Patents

Literature

58results about How to "Lower the starting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

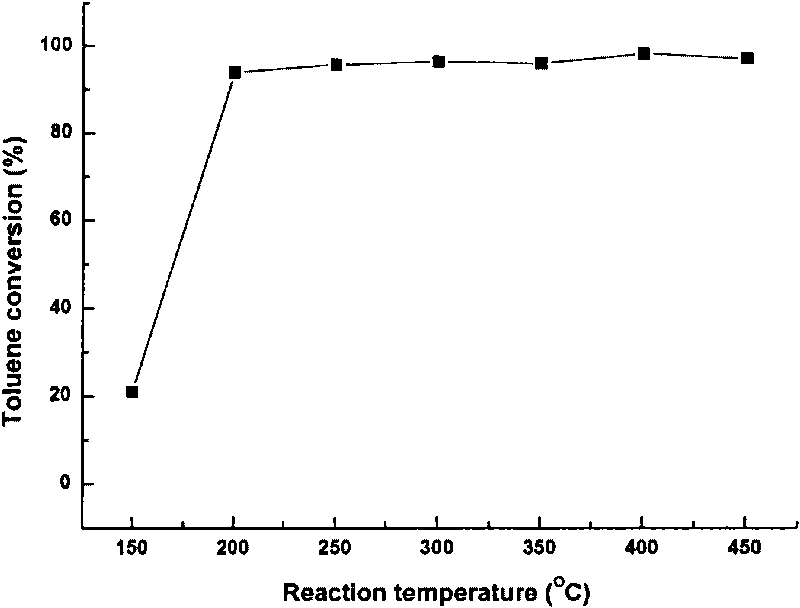

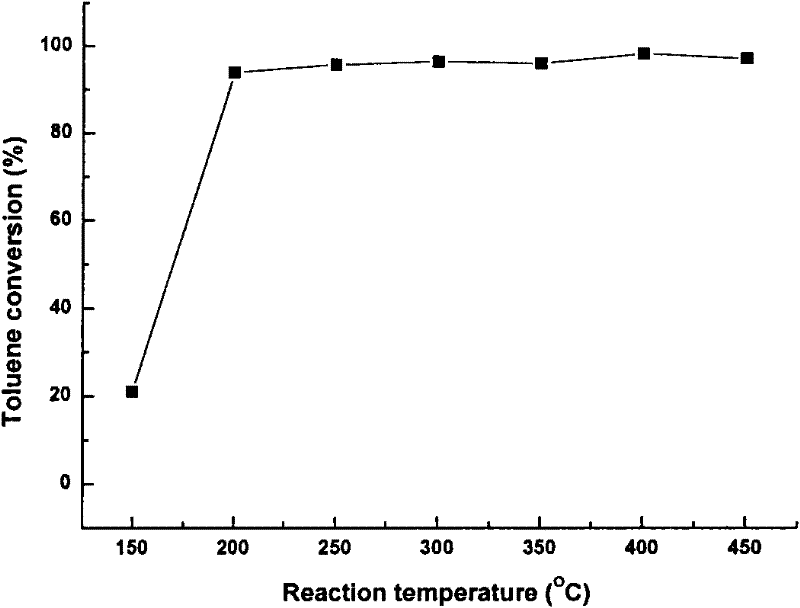

Catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and preparation method thereof

InactiveCN102240557AHigh strength combinationSuitable for handlingMolecular sieve catalystsDispersed particle separationAlkaneRare earth

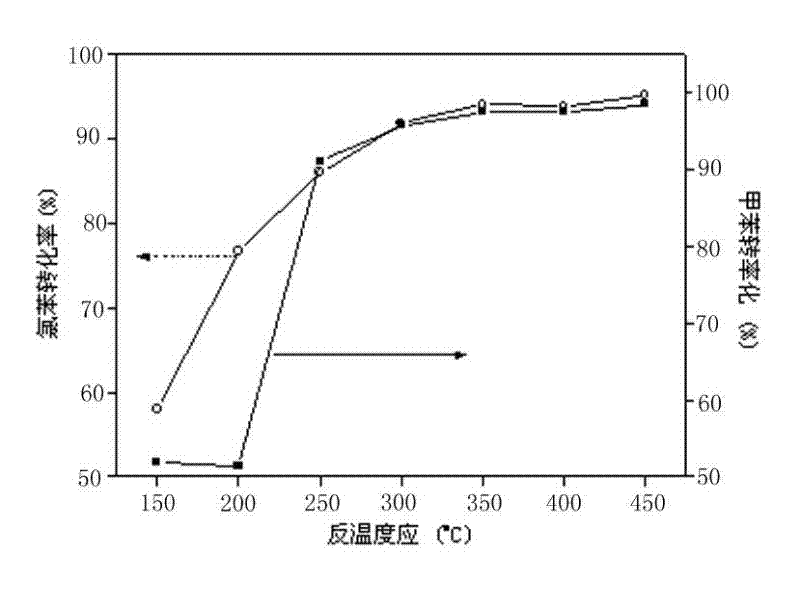

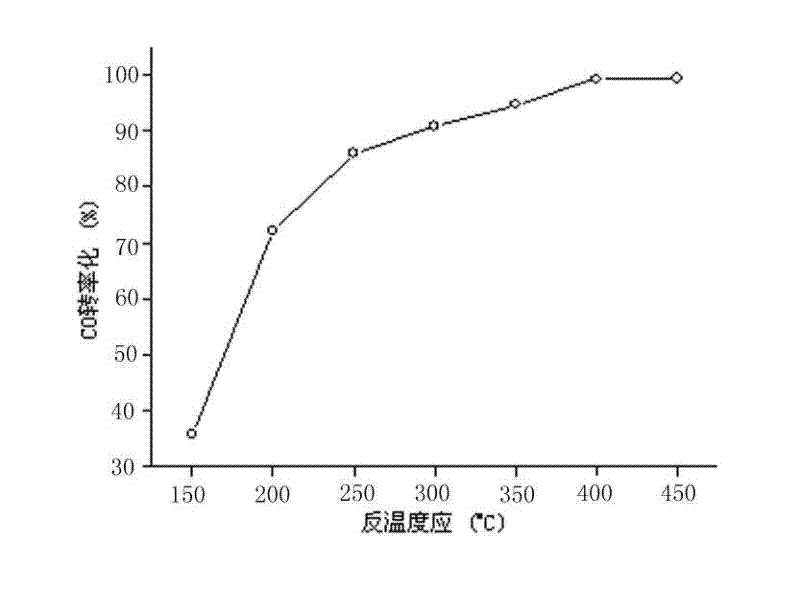

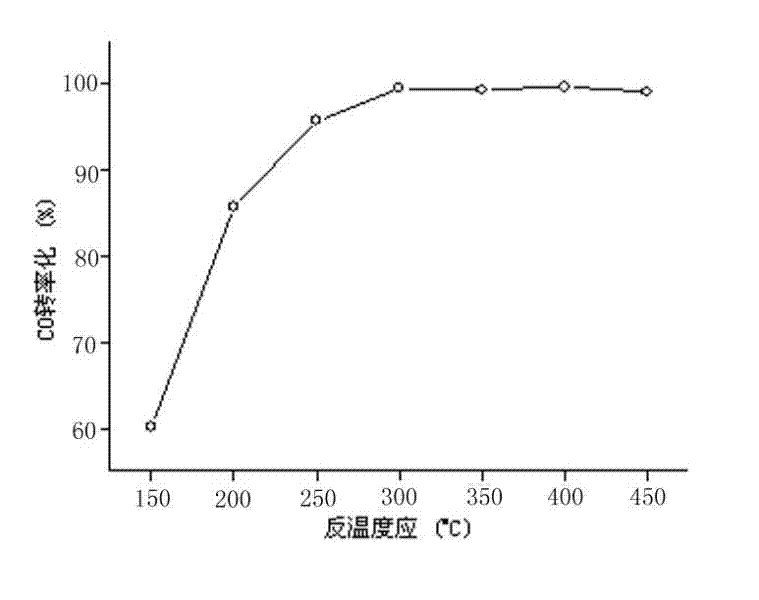

The invention relates to a catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and a preparation method thereof and belongs to the fields of atmospheric pollution abatement technique and environment-friendly catalytic material. In the catalyst, the nickel-iron-manganese compound oxide is taken as a first active component; one or two of other transition metal, rare-earth metal or precious metal oxides are taken as a second active component; a self-made carrier or natural inorganic material carrier is taken as the carrier of the catalyst; and the contents (in percentage by weight) of the loads of the first and the second active components are respectively 5-20% and 0-10% on the basis of the weight of the carrier. The catalyst is a polymorphous catalyst, which can be spherical, columnar, starlike, bar-shaped, netty, flaky, ringlike, strip-shaped, block-shaped, honeycomb or powdery. The catalyst can be used for completely catalytically oxidizing CO(carbon monoxide), alkane, halogenated hydrocarbon, aromatic hydrocarbon and heterocyclic compounds at 200-350 DEG C. The catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas has the advantages of low initiation temperature, high conversion efficiency, low cost, wide application scope, and meets the industrial waste gas treatment requirements of various enterprises.

