Oxygen-free non-melting Polycarbosilane fiber preparation method and device

A polycarbosilane fiber and melting device technology, which is applied in the chemical characteristics of fibers, chemical post-processing of synthetic polymer rayon filaments, textiles and papermaking, etc. The effect of lowering temperature and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

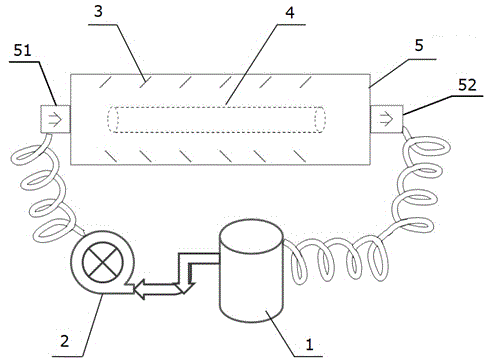

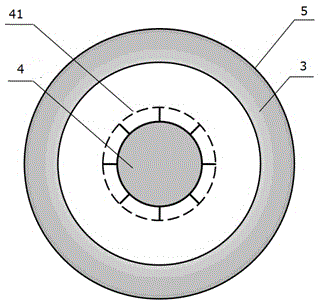

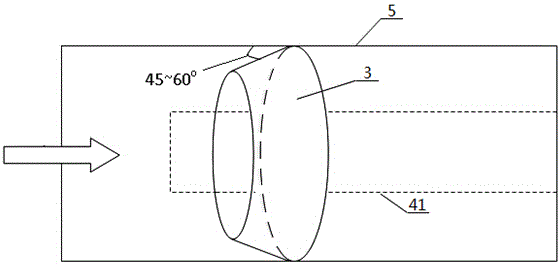

Method used

Image

Examples

Embodiment 1

[0048] (1) Impregnate 100g of polycarbosilane fibers with 10g of dibenzoyl peroxide solution (solvent is acetone) with a mass fraction of 10% in a continuous method, the impregnation speed is 0.5m / min, the impregnation time is 24s, and wound into polycarbonate Silane fiber precursor tube; (2) Then, place the impregnated polycarbosilane fiber precursor tube in a blast oven at 60°C and dry until the moisture content is 0.5wt%; (3) Dry the polycarbosilane fiber precursor tube The carbosilane fiber precursor tube is placed on the round roller heated by the shaft center, the anaerobic non-melting device is evacuated to 10Pa, and then the nitrogen gas (purity is 99.999%) is replaced to normal pressure, and repeated three times, 100g of divinylsilane After the gasification chamber is gasified, it circulates in the device through the circulating fan; (4) raise the temperature of the tube furnace to 100°C at a rate of 5°C / h, keep the temperature constant for 6h, and then raise the tempe...

Embodiment 2

[0052] (1) Impregnate 100g of polycarbosilane fibers with 5g of di-tert-butyl peroxide solution (solvent is ethanol) with a mass fraction of 5% by continuous method, the impregnation speed is 0.6m / min, the impregnation time is 20s, and wound into polycarbonate Silane fiber precursor tube; (2) Then, place the impregnated polycarbosilane fiber precursor tube in a blast oven at 50°C and dry until the water content is 0.5wt%; (3) Dry the polycarbosilane fiber precursor tube The carbosilane fiber precursor tube is placed on the round roller heated by the shaft center, the anaerobic non-melting device is evacuated to 8Pa, and then the argon gas (purity is 99.999%) is replaced to normal pressure, and repeated three times, 50g of tetravinylsilane is placed in After gasification in the gasification chamber, the circulating fan circulates in the device; (4) Heat the tube furnace to 130°C at a rate of 10°C / h, keep the temperature constant for 12 hours, and then raise the temperature to 40...

Embodiment 3

[0054] (1) Impregnate 300g of polycarbosilane fibers with 15% mass fraction of azobisisobutyronitrile solution (the solvent is a mixed solution, in which ethanol accounts for 95wt% and water accounts for 5wt%) 20g by continuous method, and the impregnation speed is 1.0m / min, the impregnation time is 12s, and it is wound into a polycarbosilane fiber precursor tube; (2) Then, place the impregnated polycarbosilane fiber precursor tube in a blast oven at 40°C and dry until the water content is 0.5wt%; (3) Place the dried polycarbosilane fiber precursor cylinder on a round roller heated at the center of the axis, vacuumize the anaerobic non-melting device to 5Pa, and then replace argon (purity is 99.999%) to Normal pressure, repeated four times, after gasification of 180g divinylmethylphenylsilane in the gasification chamber, circulate in the device through the circulation fan; (4) raise the temperature of the tube furnace to 155 ℃, and keep the temperature constant for 16 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com