Self-starting equipment of vertical axis wind turbine

A self-starting, wind turbine technology, applied to wind engines, wind engines at right angles to the wind direction, machines/engines, etc., can solve the problems of reducing wind energy utilization efficiency and poor self-starting performance, and achieve the effect of improving wind energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

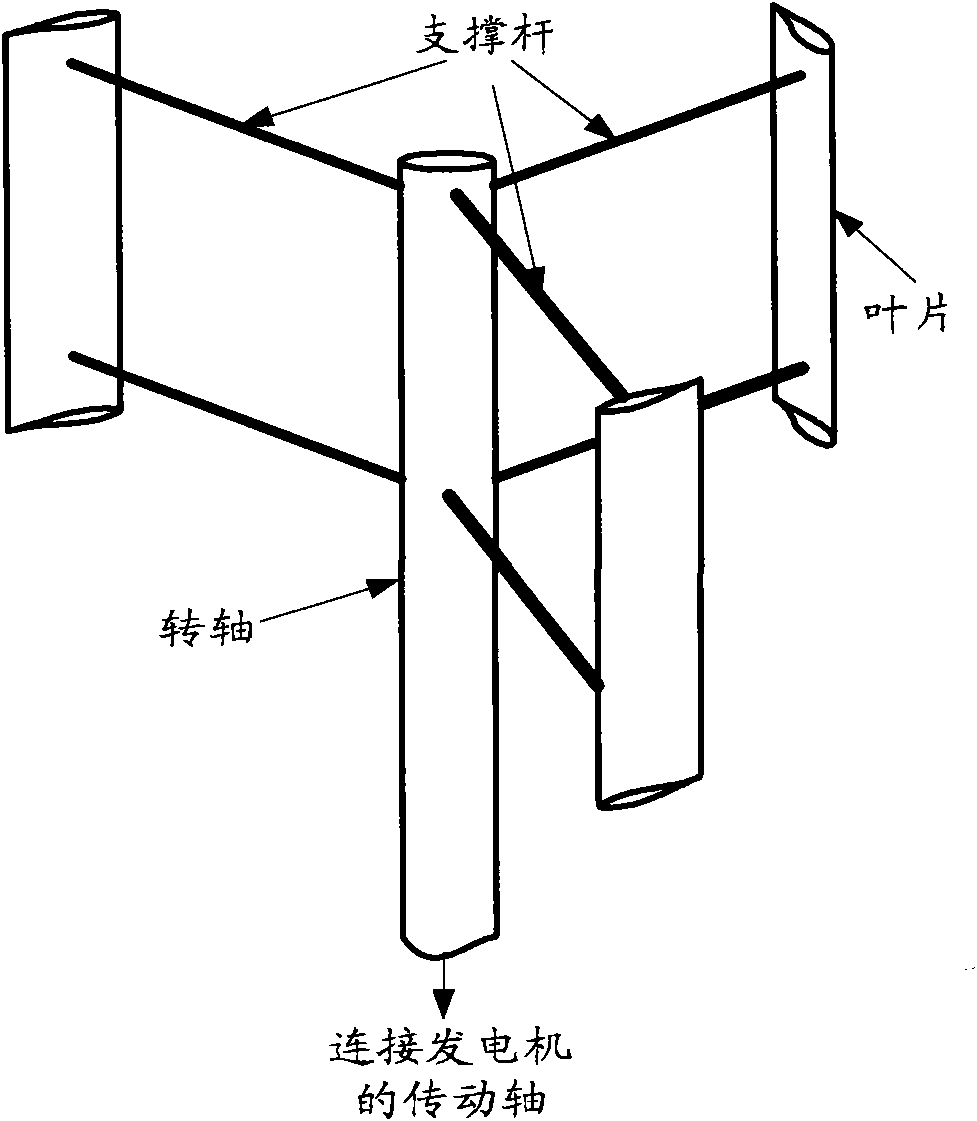

[0040] see Figure 4 , Figure 4 It is a schematic structural diagram of a self-starting device for a vertical axis wind turbine provided in Embodiment 1 of the present invention. like Figure 4 As shown, the self-starting device may include:

[0041] A rotating shaft (1), a blade (2) and a support rod (3);

[0042] Wherein, the blade (2) is a straight blade; the cross-section of the support rod (3) is in the shape of a concave front and a pointed rear;

[0043] Wherein, the number of blades (2) is at least two, and at least one support rod (3) is connected between each blade (2) and the rotating shaft (1);

[0044] Wherein, the lower end of the rotating shaft (1) is connected to the transmission shaft of the generator to realize torque transmission and wind energy conversion.

[0045] In Embodiment 1 of the present invention, the blade (2) may be a whole blade, or may be formed by connecting multiple blades.

[0046] In Embodiment 1 of the present invention, each suppor...