Owner:NANJING UNIV OF TECH

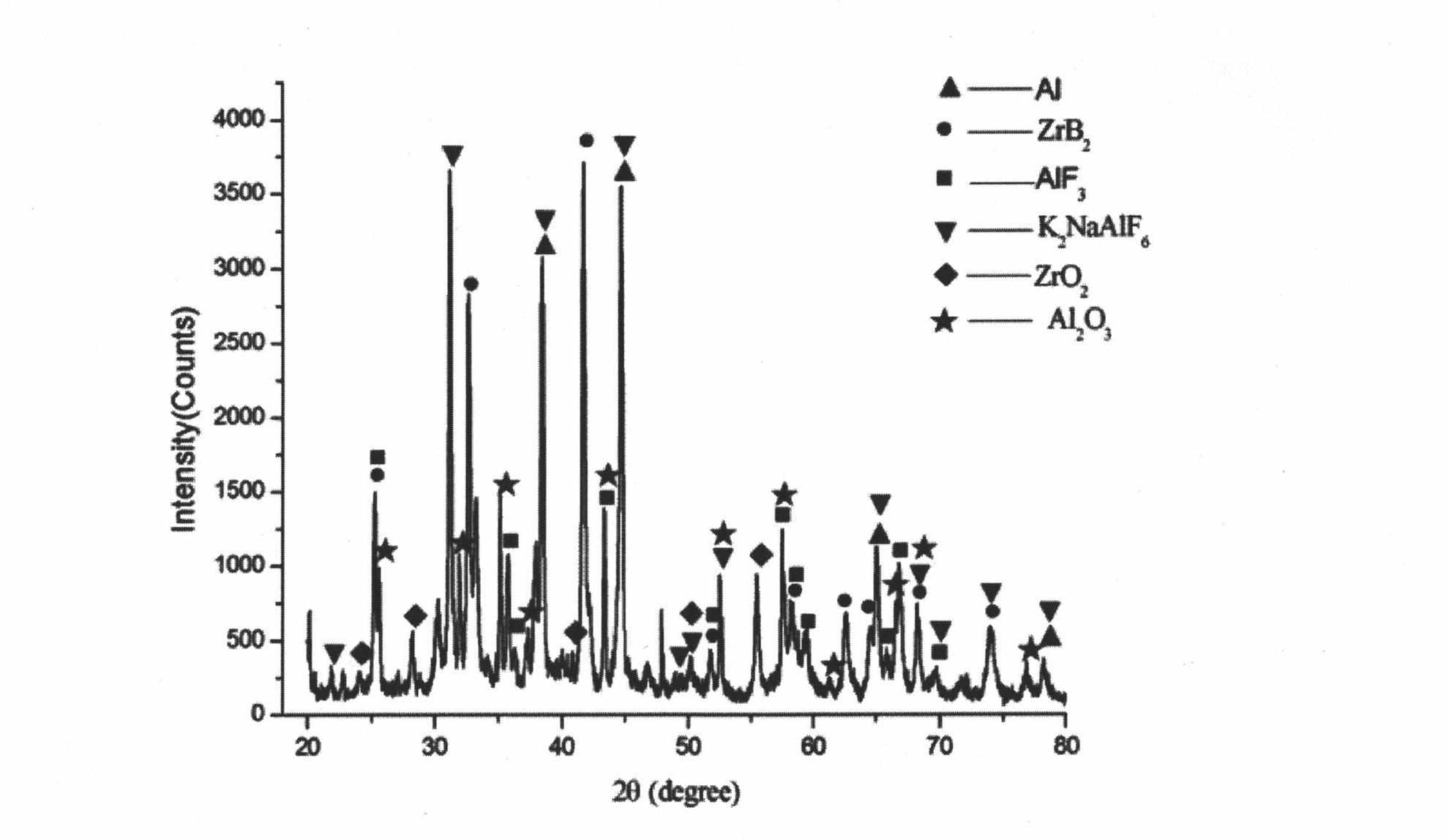

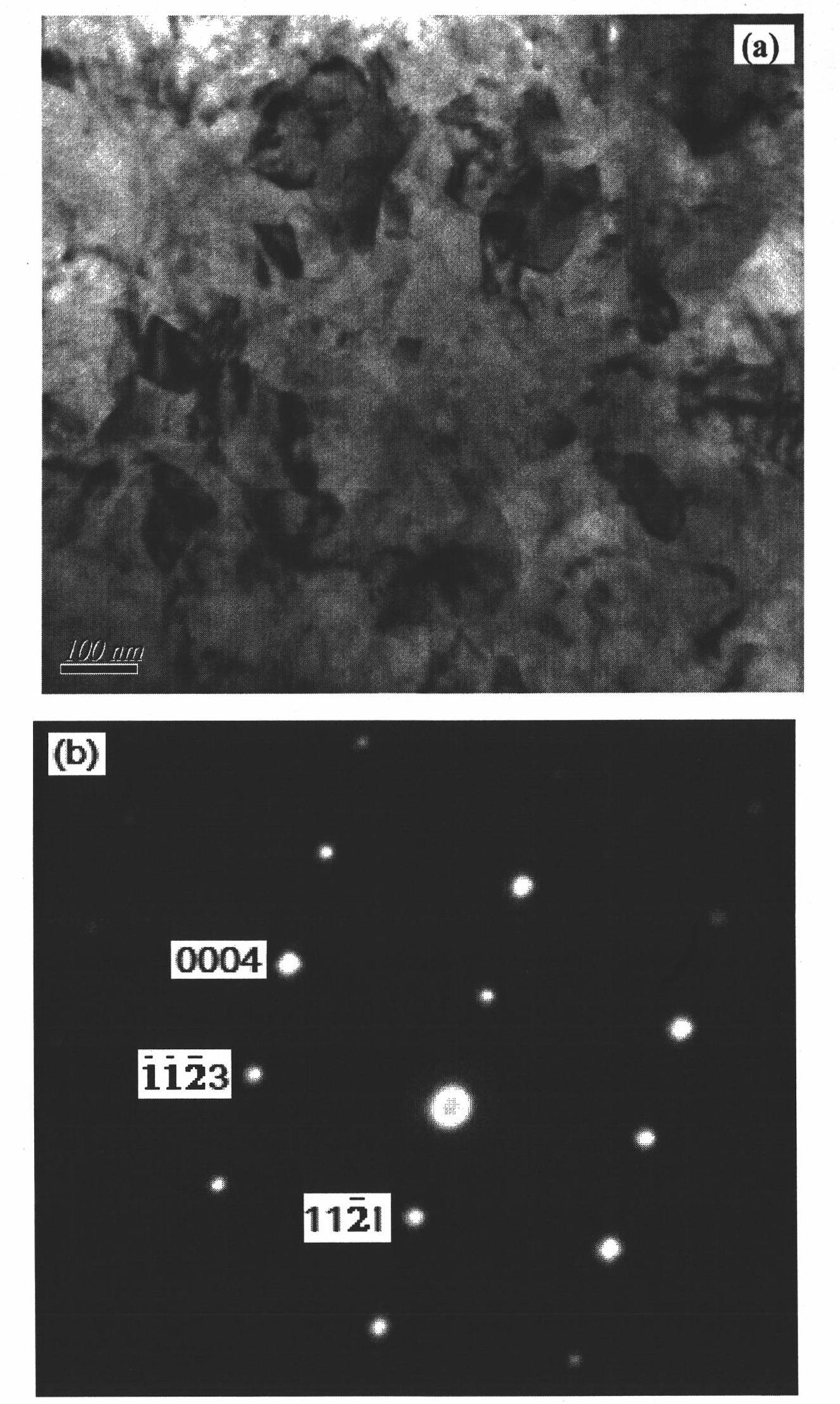

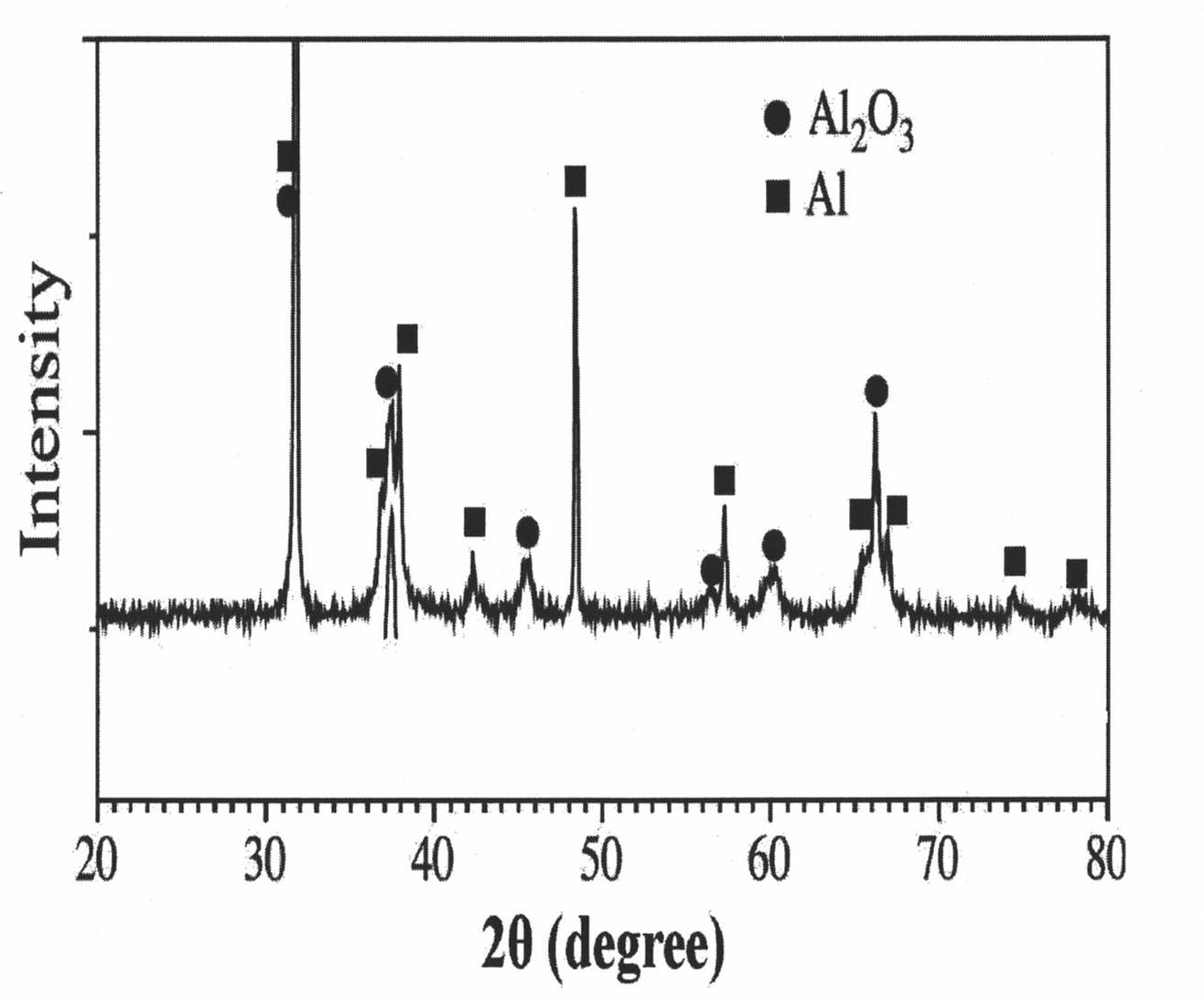

Preparation method of Al2O3 nanoparticle reinforced aluminum-based composite material

The invention provides a preparation method of a Al2O3 nanoparticle reinforced aluminum-based composite material, belonging to the technical field of the aluminum-based composite material. The method uses sodium borate (Na2B4O7.10H2O) type boride and K2ZrF6 type fluoride powder as the reaction mixed salt and adopts the direct reaction of molten metal to directly synthetize the nano-Al2O3 particlereinforced aluminum-based composite material in molten aluminum. The invention mainly has the following advantages: the reaction system can effectively control the growth of Al2O3 particles and ensure that the size of the reinforcement phase is controlled to the nanoscale; and the synthesis temperature of the reaction system is 800-850 DEG C, and the defects of the traditional method which uses oxide to prepare the Al2O3 particle reinforced aluminum-based composite material can be overcome, wherein the defects are that the particles are easy to grow, the size can not be controlled and the reaction temperature is high. In addition, with the increase of the addition amount of the reaction mixed salt in the reaction system, the reinforcing particles have smaller size and more uniform distribution; the interface binding of the particles and the substrate is good, no pollution is caused; and the preparation method is an effective method which is suitable for preparing the high-performance nanoparticle reinforced composite material at a low temperature.

Owner:JIANGSU UNIV

Catalyst containing rare-earth metal for preparing vinyl acetate using acetylene method and preparation method and use thereof

InactiveCN101391229AImprove shortcomingsLower the starting temperatureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseRare earth

The invention belongs to the field of vinyl acetate synthesized by a fixed bed type acetylene gas phase method, in particular to a catalyst for preparing vinyl acetate by a rare earth metal-bearing acetylene method as well as a preparation method thereof, and the rare earth metal-bearing catalyst is applied to the synthesis of vinyl acetate which takes acetic acid and acetylene as raw materials by adopting the fixed bed type gas phase method. The zinc acetate and lanthanum acetate are dissolved with methanol, then active carbon is dipped in the methanol solution containing the zinc acetate and lanthanum acetate under agitation, the zinc acetate and lanthanum acetate are loaded on the active carbon through an impregnation method, and the catalyst is obtained after drying. The content of the loaded active component zinc acetate is 10 to 40wt% of the total weight of catalyst, and the content of the loaded active component lanthanum acetate is 0.1 to 5wt% of the total weight of catalyst. The catalyst takes the active carbon as a carrier, and adopts two metallic salts of the loaded zinc acetate and the lanthanum acetate, and the catalyst containing lanthanum acetate has the advantage of low initial temperature of reaction compared with the usual active carbon zinc acetate catalyst.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Adsorption-catalyst for treating phenol containing waste-water, prepn. method and application thereof

InactiveCN1792441AGood adsorption performanceReduce energy consumptionWater contaminantsCatalyst activation/preparationChemistryActivated carbon

An adsorptive catalyst for treating the benzene contained sewage contains Cu (1-5 Wt%), auxiliary component (1-5) chosen from K, Zn and Ce, and activated carbon (85-98 Wt%) as carrier. Its application includes such steps as passing said sewage through said catalyst while adsorbing, drying, filling oxidizing gas and reaction.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

Method for dyeing mercerizing wool or mercerizing wool fabric by yellow chrysanthemum flower dye

InactiveCN101117775AReduce the chance of occurrenceImprove uniformityDyeing processSodium bicarbonatePhosphate

The present invention relates to a method of dyeing mercerized wool or mercerized wool fabrics with yellow chrysanthemum paint, which is taken as the paint, and the dyeing method is divided into two steps including ecological pretreatment and subsequent innocuous mordant dyeing: the first step, treatment conditions: baking soda of 1-3 percent of cloth weight, 1-5 percent coconut oil diethanol amide as detergent of 1-5 percent of cloth weight, 0.2-1.0g / L neutral phosphate, temperature 20-60 DEG C, duration 10-60min, bathing ratio 1 to 20-50; the second step, mordant dyeing: the mercerized wool or mercerized wool fabrics with ecological pretreatment is treated with mordant front dyeing, single bathing or post dyeing. The yellow chrysanthemum resources are rich, easy for expanding plantation, with sound dyeing and less damage to mercerized wool during dyeing.

Owner:HAILAN GRP +1

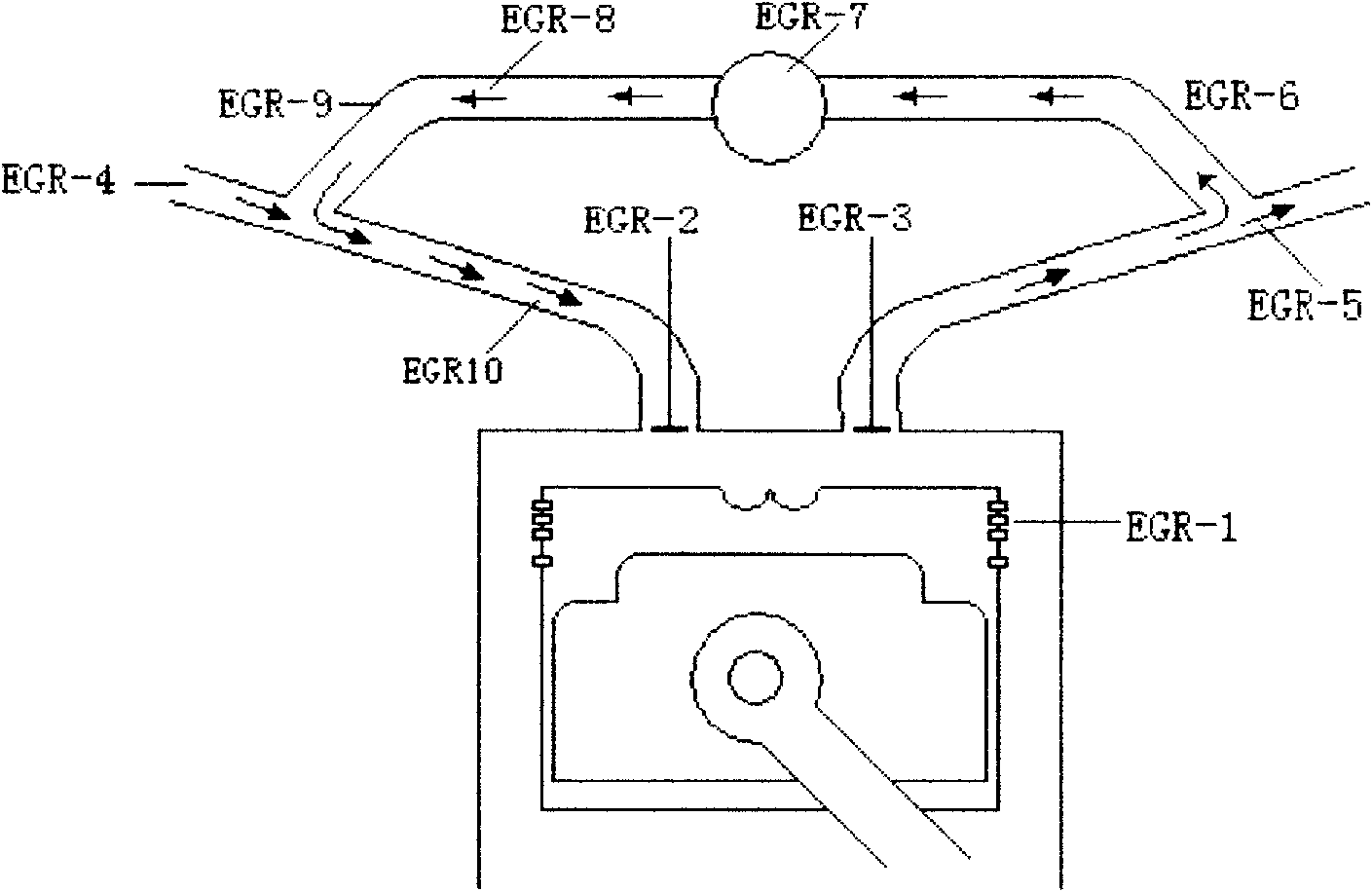

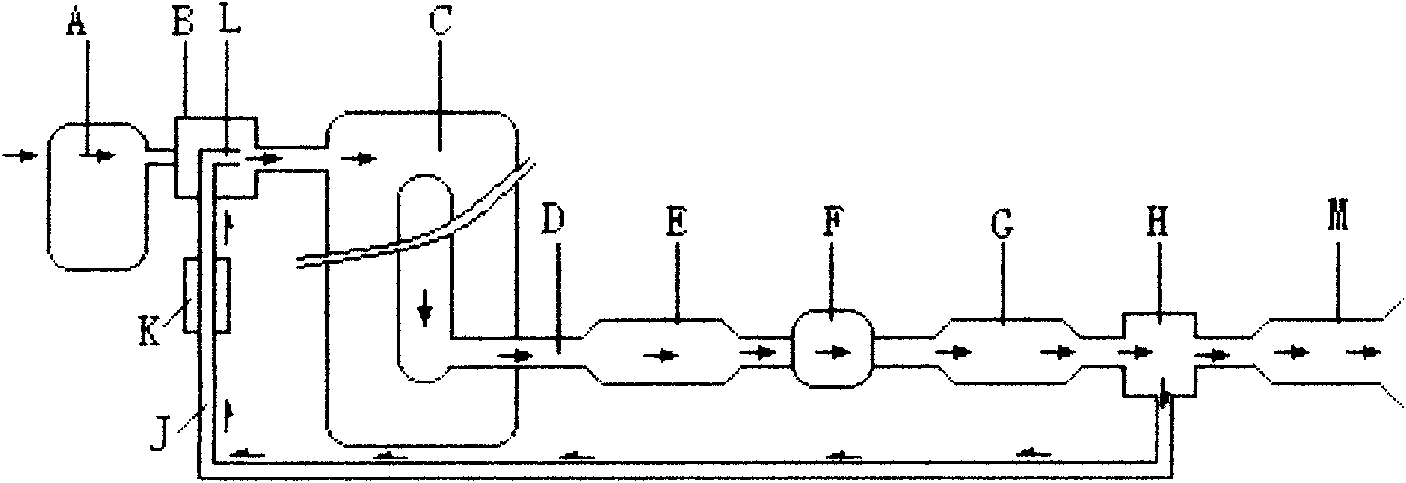

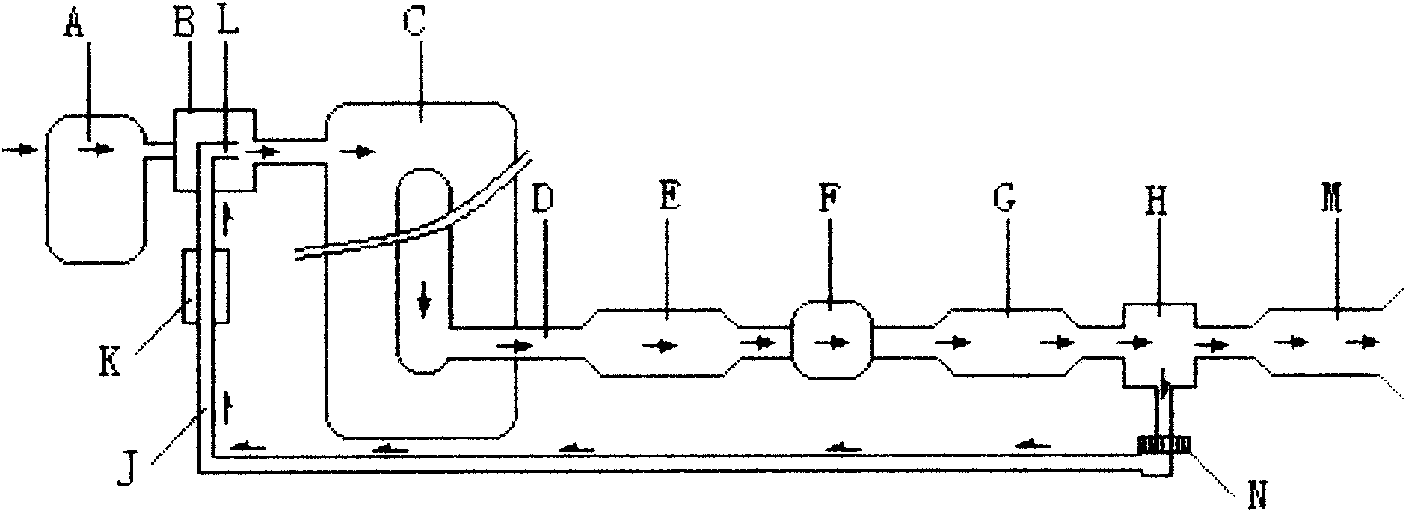

Waste gas recovery system device of noise elimination and air cooling static catalytic cracker of internal-combustion engine

InactiveCN101660468ADoes not affect flow characteristicsSpeed up chemical reactionsInternal combustion piston enginesNon-fuel substance addition to fuelInternal combustion engineRefrigerated temperature

The invention relates to a waste gas recovery system device of a noise elimination and air cooling static catalytic cracker of an internal-combustion engine, comprising a tail gas recycling device, atail gas recycling nozzle, a tail gas recycling connecting pipe, an engine exhaust system, an exhaust pipe, an air cooling static noise eliminator, an ozone generator, an air cooling static NOX catalyst, an exhaust flow divider, an air cooling NOX catalyst, a semiconductor refrigerator, an axial flow fan, an air cooling particle catcher and an air cooling static mixing catalyst. The waste gas recovery system device is connected with an air supplying system and an oil line system so as to form new external three systems. The invention is suitable for a plane, a steamship, a diesel engine generating set, an internal-combustion locomotive, a motorcycle, a gasoline car, a diesel car, an oil drilling diesel machine, an industrial boiler, a domestic gas cooker, and the like, has simple and convenient installation, i.e. an original system of the internal-combustion engine is taken down and replace with the new system, can save the oil by 15-30 percent without exhaust pollution, prolongs the service life of the internal-combustion engine, is a major energy-saving brainstorm project during the Eleventh Five-Year Plan and is the major breakthrough of the waste gas recovery system--the reformation of the external three-system of an engine in 21 century.

