Non-contact type conductive measurement device and method for phase content of gas-liquid two-phase flow

A gas-liquid two-phase flow, non-contact technology, applied in the direction of material impedance, can solve the problems of few literature reports, achieve the effect of small pressure loss, avoid mutual interference of electric field, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

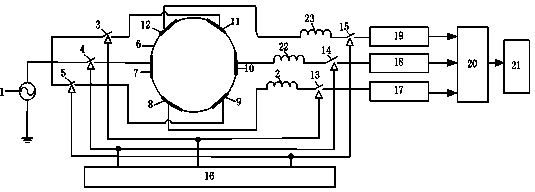

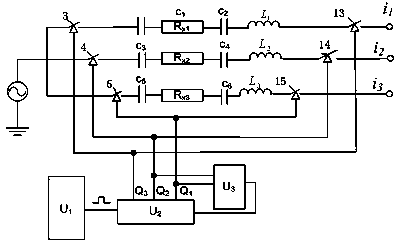

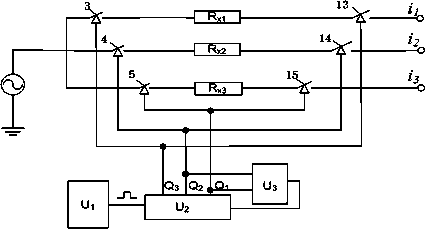

[0021] Such as figure 1 As shown, the non-contact conduction gas-liquid two-phase flow phase holdup measurement device includes an AC excitation source 1, a first inductance module 2, a first electronic switch 3, a second electronic switch 4, a third electronic switch 5, and an insulating pipeline 6 , first electrode 7, second electrode 8, third electrode 9, fourth electrode 10, fifth electrode 11, sixth electrode 12, fourth electronic switch 13, fifth electronic switch 14, sixth electronic switch 15, electronic Switch control logic circuit 16, first signal processing module 17, second signal processing module 18, third signal processing module 19, data acquisition module 20, microcomputer 21, second inductance module 22, third inductance module 23; The electrode 7, the second electrode 8, the third electrode 9, the fourth electrode 10, the fifth electrode 11, and the sixth electrode 12 are evenly distributed around the outer wall of the insulating pipe 6, and the first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com