Waste gas recovery system device of noise elimination and air cooling static catalytic cracker of internal-combustion engine

A technology for exhaust gas recovery and system installation, which is used in exhaust installations, mufflers, internal combustion piston engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

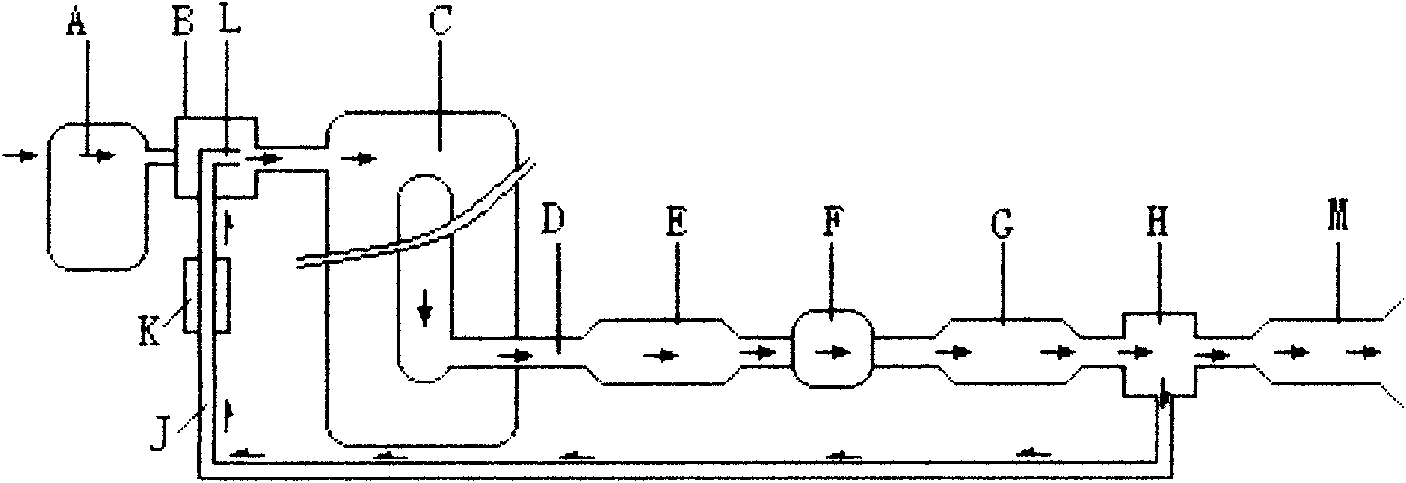

[0134] exist figure 2 Middle: (A) Air filter, (B) Exhaust gas recycling device, (L) Exhaust gas recycling nozzle, (J) Exhaust gas recycling connecting pipe, (C) Engine exhaust system, (D) Exhaust pipe, (E) Air-cooled static muffler, (F) Ozone generator, (G) Air-cooled static NO X Catalyst, (H) exhaust splitter, (M) air-cooled NO X Catalytic converter, (K) semiconductor refrigerator.

[0135] In the figure: (A) air filter is connected to (B) exhaust gas recycler, (C) engine exhaust system, (D) exhaust pipe, (E) air-cooled static muffler, (F) ozone Generator, (G) air-cooled static NO X Catalyst, (H) exhaust splitter, (M) air-cooled NO X Catalytic converter, (K) semiconductor refrigerator; exhaust gas returns to (B) exhaust gas recycling nozzle through (H) exhaust splitter (J) tail gas recycling connecting pipe in sequence ( C) Engine intake system.

