UV curing heat reducing adhesive, preparation method and application thereof

A curing heat and adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as unfavorable processing technology, unfavorable operation, hidden dangers and other problems, and achieve a large adjustable range of adhesive thickness, Fast viscosity reduction and low VOC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

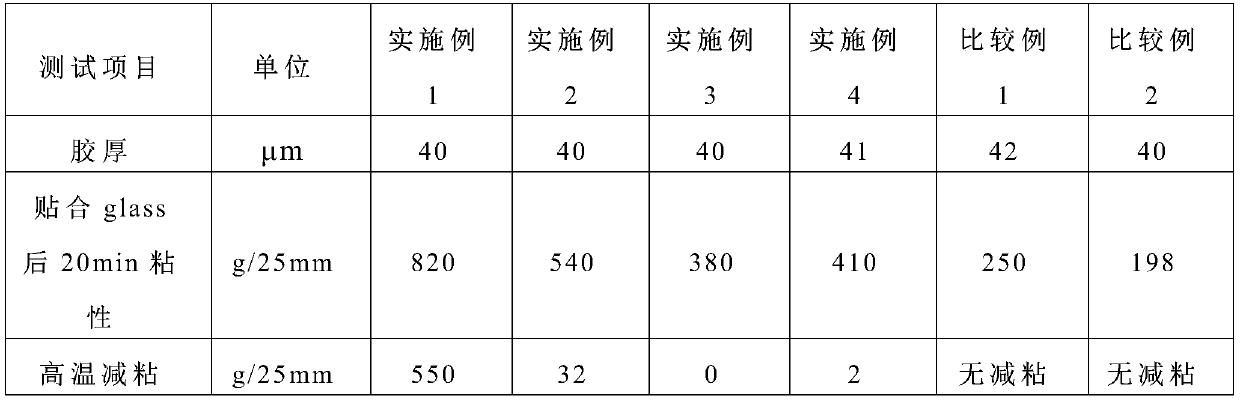

Embodiment 1

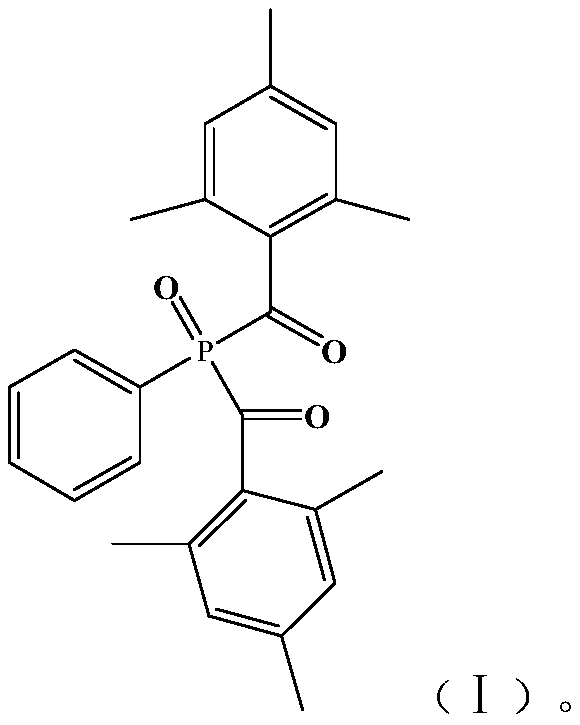

[0033] This embodiment provides a UV-curable heat-relieving adhesive and a UV-curable heat-reducing adhesive tape prepared therefrom. The preparation method specifically includes the following steps:

[0034] S1: Preparation of prepolymer resin:

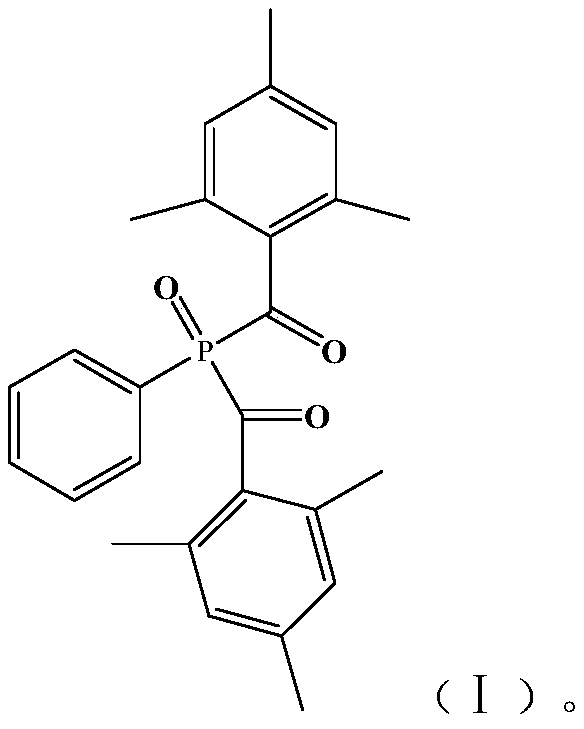

[0035] Add successively the compound shown in the isooctyl acrylate of 90g, the methacrylate of 10g, and the formula (I) of 0.05g to be placed in the compounding barrel, and polymerize while stirring under the protection of nitrogen to prepare the prepolymer. The viscosity is about 1950cps±50cps;

[0036] S2: Preparation of UV-cured heat-viscosity-reducing adhesive:

[0037] Add 80g of prepolymerized resin prepared in step (S1), 15g of Sanki Chemical Industry 6501, 0.1g of 1,6-hexanediol diacrylate, and 0.05g of 2,2 dimethoxy 2-phenylacetophenone 1. 3g of heat-expandable microspheres are placed in a glue mixing bucket, stirred and dispersed to obtain a UV-curable heat-viscosity-reducing adhesive.

[0038] S3: Preparation of UV-cur...

Embodiment 2

[0041] This embodiment provides a UV-curable heat-relieving adhesive and a UV-curable heat-reducing adhesive tape prepared therefrom. The preparation method specifically includes the following steps:

[0042] S1: Preparation of prepolymer resin:

[0043] Add successively the compound shown in the isooctyl acrylate of 90g, the methacrylate of 10g, and the formula (I) of 0.05g to be placed in the compounding barrel, and polymerize while stirring under the protection of nitrogen to prepare the prepolymer. The viscosity is about 2000cps±50cps;

[0044] S2: Preparation of UV-cured heat-viscosity-reducing adhesive:

[0045] Add 80g of prepolymerized resin prepared in step (S1), 15g of Sanki Chemical Industry 6501, 0.1g of 1,6-hexanediol diacrylate, and 0.05g of 2,2 dimethoxy 2-phenylacetophenone 1. 8g of heat-expandable microspheres were placed in a glue mixing bucket, stirred and dispersed to obtain a UV-curable heat-viscosity-reducing adhesive.

[0046] S3: Preparation of UV-cu...

Embodiment 3

[0049] This embodiment provides a UV-curable heat-relieving adhesive and a UV-curable heat-reducing adhesive tape prepared therefrom. The preparation method specifically includes the following steps:

[0050] S1: Preparation of prepolymer resin:

[0051] Add successively the compound shown in the isooctyl acrylate of 90g, the methacrylate of 10g, and the formula (I) of 0.05g to be placed in the compounding barrel, and polymerize while stirring under the protection of nitrogen to prepare the prepolymer. The viscosity is about 2100cps±30cps;

[0052] S2: Preparation of UV-cured heat-viscosity-reducing adhesive:

[0053] Add 80g of prepolymerized resin prepared in step (S1), 15g of Sartomer CN704, 0.1g of 1,6-hexanediol diacrylate, 0.05g of 2,2 dimethoxy 2-phenyl styrene The ketone and 12g of heat-expandable microspheres were placed in the glue mixing bucket, stirred and dispersed to obtain a UV-curable heat-viscosity-reducing adhesive.

[0054] S3: Preparation of UV-cured hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com