Owner:上海徕普太阳能科技有限责任公司

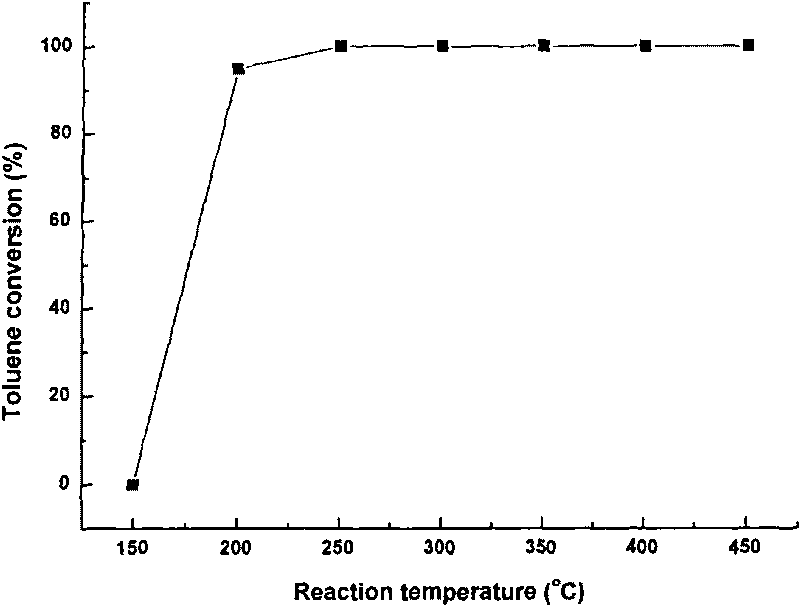

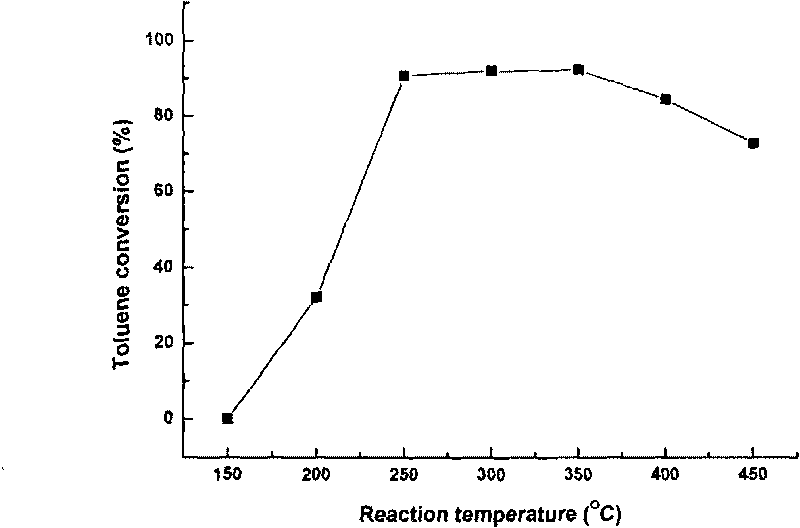

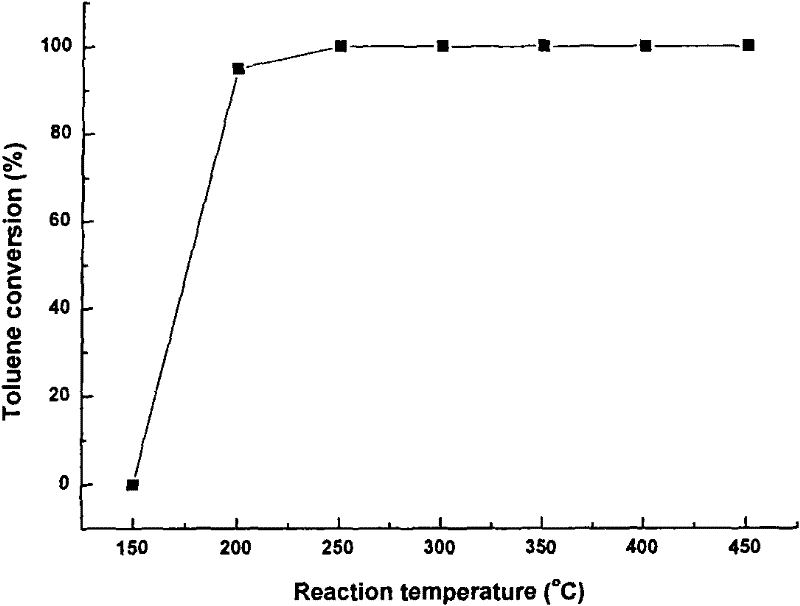

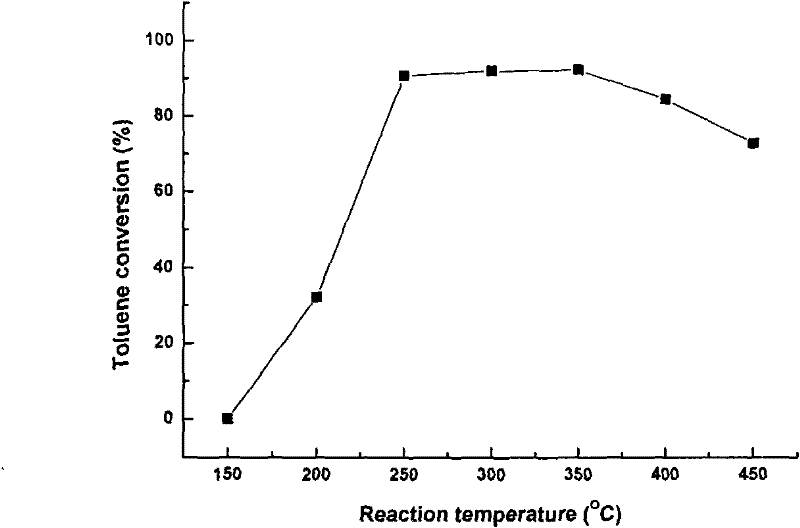

Catalyst for treating organic waste gas and preparation method thereof

InactiveCN101733127ASuitable for handlingFully catalyzedDispersed particle separationCatalyst activation/preparationPtru catalystExhaust fumes

The invention relates to a catalyst for treating organic waste gas and a preparation method thereof, belonging to the control technology of atmospheric pollution and the field of environment protection materials. In the catalyst, copper oxide, manganese oxide and titanium oxide are used as active ingredients, and a catalyst carrier is self-made; based on the mass of the carrier, the active ingredients are mixed in the molar ratio of copper oxide, manganese oxide to titanium oxide being 1-4: 1-4: 0.5-1; and the mass percentage of the capacity of the active ingredient is 1-20%. The self-made carrier is prepared by using silicon oxide, aluminum oxide, magnesium oxide and ferric oxide as components which are baked at high temperature, wherein the mass percentage of the material is 28-55% of silicon oxide, 20-40% of aluminum oxide, 10-30% of magnesium oxide and 0.5-2% of ferric oxide; and the carrier is modified or modified through an aluminum oxide coating by using 5-20% acid in mass percentage. The catalyst can completely catalyze toluene at 250 DEG C, and the complete catalysis temperature is reduced by about 20 DEG C compared with the same kind of catalysts.

Owner:NANJING UNIV OF TECH

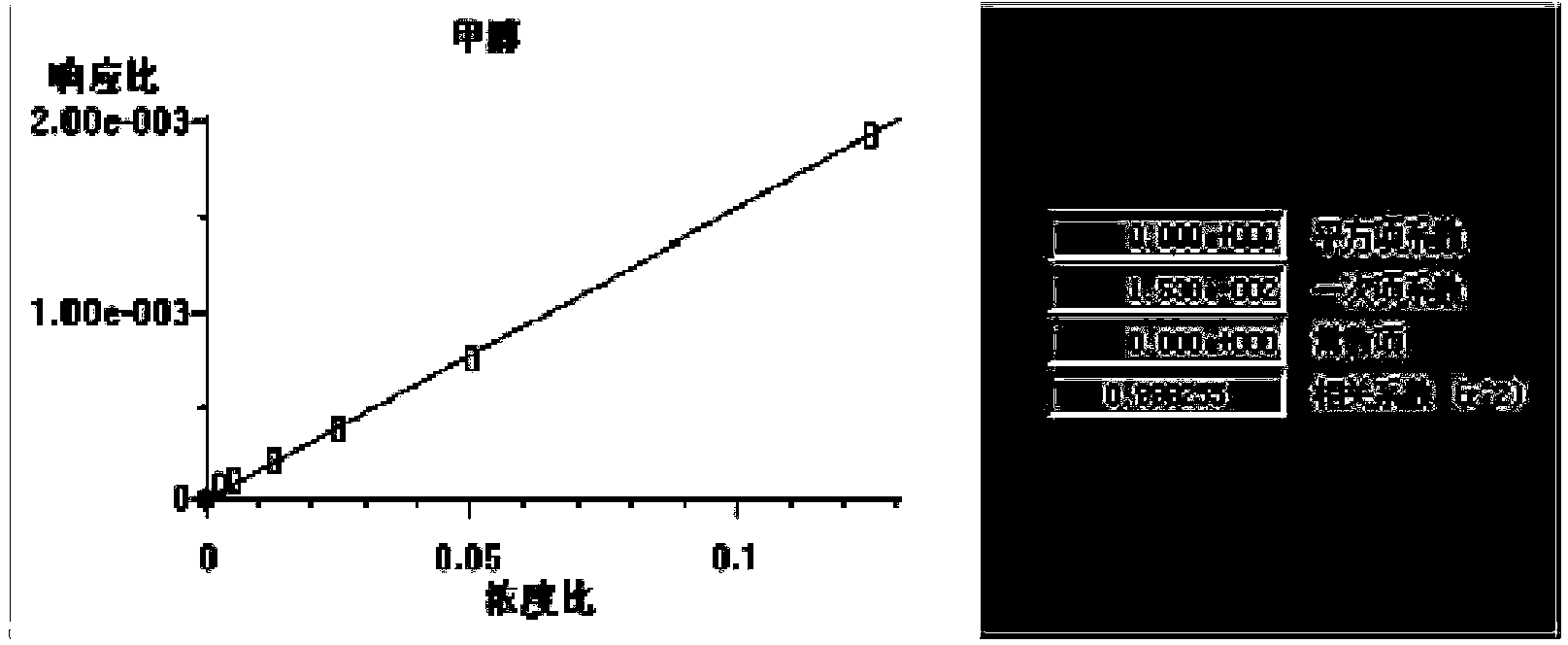

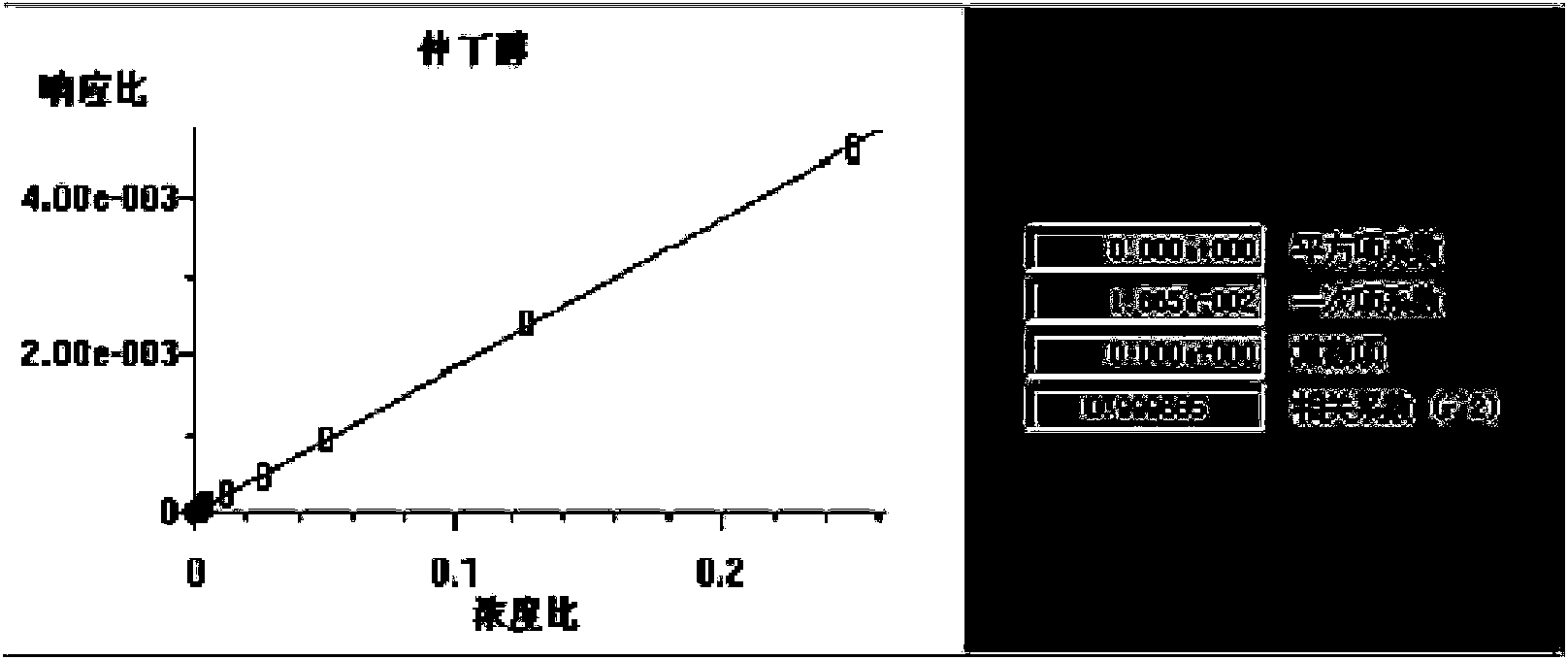

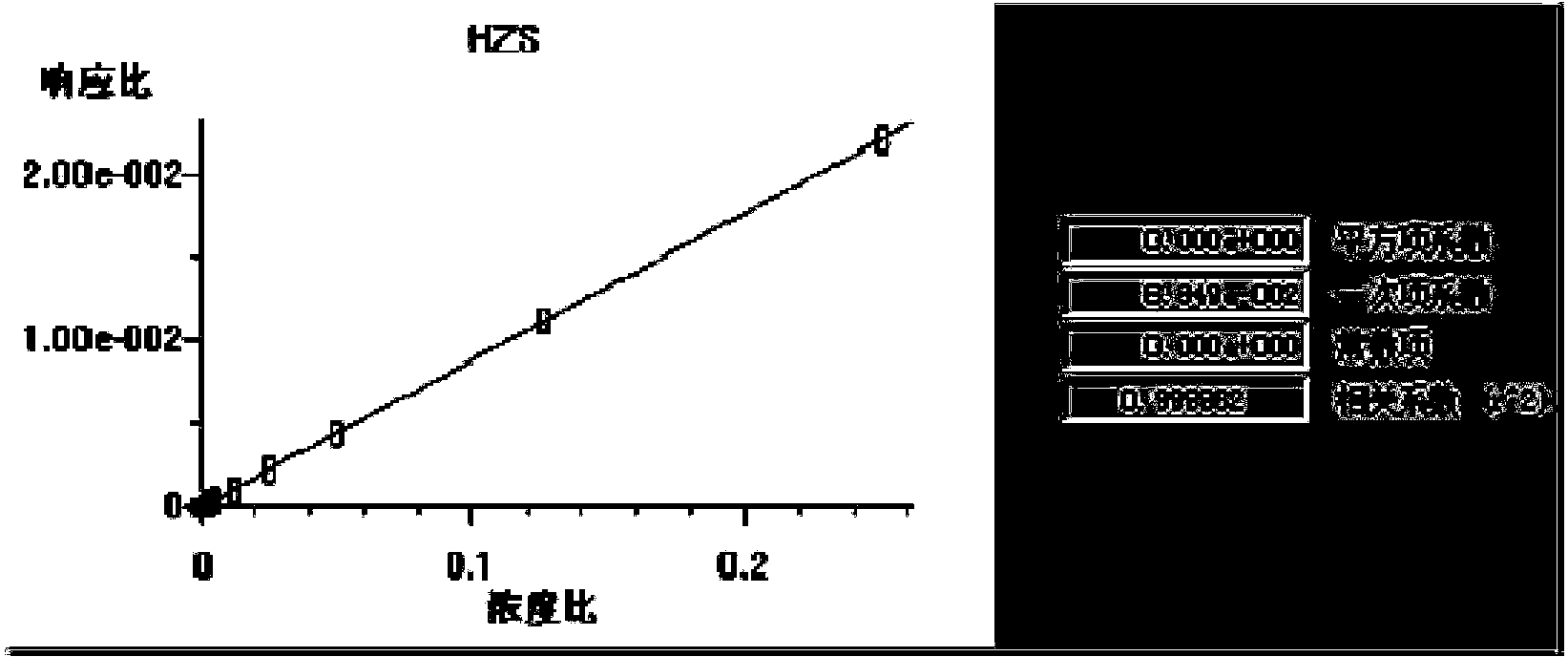

Method for detecting seven prohibited compounds in flavors and fragrances

ActiveCN103869039AEfficient detection methodModerate polarityComponent separationChemical industrySolvent

The invention discloses a method for detecting seven prohibited compounds in flavors and fragrances. The seven prohibited compounds are methanol, sec-butyl alcohol, safrole, imidazole, coumarin, musk xylene and sesamol. The detection method can accurately and rapidly detect the contents of the seven prohibited compounds in flavors and fragrances, is suitable for quality safety control of fragrance raw liquid and auxiliary solvents in the industries such as food, daily-use chemical industry, tobacco and pharmacy, and the has the characteristics of simple operation, rapidness, accuracy, good repeatability, high sensitivity and the like.

