A Design Method of Three-Dimensional Inward Turning Inlet with Full Flow Direction Suction

A design method and technology of air inlets, which are applied to the air inlets of turbine/propulsion units, calculations, combustion air/combustion-air processing, etc., which can solve the problem of reducing outlet uniformity, complex wave structure, and boundary layer separation. and other problems to achieve the effect of improving the self-starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

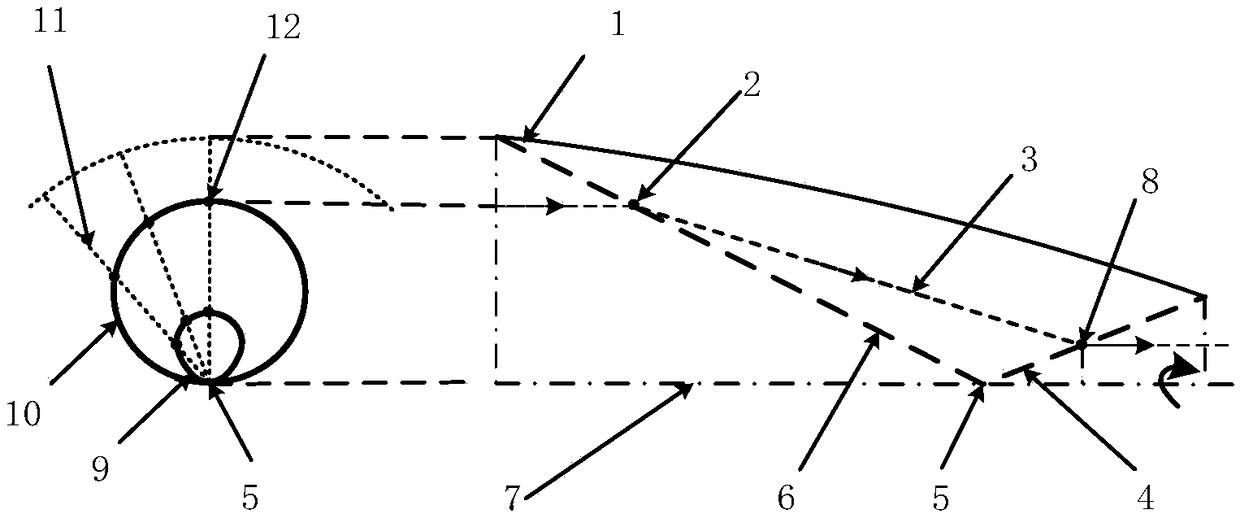

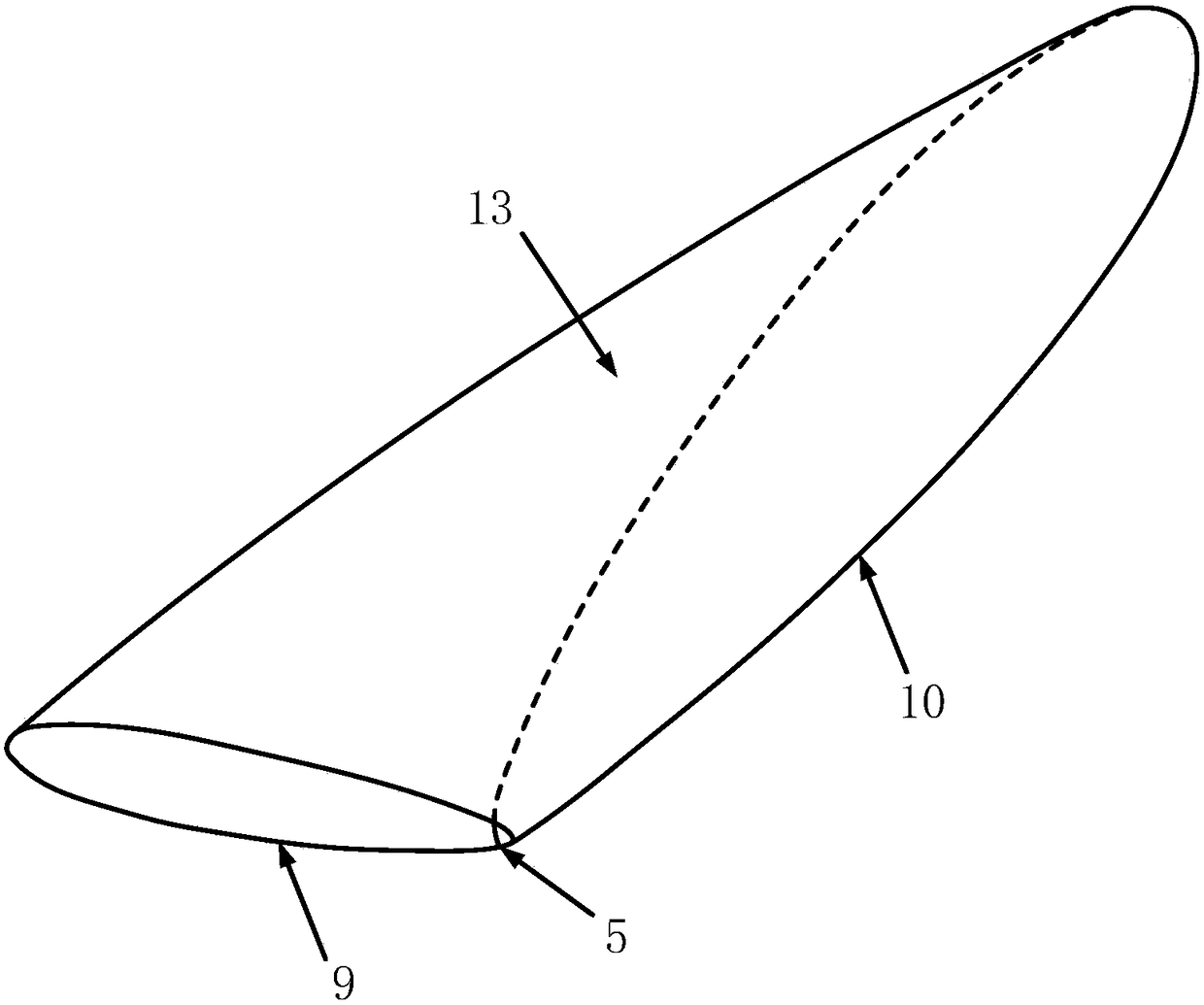

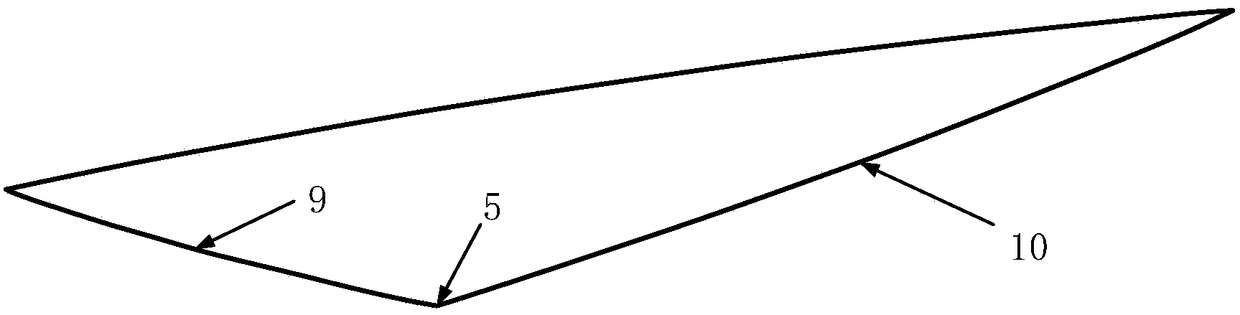

[0023] Such as Figure 1-7 As shown, the marks in the figure are: 1 indicates the reference surface of the three-dimensional inward turning inlet, 2 indicates the position of the leading edge point of the three-dimensional inward turning inlet, 3 indicates the effective part of the basic flow field streamline, and 4 indicates the reflected shock wave , 5 represents the lip of the three-dimensional inward turning inlet, 6 represents the incident shock wave at the entrance of the three-dimensional inward turning inlet, 7 represents the centerline of the basic flow field rotation, 8 represents the intersection of the streamline and the reflected shock wave, and 9 represents the three-dimensional inward turning The shape line of the inlet shoulder, 10 represents the capture shape of the leading edge of the three-dimensional inward turning inlet, 11 represents the streamline tracked by the streamline tracking method, 12 represents the discrete point set of the effective part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com