A fixed geometry binary hypersonic inlet and its design method

A hypersonic and air inlet technology, applied in the design of fixed geometry binary hypersonic air inlet, can solve the problems of increased weight, decreased reliability and complex structure, etc. To achieve the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

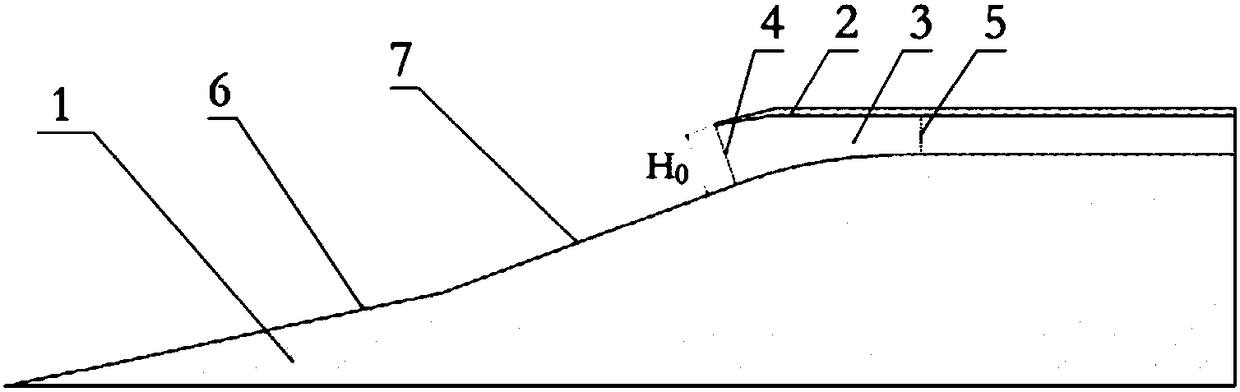

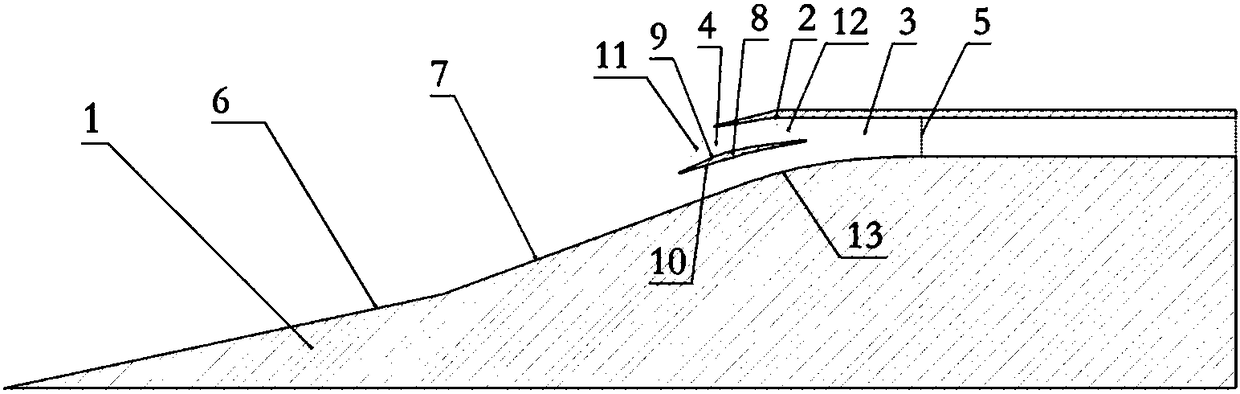

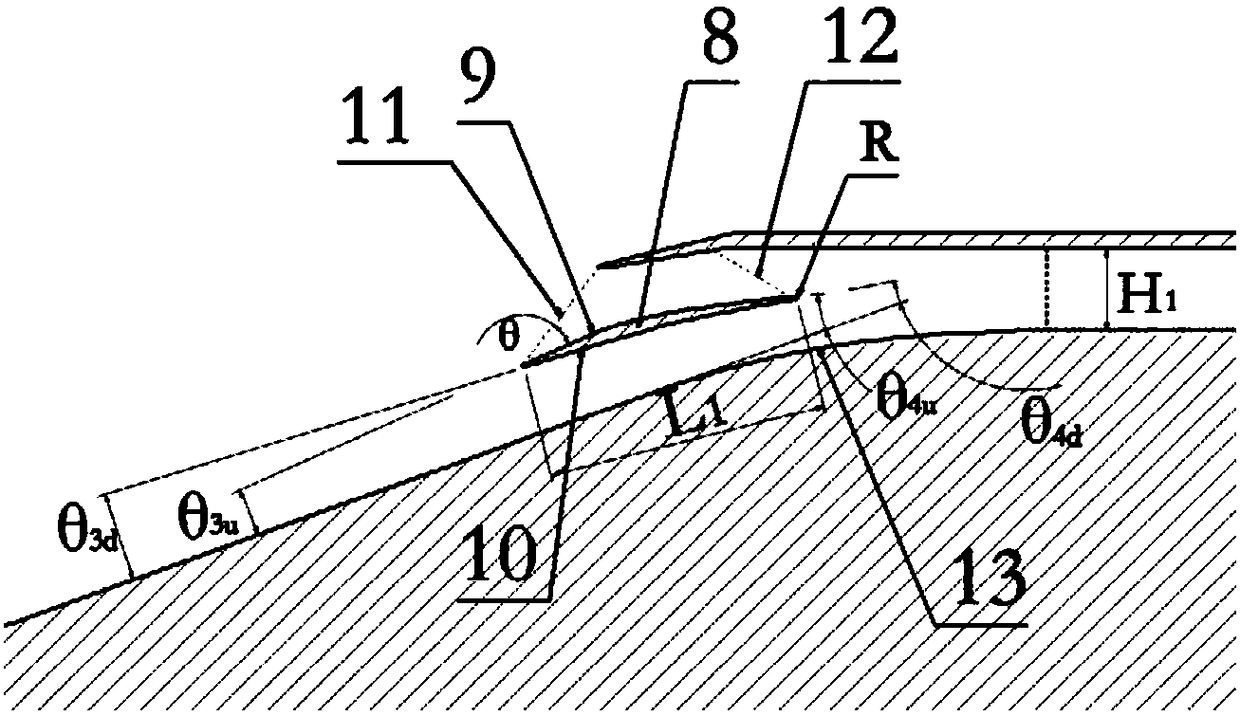

[0022] However, the present invention also provides a specific implementation of the above-mentioned optimal design method for the fixed-geometry binary hypersonic inlet, including:

[0023] Step 1: Design a binary hypersonic inlet prototype ( figure 1 As shown), the inlet contains two stages of outer compression surfaces, and the inner compression shock wave system is composed of oblique shock waves at the leading edge of the lip shroud and flat oblique shock waves at the inner profile of the lip shroud. The geometric configuration of the inlet shoulder 13 is a NURBS spline (NURBS spline reference is Piegl, L., Tiller, W., "The NURBS book," Springer-Verlag Berlin Heidelberg, 1997, pp.117. ) to fit the curve, take 4 points for spline fitting, the tangent direction at the start end is the direction of the second-stage compression surface 7, and the tangent direction at the end is the horizontal direction. According to the configuration of the binary hypersonic inlet, the airfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com