Owner:CHINA TOBACCO FUJIAN IND +1

Method for preparing polyacrylate-2-acrylamide-2-methyl propane sulfonic acid

The invention discloses a method for preparing polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method mainly comprises the following steps: 5 to 30 mass percent of crylic acid, 1 to 15 mass percent of 2-acrylamide-2-methyl propanesulfonic acid, 0.5 to 6 mass percent of persulfate, 0.2 to 3 mass percent of sodium sulfite, 0.05 to 3 mass percent of L-ascorbic acid, 0.5 to 9 mass percent of ethanol, 0.5 to 3 mass percent of dodecyl mercaptan and 50 to 85 mass percent of water are mixed to have polymerization reaction for not less than one hour at a temperature of between 35 and 60 DEG C to obtain the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method has the advantages the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid with low molecular weight is synthesized once, has low starting reaction temperature, less energy consumption, rapid reaction speed, high utilization efficiency of equipment, a simple process and convenient operation.

Owner:娄底市裕德科技有限公司

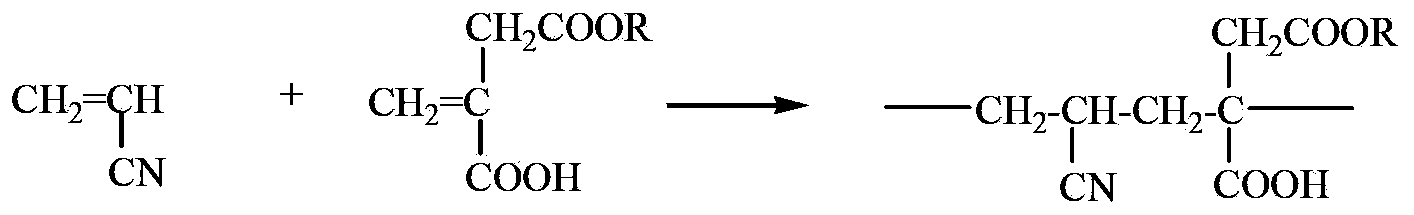

Preparing method of polyacrylonitrile (PAN) used for carbon fiber

A preparing method of polyacrylonitrile (PAN) used for carbon fiber is provided. The preparing method adopts a water-phase precipitation polymerization reaction, adopts water-soluble ammonium sulfate-sodium bisulfite-ferrous sulfate as an oxidation-reduction initiation system, adopts a monoester of itaconic acid as a bifunctional copolymerization monomer, and adopts sulfuric acid as a pH conditioner. The bifunctional copolymerization monomer and acrylonitrile are subjected to a precipitation polymerization reaction in a water phase, then the reaction system is alkalified by aqueous ammonia, and after separation, washing and drying, PAN powder is obtained. The preparing method is low in cost, short in polymerization time, and high in production efficiency, and the prepared polyacrylonitrile is high in purity and good in spinnability and preoxidation controllability, so that the preparing method is suitable for large-scale production of carbon fiber precursor and facilitates reduction of the production cost of carbon fiber.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

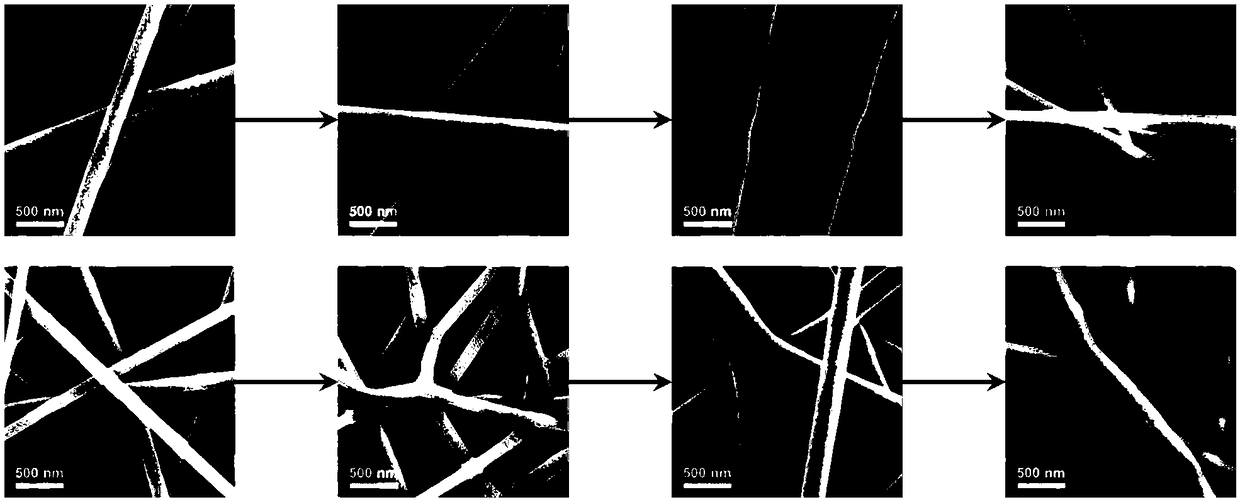

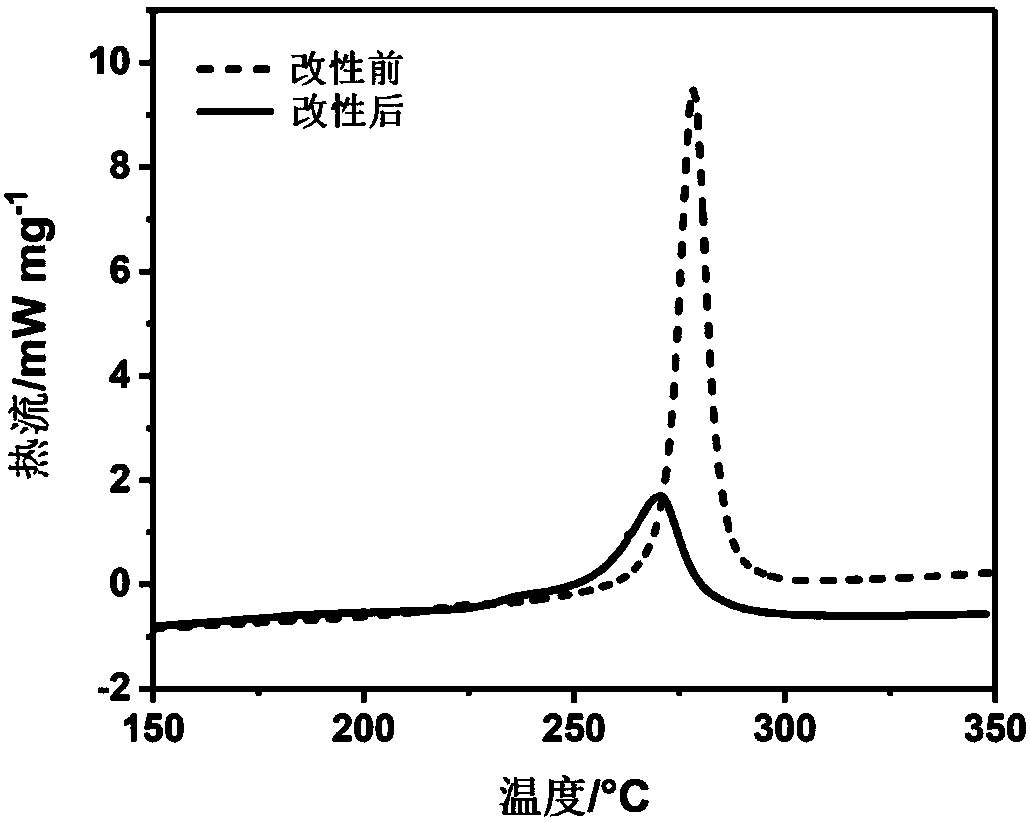

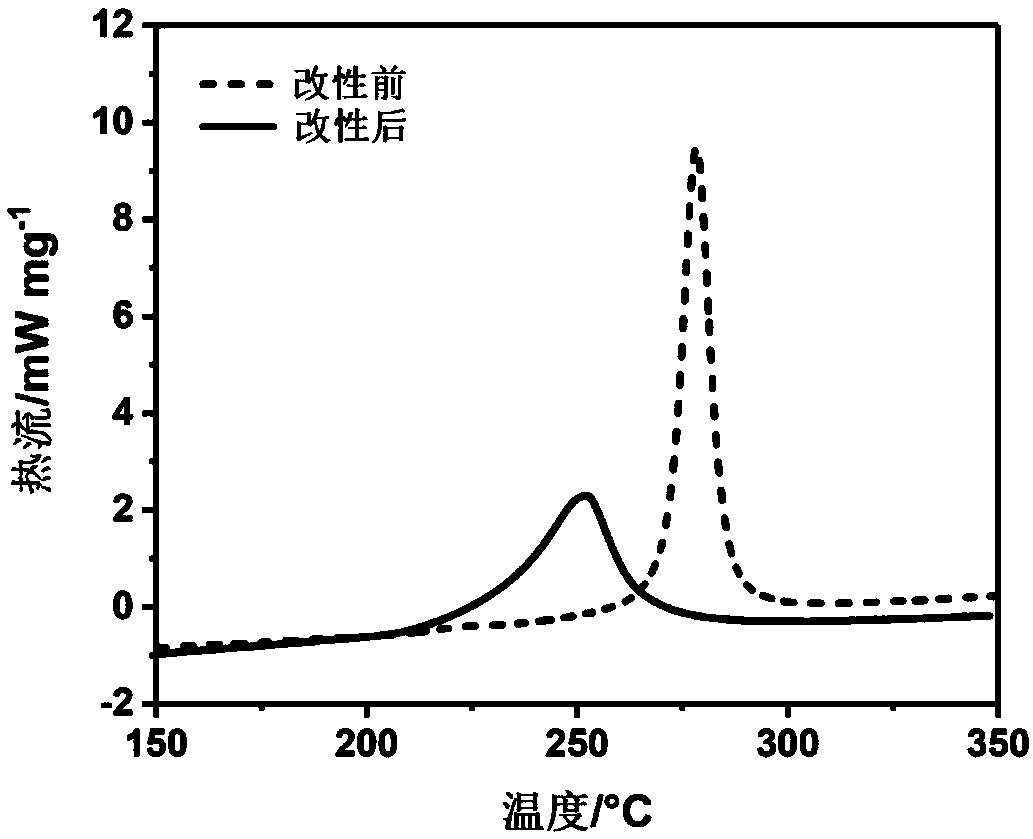

Method for preparing carbon nanofibers from wearing acrylic fibers or waste wearing acrylic fibers

The invention relates to a method for preparing carbon nanofibers from wearing acrylic fibers or waste wearing acrylic fibers, and belongs to the technical field of preparation of the carbon nanofibers. The method includes performing washing, impurity removal and drying pretreatment on the wearing acrylic fibers or the waste wearing acrylic fibers, then re-dissolving the acrylic fibers by good solvents, adding metal salt for modifying, controlling modification temperature and time to obtain spinning precursors, and performing spinning, pre-oxidation and carbonation on the spinning precursors to obtain the carbon nanofibers. The metal salt for modification refers to one or two or more of cobalt acetate, manganese acetate, zinc acetate, ferric acetate, nickelous acetate, copper acetate, magnesium acetate, sodium acetate, cobalt chloride, zinc chloride, manganese chloride, ferric chloride, copper chloride, cuprous chloride or stannous chloride. Raw materials applied to the method are waste. The method has the advantages that cyclization reaction triggering mechanisms of the acrylic fibers during pre-oxidation can be changed, cyclization reaction starting temperatures of the acrylic fibers can be lowered remarkably at the same time, energy conservation and environmental protection can be achieved, and production costs can be reduced remarkably.

Owner:ZHEJIANG SCI-TECH UNIV

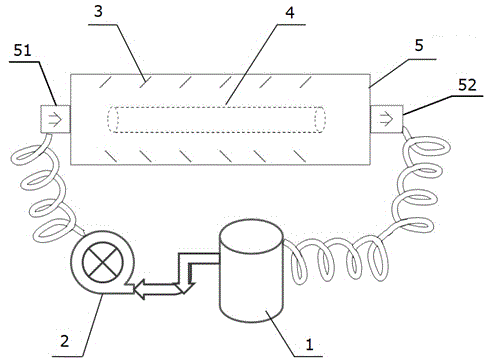

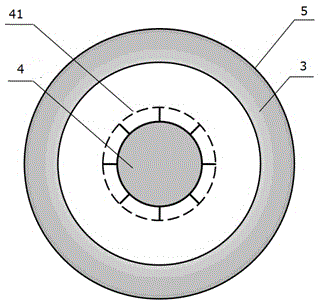

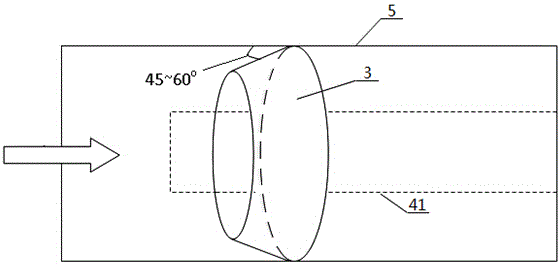

Oxygen-free non-melting Polycarbosilane fiber preparation method and device

ActiveCN104088034AAvoid introducingDoes not melt to achieveSynthetic polymer filament chemical after-treatmentFiberPolymer science

The invention provides an oxygen-free non-melting polycarbosilane fiber preparation method and device. The method comprises the following steps: immersing polycarbosilane fibers into a solution of a peroxide or azo-compound free radical initiator; drying and putting the polycarbosilane fibers into a heating device; vacuumizing and replacing nitrogen or argon; gasifying silane containing vinyl or silazane containing vinyl and circulating in the device; carrying out two-section temperature rising heating under an axis-heating temperature field; and cooling to a room temperature to obtain oxygen-free non-melting polycarbosilane fibers. The invention further provides the oxygen-free non-melting polycarbosilane fiber preparation device which comprises a gasification chamber (1), a circulating fan (2), a reverse spoiler (3), an axis heating circular roller (4) and a tube furnace (5). The oxygen-free non-melting polycarbosilane fiber preparation method and device have the advantages that a chemical gas phase non-melting method is adopted to prevent introduction of oxygen; the non-smelting process of the polycarbosilane fibers is completed under a low temperature; an airflow field of an active atmosphere is uniform; the axis heating is used for uniformly heating the fibers at different positions.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing polyacrylic acid or sodium polyacrylate

InactiveCN101423577BLower the starting temperatureReduce energy consumptionPersulfateReaction temperature

