Fluid flow rate and flow measurement device and method

A flow measurement device, fluid flow rate technology, applied in the direction of fluid velocity measurement, measurement device, liquid/fluid solid measurement, etc., can solve problems such as blanks, and achieve the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

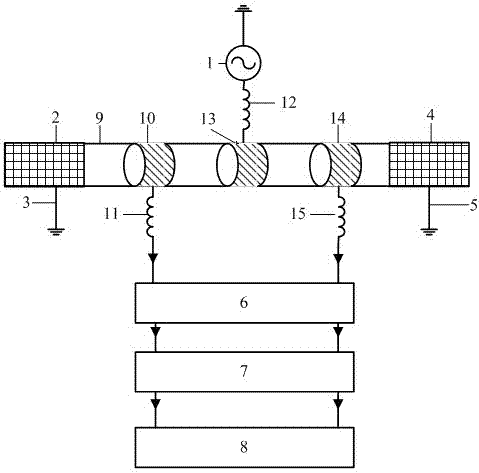

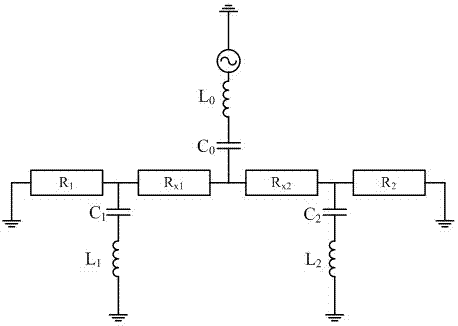

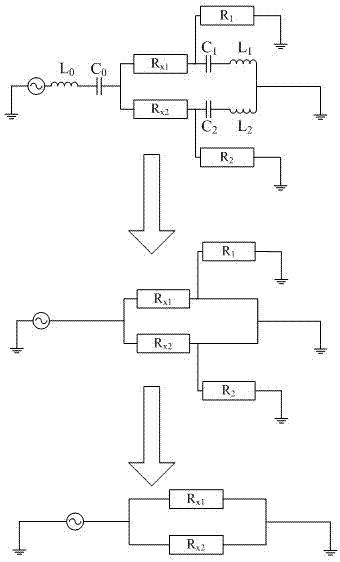

[0020] like figure 1As shown, the fluid velocity flow measurement device includes an AC excitation source 1, a first metal flange connector 2, a first ground wire 3, a second metal flange connector 4, a second ground wire 5, a signal processing module 6, a data Acquisition module 7, microcomputer 8, insulation measurement pipeline 9, first detection electrode 10, first inductance module 11, third inductance module 12, excitation electrode 13, second detection electrode 14, second inductance module 15, by insulation measurement The pipeline 9, the first detection electrode 10, the first inductance module 11, the third inductance module 12, the excitation electrode 13, the second detection electrode 14, and the second inductance module 15 constitute a three-electrode non-contact conductivity sensor. The outer wall of the first detection electrode 10, the excitation electrode 13 and the second detection electrode 14 are installed at equal intervals, the excitation electrode 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com