Catalyst for treating organic waste gas and preparation method thereof

A technology of organic waste gas and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of poor anti-toxicity, scarce resources, high price, etc., and achieve strong water vapor resistance, The effect of wide active temperature window and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

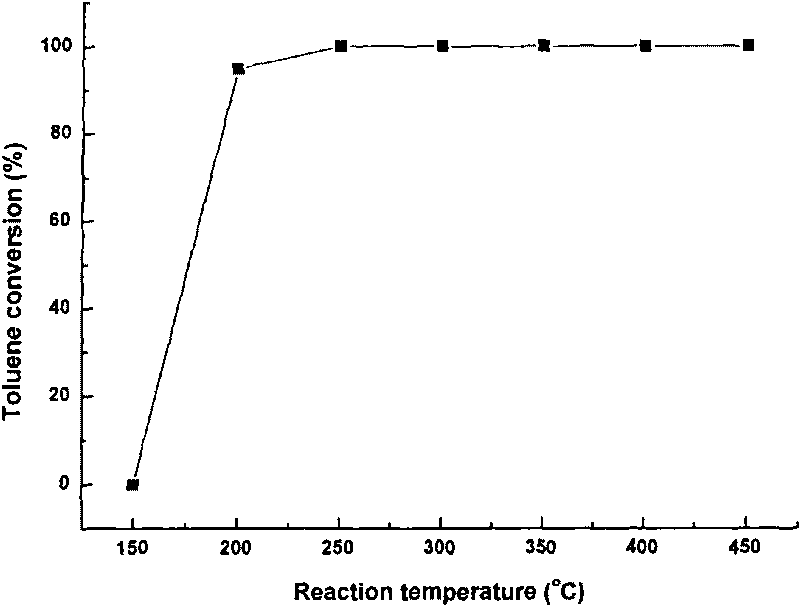

Embodiment 1

[0030] (1) Preparation and modification of self-made carrier

[0031] Take 28g of silicon oxide, 40g of aluminum oxide, 30g of magnesium oxide and 2g of iron oxide and mix evenly. The mixture is roasted at 1300°C and the holding time is controlled at 6h; the self-made carrier is modified with 5wt% oxalic acid solution, boiled on the electric furnace and kept for 2h, and dried The temperature is 80°C, the drying time is 2h; the calcination temperature is 400°C, the calcination time is 6h, and the modified carrier is obtained after calcination;

[0032] (2) Preparation of active component impregnation solution

[0033] Take 64.7g solid CuC 2 o 4 .1 / 2H 2 O, 71.6 g solid MnC 2 o 4 .2H 2 O and 181.7 g of distilled water were prepared to make Cu 2+ and Mn 2+ The mixed solution with a molar ratio of 1:1 was mixed with titanium gel containing 12.0 g of titanium dioxide to prepare an impregnation solution with a molar ratio of copper oxide, manganese oxide and titanium oxide of...