Owner:娄底市裕德科技有限公司

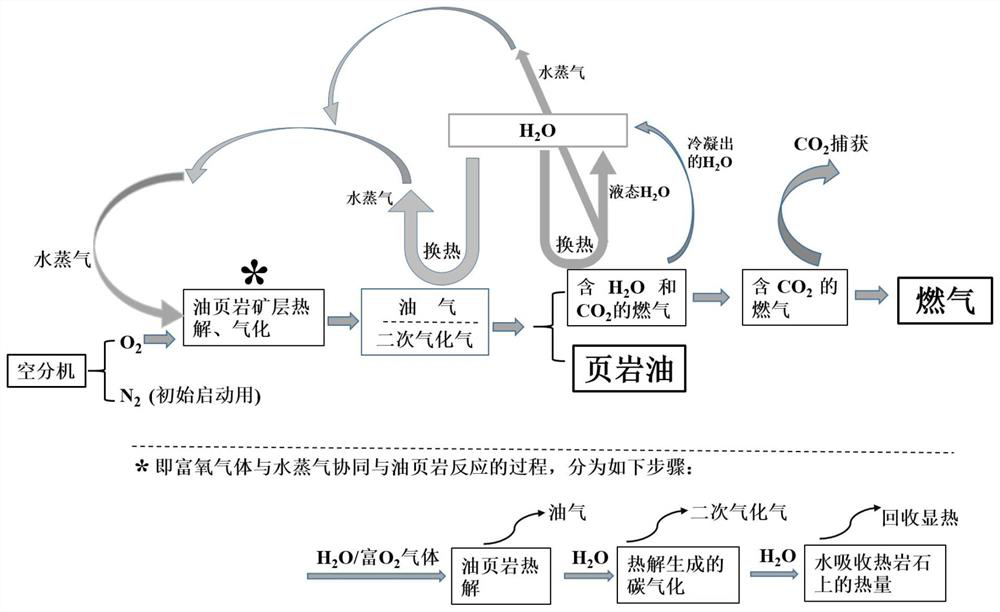

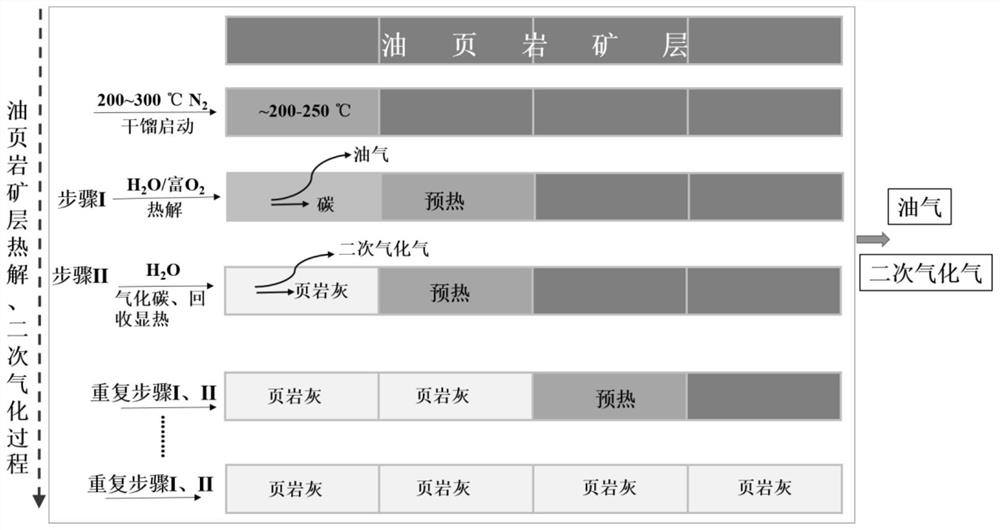

Method for extracting shale oil and high-calorific-value fuel gas by self-heating type underground dry distillation of oil shale

ActiveCN113374460AImprove utilization efficiencyAchieve recyclingMultiple-effect/fractional condensationFluid removalThermodynamicsWater vapor

The invention discloses a method for extracting shale oil and high-calorific-value fuel gas by self-heating type underground dry distillation of oil shale. The method has the advantages that the dry distillation is completed by the synergistic reaction of oxygen-enriched gas and water vapor and the oil shale, so that the pyrolysis reaction is promoted, the reaction of the oil shale is thorough, and the self-cracking dry distillation process is formed by the coupled heat release / heat absorption pyrolysis reaction; after the dry distillation is started, the required heat is mainly provided by the heat released by low-temperature oxidizing of fixed carbon produced by cracking of the oil shale, the remained fixed carbon is gasified into the fuel gas of H2, CO and the like, and the high-temperature sensible heat produced after the dry distillation reaction is also recycled; the problems of complicated oil and gas extraction systems by dry distillation of the oil shale, large management difficulty, low oil yield and the like are solved; and the operation is simple, the extraction cost is lower, the extraction efficiency and resource utilization rate are higher, the emission of three wastes is little, the environment benefit is obvious, and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

UV curing heat reducing adhesive, preparation method and application thereof

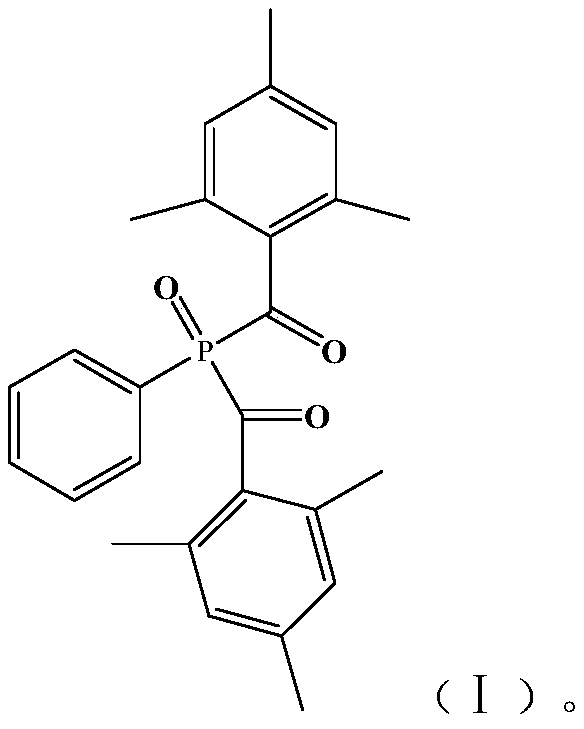

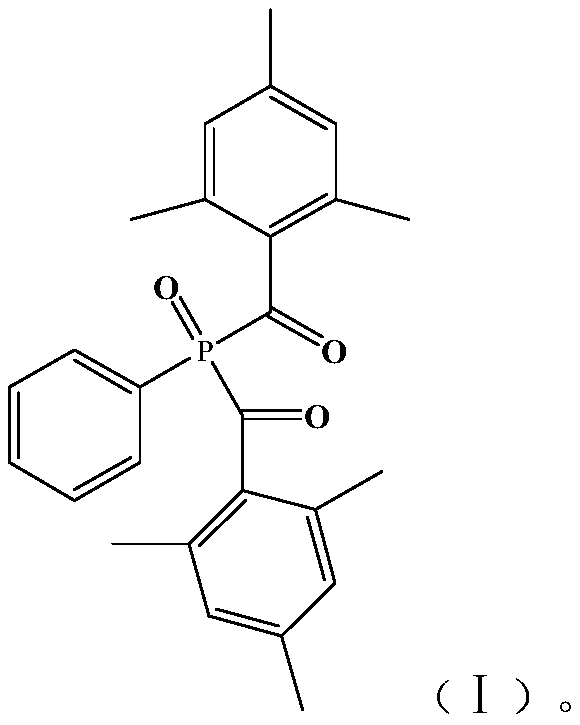

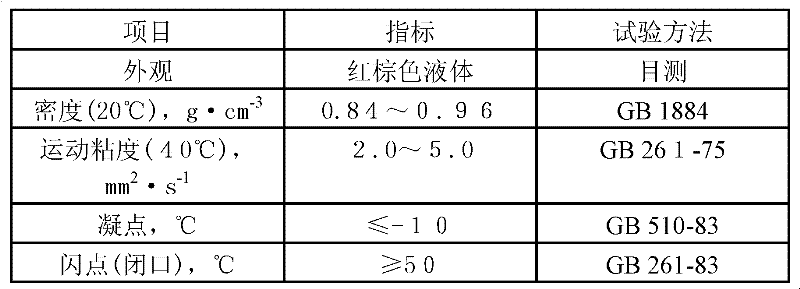

ActiveCN109749672AGood initial adhesionLower the starting temperatureFilm/foil adhesivesPolyureas/polyurethane adhesivesIsooctyl acrylatePolymer science

The invention discloses a UV curing heat reducing adhesive, a preparation method and an application thereof. Adhesive raw materials comprise prepolymer resin, polyurethane acrylate, a reactive diluent, a photoinitiator and thermal expansion microspheres. According to the mass percentage, the raw materials of the prepolymer resin comprise 60-94.5% of 2-ethylhexyl acrylate, 5-39.5% of (meth) acrylate and 0.01-1% of the compound shown in a formula (I), and the prepolymer resin are prepared by reacting the three raw materials. The preparation method includes, firstly, preparing the prepolymer resin, and then mixing the prepolymer resin with other raw materials of the adhesive to prepare the prepolymer resin. The invention discloses the application of a UV curing heat reducing adhesive tape made of the adhesive and the adhesive tape in the 2.5D and 3D glass edge sweeping processes. The adhesive has the advantages of excellent initial adhesive force, low initial temperature of thermal viscosity reduction and high viscosity reduction speed, and the heat reducing adhesive tape prepared from the adhesive does not have the phenomena of powder crumbs and residual glue in the use process, andthe adhesive has the advantages of low VOC, high coating production speed and the like.

Owner:CYBRID TECHNOLOGIES INC

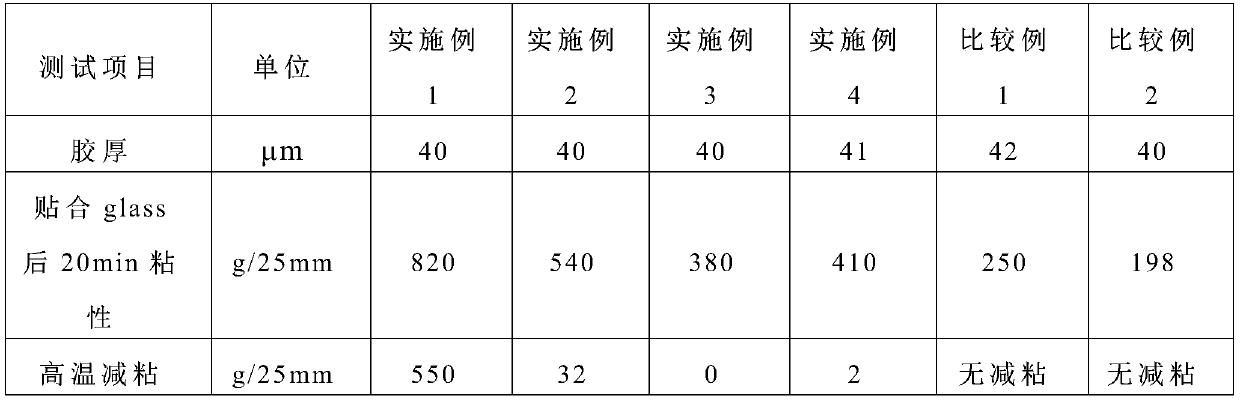

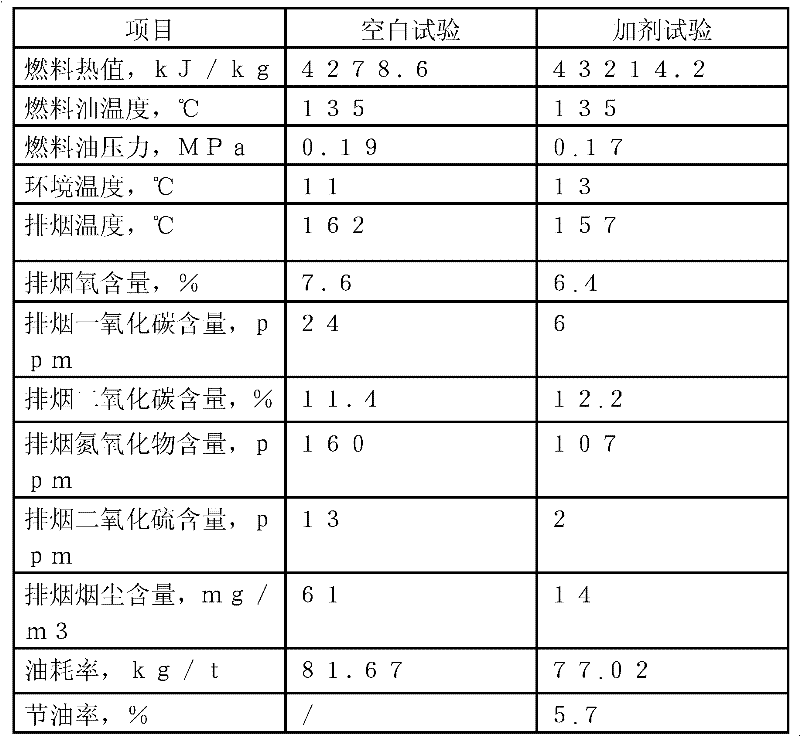

Multifunctional ashless combustion accelerant of heavy oil

InactiveCN102199458AHigh thermal efficiencyReduce consumptionLiquid carbonaceous fuelsAir quality improvementFuel oilNitric oxide

The invention relates to a multifunctional ashless combustion accelerant of heavy oil. The multifunctional ashless combustion accelerant is characterized by comprising a free oxygen generating agent, a catalyst, a dispersing agent and a solvent. The invention aims at solving the technical problem of providing a multifunctional ashless combustion accelerant, which has the advantages of combustion acceleration (oil saving), smoke abatement and reduced emission of harmful gases. According to the multifunctional ashless combustion accelerant of the heavy oil, the calorific value of a fuel can be increased, and the discharged smoke content and the oil consumption are reduced; the fuel oil undergoes a more complete combustion after the multifunctional ashless combustion accelerant of the heavy oil is added; in addition, the nitric oxide content and the sulfur dioxide content in discharged smoke are remarkably reduced, and the atmospheric pollution can be improved after the multifunctional ashless combustion accelerant of the heavy oil is added. When the addition amount of the multifunctional ashless combustion accelerant of the heavy oil is 0.3 percent, the oil saving ratio can reach more than 5 percent.

Owner:JIANGSU KECHUANG PETROCHEM

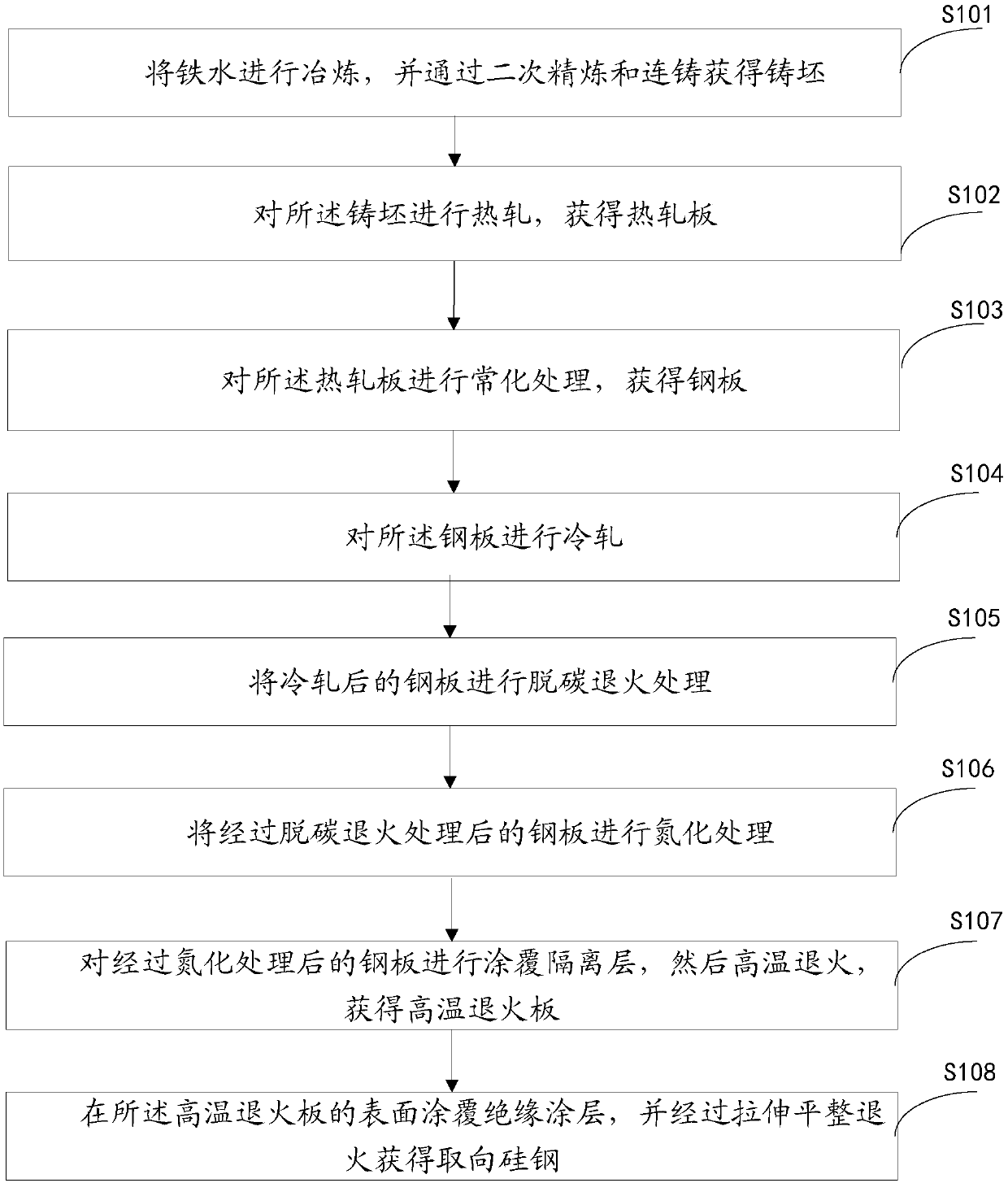

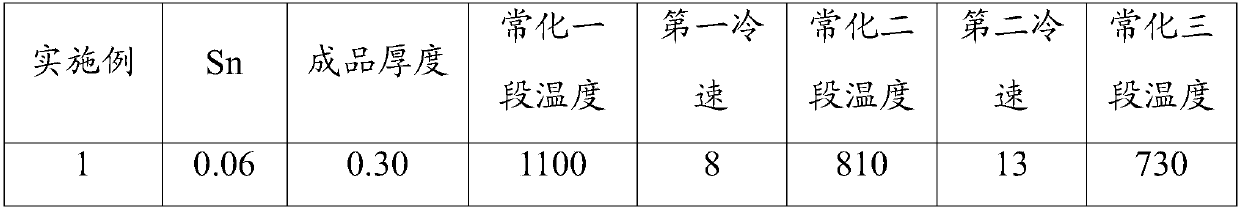

Production method of oriented silicon steel

An embodiment of the invention discloses a production method of oriented silicon steel. The method includes: smelting molten iron, and performing secondary refining and continuous casting to obtain casting blanks; performing hot rolling on the casting blanks to obtain hot-rolled plates; normalizing the hot-rolled plates to obtain steel plates; performing cold rolling on the steel plates, and performing decarburization annealing on the cold-rolled steel plates; performing nitriding on the steel plates after the decarburization annealing; coating the steel plates after the nitriding with isolating layers, performing high-temperature annealing to obtain high-temperature-annealed plates; coating the surfaces of the high-temperature-annealed plates with insulating coating layers, and performingstretching, flattening and annealing to obtain the oriented silicon steel. By the production method, the technical problem that a method using a two-stage normalizing process to produce the orientedsilicon steel is poor in magnetic performance and rolling performance in the prior art is improved.

