Rare earth grid alloy for lead-acid storage batteries and production method thereof

A lead-acid battery, grid technology, used in battery electrodes, circuits, electrical components, etc., can solve the problems of intergranular corrosion, early capacity loss, etc., and achieve the effect of improving strength, reducing alloy cold cracking, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

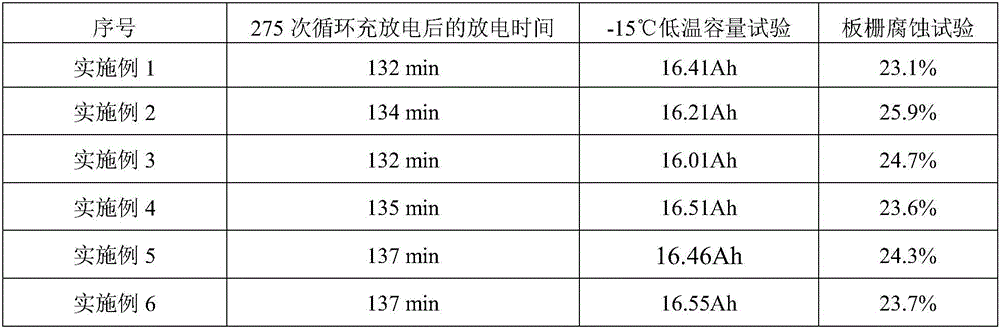

Examples

Embodiment 1

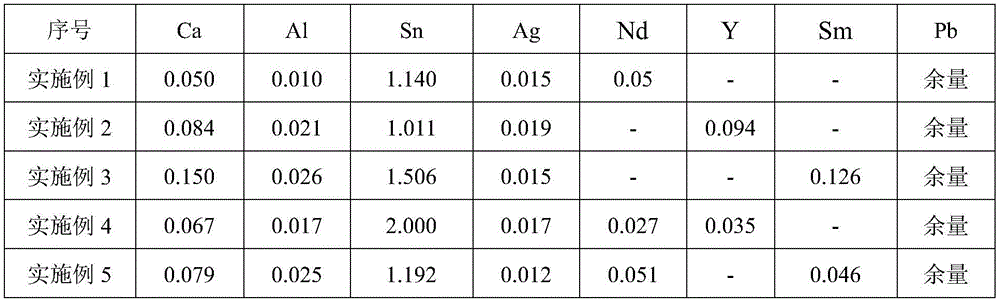

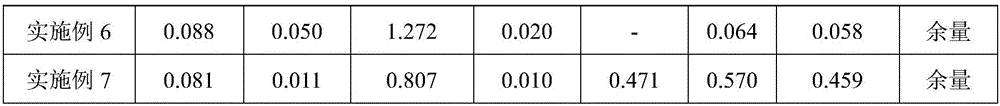

[0024] The chemical composition of the rare earth grid alloy for lead-acid batteries is shown in Table 1: Example 1, wherein the rare earth element is Nd: the specific preparation method is as follows:

[0025] (1) Weigh the raw materials according to the chemical composition of the rare earth grid alloy for lead-acid batteries;

[0026] (2) heating the refined lead to 400-550 ℃ in a lead pot to make lead liquid;

[0027] (3) take 75%-85% of the weight of the lead liquid obtained in step (2), add Ca to it, and melt it completely at 500°C-600°C to form a Pb-Ca alloy solution; add rare earth elements to the rest of the lead liquid, at 600- The rare earth elements are completely melted at 720°C to form a Pb-rare earth element alloy solution;

[0028] (4) Mix the Pb-Ca alloy solution and the Pb-rare earth element alloy solution obtained in step (3) according to a certain proportion, add a certain proportion of Sn, Al and Ag, smelt, mix and stir evenly at 500-550 ° C, and cast Co...

Embodiment 2

[0030] The chemical composition of the rare earth grid alloy for lead-acid batteries is shown in Table 1: Example 2.

Embodiment 3

[0032] The chemical composition of the rare earth grid alloy for lead-acid batteries is shown in Table 1: Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com