Embodiment 2

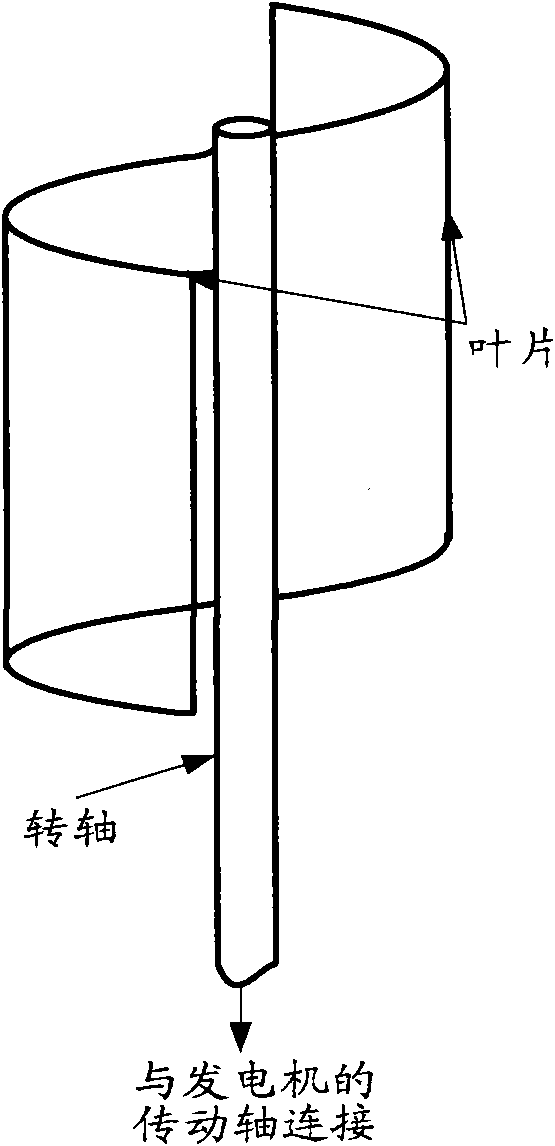

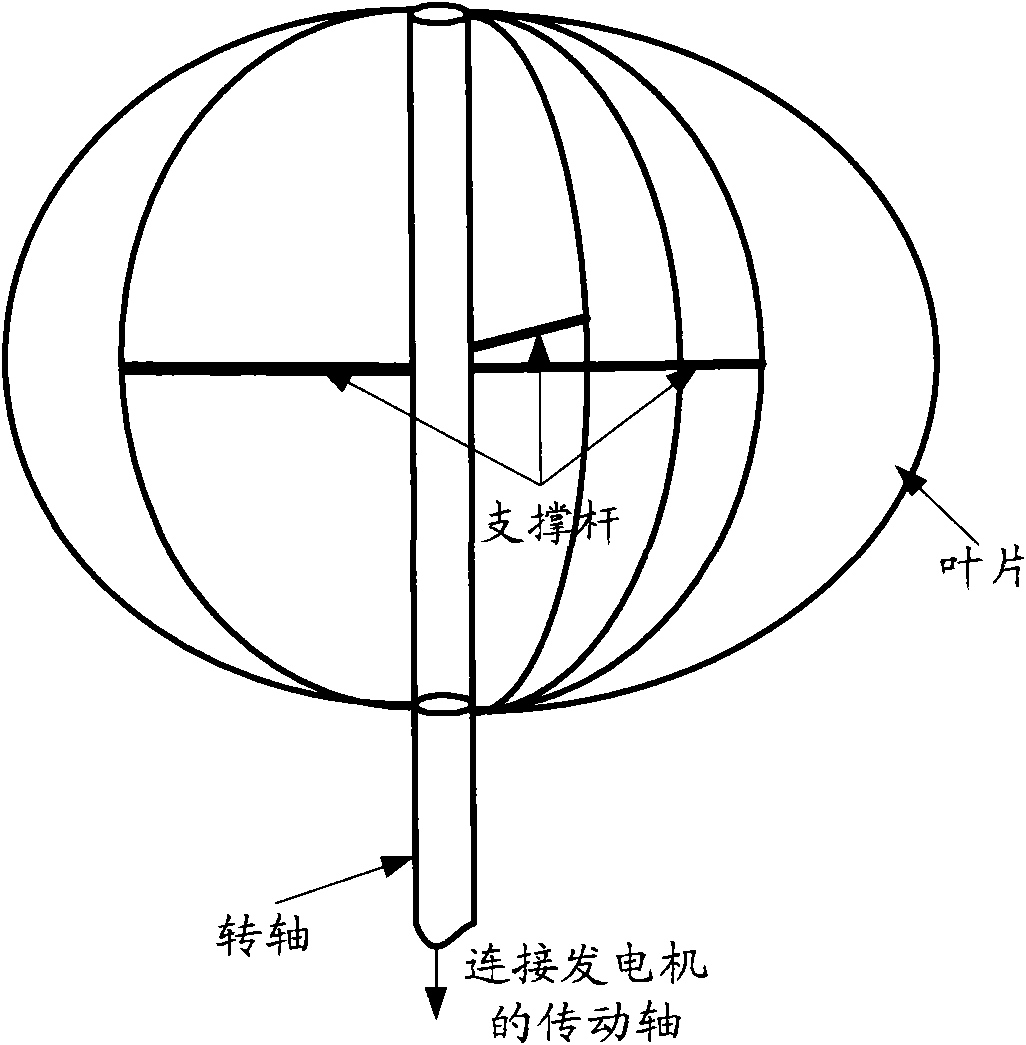

[0056] see Figure 7 , Figure 7 It is a structural schematic diagram of another self-starting device for a vertical axis wind turbine provided in Embodiment 2 of the present invention. like Figure 7 As shown, the self-starting device may include:

[0057] A rotating shaft (1), a blade (2) and a support rod (3);

[0058] Wherein, the blade (2) is in the shape of a crescent moon; the cross section of the support rod (3) is in the shape of a concave front and a pointed rear;

[0059] Wherein, both ends of each blade (2) are fixedly connected to the rotating shaft (1), and at least one support rod (3) is connected between the inner edge of each blade (2) and the rotating shaft (1);

[0060] Wherein, the lower end of the rotating shaft (1) is connected to the transmission shaft of the generator to realize torque transmission and wind energy conversion.

[0061] In the second embodiment of the present invention, the blade (2) may be a whole piece of curved blade, or may be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com