Owner:BEIJING SHOUGANG CO LTD

Method for generating polyether by virtue of ethoxylation reaction under photocatalysis conditions

The invention relates to a method for generating polyether by virtue of ethoxylation reaction under photocatalysis conditions. The method comprises the following steps: adding an alkenyl alcohol compound into a reaction reactor; adding a nanometer TiO2 photocatalyst and a reducing agent, introducing ethylene oxide or epoxypropane after N2 replacement, fully contacting the materials by virtue of a stirring and outer circulation mode, uniformly mixing, and maintaining the pressure of the reaction system to be 2-3kg / cm<2>; introducing a light source into the reaction system for irradiating, heating to the temperature of 70-80 DEG C, and reacting in the temperature range for 2-3 hours. The environment-friendly photocatalytic polymerization process is adopted, the reaction conditions are mild, the production process is easy to control, the hydroxyl value of the product is stable, the reaction activity is high, the molecular weight distribution is uniform, and the production cost is low.

Owner:SHANXI KAIDI BUILDING MATERIALS

Method for preparing silicoferrite-containing Al13 by utilizing aluminum ash slag

InactiveCN101817580AImprove performanceHigh dissolution rateSedimentation separationAluminium chloridesSlagFerrosilicon

The invention relates to a method for preparing silicoferrite-containing Al13 by utilizing aluminum ash slag, which belongs to the technical field of harmless and resourceful treatment of wastes. The method is completed as follows: the method for preparing the silicoferrite-containing Al13 by utilizing the aluminum ash slag comprises the following steps: (1) uniformly mixing aluminum ash with Na2CO3, then placing in a furnace for calcination, and obtaining off-white powder; (2) placing the off-white powder into a container, and then adding hydrochloric acid for carrying out acid leaching reaction; (3) carrying out solid-liquid separation on acid-leached products, and obtaining sediments and solution containing Fe3+ and AlCl3; (4) adding alkaline solution into the obtained sediments for carrying out reaction, carrying out the solid-liquid separation and obtaining the sediments and Na2SiO3 solution; and (5) adding the Na2SiO3 solution into the AlCl3 solution, uniformly mixing, regulating the pH of the solution and obtaining the silicoferrite-containing Al13. The method has the advantages of simple process, less residue, low cost and less pollution.

Owner:ZHEJIANG NORMAL UNIVERSITY

Polyacrylic acid or copolymer thereof and preparation method of polyacrylate or copolymer salt thereof

ActiveCN101921359BGood production safetyPromote environmental protectionPolymer scienceSodium Hypophosphite Monohydrate

Owner:湖南葆华环保科技有限公司

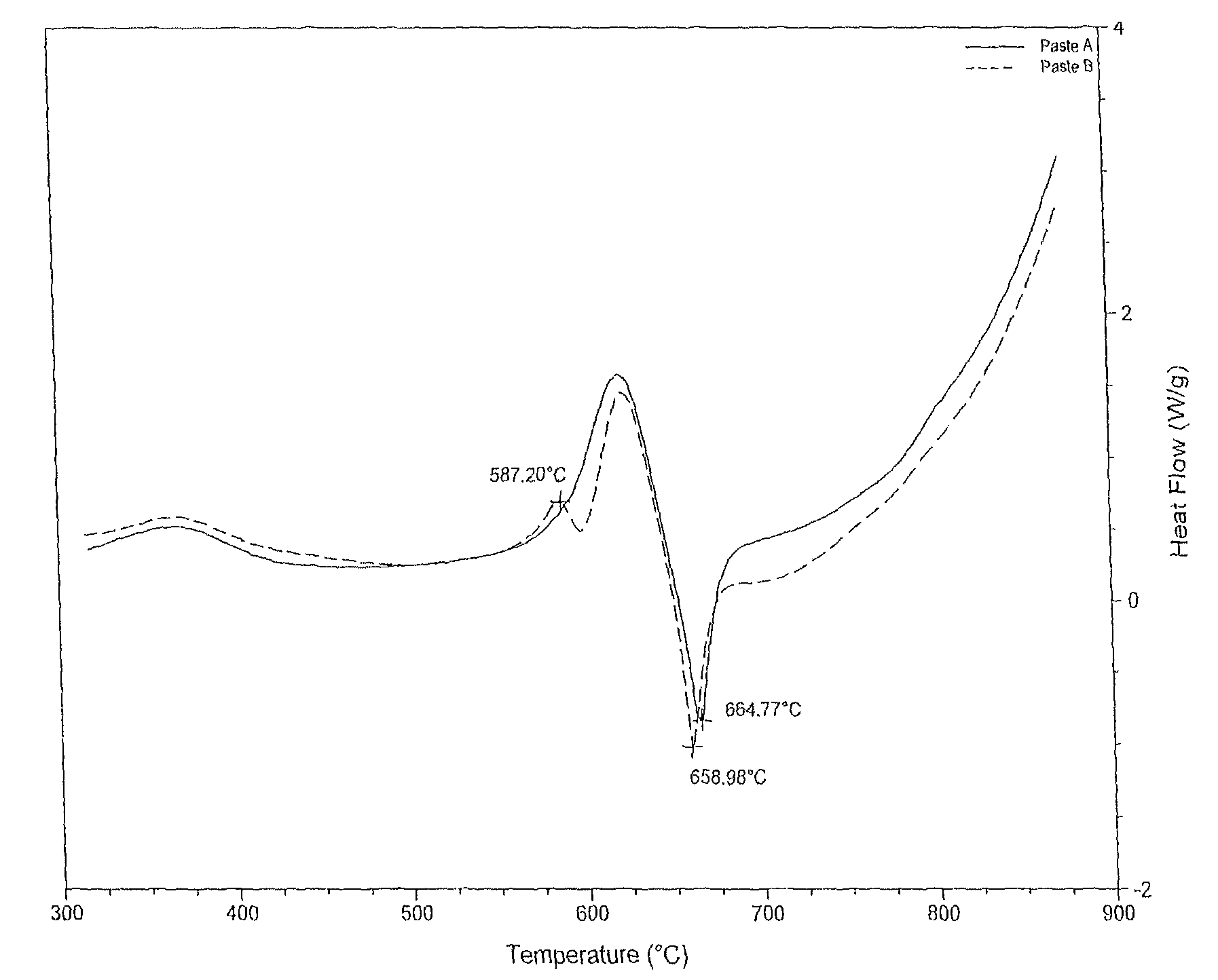

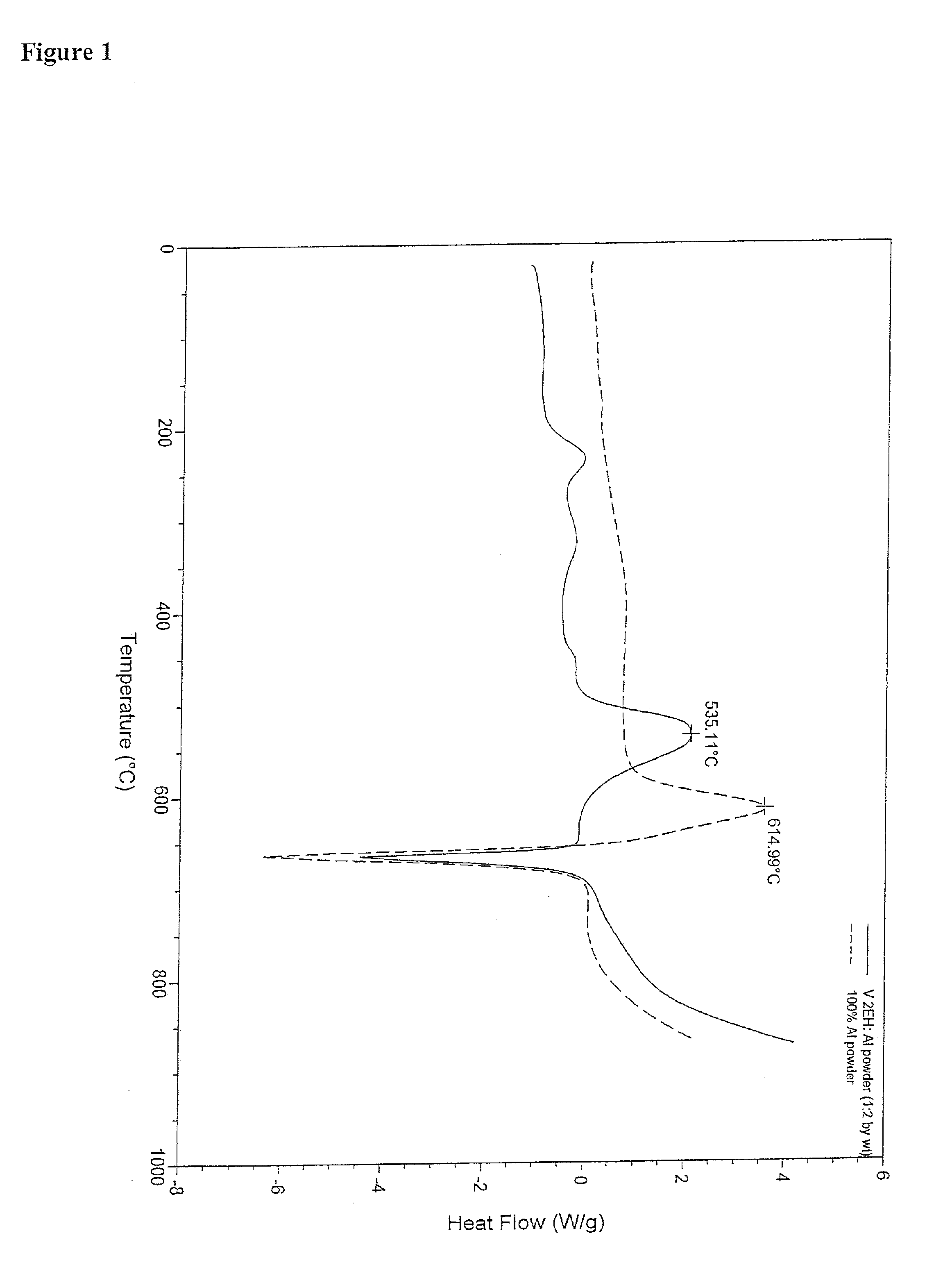

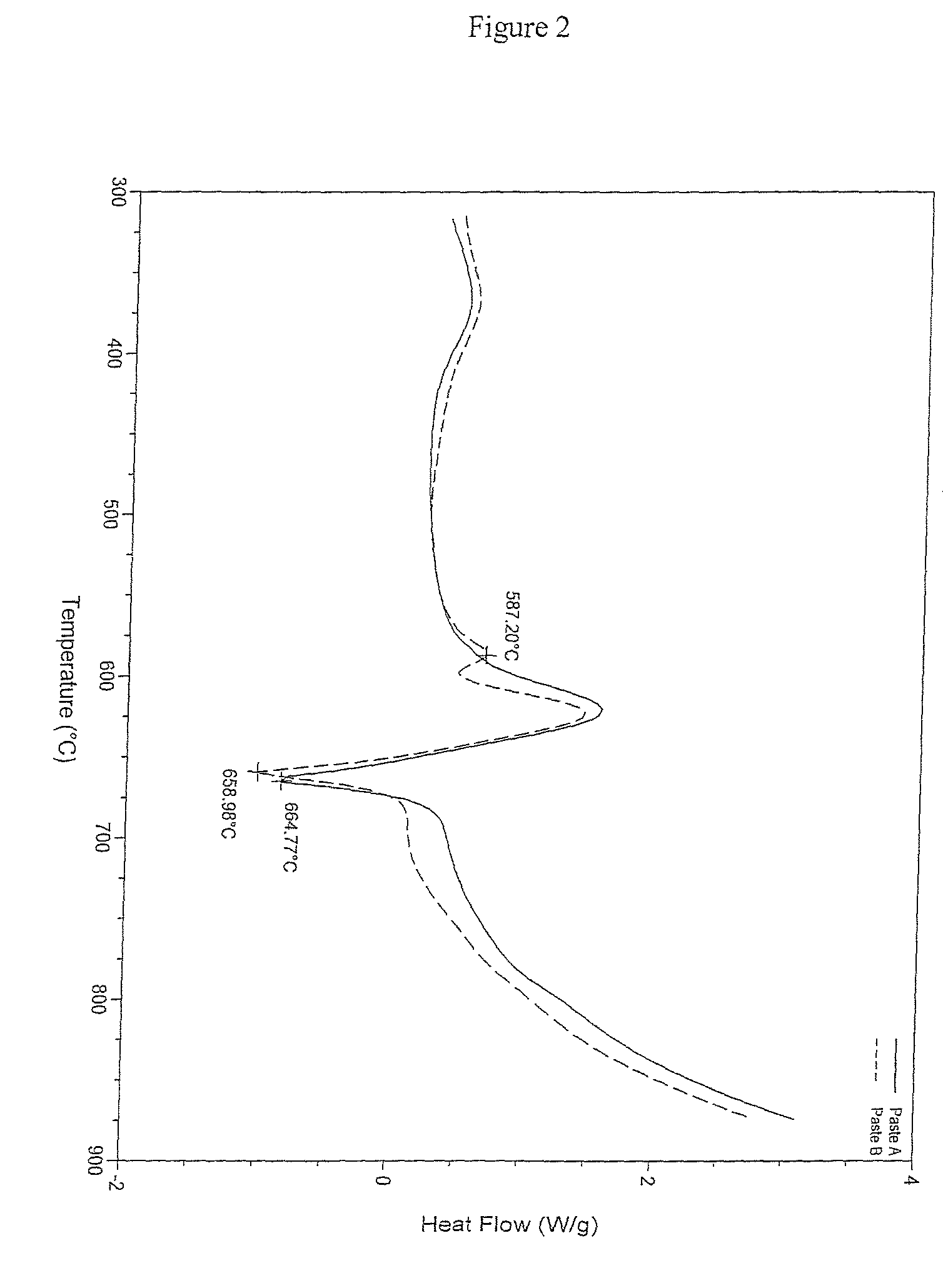

Vanadium, cobalt and strontium additives for use in aluminum back solar cell contacts

InactiveUS8709862B2Electrical performance be improveImprove electrical performanceSemiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialPhysical integrityElectricity

Al pastes with additives of Co, Sr, V, compounds thereof and combinations thereof improve both the physical integrity of a back contact of a silicon solar cell as well as the electrical performance of a cell with such a contact.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

