Method and device for continuously rectifying and separating medium/low-temperature coal tar crude phenols

A low-temperature coal tar and rectification separation technology, which is applied in the field of coal chemical industry, can solve the problems of many operation links, affected product output and quality, and high labor intensity of workers, so as to achieve a high degree of automation, reduce operators and labor intensity, The effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

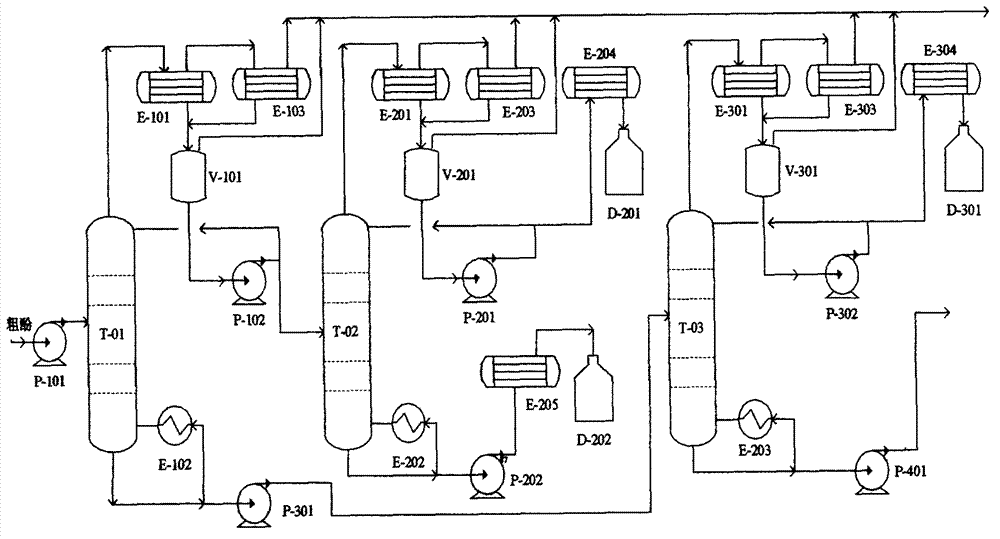

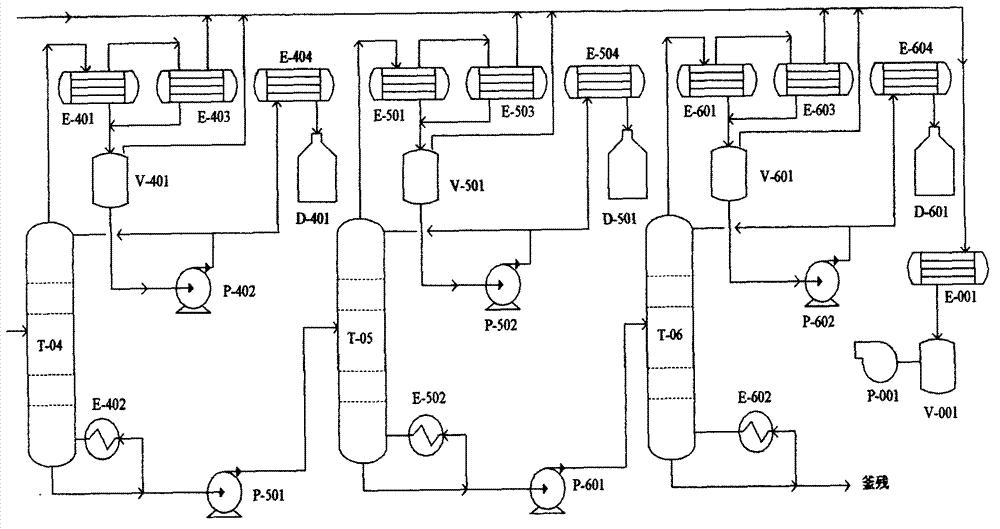

Embodiment 1

[0064] The crude phenol obtained from the treatment of medium and low temperature coal tar in a semi-coke enterprise is used as the raw material solution (the components are roughly 5.2% phenol, 6.7% o-cresol, 12.3% m-cresol, 6.3% p-cresol, 22.1% xylenol, B base phenol 13.5%, tricresyl 7.3%, heavy phenol 22.0%), the crude phenol raw material enters the rectification column after pretreatment, and separates and obtains each target component successively. The raw material crude phenol is transported to the light component tower T-01 by the feed pump P-101, and the mixed phenol of phenol and o-cresol is extracted from the top of the tower, and the steam at the top of the tower enters the condenser E-101 of T-01, and the uncondensed steam Enter the trap E-103 to condense, and the operating conditions of the light component tower T-01 are: the top pressure of the tower is 5KPa, the reflux ratio is 8, and the temperature is 104.5°C; the bottom pressure of the tower is 15KPa, and the ...

Embodiment 2

[0066] The crude phenol obtained from the treatment of medium and low temperature coal tar in a semi-coke enterprise is used as the raw material solution (the components are roughly 7.1% phenol, 6.3% o-cresol, 10.8% m-cresol, 5.9% p-cresol, 23.2% xylenol, B base phenol 11.9%, tricresyl 9.2%, heavy phenol 20.6%), the crude phenol raw material enters the rectification column after pretreatment, and separates and obtains each target component successively. The raw material is transported to the light removal component T-01 by the feed pump, and the mixed phenol of phenol and o-cresol is extracted from the top of the tower, and the steam at the top of the tower enters the condenser of T-01, and the uncondensed steam enters the trap to condense, and the light removal group The operating conditions of sub-column T-01 are: the pressure at the top of the tower is 10KPa, the reflux ratio is 7.5, and the temperature is 125.9°C; the pressure at the bottom of the tower is 20KPa, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com