepared by homogenization method and cut into 2cm×2cm size as the growth substrate, put them into the reaction solution and grow in sealed at 90°C for 24 hours.

[0031] 3. After the reaction is finished, a uniform milky white film is obtained, which is the prepared ZnO nanorod array.

[0032] 4. Take a silica sol with a concentration of about 20-26 wt%, and after ultrasonic treatment for 15 minutes, obtain a colloidal solution with an appropriate viscosity. Use a dropper to draw the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin for 5 seconds in low gear at 1000 rpm and 15 seconds in high gear at 3000 rpm. A colloidal layer ...

example 3

[0035] 1. Dissolve chemically pure zinc nitrate and hexamethylenetetramine in equimolar amounts into deionized water to prepare a reaction solution with a molar concentration of 0.05 mol / L.

[0036] 2. Select a stainless steel substrate plated with a 100nm thick ZnO film as a seed layer and cut it into 2cm×2cm size as a growth substrate, put it into the reaction solution and grow it at 90°C for 12 hours in a sealed manner.

[0037] 3. After the reaction is finished, a uniform translucent milky white film is obtained, which is the prepared ZnO nanorod array.

[0038] 4. Take a silica sol with a concentration of about 20-26 wt%, and after ultrasonic treatment for 15 minutes, obtain a colloidal solution with an appropriate viscosity. Use a dropper to draw the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin for 5 seconds in low gear at 1000 rpm and 15 seconds in high gear at 3000 rpm. A colloidal layer with a unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com