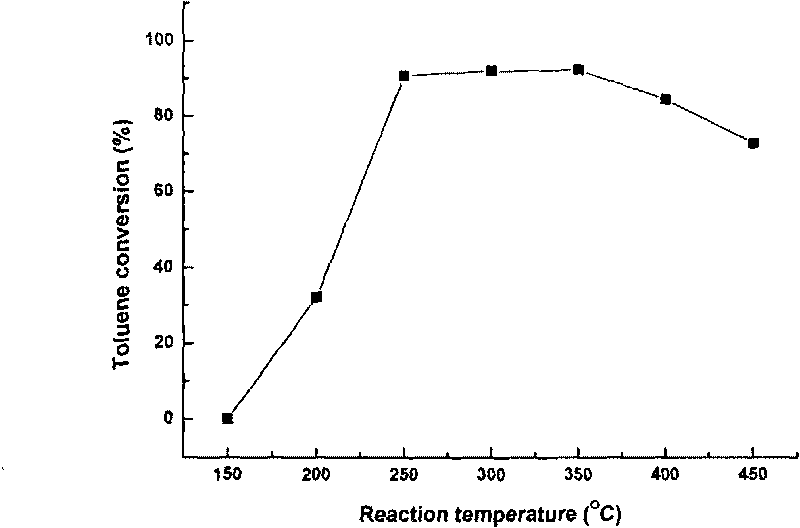

Embodiment 2

[0039] (1) Preparation and modification of self-made carrier

[0040] Take 50g of silica, 35g of alumina, 14g of magnesia and 1g of iron oxide and mix evenly. The mixture is roasted at 1350°C, and the holding time is controlled at 5h; the self-made carrier is modified with 10wt% oxalic acid solution, boiled on the electric furnace and kept for 2h; dry The temperature is 100°C, and the drying time is 1h; the calcination temperature is 500°C, and the calcination time is 5h, and the modified carrier is obtained through calcination.

[0041] (2) Preparation of active component impregnation solution

[0042] Take 40.0g solid CuC 2 o 4 .1 / 2H 2 O, 89.5 g solid MnC 2 o 4 .2H 2 O and 192.5 g of distilled water to prepare Cu 2+ and Mn 2+ The mixed solution with a molar ratio of 1:2 was mixed with titanium gel containing 11.3g of titanium dioxide to prepare an impregnation solution with a molar ratio of copper oxide, manganese oxide and titanium oxide of 1:2:0.75.

[0043] (3) L...

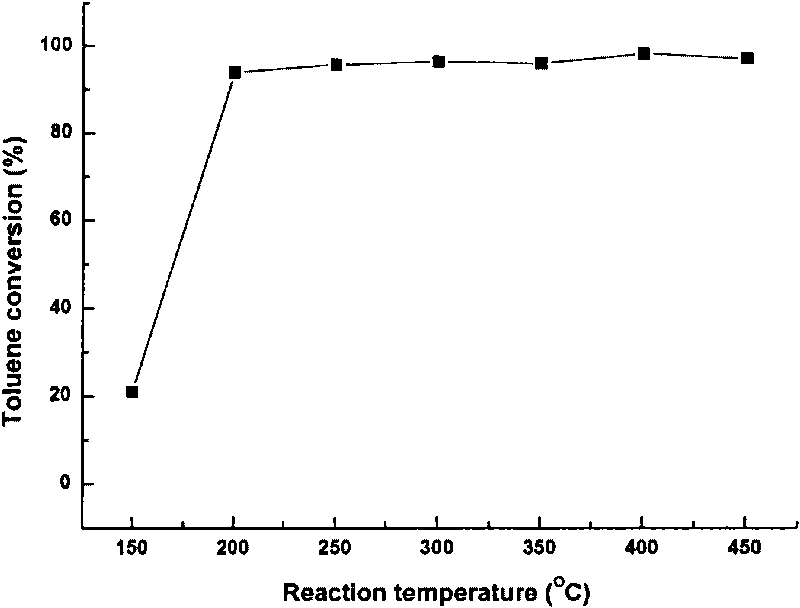

Embodiment 3

[0048] (1) Preparation and modification of self-made carrier

[0049] Take 55g of silicon oxide, 29.5g of aluminum oxide, 15g of magnesium oxide and 0.5g of iron oxide and mix evenly. The mixture is roasted at 1350°C, and the holding time is controlled at 6h; the self-made carrier is modified with 10wt% oxalic acid solution, boiled on the electric furnace and kept for 2h ; The drying temperature is 100°C, and the drying time is 1h; the calcination temperature is 500°C, and the calcination time is 5h, and the modified carrier is obtained through calcination.

[0050] (2) Preparation of active component impregnation solution

[0051] Take 25.3g solid CuC 2 o 4 .1 / 2H 2 O, 114.6 g solid MnC 2 o 4 .2H 2 O and 207.8 g of distilled water to prepare Cu 2+ and Mn 2+ The mixed solution with a molar ratio of 1:4 was mixed with titanium gel containing 9.6g of titanium dioxide to prepare an impregnation solution with a molar ratio of copper oxide, manganese oxide and titanium oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com