A dynamic performance test device for a large diameter ultra-high pressure electro-hydraulic proportional cartridge valve

An electro-hydraulic ratio and testing device technology, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, servo motor components, etc., can solve the problems of large space occupation, high risk factor and high cost of the experiment, and achieve simple structure , strong anti-interference ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

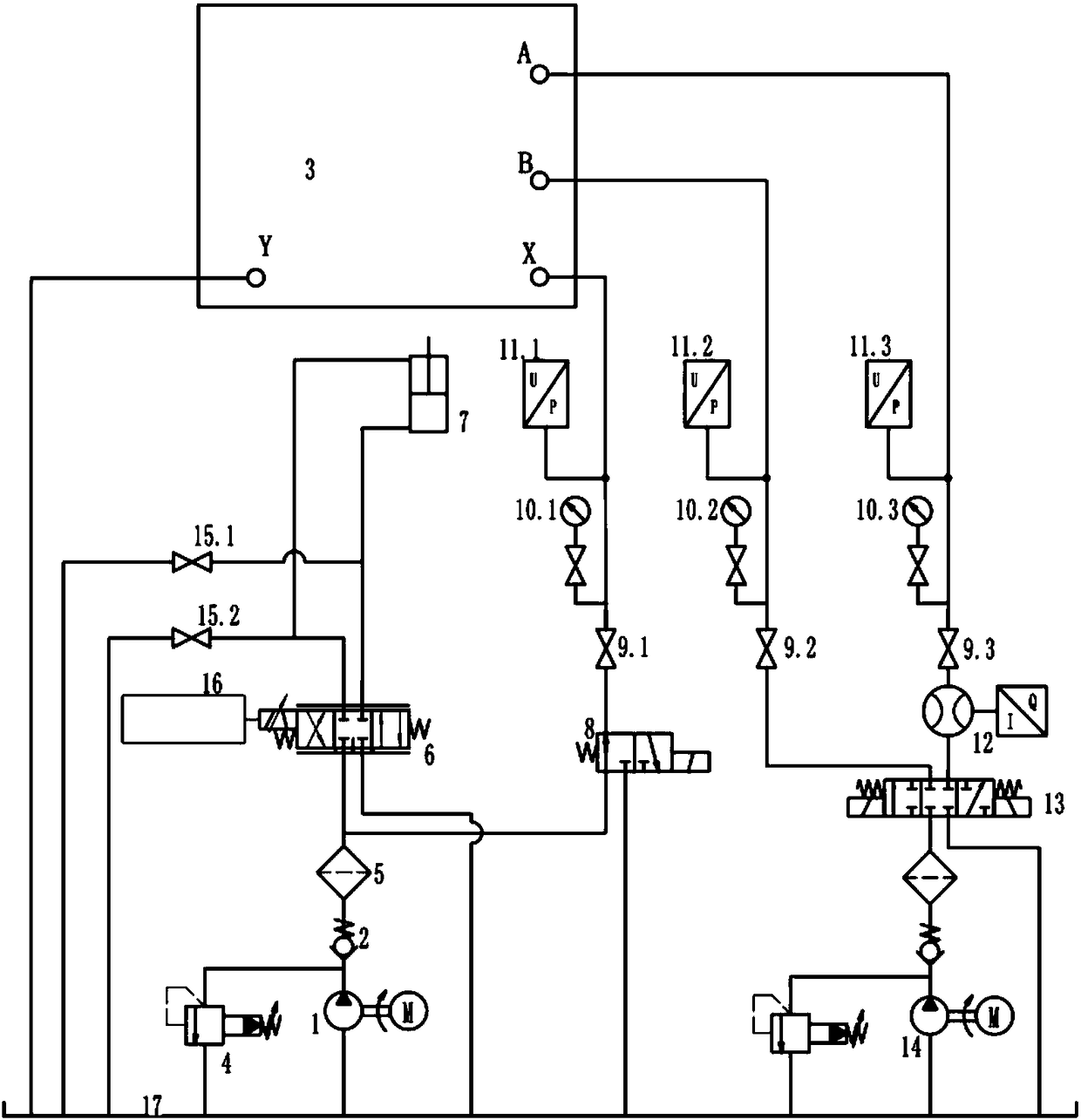

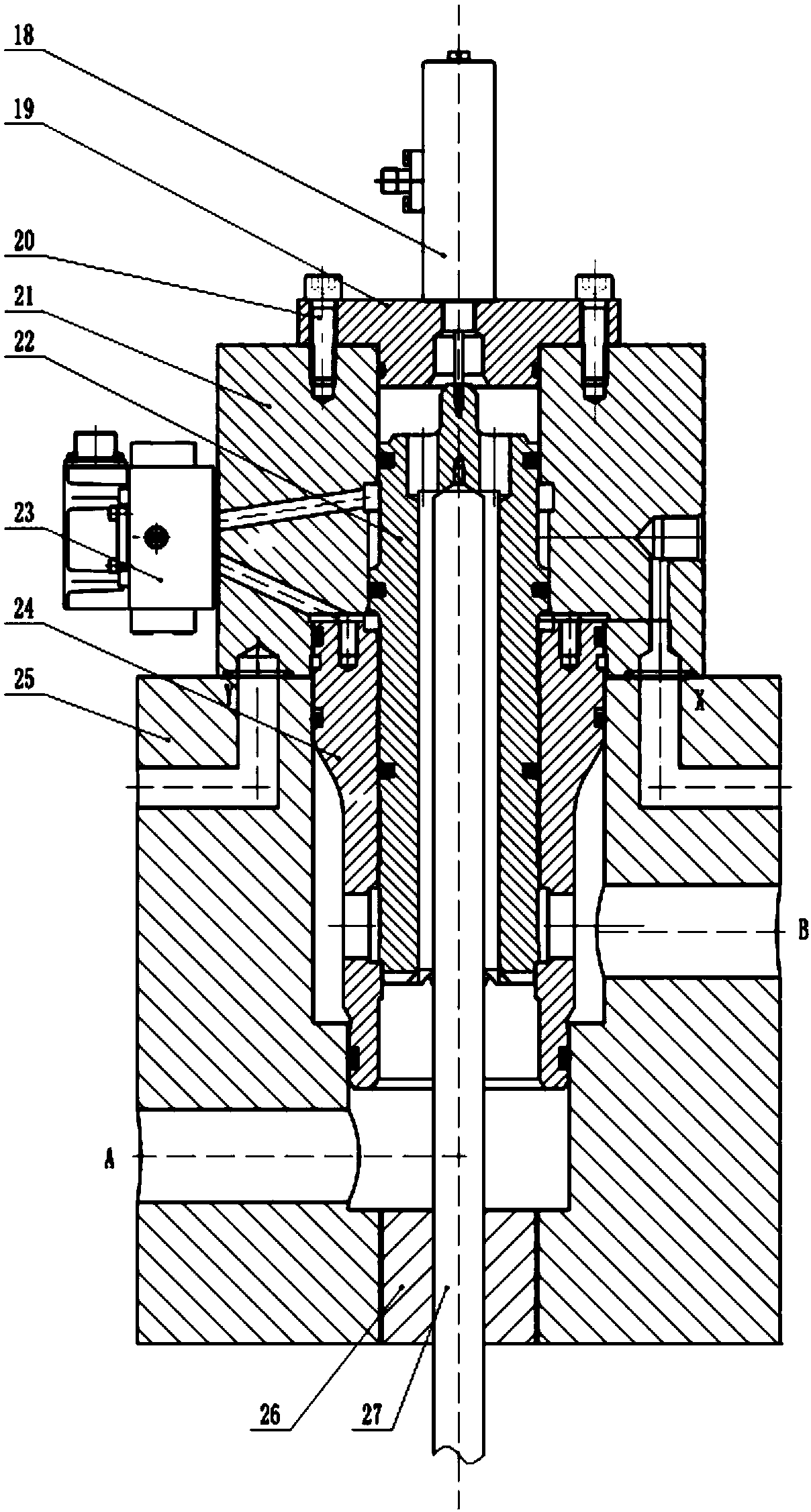

[0018] exist figure 1 The high-frequency hydraulic cylinder shown is set in the schematic diagram of the output force control system of the hydraulic cylinder. The test control pump 1 of the output force control system of the hydraulic cylinder is connected to the oil tank 17 at its inlet end and connected to two pipelines at its outlet end. An overflow valve A4 is provided on the branch pipeline, and the overflow valve A is connected to the oil tank, and a one-way valve A2 and an oil filter 5 connected in series are installed on the other branch pipeline, and the outlet of the filter is connected to two pipelines, one of which is The branch circuit is connected to the oil tank through one port of the servo valve 6 through the shut-off valve 15.2, and the other port of the servo valve is connected to the oil inlet port of the high-frequency hydraulic cylinder 7, and there are also two pipelines connected to the oil return port of the high-frequency hydraulic cylinder , one is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com