Preparation method of Mo2FeB2-base metal ceramic coating applied to surface of die steel

A ceramic coating, mo2feb2 technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve the problems of metal materials can not meet the mold requirements, material waste economy, failure and scrap, etc., to improve the diffusion driving force , The effect of reducing the initial temperature and increasing the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

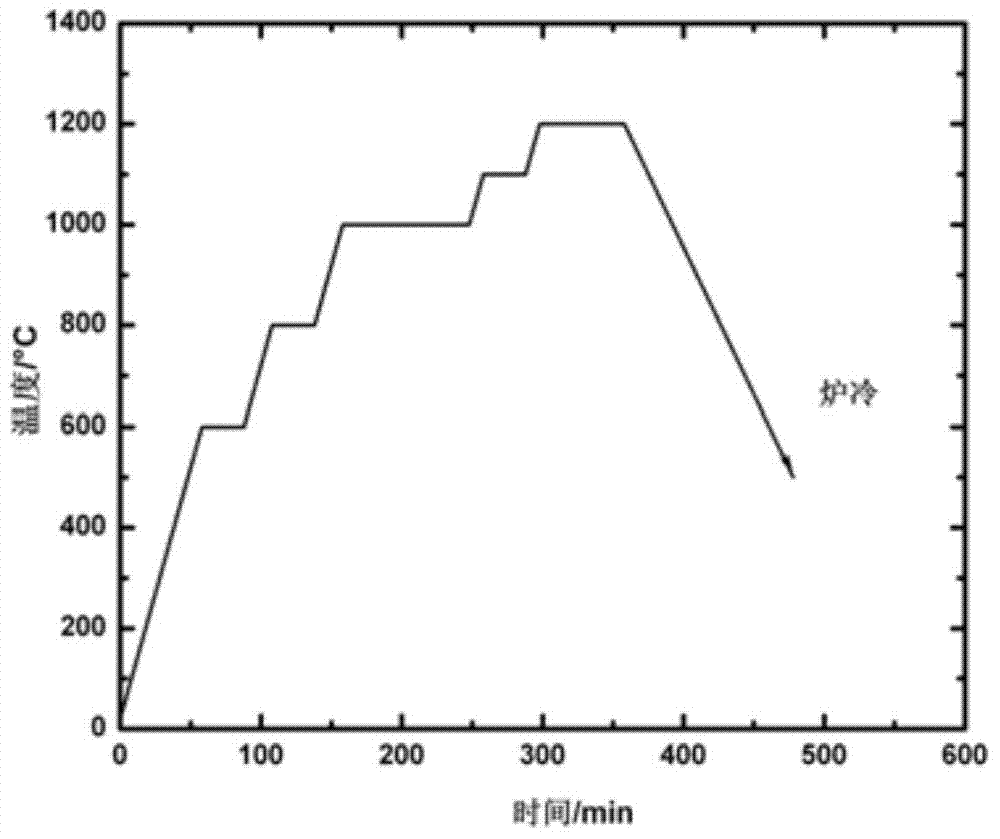

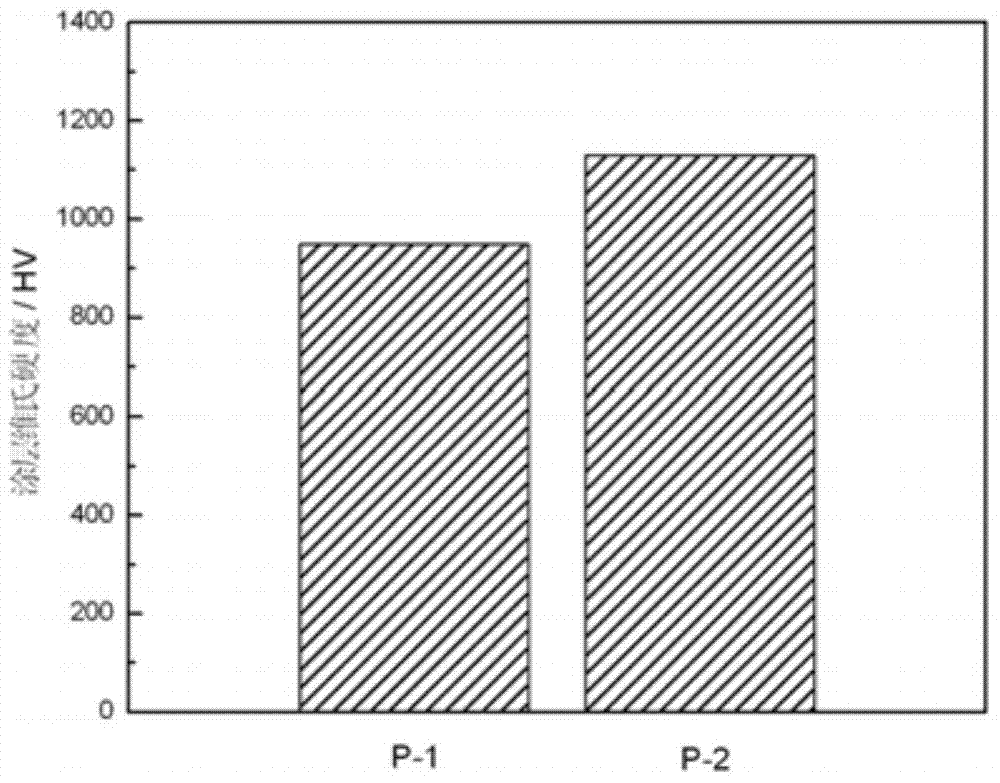

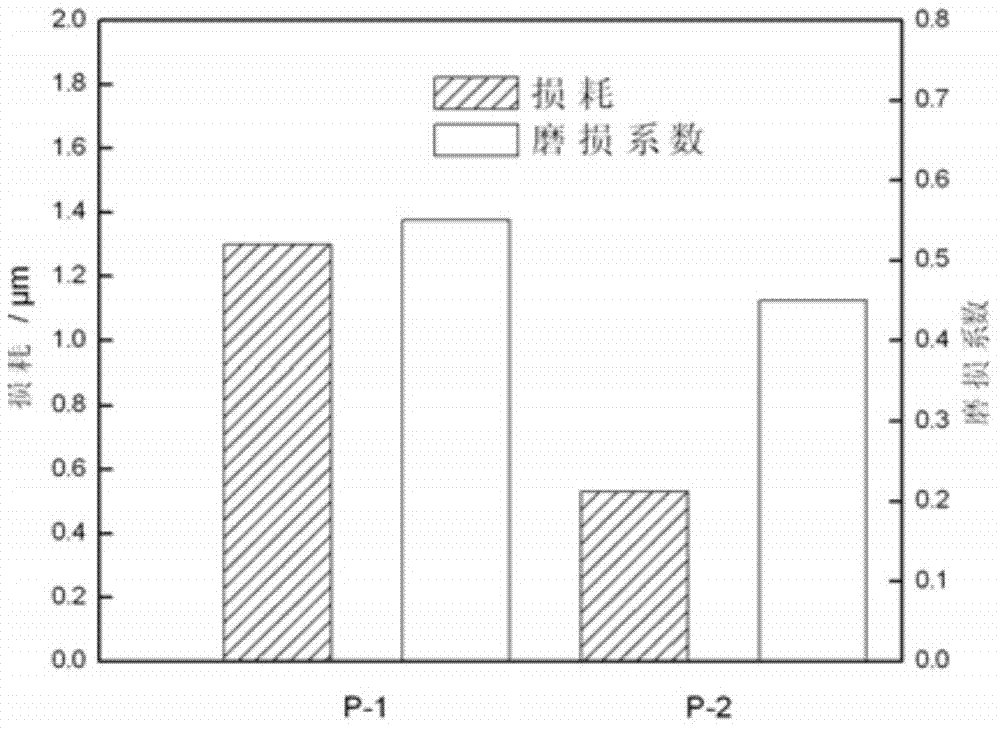

[0028] Fe powder 16.00%, FeB powder 30.00%, Mo powder 45.00%, B powder 0.66%, Cr powder 2.50%, Ni powder 3.00%, Mn powder 2.34%, C powder 0.50%. The above raw materials were fully ball-milled in a QM-3SP2 planetary ball mill for 4 hours, dry-milled under the protection of argon, and sieved; then the ball-milled powder was sprayed on the surface of H13 mold steel; 2 FeB 2 The H13 mold steel with cermet coating is sintered in a GSL1300 vacuum sintering furnace. The sintering system is to put the sample into the sample after heating up to 600°C, and after sintering at 600°C×30min+800°C×30min+1000°C×90min+1100°C×30min+1200°C×60min, it is cooled to room temperature with the furnace, and the sintering process refers to figure 1 .

Embodiment 2

[0030] Fe powder 15.18%, FeB powder 34.00%, Mo powder 40.00%, B powder 1.32%, Cr powder 3.00%, Ni powder 3.00%, Mn powder 3.00%, C powder 0.50%. The above raw materials were fully ball-milled in a QM-3SP2 planetary ball mill for 4 hours, dry-milled under the protection of argon, and sieved; then the ball-milled powder was sprayed on the surface of H13 mold steel; 2 FeB 2 The H13 mold steel with cermet coating is sintered in a GSL1300 vacuum sintering furnace. The sintering system is to put the sample into the sample after heating up to 600°C, and after sintering at 600°C×30min+800°C×30min+1000°C×90min+1100°C×30min+1200°C×60min, it is cooled to room temperature with the furnace, and the sintering process refers to figure 1 .

[0031] The above embodiments all use mechanical ball milling to fully mix the metal powder, and finally carry out a series of technical routes such as plasma spraying. 2 FeB 2 In the design of the sintering process of the base cermet, the holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com