Production method of oriented silicon steel

A technology of oriented silicon steel and production method, which is applied in the field of metal material preparation and processing, can solve the problems of poor magnetic properties and rolling performance, achieve the effect of reasonable allocation of cooling speed and prolonging the normalization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

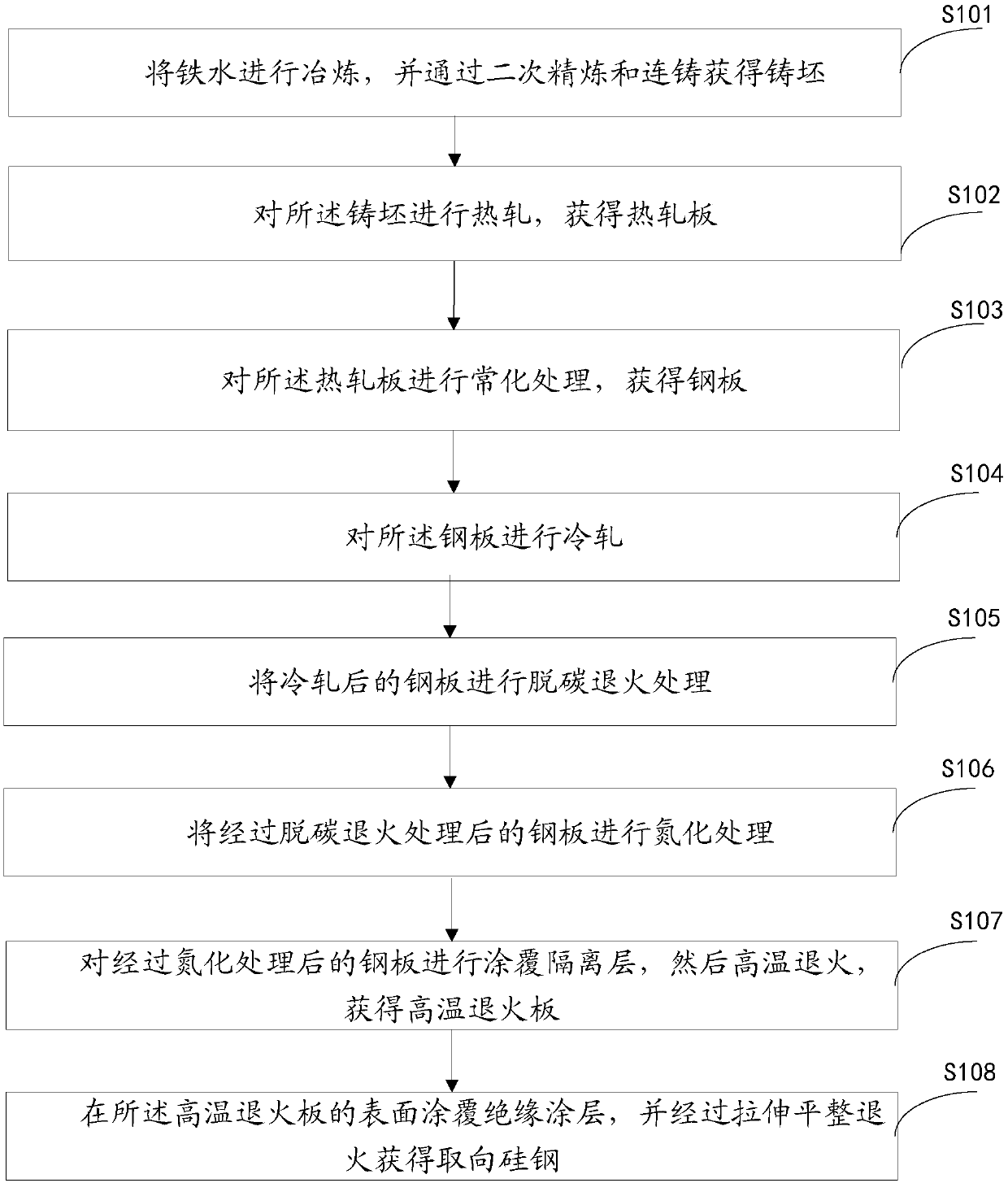

[0028] The embodiment of the present invention provides a production method of grain-oriented silicon steel, which is used to improve the technical problems of poor magnetic properties and rolling performance in the method of producing grain-oriented silicon steel through a two-stage normalization process in the prior art.

