Surface overlaying method of thin-walled metal

A surface surfacing and metal technology, applied in metal processing equipment, welding equipment, welding accessories, etc., can solve the problems of thin-walled metal back burn-through, excessive oxidation, metal internal medium leakage, etc., to avoid excessive metal temperature, The effect of reducing the dwell time and reducing the welding swing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

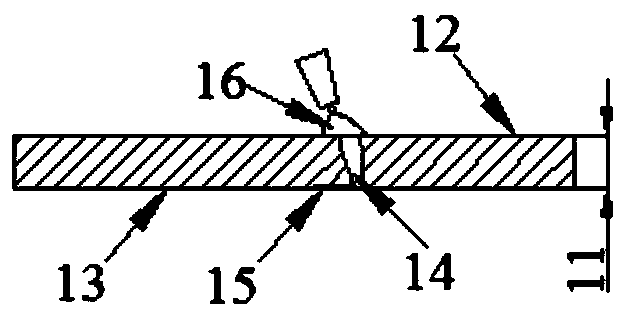

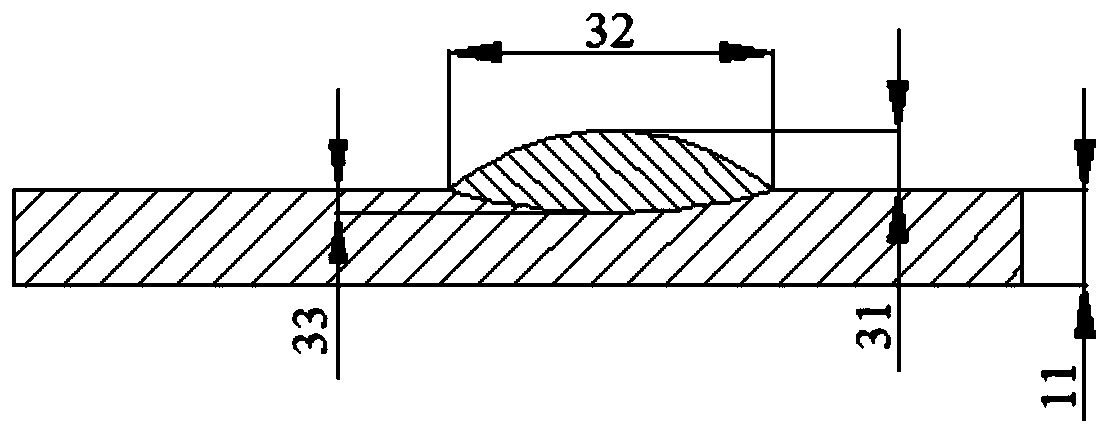

[0033] Please refer to Figures 2 to 5 Shown, the surface welding method of thin-walled metal of the present invention comprises the following steps:

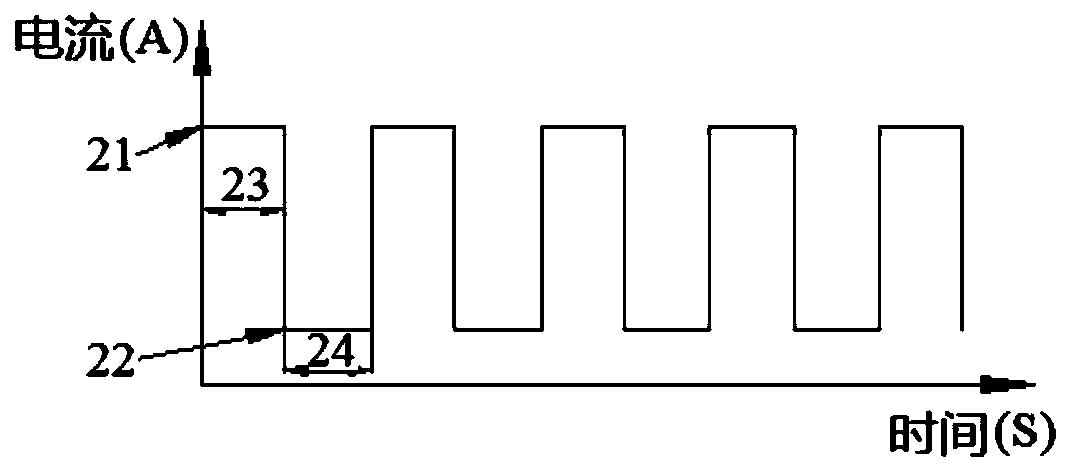

[0034] 1) Select a power supply that can realize peak-valley current output, and obtain a welding bead that meets the requirements by adjusting the peak current, peak current time, valley current, and valley current time;

[0035] 2) completing the welding of different welding passes in sequence to form a welding layer; and

[0036] 3) Repeat step 2) to complete the welding of different welding l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com