Preparation method of 3- careen-5-keto

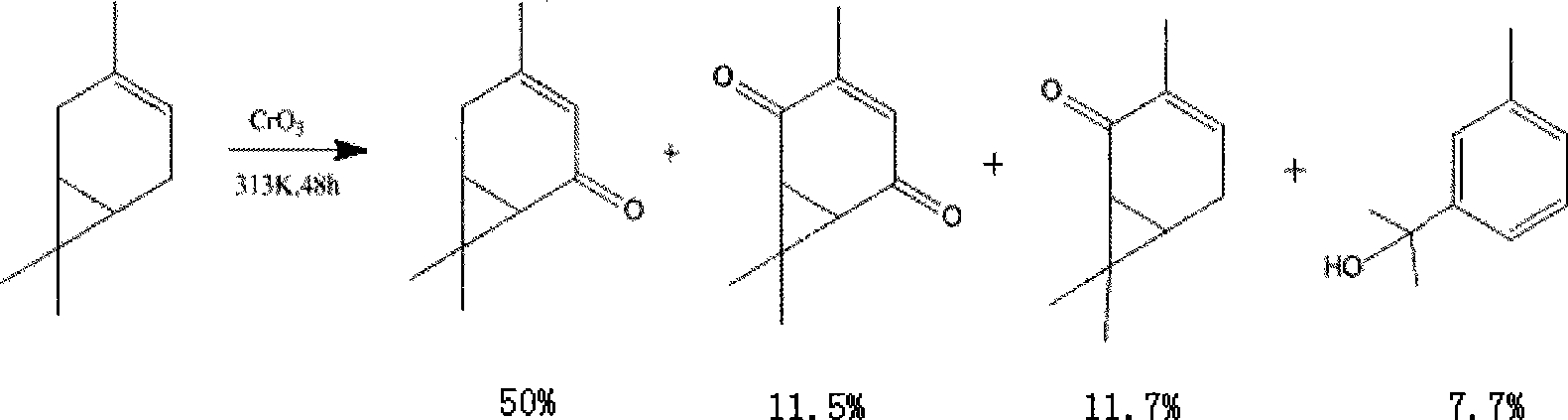

A technology of carene and chromium trioxide is applied in the field of preparing 3-carene-5-one, and can solve the problem of poor selectivity of 3-carene-5-one, long reaction time, and production of 3-carene-5-one. problems such as low rate, to achieve the effect of shortening the reaction time and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 19ml of tert-butanol and 10ml of benzene into a 100ml round bottom flask, and mix evenly under the action of magnetic stirring; Weigh 10g of chromium trioxide into the round bottom flask and stir for half an hour; Pour the mixed solution into a separatory funnel for extraction, 20ml Wash the reaction bottle with benzene, the resulting bright red oil layer is the required oxidant solution, dry with magnesium sulfate, and set aside;