[0029] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

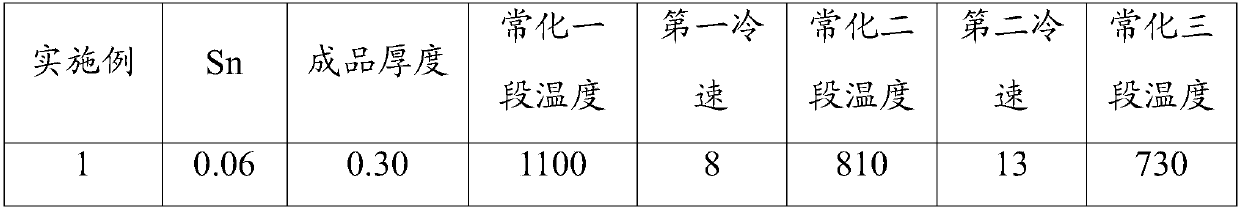

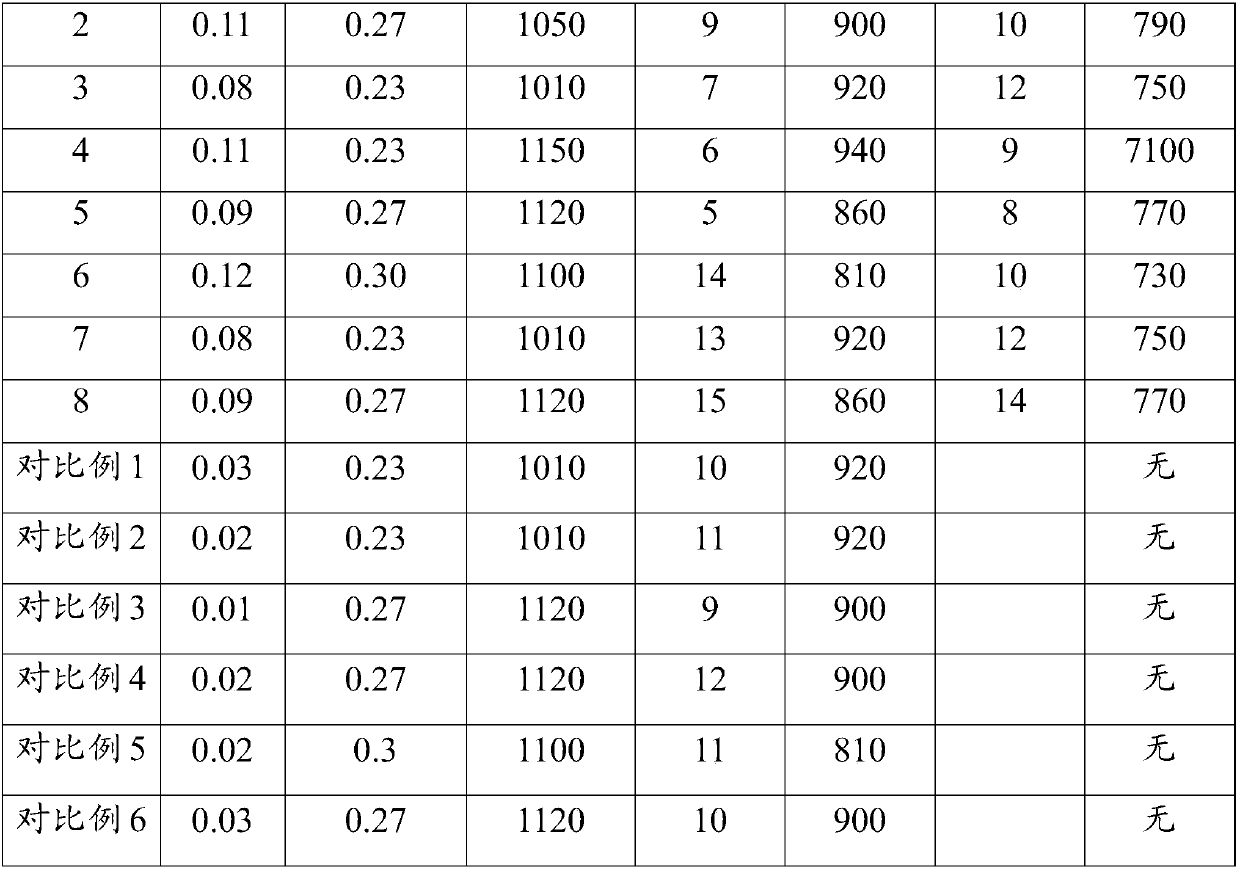

[0030] A method for producing grain-oriented silicon steel, comprising: smelting molten iron, and obtaining a slab through secondary refining and continuous casting, wherein the weight percentage of the components of the slab is as follows: 0.03%<C≤0.08%, 2.6% ≤Si≤4%, 0.07%≤Mn≤0.2%, 0.005%≤S≤0.01%, 0.01%≤Als≤0.03%, 0.004%≤N≤0.01%, 0.02%≤Sn≤0.2%, the rest are Fe and Impurities; hot rolling the slab to obtain a hot-rolled plate; normalizing the hot-rolled plate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com