Novel incinerator fuel gas excess heat deeply-recycling and energy level improving technology system

A flue gas waste heat and process system technology, applied in climate change adaptation, climate sustainability, combustion technology mitigation, etc., can solve the problems of insufficient waste heat recovery and low recovery efficiency of flue gas in tail gas incinerators, and achieve energy level improvement. , The effect of high recovery efficiency and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

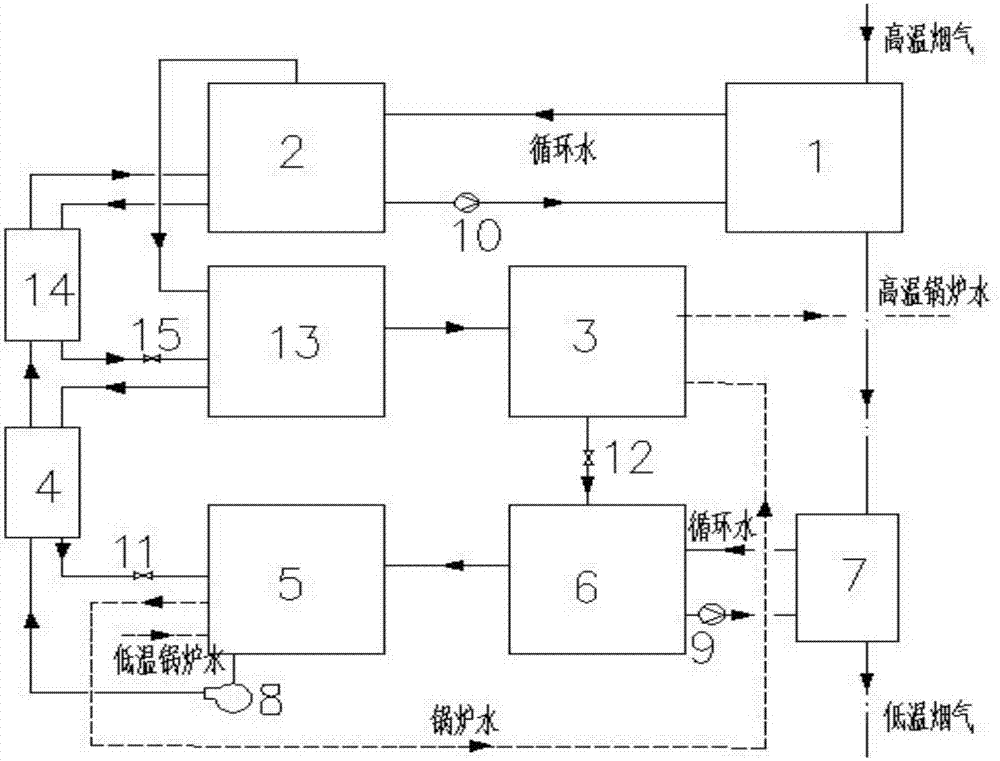

[0022] A new type of incinerator flue gas waste heat deep recovery and energy level upgrading process system, such as figure 2 shown. Composed of high-pressure heat exchanger 1, generator 2 and low-pressure generator 13, condenser 3, heat exchanger 4 and high-temperature heat exchanger 14, absorber 5, evaporator 6, circulating water heating anti-corrosion heat exchanger 7, The lithium bromide solution circulating pump 8, the first circulating water pump 9 and the second circulating water pump 10, the lithium bromide solution throttling device 11 and the refrigerant water throttling device 12 are composed of. The generator 2 is a high-pressure generator, and the heat exchanger 4 is a low-temperature heat exchanger. The specific implementation plan is as follows: the high-temperature flue gas from the incinerator first passes through the high-pressure heat exchanger 1 to exchange heat with high-pressure circulating water, and the high-temperature and high-pressure hot water af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com