Embodiment 2

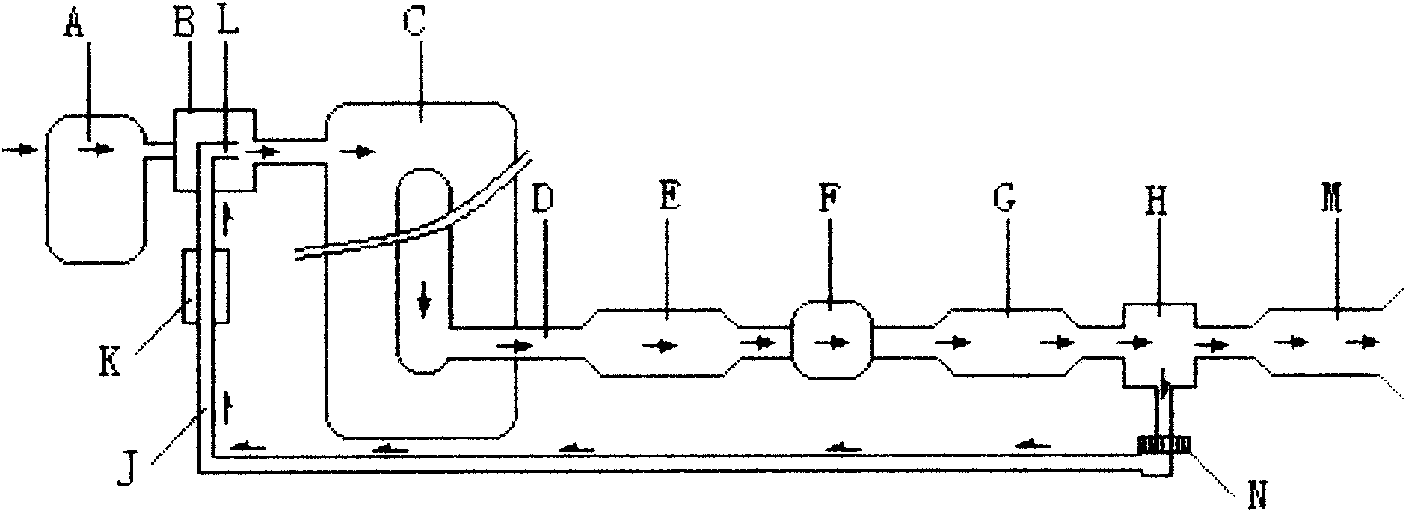

[0137] exist image 3 Middle: (A) Air filter, (B) Exhaust gas recycling device, (L) Exhaust gas recycling nozzle, (J) Exhaust gas recycling connecting pipe, (C) Engine exhaust system, (D) Exhaust pipe, (E) Air-cooled static muffler, (F) Ozone generator, (G) Air-cooled static NO X The catalytic converter is divided into two paths through the (H) exhaust splitter; the exhaust gas from one path is returned to the (L) in the (B) exhaust gas recycler through the (K) semiconductor refrigerator connected to the (J) exhaust gas recycling connecting pipe in sequence. Exhaust gas recovery nozzle enters (C) engine intake system; the other path passes through (H) exhaust splitter and connects to (M) air-cooled NO X Emissions after the catalytic converter.

[0138] In the figure: (A) air filter is connected to (B) exhaust gas recycler, (C) engine exhaust system, (D) exhaust pipe, (E) air-cooled static muffler, (F) ozone Generator, (G) air-cooled static NO X The catalytic converter is d...

Embodiment 3

[0140] exist Figure 4 Middle: (A) Air filter, (B) Exhaust gas recycling device, (L) Exhaust gas recycling nozzle, (J) Exhaust gas recycling connecting pipe, (C) Engine exhaust system, (D) Exhaust pipe, (E) Air-cooled static muffler, (F) Ozone generator, (Q) Air-cooled particulate filter, (H) Exhaust splitter, (N) Axial fan, (R) Air-cooled static hybrid catalyst.

[0141] In the figure: (A) air filter is connected to (B) exhaust gas recycler, (C) engine exhaust system, (D) exhaust pipe, (E) air-cooled static muffler, (F) ozone Generator, (Q) air-cooled particle trap is divided into two paths through (H) exhaust splitter; return exhaust is pumped by (N) axial flow fan to (J) exhaust gas recycling connecting pipe and returned to (B) ) The (L) exhaust gas recycling nozzle in the exhaust gas recycler enters (C) the engine intake system; the exhaust gas is discharged after being connected to (R) the air-cooled static hybrid catalytic converter through the (H) exhaust splitter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com