Heat exchanging device based on hydrogen compound

A technology of heat exchange device and hydrogen compound, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems that the high temperature resistance and corrosion resistance of heat exchangers cannot meet the needs of smelting, so as to avoid partial The effect of high temperature, easy installation, and improved energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

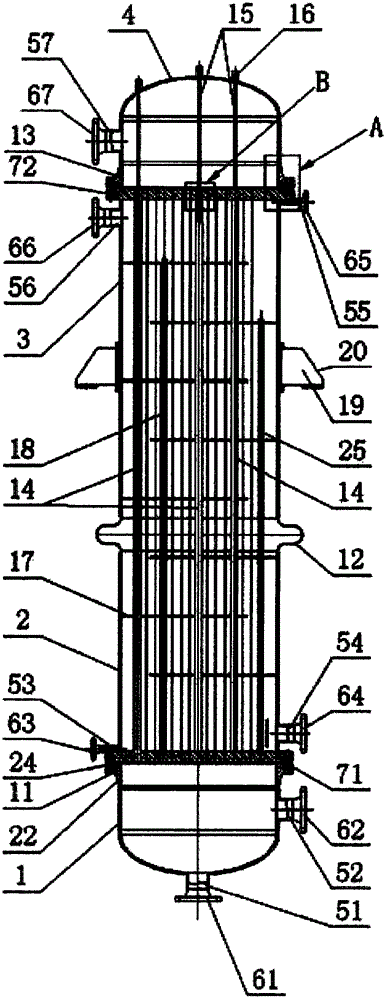

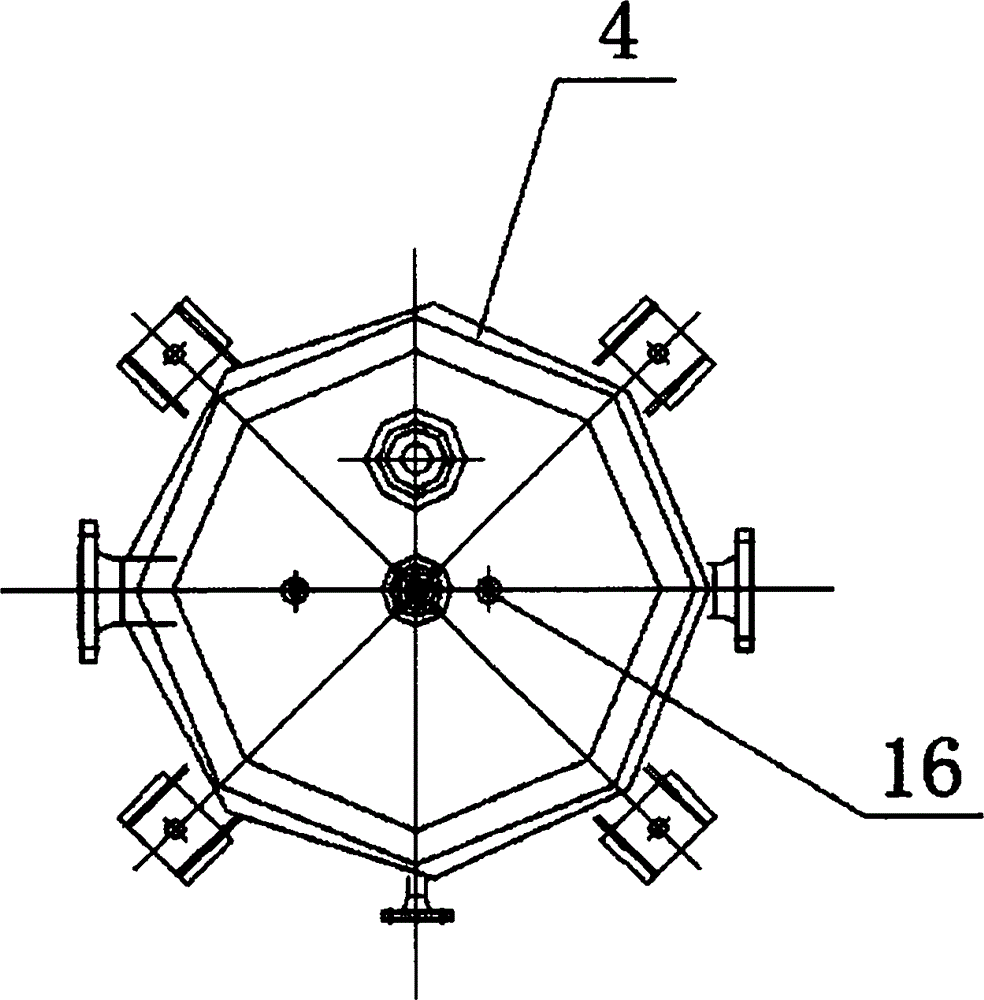

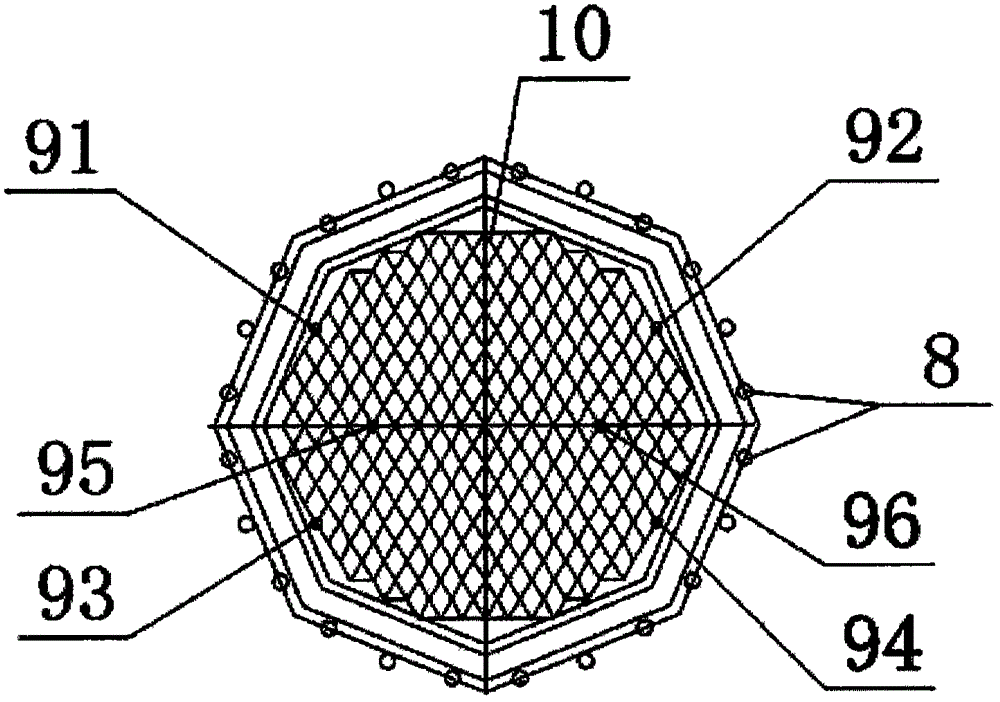

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a heat exchange device based on hydrogen compounds includes a cylinder of the heat exchanger, and the cylinder is composed of a lower short joint 1, a lower cylinder 2, an upper cylinder 3 and an upper cylinder connected sequentially from bottom to top. The short joint 4 is composed; the lower short joint 1, the lower cylinder body 2, the upper cylinder body 3 and the upper short joint 4 have the same inner diameter. The bottom of the lower short joint 1 is a spherical structure, the upper end of the lower short joint 1 is open and connected to the bottom of the lower cylinder 2; the bottom of the lower short joint 1 is connected with a first connecting pipe 51 with an opening downward, so A first flange 61 is installed on the bottom of the first connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com