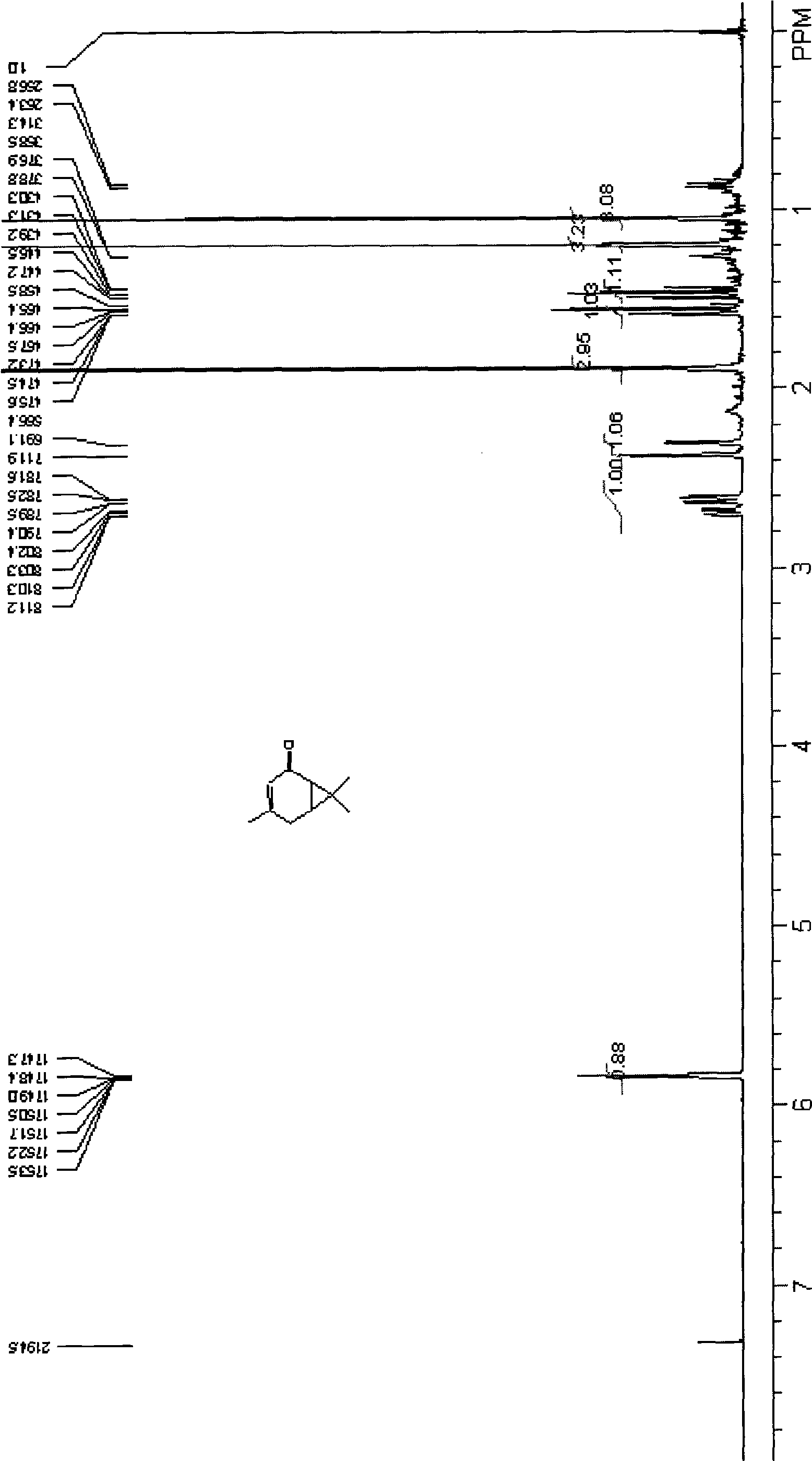

[0018] Add 4.1ml (3.51g, 0.026mol) 3-carene into a 250ml three-necked flask, then add the prepared oxidant solution, connect the three-necked flask with a thermometer and a glass stopper respectively; then place the three-necked flask in an ultrasonic cleaner In the water tank (ultrasonic power 100W), fill the tank with water, keep the reaction temperature in the there-necked bottle <45°C, and apply the ultrasonic wave continuously for 2 hours; stop the ultrasonic wave, slowly add 60ml (20g) oxalic acid solution within half an hour, and c...

Embodiment 2

[0022] Add 38ml of tert-butanol and 10ml of benzene into a 100ml round-bottomed flask, and mix evenly under the action of magnetic stirring; weigh 10g of chromium trioxide into the round-bottomed flask, and stir for half an hour; pour the mixed solution into a separatory funnel for extraction, 20ml Wash the reaction bottle with benzene, the resulting bright red oil layer is the required oxidant solution, dry with magnesium sulfate, and set aside;

[0023] Add 4.1ml (3.51g, 0.026mol) 3-carene into a 250ml three-necked flask, then add the prepared oxidant solution, connect the three-necked flask with a thermometer and a glass stopper respectively; then place the three-necked flask in an ultrasonic cleaner In the water tank (ultrasonic power 100W), fill the tank with water, keep the reaction temperature in the there-necked bottle <45°C, and apply the ultrasonic wave continuously for 3 hours; stop the ultrasonic wave, slowly add 60ml (20g) oxalic acid solution within half an hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com