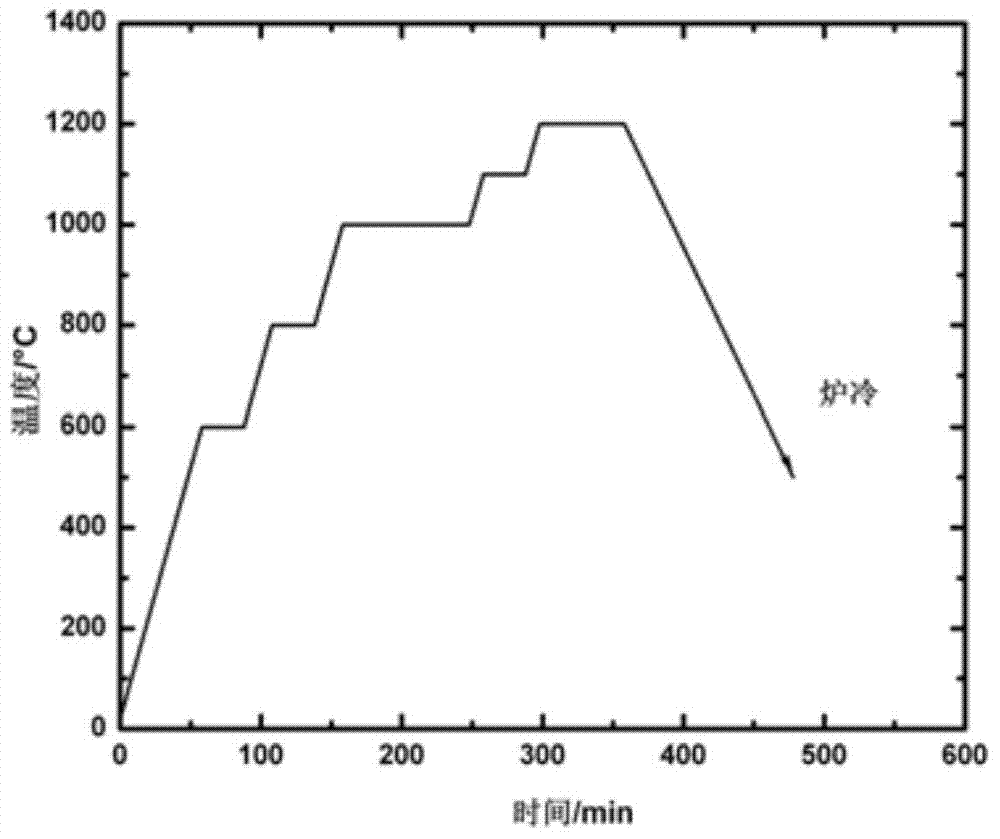

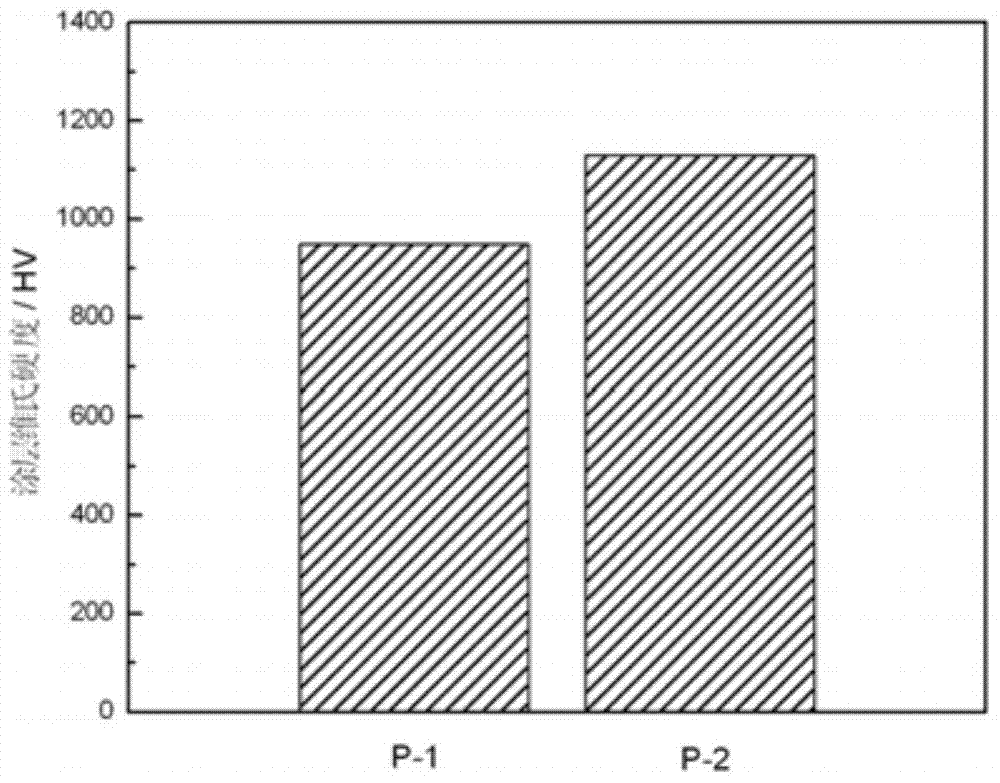

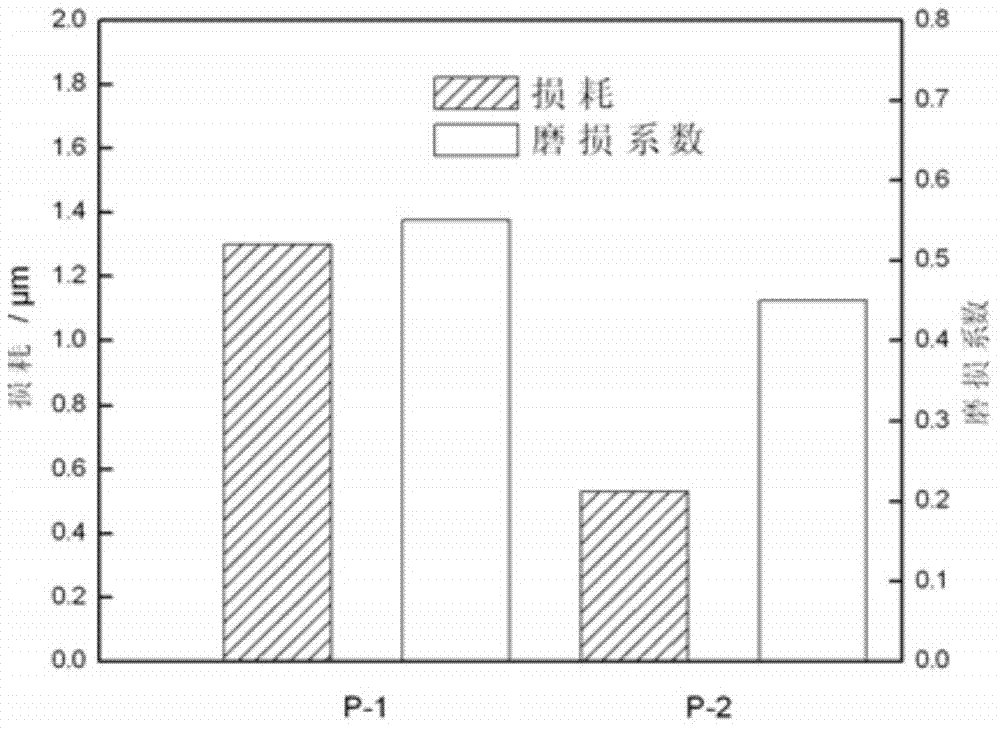

Preparation method of Mo2FeB2-base metal ceramic coating applied to surface of die steel

InactiveCN104264092ARaw materials are easy to getReduce manufacturing costMolten spray coatingCeramic coatingArgon gas

The invention discloses a preparation method of Mo2FeB2-base metal ceramic coating applied to surface of die steel. The preparation method of the Mo2FeB2-base metal ceramic coating applied to the surface of the die steel comprises the following steps: burdening the following raw materials in percentage by mass: 12.00-16.00% of Fe powder, 30.00-35.00% of FeB powder, 40.00-45.00% of Mo powder, 0.50-2.00% of B powder, 2.00-3.00% of Cr powder, 2.00-3.00% of Ni powder, 2.00-3.00% of Mn powder and 0.20-0.50% of C powder; carrying out dry grinding in presence of argon, and then filtering; then spraying mixed powder onto the surface of die steel; and finally sintering at the temperature of 1200 DEG C in a vacuum sintering furnace. By adopting the preparation method of the Mo2FeB2-base metal ceramic coating, the hardness, elastic modulus and abrasion resistance of the metal ceramic coating are improved.

Owner:TIANJIN UNIV

Pretreatment method of polyacrylonitrile base carbon fiber precursor

InactiveCN102720058ALower the starting temperaturePrevent fusion bondingFibre treatmentFibre chemical featuresPretreatment methodCarbon fibers

The invention belongs to the technical field of carbon fiber preparation, and particularly relates to a pretreatment method of polyacrylonitrile base carbon fiber precursor. In the method, the polyacrylonitrile base carbon fiber precursor needing pre-oxidation is soaked for a certain time in an amino acid solution with concentration of 7-30% by mass, wherein the amino acid comprises lysine and arginine, and the soaking temperature is 25-85 DEG C. Through the invention, the technical problems of complicated operation, environmental pollution and the like of the existing precursor pretreatment technology are solved. The method provided by the invention is simple to operate and pollution-free, can effectively reduce the starting temperature of the cyclization reaction, reduces the heat discharge in the pre-oxidation process, and avoids the fusion bonding of the precursor in the subsequent treatment processes.

Owner:FUDAN UNIV

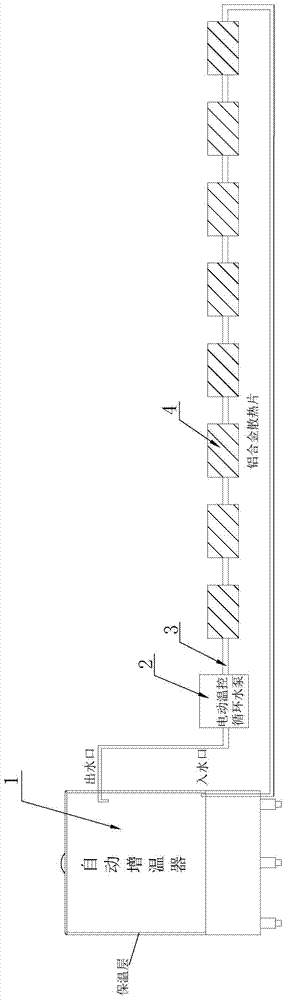

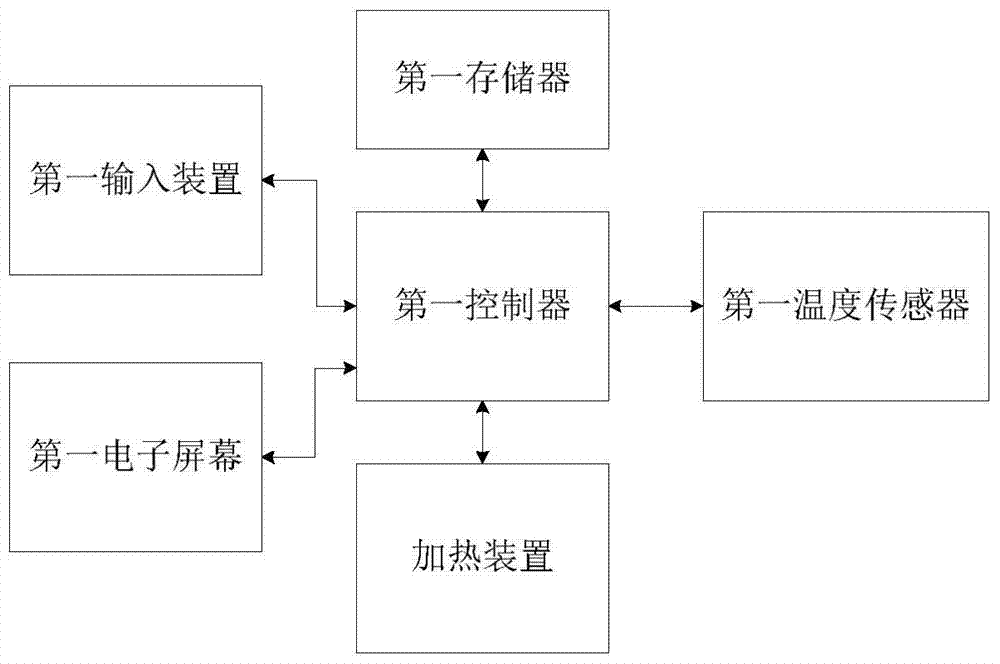

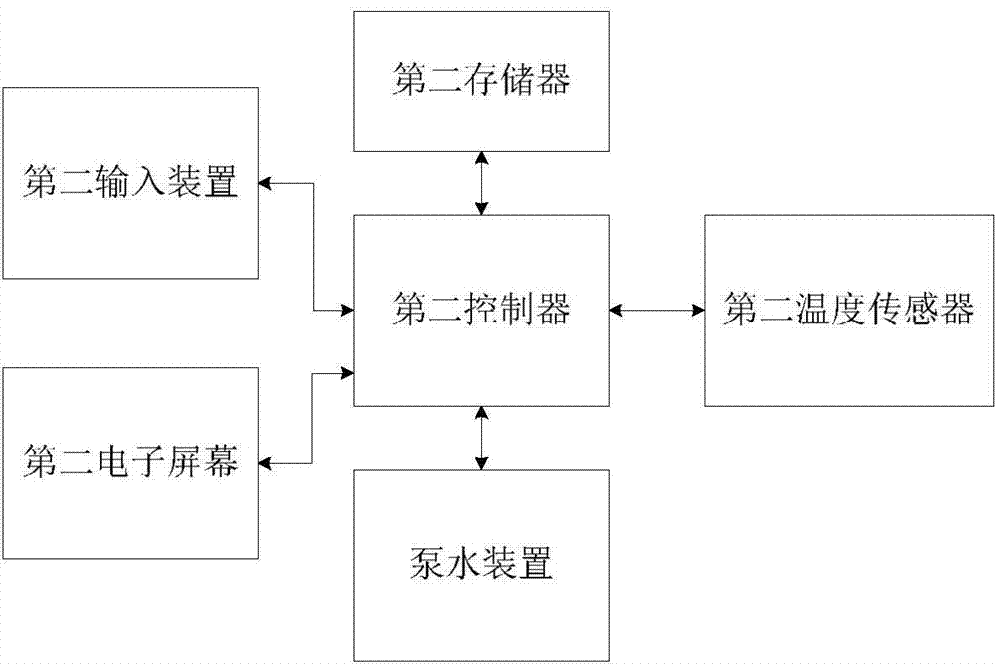

Full-automatic low-energy-consumption warming system of greenhouse

ActiveCN104488610ANo need to addNo pollution in the processClimate change adaptationSaving energy measuresWater useTemperature control

The invention discloses a full-automatic low-energy-consumption warming system of a greenhouse. The full-automatic low-energy-consumption warming system comprises an electric temperature control circulating water pump, a water conveying pipe, heat radiation sheets and an automatic warming device with a heat preservation function, wherein the automatic warming device is provided with a liquid capacity cavity, a water outlet and a water inlet; the water outlet of the automatic warming device, the electric temperature control circulating water pump, the plurality of heat radiation sheets and the water inlet are connected in sequence by the water conveying pipe to form a heat-transfer cycle loop; heat absorption coatings coat the outer parts of the heat radiation sheets. The starting temperature of repeatedly heating a heat transfer medium is very high through the heat preservation function of the automatic warming device and the heat absorption function of the heat radiation sheets coated with heat absorption materials, so that the energy consumption is extremely saved, the energy efficiency is high and the warming cost is saved. Overall, the full-automatic low-energy-consumption warming system has the advantages of energy conservation, environment friendliness and no pollution, uniformity in warming, low cost and high energy efficiency, full-automatic warming, water conservation, and flexibility and convenience for setting, and can be widely popularized and applied.

Owner:李众彻

Catalyst for treating organic waste gas and preparation method thereof

InactiveCN101733127BSuitable for handlingFully catalyzedDispersed particle separationCatalyst activation/preparationPhysical chemistryCopper oxide

The invention relates to a catalyst for treating organic waste gas and a preparation method thereof, belonging to the control technology of atmospheric pollution and the field of environment protection materials. In the catalyst, copper oxide, manganese oxide and titanium oxide are used as active ingredients, and a catalyst carrier is self-made; based on the mass of the carrier, the active ingredients are mixed in the molar ratio of copper oxide, manganese oxide to titanium oxide being 1-4: 1-4: 0.5-1; and the mass percentage of the capacity of the active ingredient is 1-20%. The self-made carrier is prepared by using silicon oxide, aluminum oxide, magnesium oxide and ferric oxide as components which are baked at high temperature, wherein the mass percentage of the material is 28-55% of silicon oxide, 20-40% of aluminum oxide, 10-30% of magnesium oxide and 0.5-2% of ferric oxide; and the carrier is modified or modified through an aluminum oxide coating by using 5-20% acid in mass percentage. The catalyst can completely catalyze toluene at 250 DEG C, and the complete catalysis temperature is reduced by about 20 DEG C compared with the same kind of catalysts.

