Near wall flow velocity measuring device

A flow velocity measurement and wall surface technology, which is applied in the direction of measuring fluid velocity by using thermal variables, can solve the problems of unmeasured flow field disturbance, etc., and achieve the effects of simple structure, improved measurement accuracy, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

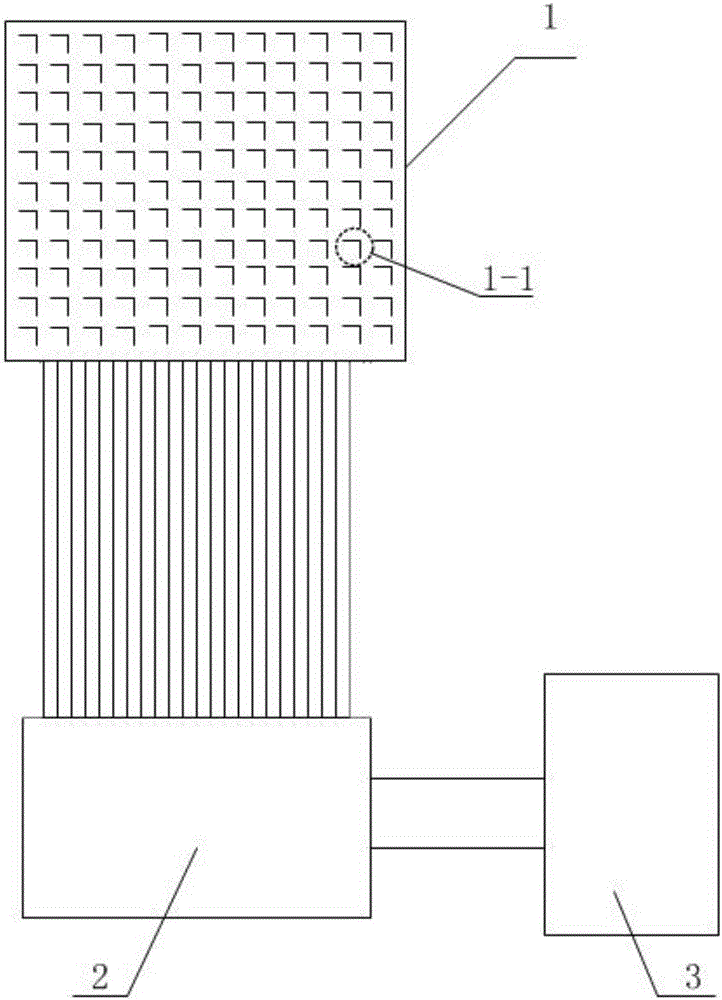

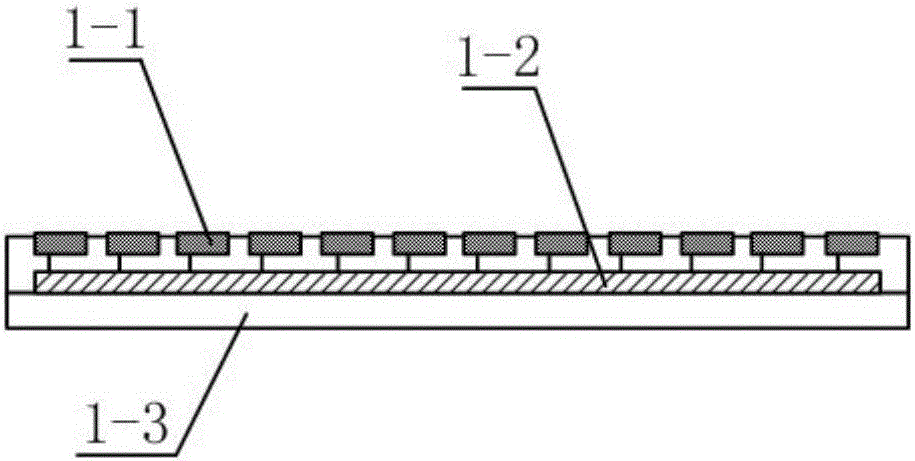

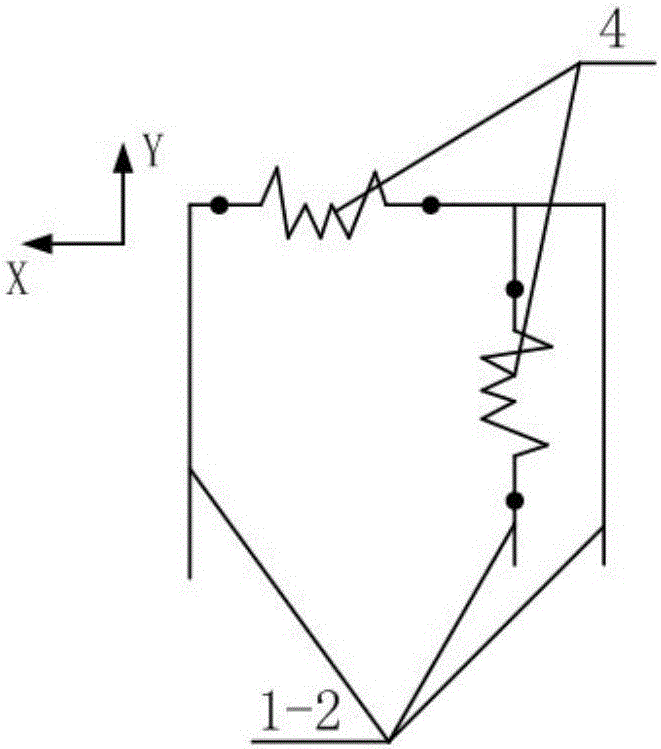

[0020] Such as Figure 1~3 As shown, a near-wall flow velocity measurement device is composed of a flexible film 1, a multi-channel thermostat controller 2 and a computer 3, the computer 3 is connected to the multi-channel thermostat controller 2, and the multi-channel thermostat controller 2 is connected to the flexible film 1, wherein: the flexible film 1 has an array of measuring elements 1-1 printed on its upper surface, and a power supply line 1-2 printed on its lower surface, the measuring element 1-1 is connected to the power supply line 1-2, and the measuring element 1-1 is a heating wire 4; the multi-channel constant temperature controller 2 is used to provide a power supply with controllable output power for each measuring element 1-1, and through fast output power adjustment, the measuring element 1-1 is always maintained A certain constant temperature; the computer 3 is used to calculate and record measurement data. Specifically, the multi-channel constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com