Method for extracting shale oil and high-calorific-value fuel gas by self-heating type underground dry distillation of oil shale

A technology for retorting oil and shale oil, which is applied in chemical instruments and methods, separation methods, earthwork drilling and production, etc., and can solve problems such as difficulty in obtaining practical application of underground technology, difficulty in condensing and recovering oil, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

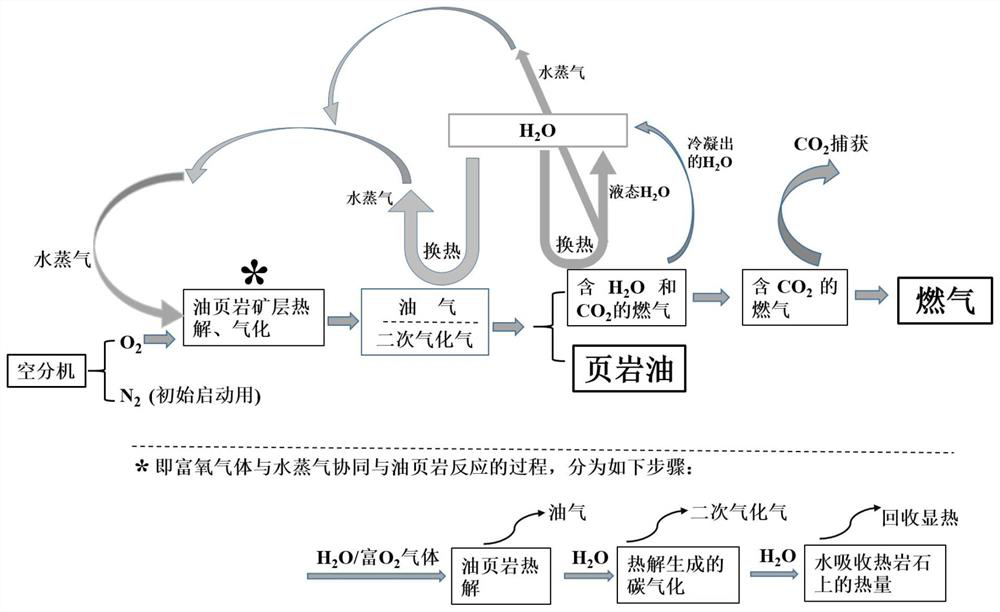

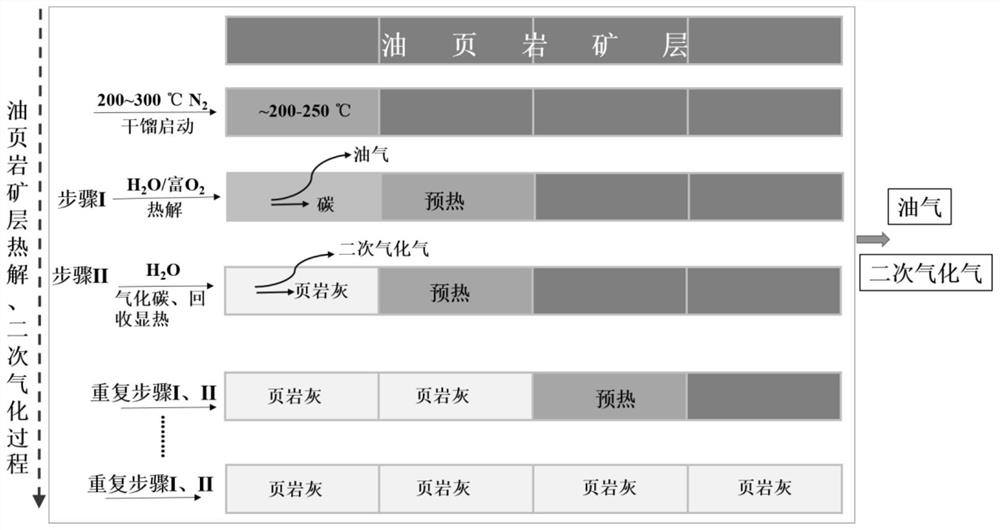

[0028] like figure 1 , figure 2 As shown, this embodiment provides a method for extracting shale oil and high calorific value fuel gas from self-heating underground retort oil shale, including the following steps:

[0029] S1. Drill several injection wells and production wells to the target oil shale layer, and collect water in the oil shale layer; the injection well is used to pass the oxygen-enriched gas, water vapor and nitrogen required for the process into the oil shale layer, and produce Wells are used to collect oil and gas generated by pyrolysis of oil shale and gasification gas with fixed carbon; the water collected during drilling can be used as con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com