Owner:NANJING TECH UNIV

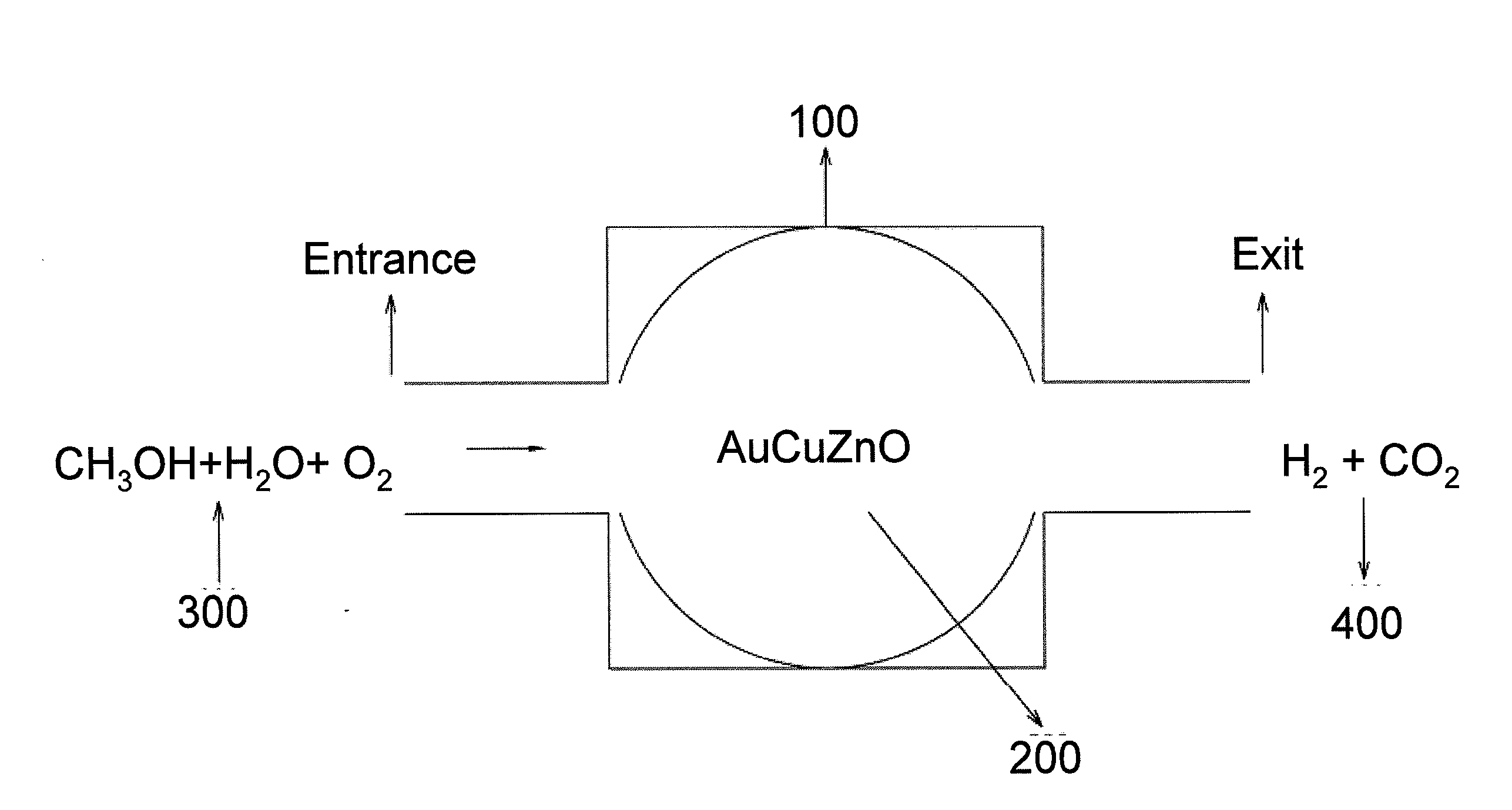

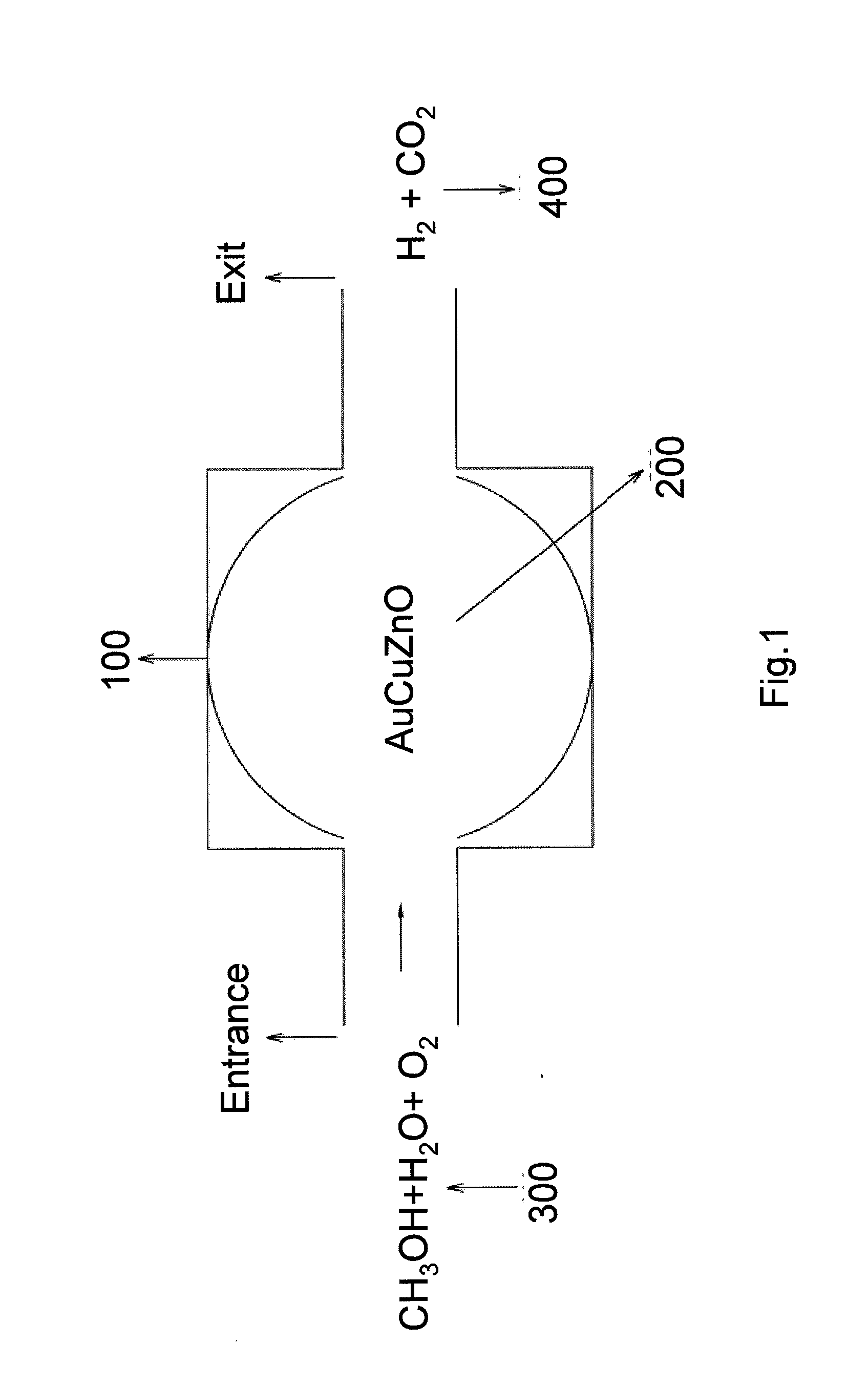

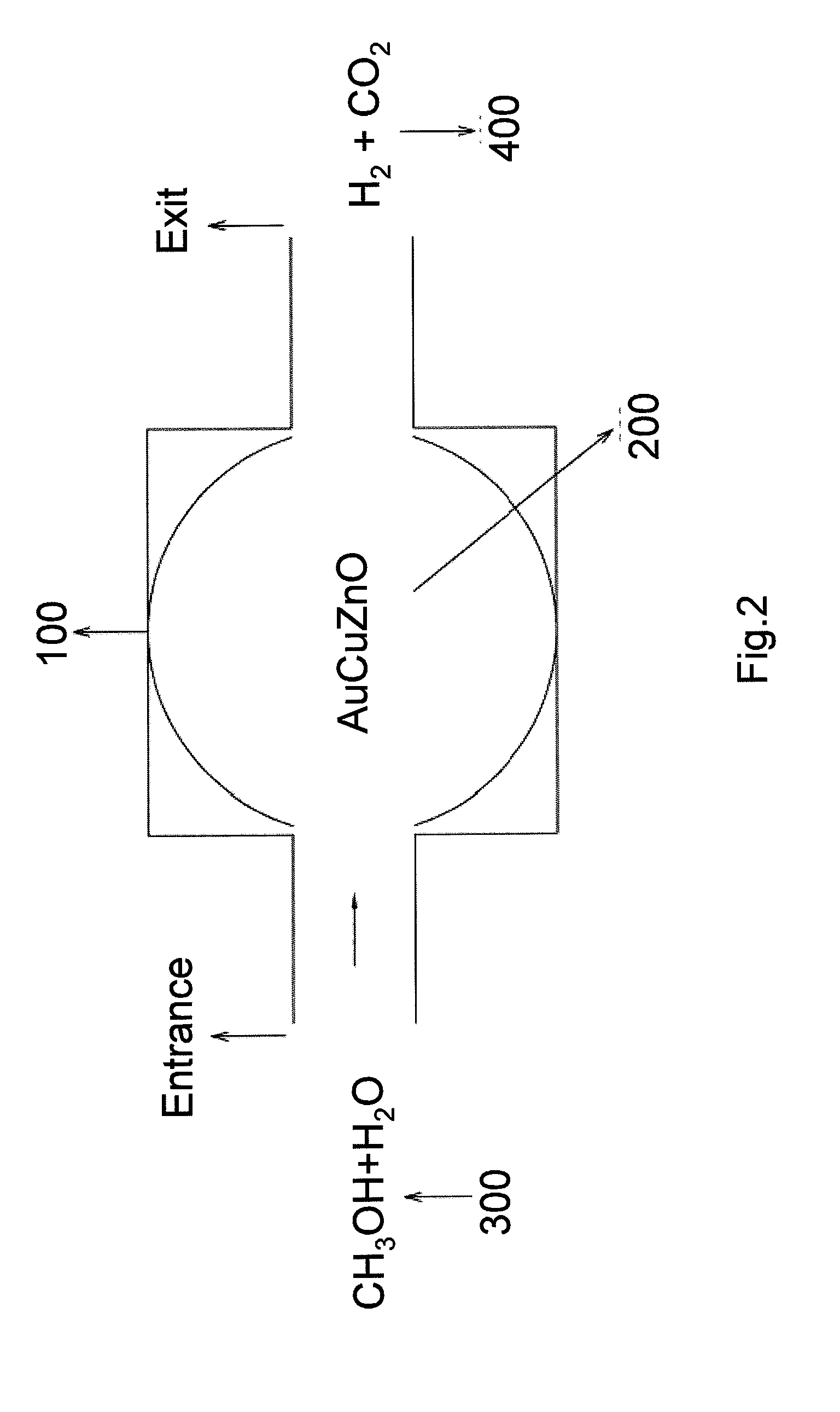

Process for producing hydrogen at low temperature

InactiveUS20110305628A1Lower the starting temperatureHigh catalytic efficiencyHeterogenous catalyst chemical elementsCatalyst activation/preparationSteam reformingHydrogen

An oxidative steam reforming of methanol (OSRM) process at low temperature includes providing a gas mixture comprising methanol, steam and oxygen and conducting the gas mixture to flow through an AuCu / ZnO-based catalyst for undergoing OSRM process to generate hydrogen, wherein an initiation temperature of OSRM is less than 175° C. The AuCu / ZnO catalyst of the present invention may lower the initiation temperature of the OSRM process and remains to have good catalytic efficiency without undergoing pre-reduction. A steam reforming of methanol (SRM) process is also herein provided.

Owner:NATIONAL TSING HUA UNIVERSITY

Surface overlaying method of thin-walled metal

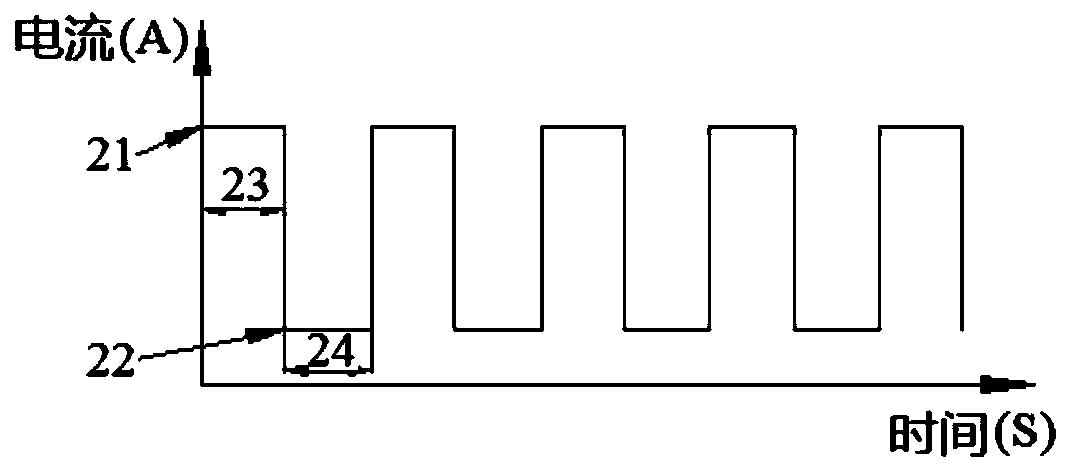

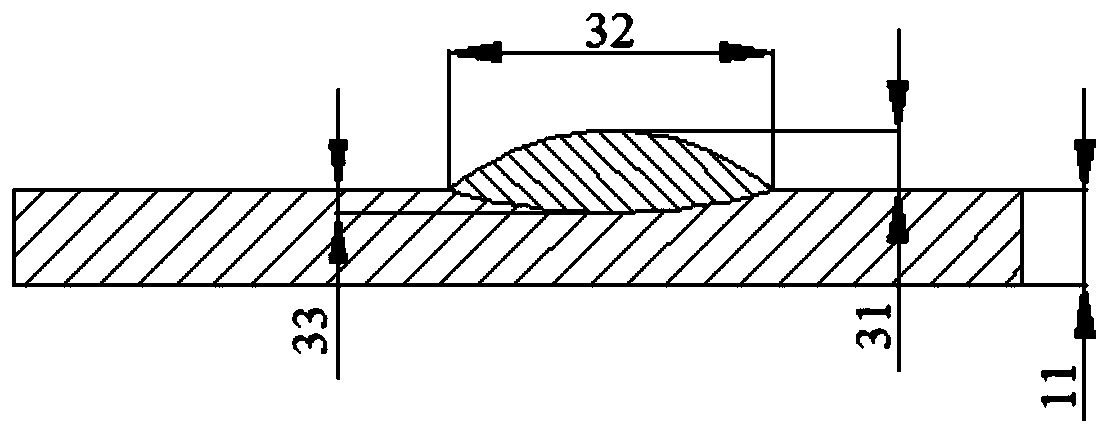

ActiveCN111421204AAdvantages of surface welding methodIncrease temperatureWelding accessoriesPeak currentCurrent switch

The invention discloses a surface overlaying method of thin-walled metal. The surface overlaying method of the thin-walled metal comprises the following steps that (1) a power source capable of achieving peak current-valley current output is selected, and by adjusting a peak current, the time of the peak current, a valley current and the time of the valley current, weld beads meeting requirementsare obtained; (2) welding of different weld beads is sequentially completed, so that a weld layer is formed; (3) the step (2) is repeatedly executed, welding of different weld layers is sequentially completed, and then welding of all the weld layers is completed. Compared with the prior art, the surface overlaying method of the thin-walled metal utilizes the power source with the peak current-valley current switching feature to avoid the situation that the peak current continuously heats the surface of the metal and causes the temperature of the metal to be excessively high, and the quality problems of burning through of the back face of the metal, excessive oxidization and the like can be avoided.

Owner:LINGAO NUCLEAR POWER +5

Low-temperature-resistant spandex fiber and preparation method thereof

PendingCN114293281AHigh response rateLower the starting temperatureMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to a low-temperature-resistant spandex fiber and a preparation method thereof. The low-temperature-resistant spandex fiber is prepared by the following steps: reacting polyether glycol with diisocyanate to obtain a polyurethane prepolymer, reacting the polyurethane prepolymer with mixed amine to obtain a polyurethane urea solution, and carrying out dry spinning by taking the polyurethane urea solution as a raw material, wherein the polyether glycol contains a side group structure. The preparation method comprises the following steps: mixing polyether glycol and diisocyanate to react, so as to obtain an isocyanate group-terminated polyurethane prepolymer; dissolving the polyurethane prepolymer by adopting an organic solvent to obtain a prepolymer solution; adding a mixed amine solution into the prepolymer solution to carry out chain extension reaction to obtain a polyurethane urea solution, adding a plasticizer, fully curing to obtain a spinning solution, and carrying out dry spinning on the spinning solution to obtain the low-temperature-resistant spandex fiber. The prepared spandex fiber has good low temperature resistance and excellent fatigue resistance and mechanical properties.

Owner:ZHEJIANG HUAFENG SPANDEX

Adsorption-catalyst for treating phenol containing waste-water, preparation method and application thereof

InactiveCN100528346CImprove adsorption capacityMild conditions for catalytic oxidationWater contaminantsCatalyst activation/preparationActivated carbonPtru catalyst

An adsorption-catalyst for treating phenol-containing wastewater, characterized in that Cu is used as an active component, K, Zn or Ce is used as an auxiliary component, activated carbon is used as a carrier, and its weight percentage is composed of: Cu1%-5%, auxiliary components 1%-5%, activated carbon 85%-98%, and the surface area of activated carbon is 500-1500m2 / g. Prepared by equal volume co-impregnation method. The phenol-containing wastewater is passed through the adsorption-catalyst with activated carbon as the carrier. After the adsorption is completed, it is dried at room temperature, and the oxidizing gas is passed through to react. The adsorption-catalyst of the present invention has the advantages of good adsorption performance, mild catalytic oxidation conditions, low energy consumption, simple process, simple operation, in-situ catalytic oxidation, and no secondary pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com